Plate rolling machine for repairing plate blank line

A slab line and trigger technology, which is applied in metal processing equipment, peeling devices, manufacturing tools, etc., can solve the problems of single shaping shape, high use limitations, and laborious plate disassembly, and achieve good shaping quality and production. High efficiency and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

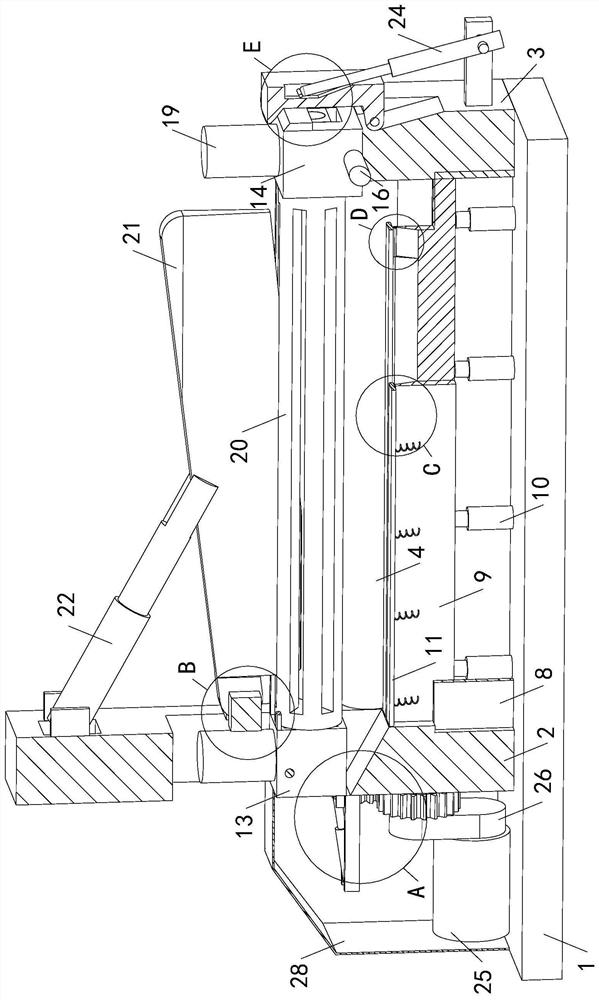

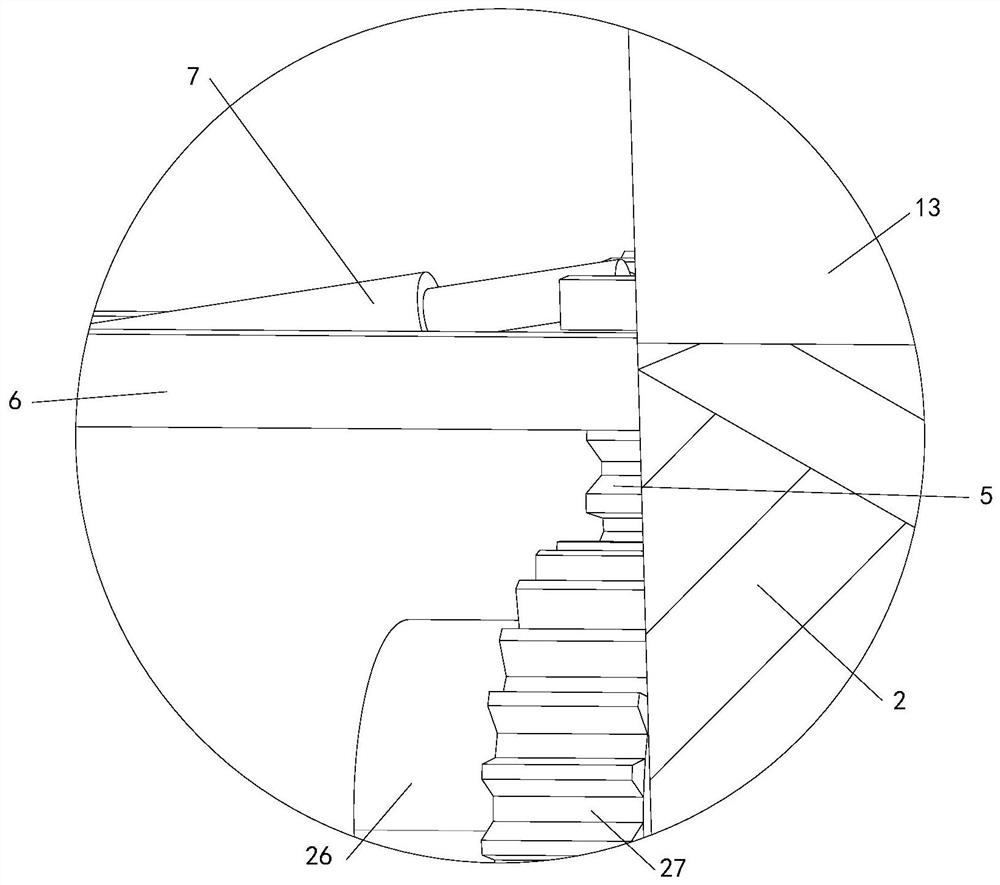

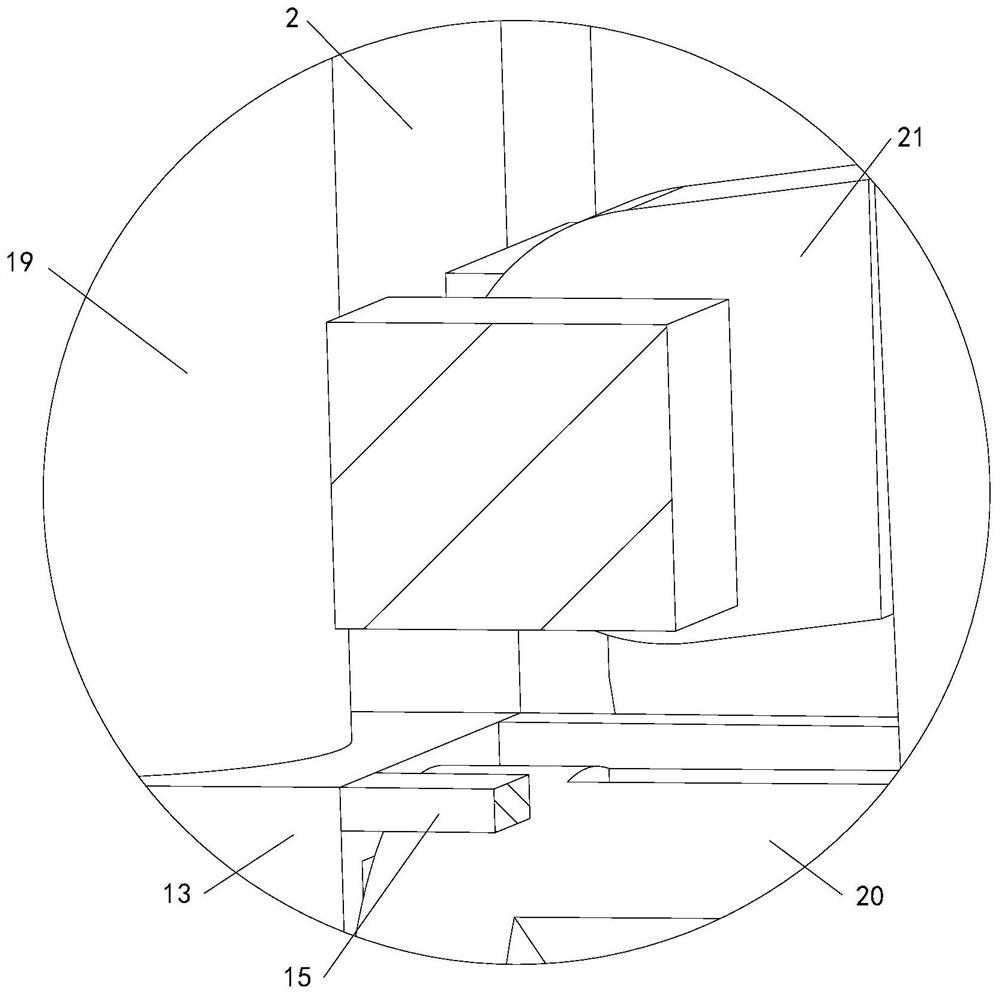

[0034] see Figure 1-8 , a plate rolling machine for slab line repair, including a base 1, and also includes a mounting frame 2 and a supporting frame 3, the mounting frame 2 and the supporting frame 3 are fixedly connected to the base 1, and the mounting frame 2 and the supporting frame 3 are connected in rotation The two lower round rollers 4 are convenient to cooperate with the upper round roller 20 to realize the bending and shaping of the plate. The left ends of the two lower round rollers 4 are fixedly connected with the driven gear 5, and the installation frame 2 and the support frame 3 are fixedly connected with a lifting mechanism. The lower mold mechanism, the lifting lower mold mechanism includes a guide sleeve 8, the base 1, the installation frame 2 and the support frame 3 are all fixedly connected with the guide sleeve 8, and a V-shaped installation bar 9 is slidably connected to the guide sleeve 8, and the guide sleeve 8 is set There are a plurality of electric t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com