Civil defense door board bending process and device thereof

A bending device and civil air defense door technology, which is applied in the field of civil air defense doors, can solve problems such as unstable bending and forming, and achieve the effects of avoiding processing, avoiding waste of resources, and improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

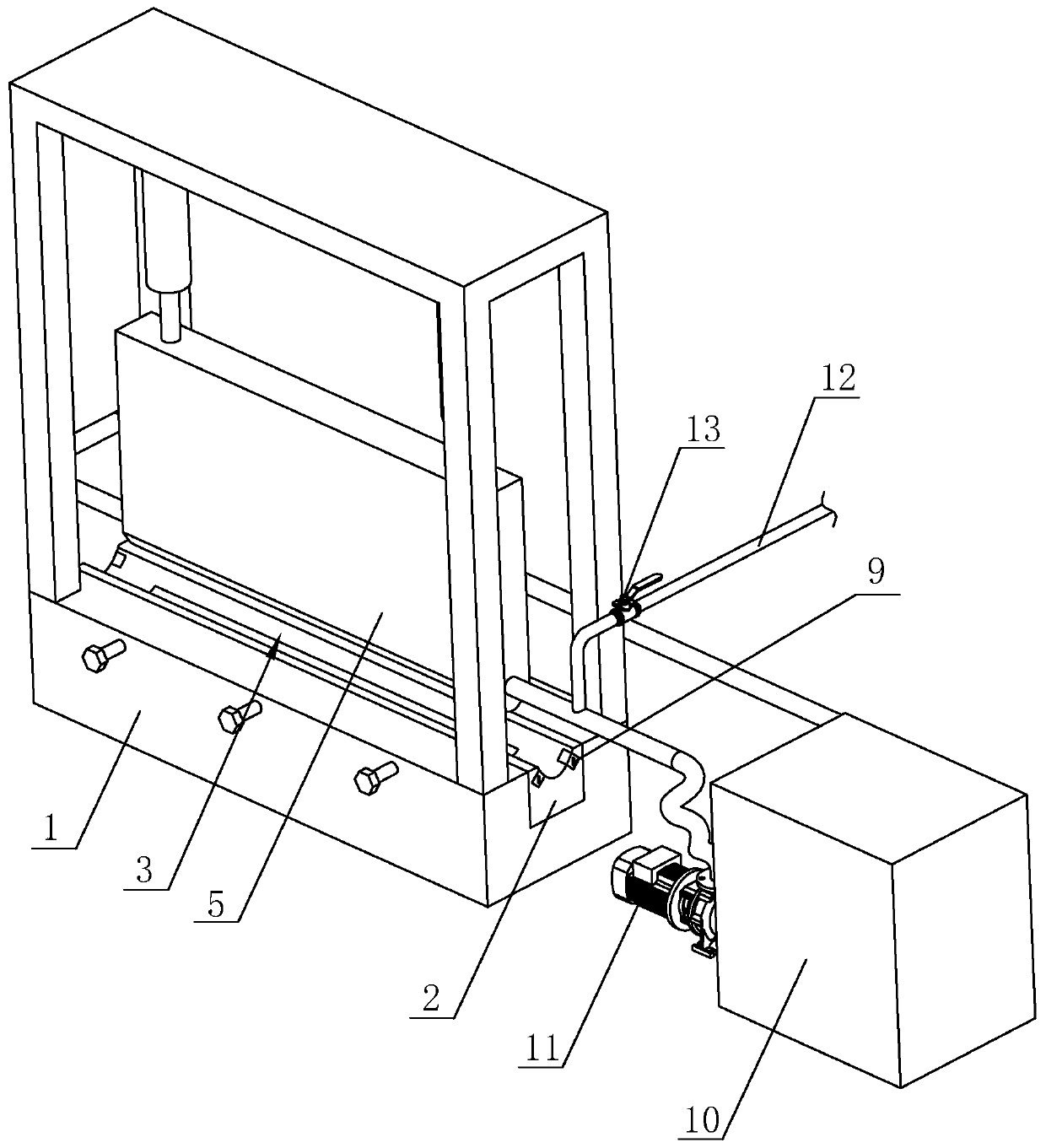

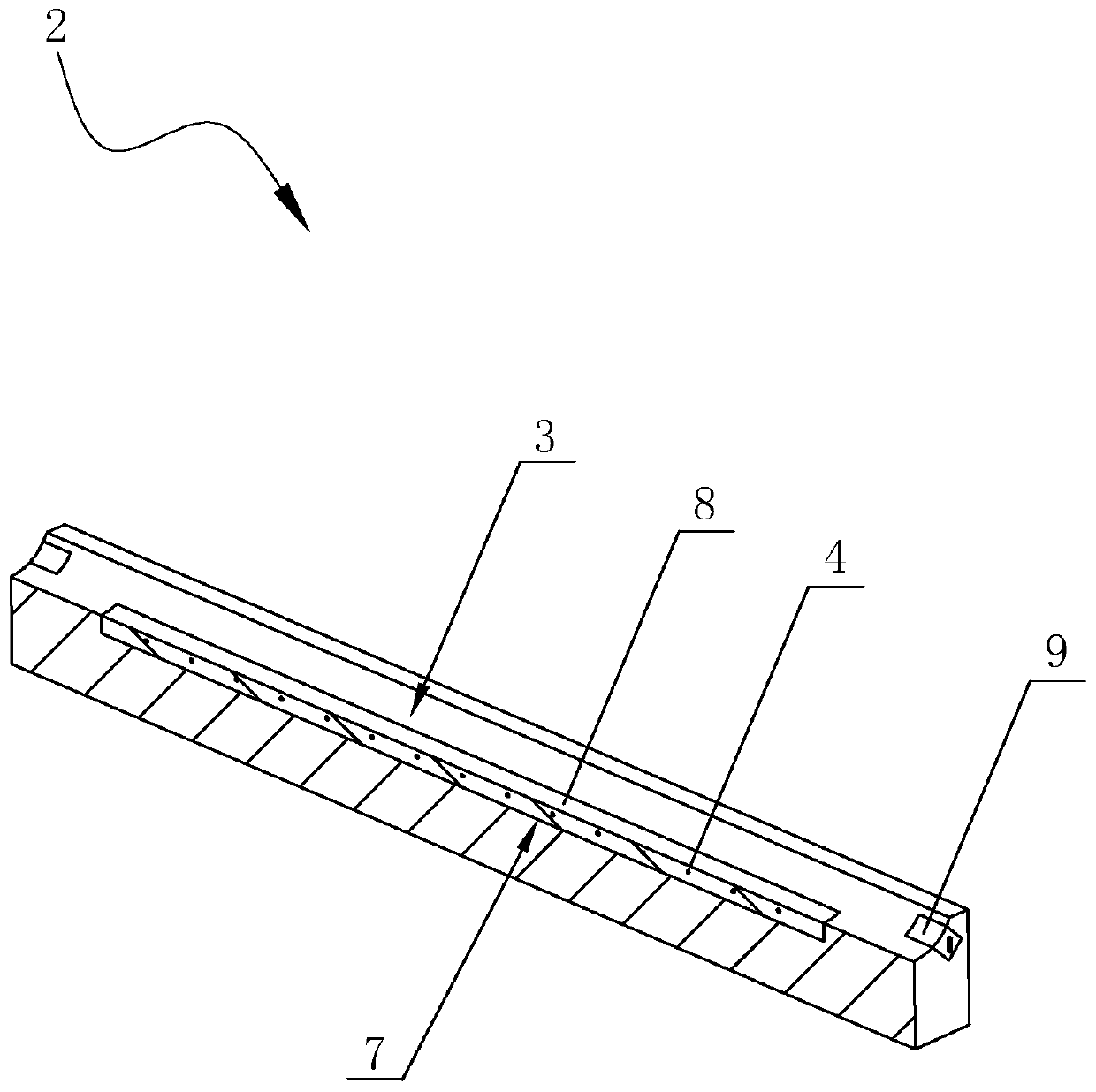

[0040] In order to make the purpose, technical solutions and beneficial effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

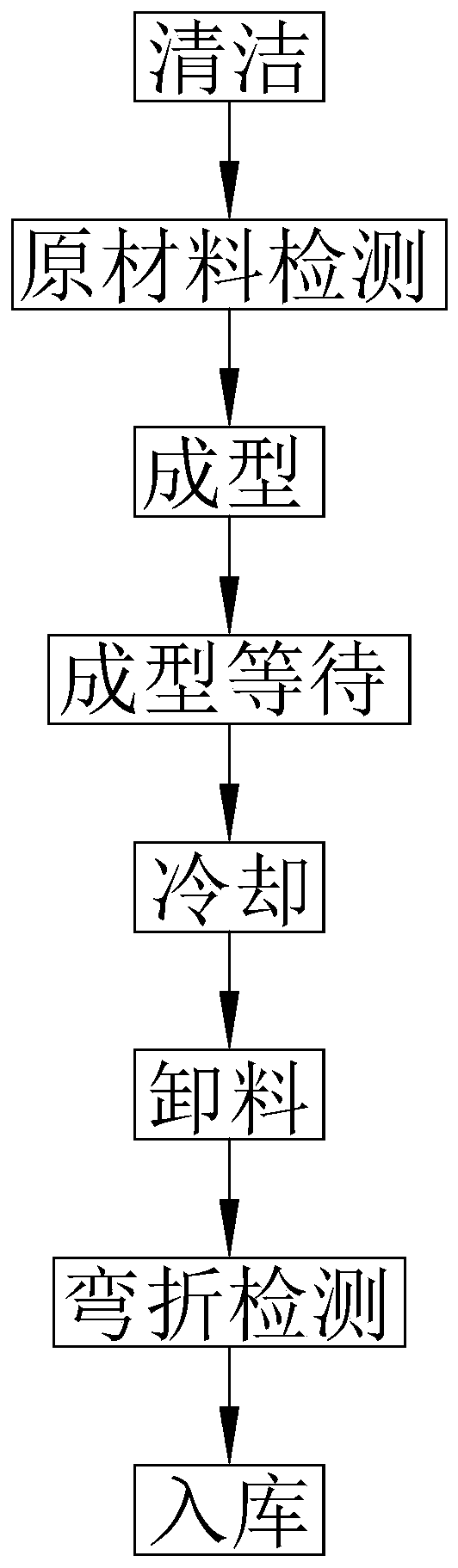

[0041] like figure 1 and figure 2 Shown, a kind of civil air defense door plate bending process is characterized in that, comprises the steps:

[0042] Step S1, cleaning: use a high-pressure air gun to spray high-pressure air on the surface of the steel plate, remove dust and other particles attached to the surface of the steel plate, and reduce subsequent detection errors;

[0043] Step S2, Raw material inspection: Use an ultrasonic detector to detect the structural strength and flatness of the steel plate, and remove unqualified steel plates to ensure that the structural strength and flatness of the product meet the standards;

[0044] Step S3, forming: heating the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com