Angle grinder positioning tool

A technology for positioning tooling and angle grinders. It is applied in the direction of grinding/polishing safety devices, grinding machines, manufacturing tools, etc. It can solve the problems of low cutting efficiency and low cutting precision, and achieve the purpose of increasing cutting speed, solving overwork and reducing force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

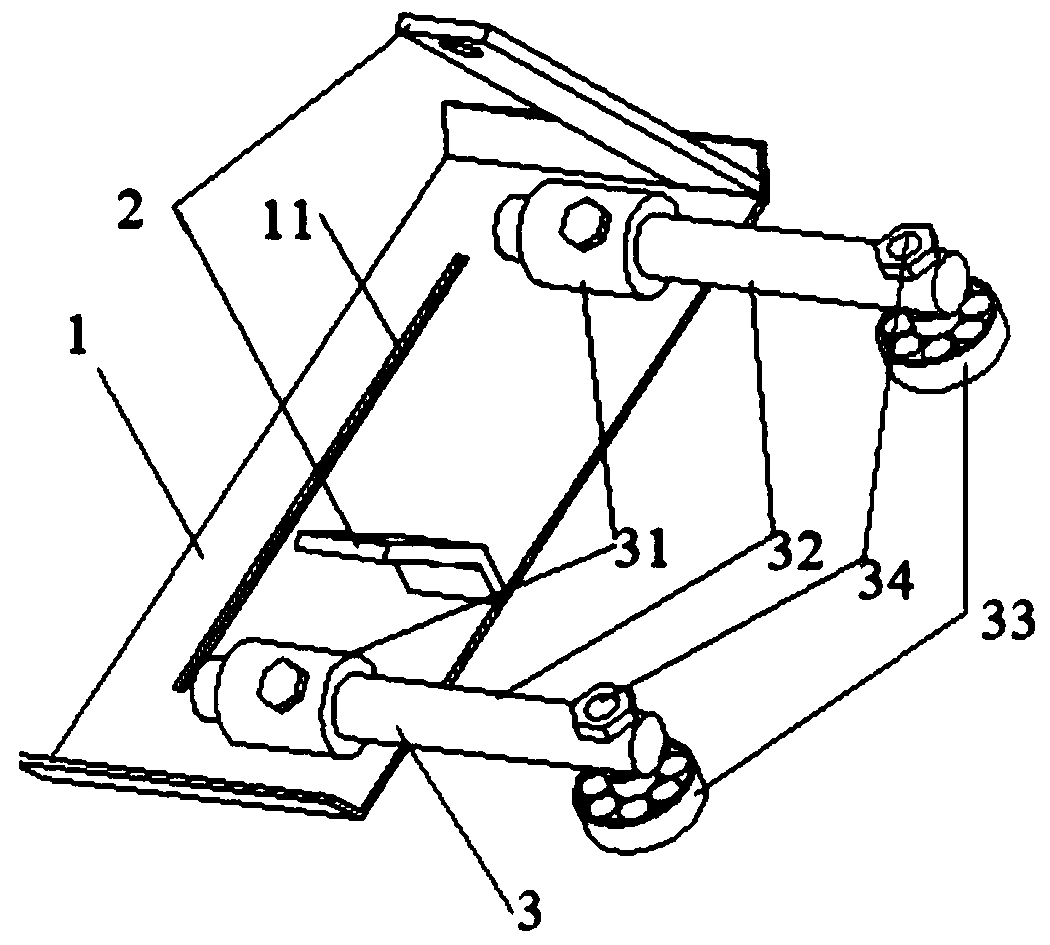

[0029] see figure 1 , the present invention provides a positioning tool for an angle grinder, comprising a guide plate 1, a mounting bracket 2 fixedly connected to the guide plate 1 and a positioning device 3 fixed on the guide plate 1, the guide plate 1 is provided with a Parallel to the cutting grooves 11 , the upper end of the mounting bracket 2 is provided with a connection hole, and the installation direction of the positioning device 3 is perpendicular to the direction of the cutting edge 11 . The positioning tool is used in conjunction with the angle grinder. There is a connecting hole on both sides of the angle grinder body, which is placed on the guide plate 1. The cutting blade installed on the angle grinder is stuck in the cutting groove 11 on the guide plate. The body is fixedly connected together with the connecting hole on the upper end of the mounting bracket 2 through screws. In this embodiment, the mounting bracket 2 includes two, and the angle grinder body is...

