Transportable packaging unit and method for producing said type of packaging unit

a transportation packaging and packaging unit technology, applied in the field of transportation and the storage of goods, can solve the problems of expensive technical devices, large deviation of the effect of the transportation method, and the need to remove the last goods from the warehouse, etc., and achieve the effect of rapid and secure closure and greater deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

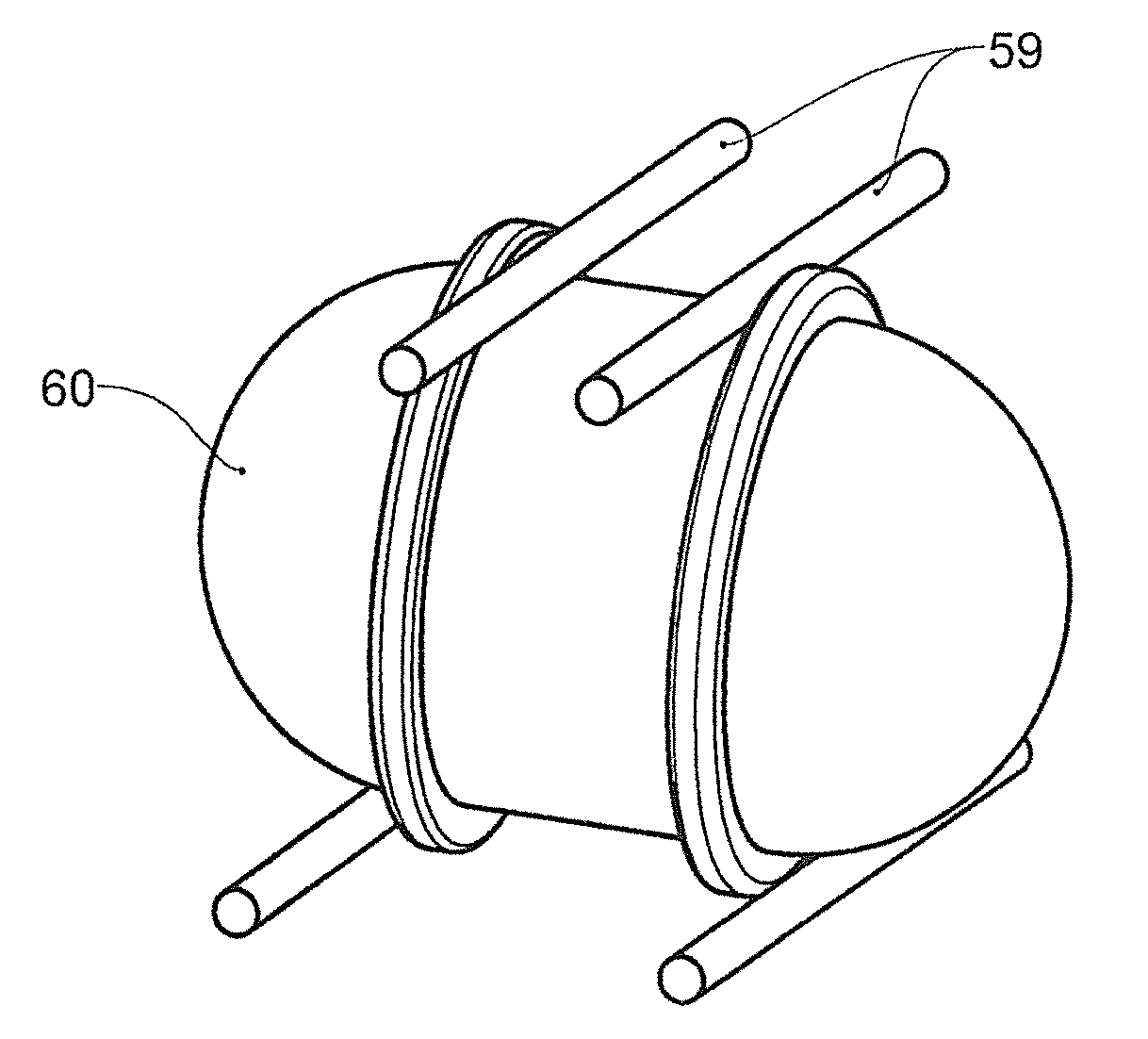

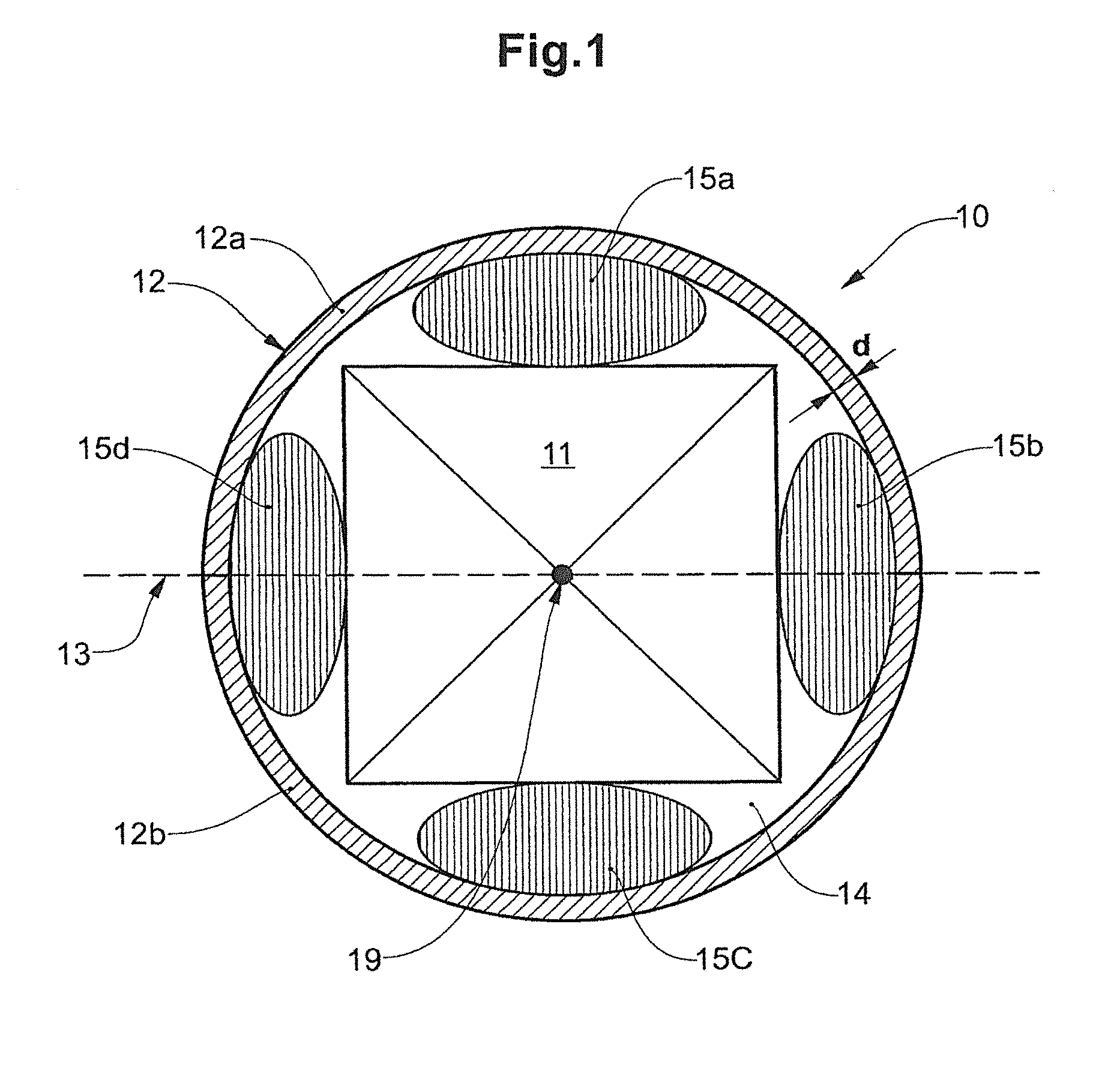

