Aluminum rod piece forming machining device

A technology for forming and processing rods, applied in the field of press brakes, can solve the problems of poor forming effect, inconvenient production, affecting the quality of pipe bending and forming, and achieve the effect of facilitating bending and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

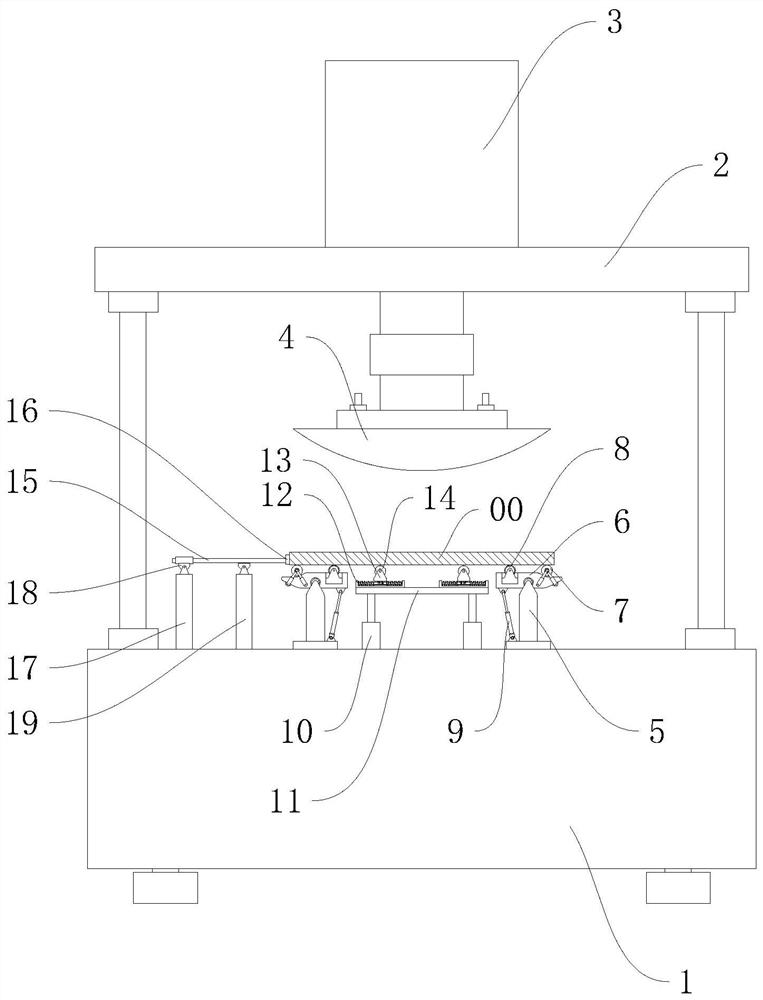

[0033] refer to Figure 1-3 As shown, this embodiment discloses an aluminum bar forming processing device, which includes a lower frame 1 and an upper frame 2, and a mold frame is installed between the lower frame 1 and the upper frame 2, and the mold frame is realized by a hydraulic rod. Up and down, the bending die 4 is installed on the lower part of the formwork, the structure of the bending die 4 can be selected and installed according to the parameters of the bending, and it is specifically an arc structure with the middle protruding downward and the two sides upward; Two main support components are installed on the frame 1 corresponding to the lower sides of the bending die 4. The support components can support the two ends of the aluminum rod 00, thereby forming a character-shaped force state with the upper bending die 4. The aluminum tube is bent; the distance between the two supporting components can be adjusted, and they are installed through different positions of s...

