Method and device for removing high-concentration dust in flue gas of glass kiln

A glass furnace and high-concentration technology, which is applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of low melting point of smoke and dust, burning loss, blockage, etc., and achieve the effect of efficient capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

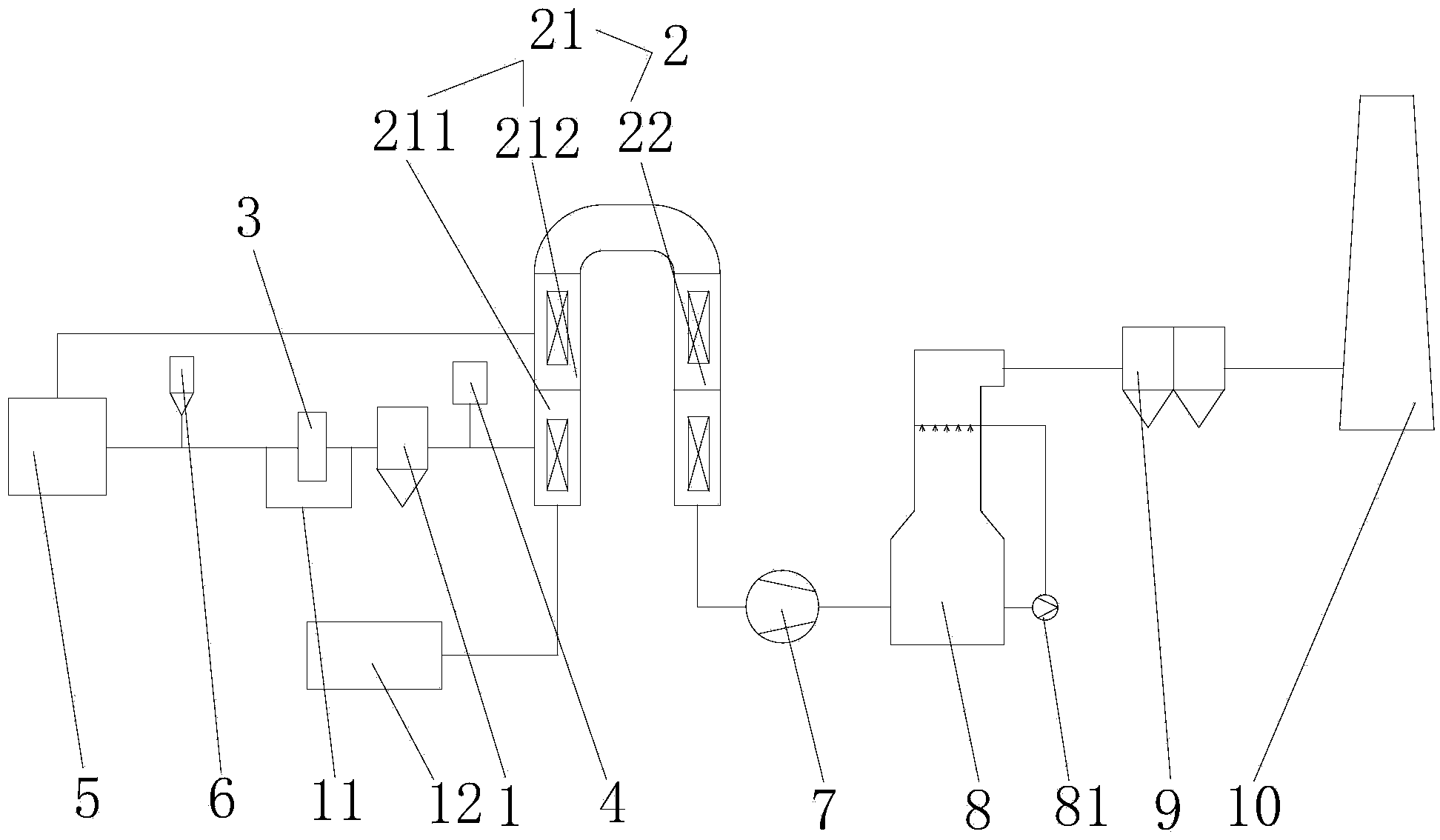

[0029] See Figure 1-3 , a method for removing high-concentration dust in the flue gas of a glass kiln, using the waste heat boiler 2 to receive the high-temperature flue gas discharged from the glass kiln, making the high-temperature flue gas in the waste heat boiler 2 enter the electric precipitator 1 for dust removal, and Add conditioning substances before this process, use denitrification equipment 5 to denitrify the high-temperature flue gas after dust removal by the electrostatic precipitator 1, and add a reducing agent before this process, so that the high-temperature flue gas after denitrification returns to the waste heat boiler 2 , use the waste heat boiler 2 to cool the high-temperature flue gas to form low-temperature flue gas, use the induced draft fan 7 to guide the low-temperature flue gas from the waste heat boiler 2 to the desulfurization equipment 8, use the desulfurization equipment 8 to desulfurize through the wet desulfurization process or the semi-dry desu...

