Back contact forming method of passivated emitter and rear contact solar cell

A technology of backside passivation and solar cells, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of battery conversion efficiency that cannot be greatly improved, high lithography production costs, and high recombination rate, so as to achieve low production costs and avoid backside damage, reducing recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

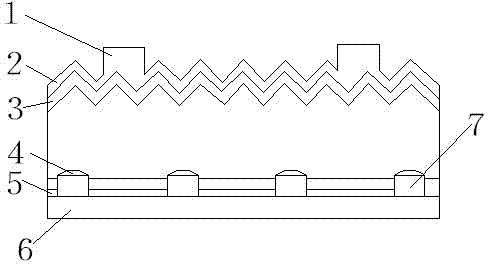

[0023] Firstly, a cell substrate of a first conductivity type for preparing a solar cell is provided. Specifically, the resistivity of p-type single crystal silicon may range from 0.1 ohm·cm to 10 ohm·cm, but is not limited to this range. The front side of the battery substrate is irradiated by sunlight, and the backside of the battery substrate is not irradiated by sunlight when the battery is working.

[0024] Further, a light trapping mechanism is formed on the front side of the battery substrate. Several pyramid-shaped suede surfaces are formed on the front surface of the battery substrate. The textured surface can be formed by anisotropic etching of a chemical solution or mask photolithography, and is usually formed by selective chemical etching. The specific shape of the suede is related to the selected manufacturing pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com