Beam splitting laser cutting method for silicon carbide based wafers

A laser cutting, silicon carbide-based technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., to achieve the effect of eliminating wafer chipping, reducing the width of the cut mark, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, the present invention will be further described with reference to the drawings and specific embodiments.

[0047] First describe the conceptual design of the present invention as follows:

[0048] 1. Brief introduction of cutting process

[0049] Film application steps:

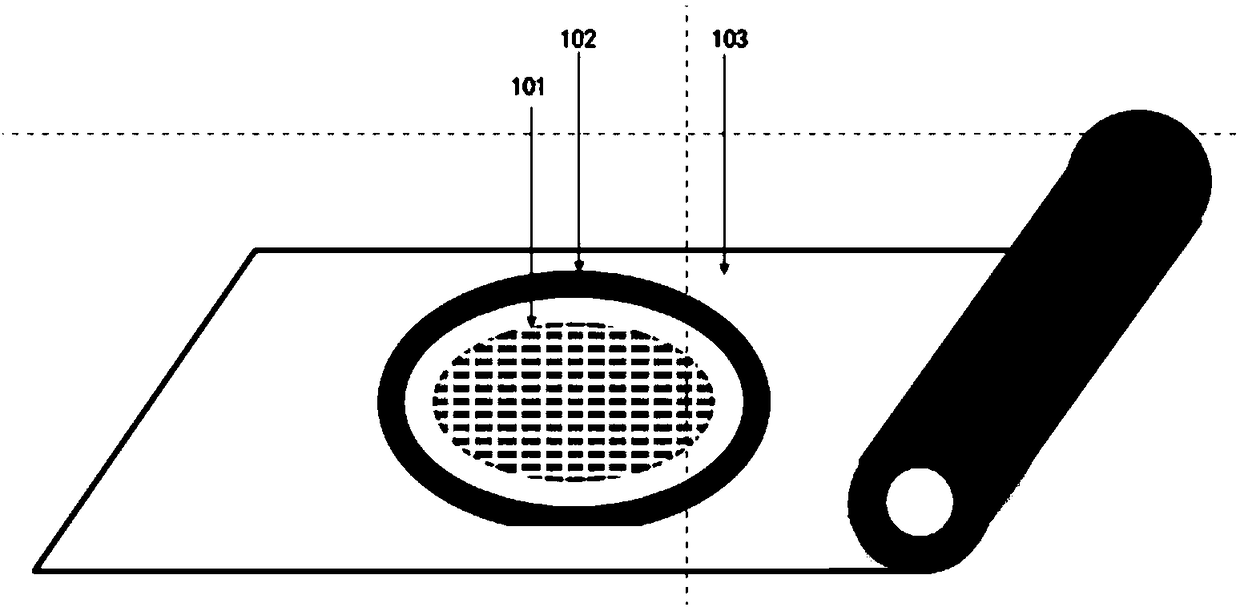

[0050] Such as figure 1 As shown, the silicon-based wafer 101 and the iron ring 102 are pasted on the film 103, the film part outside the iron ring 102 is scratched off with a blade, and the film part inside the iron ring 102 is retained.

[0051] Purpose: to paste the silicon-based wafer 101 on the film 103 and fix it with the iron ring 102, which is convenient for processing, cutting and patching.

[0052] Cutting steps:

