Preparation method for diamond particles deposited with WC/W (wolfram carbide/wolfram) composite coating on surfaces

A diamond particle and composite coating technology, which is applied in coatings, metal processing equipment, grinding/polishing equipment, etc., can solve the problems that titanium trichloride is easy to pollute the environment, lose its industrial application value, and reduce the strength of diamonds. Good compatibility, no pretreatment process, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method for depositing a WC / W composite coating on the surface of diamond particles, the main preparation process steps are:

[0027] (1) First put the diamond particles into 10% HNO by weight 3 Boil and rinse in 5% NaOH solution for cleaning and roughening pretreatment. The treated diamond particles are placed in a tray in a double cathode plasma sputtering deposition furnace.

[0028] (2) Subsequent double-cathode plasma sputtering deposition to prepare WC / W nanocomposite coatings. The parameters of the double-cathode plasma sputtering deposition process are as follows: 820V, current 3.5A, tray voltage 360V, distance between target and tray 10mm, working pressure of argon, air pressure 32Pa, tray temperature 600°C, deposition time 2 hours.

[0029] c. The type of sputtering target: W with a purity of 99.9%;

[0030] d. The type of workpiece material: diamond particles

[0031] The grain size of the WC layer of the obtained nano coating is 30-40nm, the...

Embodiment 2

[0033] A preparation method for depositing a WC / W composite coating on the surface of diamond particles, the main preparation process steps are:

[0034] (1) First put the diamond particles into 10% HNO by weight 3 Boil and rinse in 5% NaOH solution for cleaning and roughening pretreatment. The treated diamond particles are placed in a tray in a double cathode plasma sputtering deposition furnace.

[0035] (2) Subsequent double-cathode plasma sputtering deposition to prepare WC / W nanocomposite coatings. The parameters of the double-cathode plasma sputtering deposition process are as follows: 950V, current 3.8A, tray voltage 420V, distance between target and tray 16mm, working pressure of argon, air pressure 35Pa, tray temperature 600°C, deposition time 2 hours.

[0036] c. The type of sputtering target: W with a purity of 99.9%;

[0037] d. The type of workpiece material: diamond particles

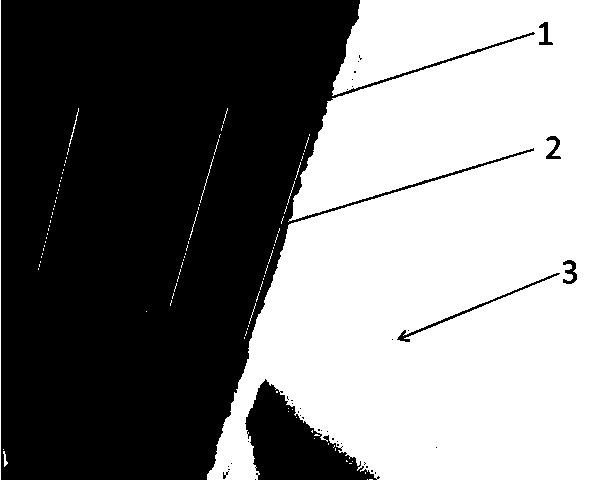

[0038] figure 1It is the SEM photo of the WC / W nanocomposite coating prepared on ...

Embodiment 3

[0040] A preparation method for depositing a WC / W composite coating on the surface of diamond particles, the main preparation process steps are:

[0041] a. First put the diamond particles into 10% HNO by weight 3 Boil and rinse in 5% NaOH solution for cleaning and roughening pretreatment. The treated diamond particles are placed in a tray in a double cathode plasma sputtering deposition furnace.

[0042] b. Subsequent double-cathode plasma sputtering deposition to prepare WC / W nanocomposite coatings. The parameters of the double-cathode plasma sputtering deposition process are as follows: 1000V, current 4.6A, tray voltage 400V, distance between target and tray 16mm, working pressure of argon, gas pressure of 35Pa, tray temperature of 600°C, and deposition time of 2 hours.

[0043] c. The type of sputtering target: W with a purity of 99.9%;

[0044] d. The type of workpiece material: diamond particles

[0045] The grain size of the obtained nano-coating WC layer is 35-50 n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com