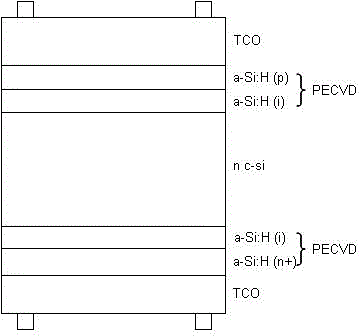

Technology for increasing capacity of silicon-based heterojunction solar cells

A solar cell and heterojunction technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of affecting the temperature environment, easily damaged heating components, unstable heating environment, etc., to save equipment costs, improve equipment productivity, The effect of saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

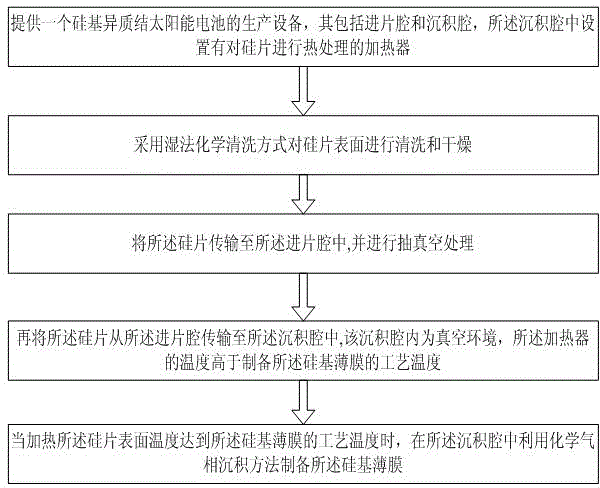

[0053] The invention provides a process for increasing the production capacity of a silicon-based heterojunction solar cell, which is used to prepare a silicon-based thin film in the silicon-based heterojunction solar cell, image 3 A schematic flow diagram of the first embodiment is shown, the process includes the following steps:

[0054] Step S1, providing production equipment for silicon-based heterojunction solar cells, which includes a wafer feeding chamber and a deposition chamber, and the deposition chamber is provided with a heater for heat-treating silicon wafers;

[0055] Step S2, cleaning and drying the surface of the silicon wafer by means of wet chemical cleaning;

[0056] Step S3, transferring the silicon wafer into the wafer feeding chamber, and performing vacuuming treatment;

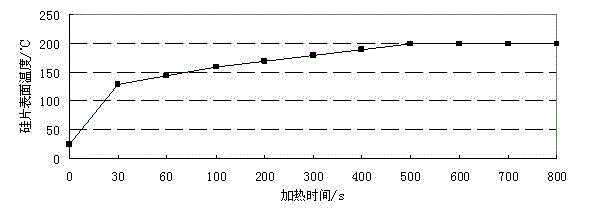

[0057] In step S4, the silicon wafer is transferred from the feeding chamber to the deposition chamber, the deposition chamber is in a vacuum environment, and the temperature of the he...

no. 2 example

[0080]In view of the industrial need to deposit different types of multi-layer amorphous silicon films on the surface of silicon-based heterojunction solar cells, such as depositing intrinsic amorphous silicon films, P-type amorphous silicon films, and N-type amorphous silicon films on silicon wafers Crystalline silicon thin film, the present invention also provides a process for increasing the production capacity of silicon-based heterojunction solar cells, which is used to prepare intrinsic amorphous silicon thin films and doped amorphous silicon films in the silicon-based heterojunction solar cells Silicon film, Figure 5 It is a schematic flow chart of the process for increasing the production capacity of silicon-based heterojunction solar cells in the second embodiment of the present invention. The process includes the following steps:

[0081] Step S1, providing production equipment for silicon-based heterojunction solar cells, which includes a wafer feeding chamber and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com