High-performance metal ceramic cutting tool and preparation method thereof

A cermet, high-performance technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of insufficient impact toughness and hardness, and achieve the effect of high cutting rate, high surface finish, good toughness and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

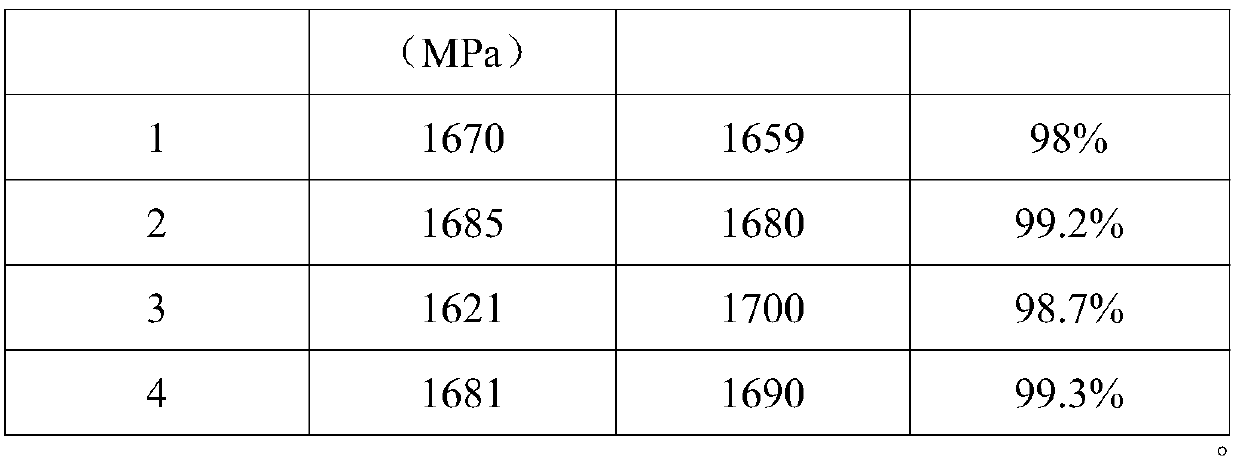

Examples

Embodiment 1

[0027] A high-performance cermet cutter, which is prepared from the following components in parts by mass:

[0028] TiC 0.5 N 0.5 55%, WC 15%, Ni7%, Co 7%, Mo 2 C 12%, NbC 4%, C, N ratio is 0.5. C, N ratio is 0.5.

[0029] The preparation method of above-mentioned cermet cutter is as follows:

[0030] Mix the powder according to the above ratio, put the prepared powder into a nylon ball mill tank and pour an appropriate amount of absolute ethanol, and use a cemented carbide ball with a diameter of 10mm for planetary ball milling for 36 hours at a speed of 150r / min;

[0031] Put the mixed slurry into a drying oven with a temperature set at 350K, dry for 24 hours, add 8wt% polyvinyl alcohol solution with a concentration of 10% after drying for granulation, and put it into a mold for pressing after granulation. The pressing pressure is 250Mpa, put it into a vacuum furnace for degreasing, the highest sintering temperature is 1500°C, and the holding time is 1.5h.

Embodiment 2

[0033] A high-performance cermet cutter, which is prepared from the following components in parts by mass:

[0034] TiC 0.5 N 0.5 55%, WC 15%, Ni7%, Co 7%, Mo 2 C 12%, NbC 4%; of which TiC 0.5 N 0.5 The particle size is 100-150nm, and the ratio of C and N is 0.5.

[0035] The preparation method of above-mentioned cermet cutter is as follows:

[0036] Mix the powder according to the above ratio, put the prepared powder into a nylon ball mill tank and pour an appropriate amount of absolute ethanol, and use a cemented carbide ball with a diameter of 10mm for planetary ball milling for 36 hours at a speed of 150r / min;

[0037] Put the mixed slurry into a drying oven with a temperature set at 350K, dry for 12 hours, add 8wt% polyvinyl alcohol solution with a concentration of 10% after drying for granulation, and put it into a mold for pressing after granulation. The pressing pressure is 250Mpa, put it into a vacuum furnace for degreasing, the highest sintering temperature is...

Embodiment 3

[0039] A high-performance cermet cutter, which is prepared from the following components in parts by mass:

[0040] TiC 0.5 N 0.5 60%, WC 10%, Ni7%, Co 7%, Mo 2 C 12%, NbC 4%; of which TiC 0.5 N 0.5 The particle size is 100-150nm, and the ratio of C and N is 0.5.

[0041] The preparation method of above-mentioned cermet cutter is as follows:

[0042] Mix the powder according to the above ratio, put the prepared powder into a nylon ball mill tank and pour an appropriate amount of absolute ethanol, and use a cemented carbide ball with a diameter of 15mm for planetary ball milling for 48 hours at a speed of 180r / min;

[0043] Put the mixed slurry into a drying oven with a temperature set at 400K, dry for 16 hours, add 8wt% polyvinyl alcohol solution with a concentration of 10% after drying for granulation, and put it into a mold for pressing after granulation. The pressing pressure is 245Mpa, put it in a vacuum furnace for degreasing, the highest sintering temperature is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com