Horizontal coating device for preparing HIT crystalline silicon solar cell

A technology of solar cells and coating devices, which is applied to circuits, electrical components, electrolysis processes, etc., to achieve the effects of improving production yield, reducing fragmentation rate, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

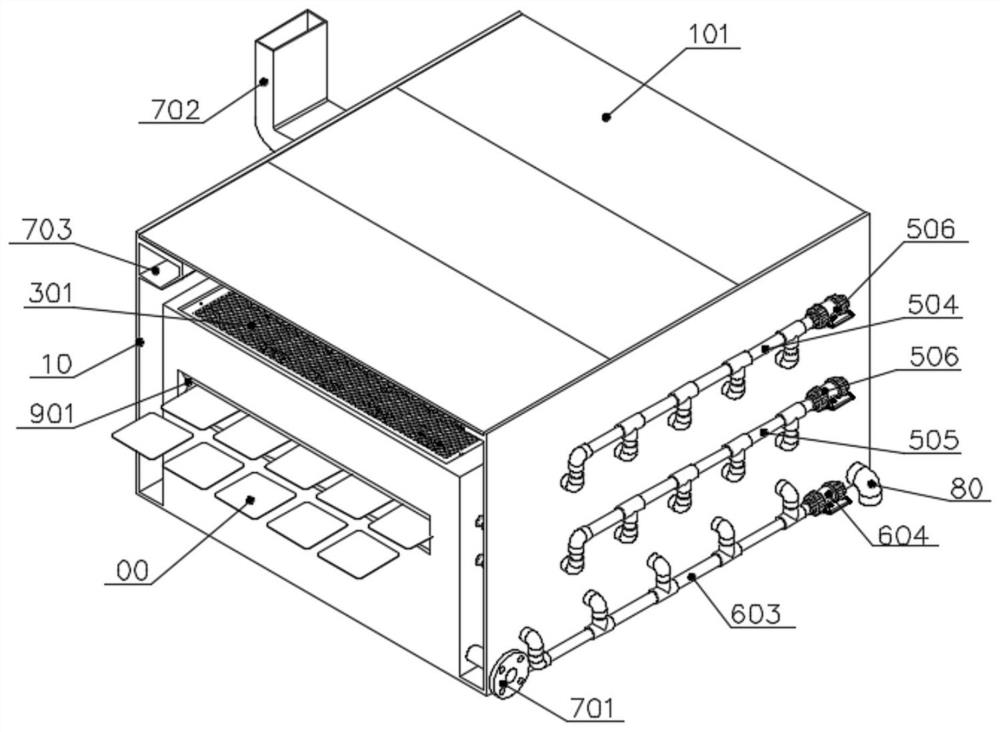

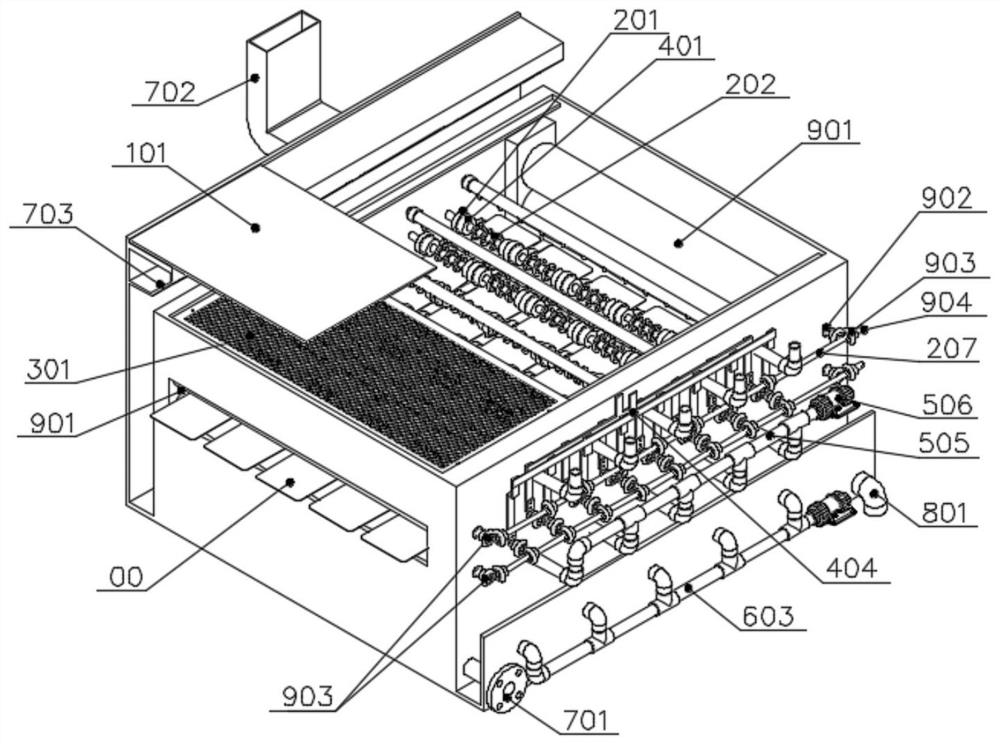

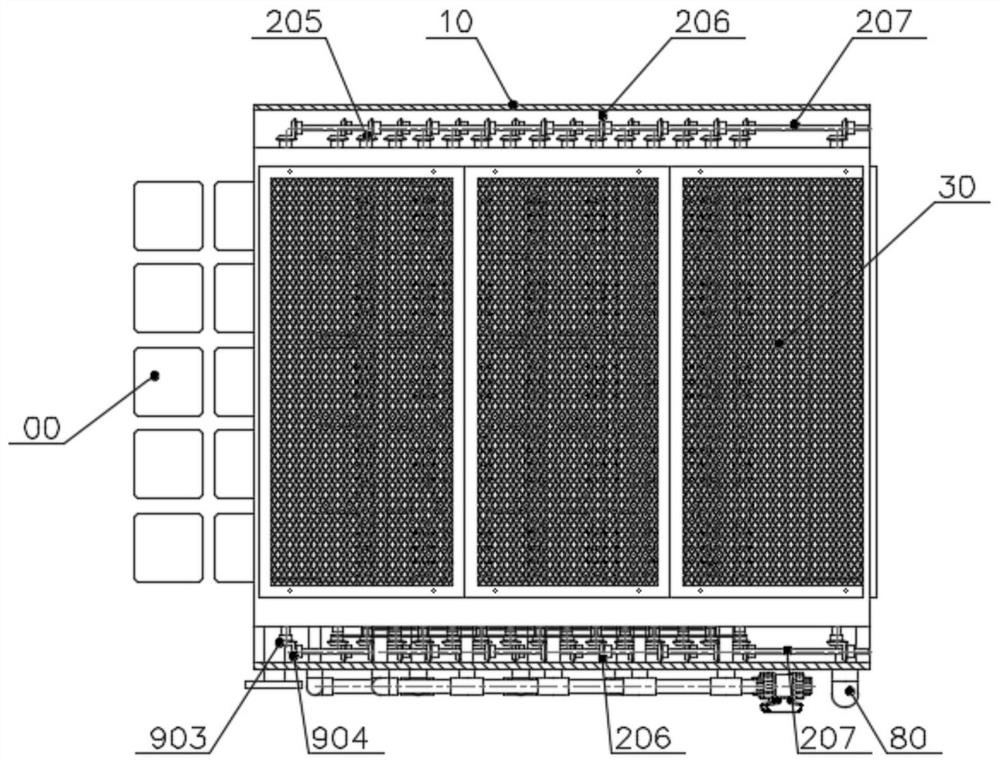

[0027] refer to Figure 1-Figure 7 , a horizontal coating device for preparing HIT crystalline silicon solar cells, comprising a cell 00, a tank body 10, a transmission mechanism 20, an anode mechanism 30, a cathode mechanism 40, a spray mechanism 50, an inflating mechanism 60, a waste discharge mechanism 70, Circulation filter mechanism 80, liquid blocking mechanism 90, the top of the tank body 10 is equipped with a transparent movable window 101, the transmission mechanism 20 is horizontally supported on both sides of the tank body 10, and the battery sheet 00 is placed in the tank body 10 through the transmission mechanism 20 The anode mechanism 30 and the cathode mechanism 40 are arranged in the tank body 10 to connect with the rectifier to generate an electric field, and the spray mechanism 50, the pumping mechanism 60 and the circulating filter mechanism 80 will remove the copper in the tank. The ions are uniformly deposited on the grid wire electrodes of multiple rows o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com