Beam splitting laser cutting method for silicon-based wafer

A laser cutting, silicon-based crystal technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., to enhance mobility, reduce risks, and improve cutting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In the following, the present invention will be further described with reference to the drawings and specific implementations.

[0046] First, the conceptual design of the present invention is described as follows:

[0047] 1. Introduction to cutting process

[0048] Filming steps:

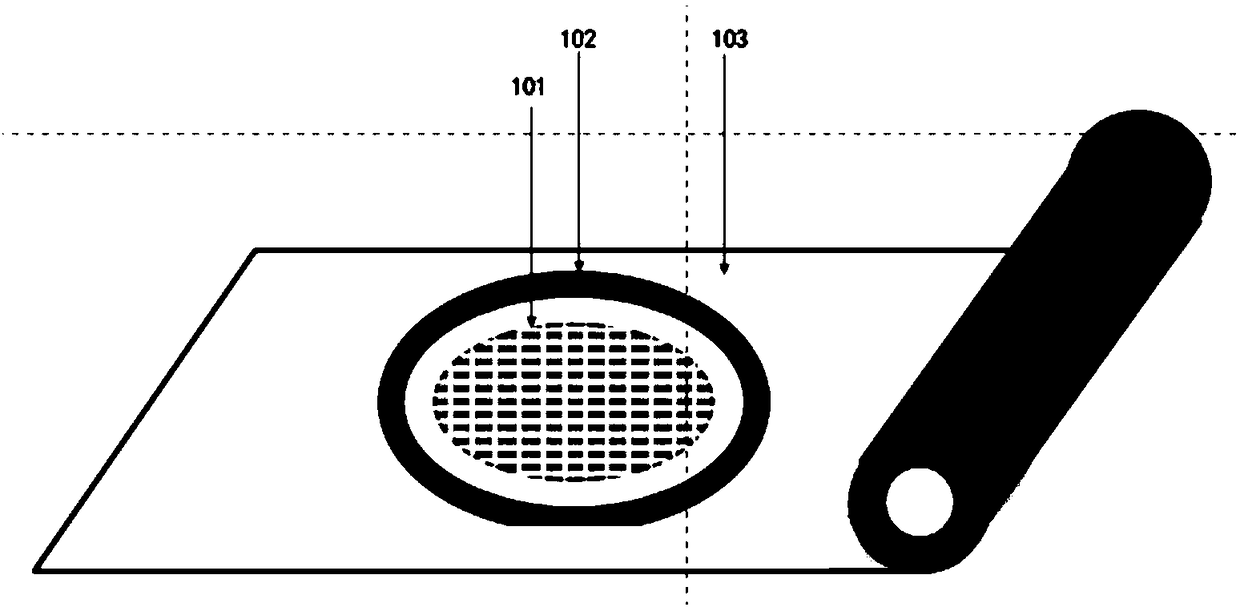

[0049] Such as figure 1 As shown, the silicon-based wafer 101 and the iron ring 102 are attached to the film 103, and the film part outside the iron ring 102 is scratched with a blade, and the film part inside the iron ring 102 is retained.

[0050] Purpose: Attach the silicon-based wafer 101 to the film 103 and fix it with the iron ring 102 to facilitate processing, cutting, and patching.

[0051] Cutting steps:

