Large 3D printer based on FDM principles

A 3D printer, the principle of technology, applied in the field of 3D printers, can solve the problems of increased feeding resistance, damage to the machine, waste of printing calibration time, etc., to achieve the effect of changing the suspension mode, reducing the distance error, and improving the unsmooth feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

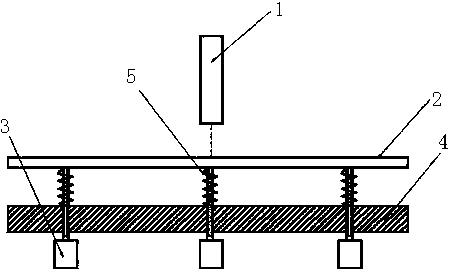

[0021] Such as figure 1 , the leveling control system mainly includes a distance measuring sensor and a threaded shaft motor, the distance measuring sensor (1) is installed above the working panel (2), and can monitor the position of the working panel, and the working panel and the three threaded shaft motors ( 3) connected with each other, the threaded shaft is provided with a spring (5), and the three threaded shaft motors are fixedly connected through the base (4).

[0022] The distance measuring sensor is fixed with the three-axis motion platform. According to the principle of determining a plane by three points, the test points of the board are arranged in an equilateral triangle, and then the distance measuring sensor is moved to the three vertices of the equilateral triangle for distance measurement. After starting the leveling program, the CPU gives the distance measuring sensor a working command, the distance measuring sensor starts to measure distance, and then feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com