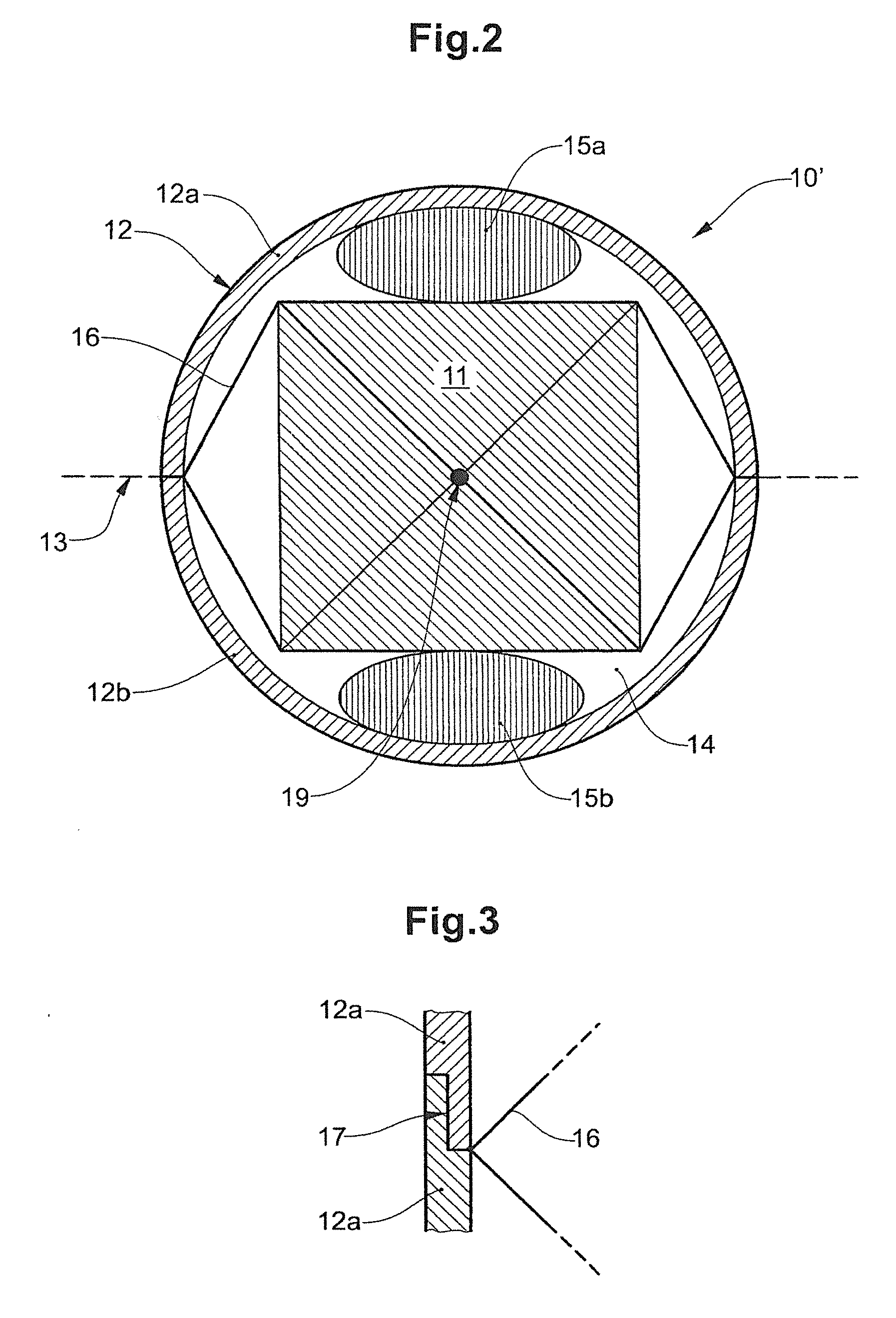

[0078]A central feature of the present solution is a packaging unit which is designed such that it is able to roll automatically on an inclined plane with sufficient gradient. The packaging contents which contain the goods to be transported and / or stored are arranged in the packaging unit. Externally, the packaging unit has a shape which is suitable for automatic rolling. This may be a spherical shape, a cylindrical shape, a barrel shape, an elliptical shape or in an extreme case a polyhedral shape. The external shape of the packaging unit is formed and provided by a casing which more or less completely encloses the packaging contents. In an extreme case, the casing may be in one piece but generally consists of a plurality of casing segments which are directly or indirectly connected together if the packaging contents are to be enclosed. The outer surface of the casing is the surface with which the packaging unit rolls on a substrate. Therefore, it should have sufficient hardness in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shape | aaaaa | aaaaa |

| barrel shape | aaaaa | aaaaa |

| spherical shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com