Embodiment 2

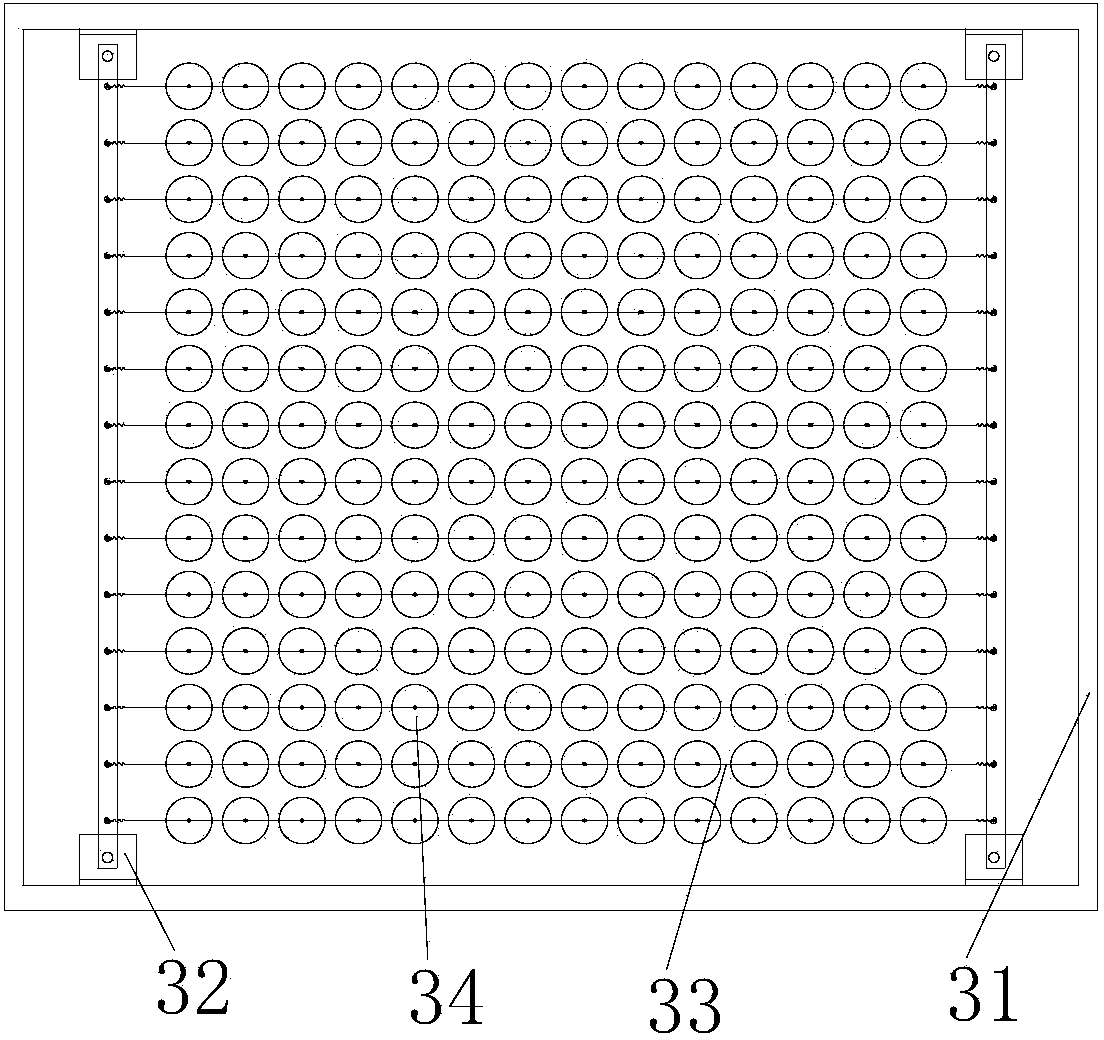

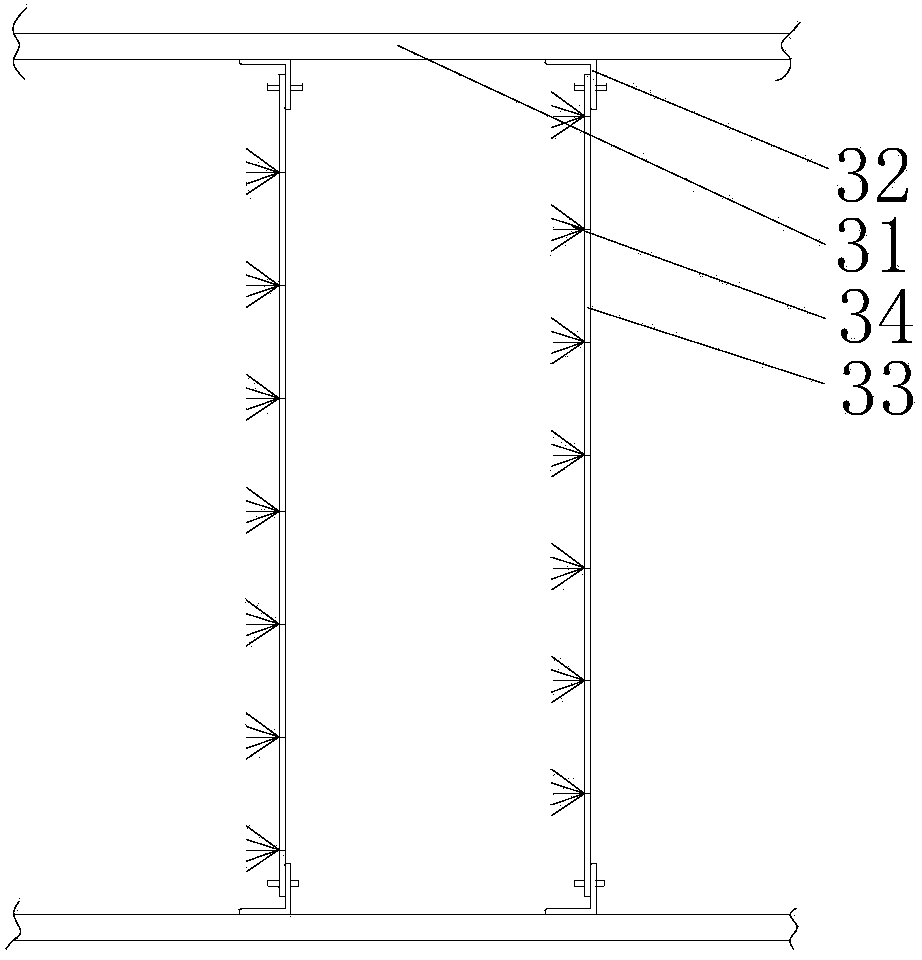

[0033] See Figure 1-3 , a device for removing high-concentration dust in glass furnace flue gas, including waste heat boiler 2, electrostatic precipitator 1, mechanical pre-collector 3, conditioning equipment 4, denitrification equipment 5, and reducing agent dosing Equipment 6, induced draft fan 7, desulfurization equipment 8, wet electrostatic precipitator 9 and chimney 10, waste heat boiler 2 includes high temperature side 21 and low temperature side 22, high temperature side 21 is divided into area A211 and area B212, and the passage between area A211 and area B212 Separated by partitions, area A211, electrostatic precipitator 1, mechanical pre-collector 3, denitrification equipment 5, area B212, low temperature side 22, induced draft fan 7, desulfurization equipment 8, wet electrostatic precipitator 9 and chimney 10 according to the electrostatic precipitator Device 1, mechanical pre-collector 3, denitrification equipment 5, area B212, low temperature side 22, induced dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com