A method and device for early warning of strip deviation on a cold-rolled galvanizing line

A technology of strip deviation and early warning device, which is applied in the field of metallurgy, can solve the problems of poor deviation correction ability of annealing furnace, etc., and achieve the effect of improving deviation correction ability, improving output and product quality, and ensuring stable plate passing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

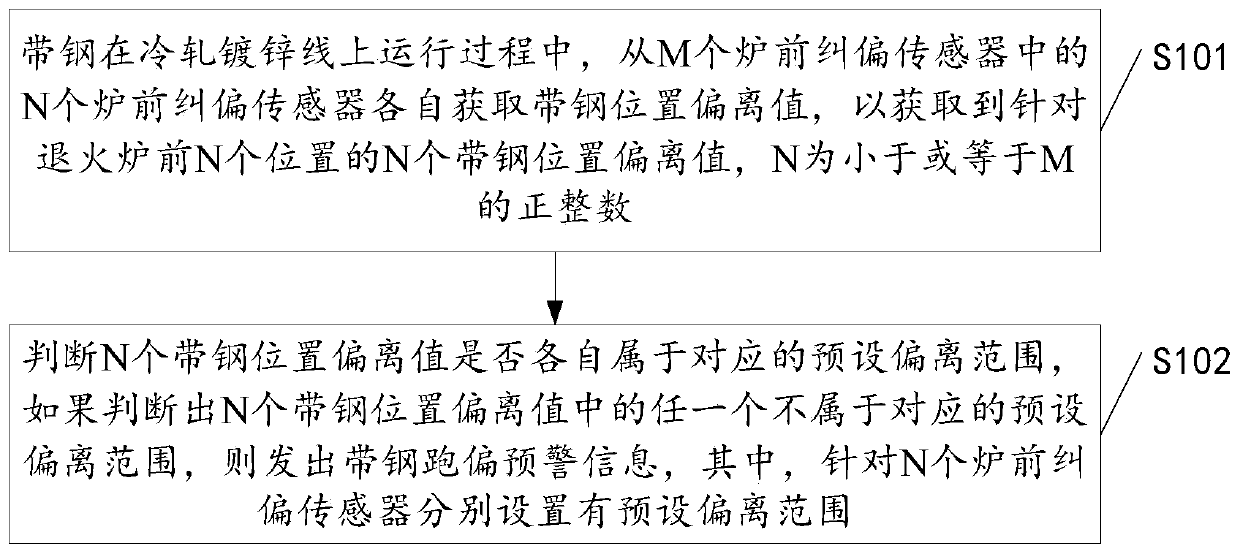

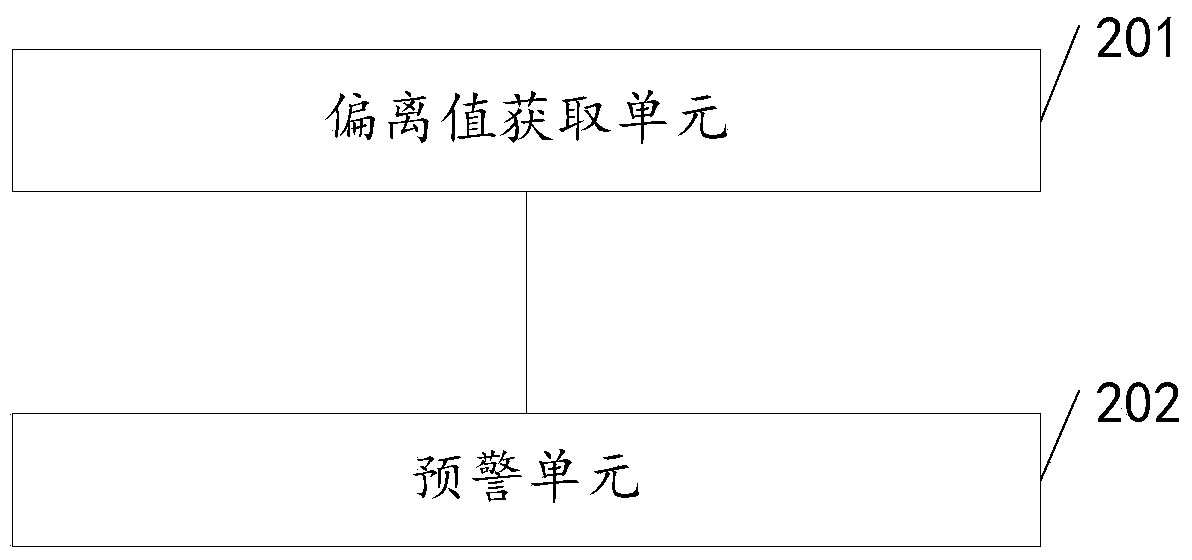

[0033] In order to solve the existing technical problem of poor deviation correction ability in the annealing furnace on the cold rolling galvanizing line, the embodiment of the present invention provides a strip deviation warning method and device on the cold rolling galvanizing line, the general idea is as follows:

[0034] The strip position deviation value will be obtained from the deviation correction sensor in front of the annealing furnace (furnace deviation correction sensor). If the obtained strip position deviation value does not belong to the corresponding preset deviation range, a strip deviation warning message will be issued.

[0035] When the strip position deviation value of the furnace front deviation correction sensor before the annealing furnace does not belong to the corresponding preset deviation range, the strip deviation warning information will be issued, so the strip deviation warning will be issued before the strip enters the annealing furnace. It make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com