Embodiment 2

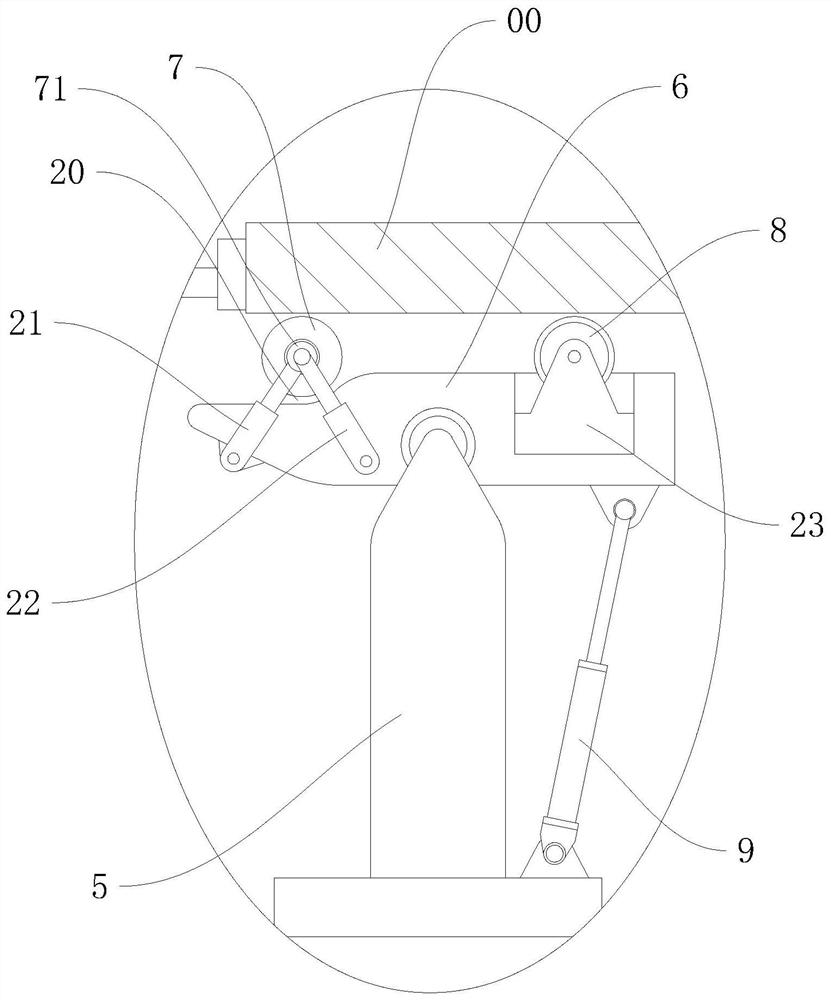

[0038] This embodiment discloses an aluminum rod forming processing device. On the basis of the embodiment, refer to Figure 1-4 As shown, the main support assembly is optimized so as to improve the bending effect on the end of the aluminum tube; in the main support assembly, the outer shaping roller 7 is located on the side away from the middle of the bending die 4, and the two sides of the outer shaping roller 7 The end is rotatably supported by the rotating seat 71, and is rotatably supported by the rotating member in the rotating seat 71; the height and position of the outer shaping roller 7 can be adjusted, specifically by adjusting the structure of the rotating seat 71.

[0039] The adjustment assembly includes two parts, push rod one 21 and push rod two 22. Push rod one 21 and push rod two 22 can adopt a telescopic structure, which can be provided by hydraulic pressure, pneumatic power, electric power or spring to realize telescopic. Push rod one 21 The fixed ends of pu...

Embodiment 3

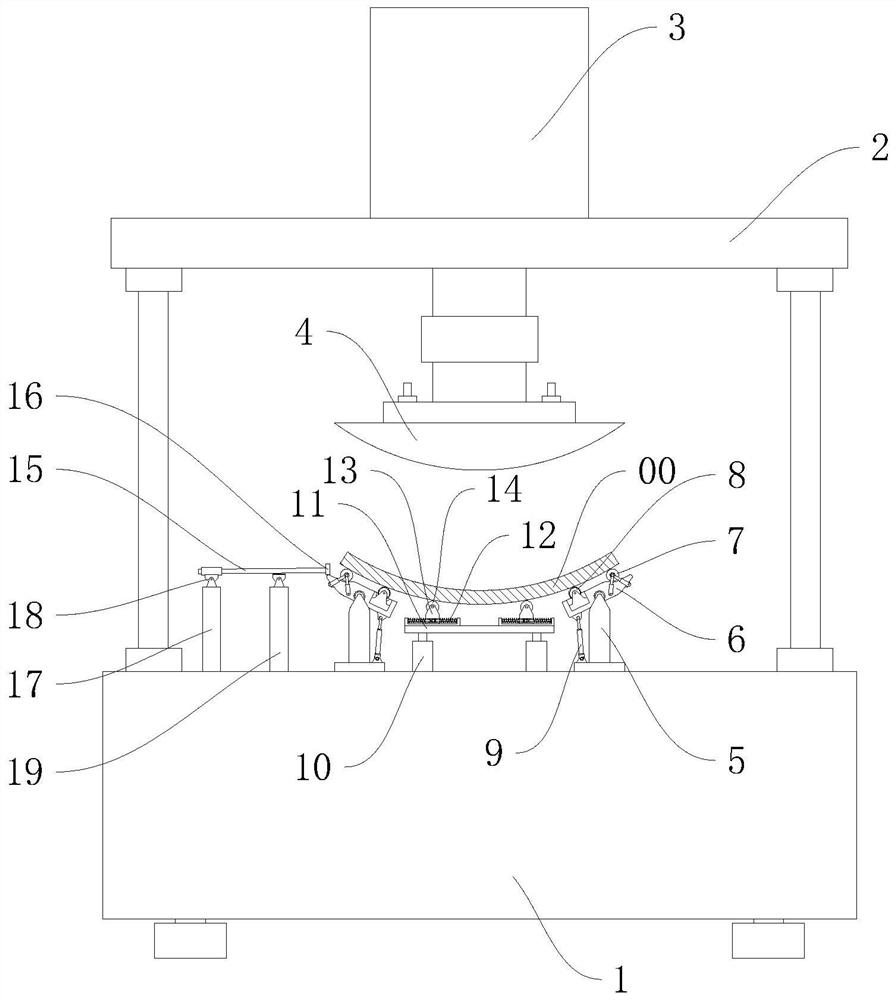

[0044] This embodiment discloses a processing device for forming aluminum rods. On the basis of the above embodiments, the supporting structure of the aluminum tube is optimized and referred to Figure 5-8 Describe in detail; an auxiliary platform 11 that can be elastically lifted is set between the two main support components to form a pressure support for the middle part of the aluminum tube, so that the degree of fit between the aluminum tube and the bending die 4 can be maintained.

[0045] The auxiliary platform 11 is installed on the upper part of the lower frame 1 through several elastic lifting rods 10, and two sets of auxiliary support assemblies are installed on both sides of the auxiliary platform 11, and the two sets of auxiliary support assemblies can press and support the lower side of the aluminum rod 00, And they are respectively used to press against the positions on both sides of the lowest point of the bending die 4 of the support. When the bending die is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com