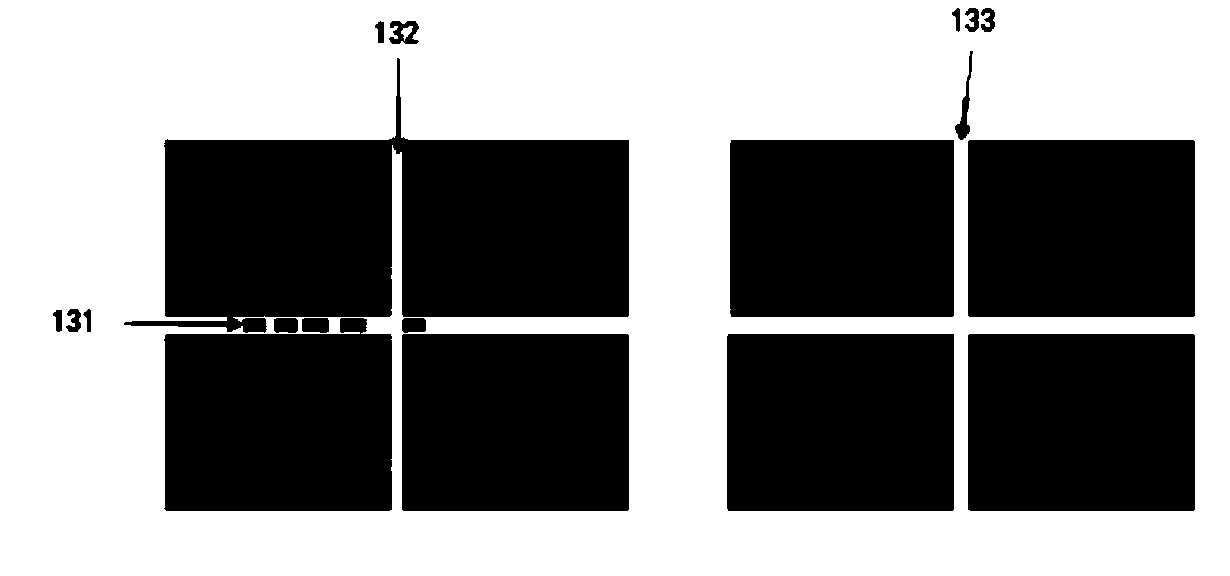

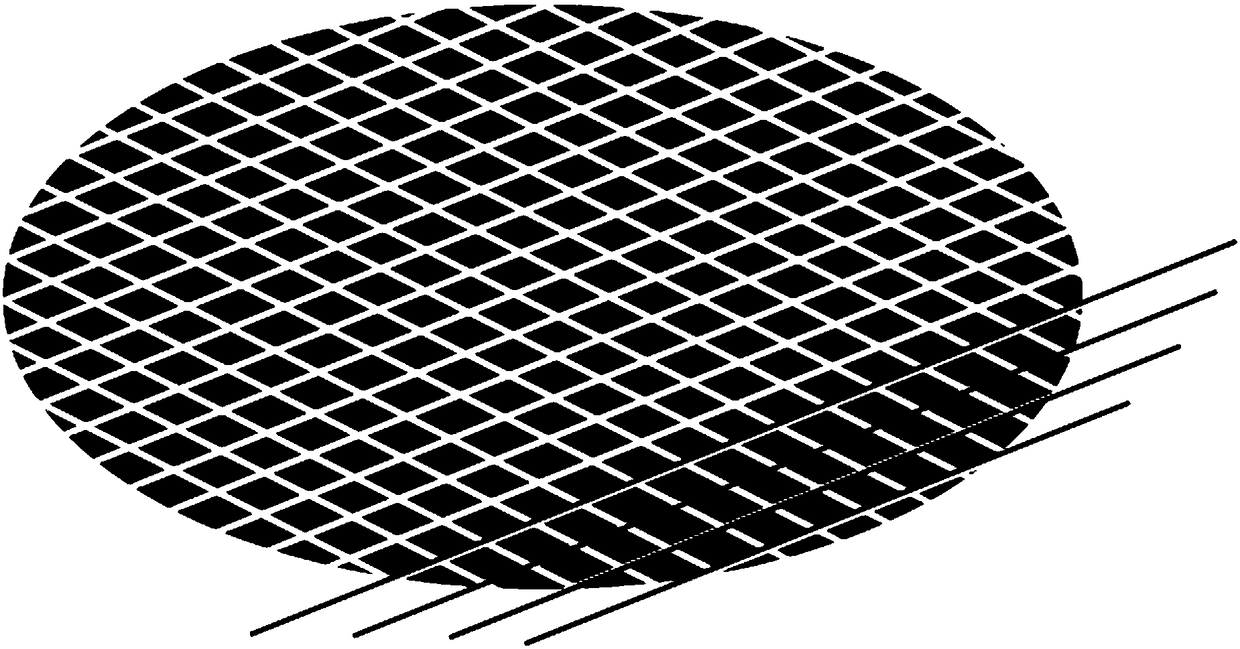

[0052] Such as figure 2 As shown, the wafer is cut once or multiple times in a certain cutting manner according to a certain cutting mode, such as depth, speed, position, and width.

[0053] Purpose: Divide the entire wafer into independent, functional chips 10.

[0054] UV irradiation ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com