Automatic sheet cutter for producing vacuum laminated glass

A technology of vacuum clips and cutting machines, which is applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of reduced production efficiency, low work efficiency, and high maintenance costs, and achieve compact and reasonable structural design and improved cutting efficiency. Effective cutting efficiency and reasonable location design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

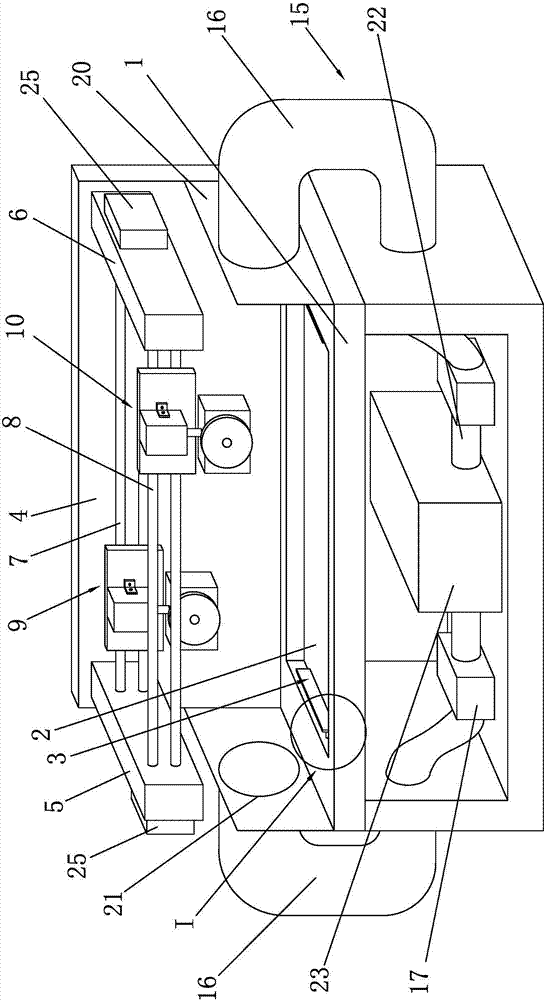

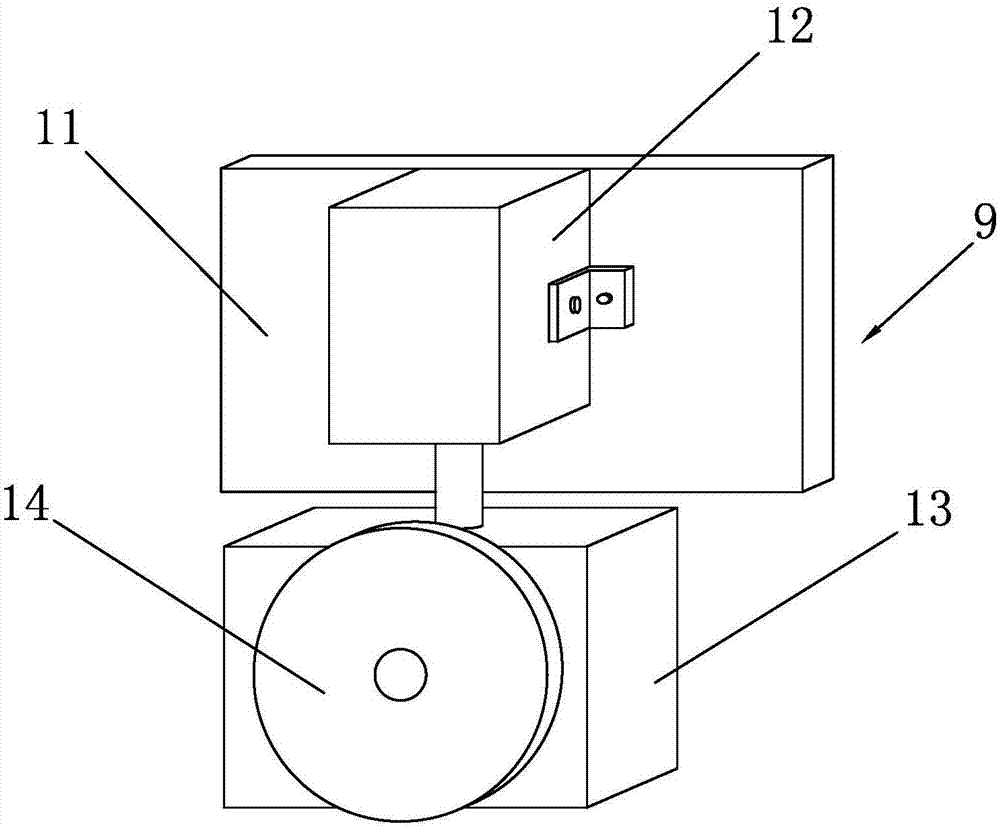

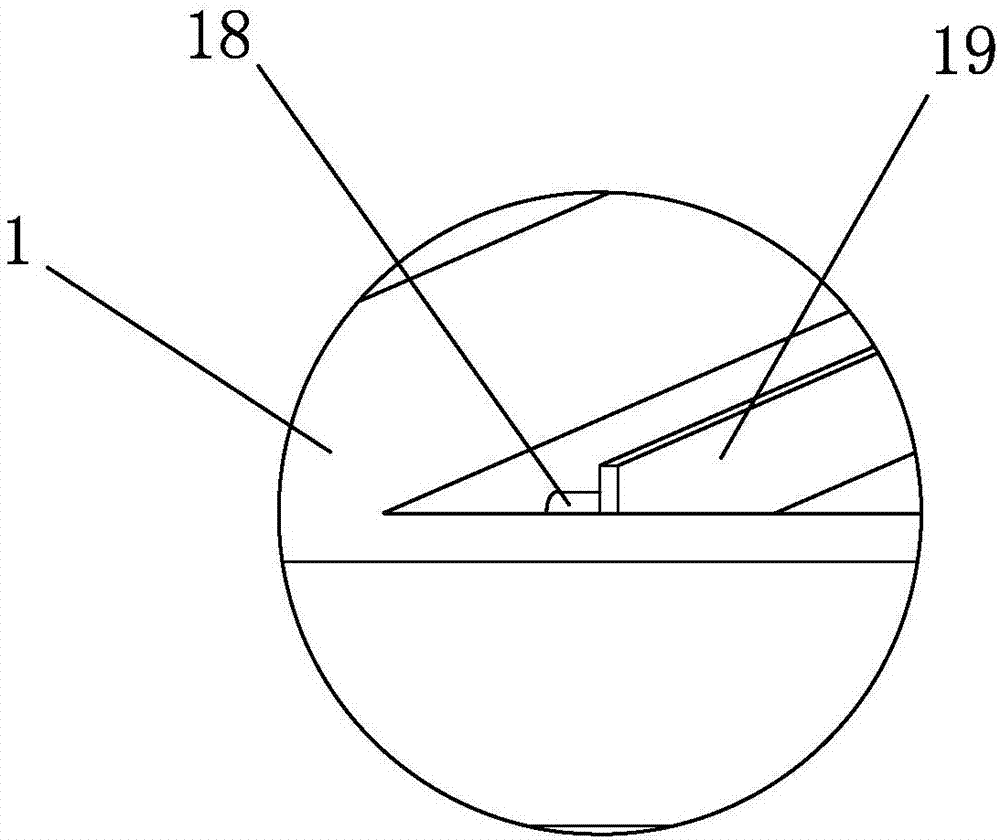

[0026] Such as Figure 1 to Figure 4 As shown, it is an automatic cutting machine for the production of vacuum laminated glass according to the present invention, which includes a cutting table 1, a cutting device and a dust collection device 15, and the left and right sides of the cutting table 1 are provided with shielding plates 20 to block The plate 20 is provided with a perforation 21, the elastic dust suction pipe 16 is connected with the shielding plate 20 through the perforation 21, the elastic dust suction pipe 16 matches the perforation 21, and the design of the shielding plate 20 can facilitate the installation and positioning of the elastic dust suction pipe 16 , the design of the perforation 21 can facilitate the limited connection between the elastic dust suction pipe 16 and the shielding plate 20, and the installation and operation are convenient.

[0027] The top surface of the cutting table 1 is provided with a placement groove 2, and the left and right sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com