A machine tool for drilling and boring inclined holes of aluminum truck wheels

A drilling, boring and wheel technology, which is applied in the field of machine tools, can solve the problems of large investment, reduced enterprise income, and long processing time, and achieves the effects of low cost, convenient operation, and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

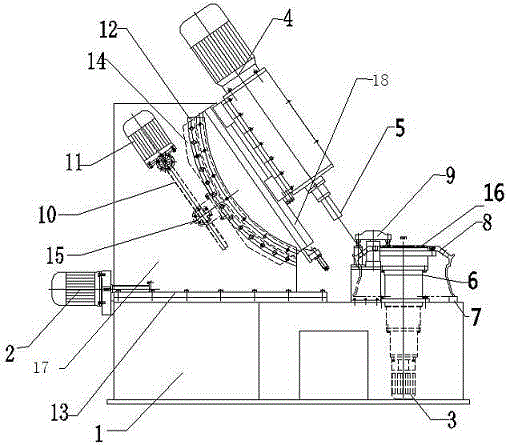

[0012] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

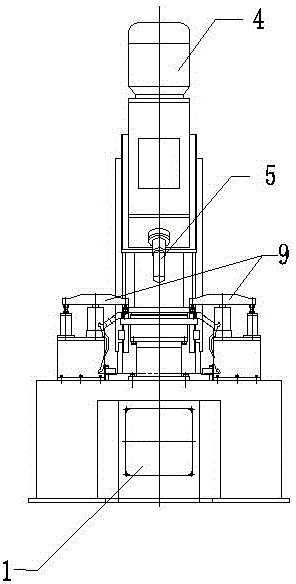

[0013] Such as figure 1 As shown in -2, the present invention is a machine tool for drilling and boring inclined holes of aluminum truck wheels. Guide rail 13 is provided, and there is a large sliding table 17 on the guide rail 13, and the longitudinal axis drive motor 2 drives the large sliding table 17 to move back and forth on the guide rail 13. There is an arc guide rail 12 on the large sliding table 17, and the arc slider 14 The arc guide rail 12 makes a rotary motion, and the rotary motion of the arc slider 14 is driven by the inclination servo motor 11. There is a guide rail and a small slide table 18 on the arc slide block 14, and the small slide table 18 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com