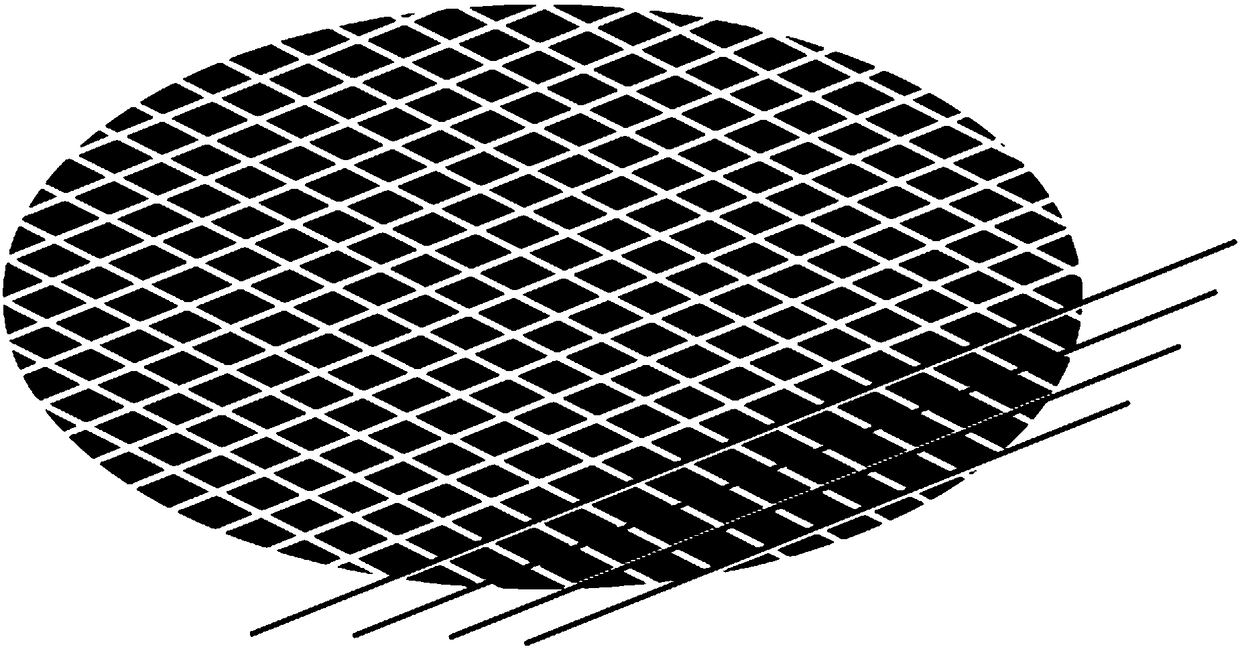

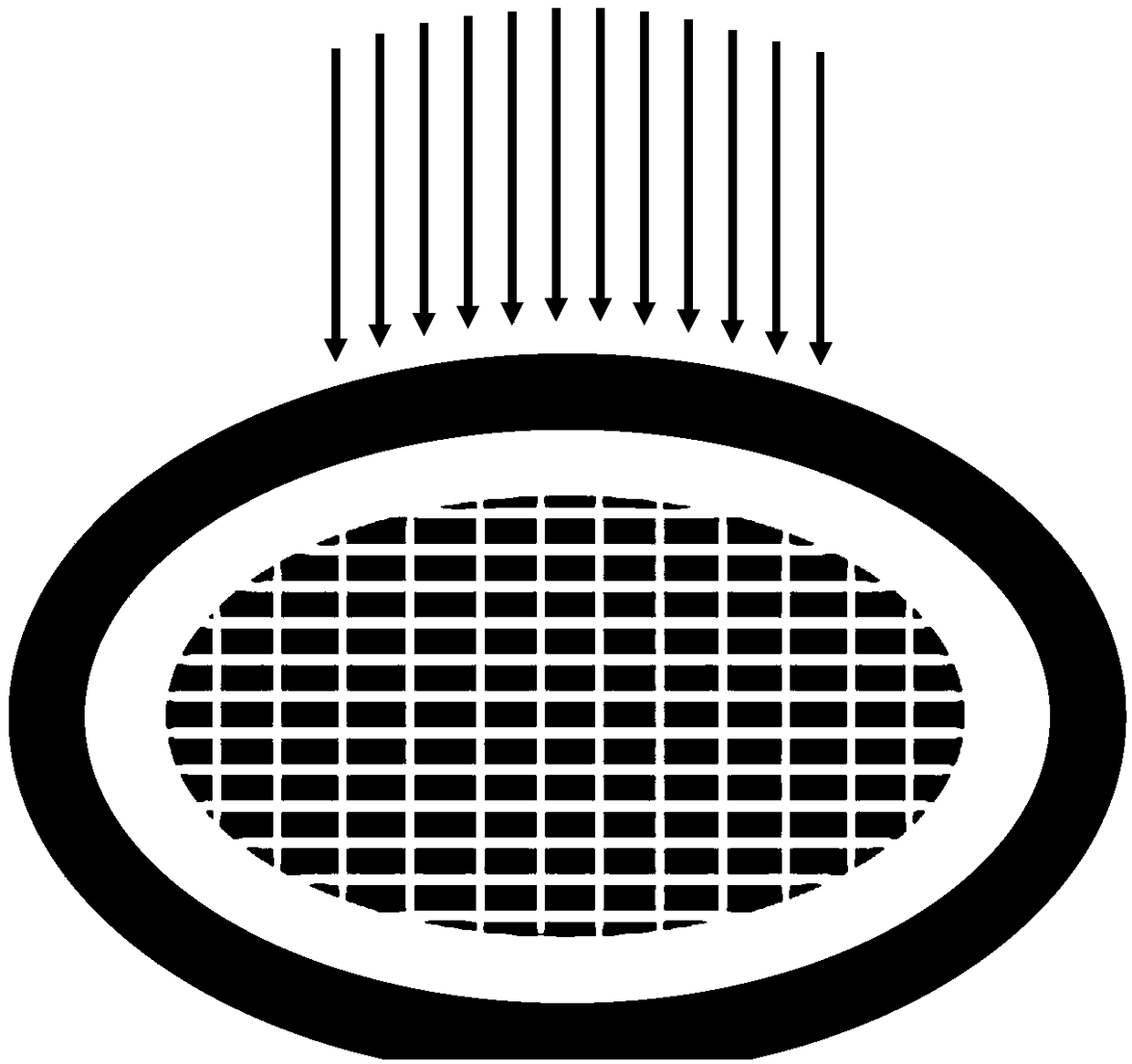

[0053] Such as figure 2 As shown, the wafer is cut one or more times in a certain cutting mode according to a certain cutting pattern, such as depth, speed, position, and width.

[0054] Purpose: to divide the entire wafer into independent, functional chips ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com