Embodiment 2

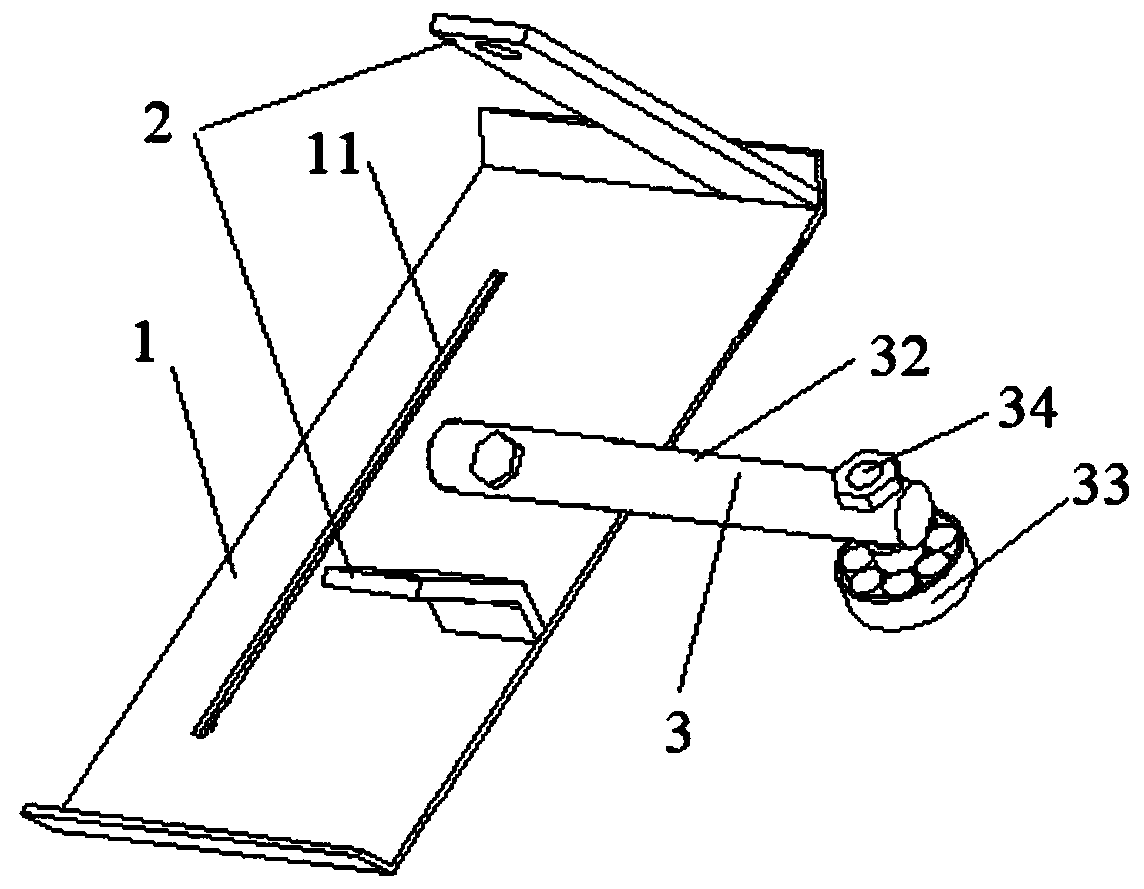

[0033] refer to figure 2 The difference between this embodiment and the first embodiment is that a set of positioning devices 3 is used, and the positioning sleeve 31 in the first embodiment is removed, so that the positioning rod 32 is directly connected to the guide plate. In this embodiment, the direction of the positioning device 3 is perpendicular to the direction of the cutting groove 11, and is located in the middle of the guide plate 1. One end of the positioning rod 32 is directly fixed on the guide plate 1. If welding is used, it is connected with the positioning roller 33. One end is provided with a plurality of screw holes, and the middle of the positioning roller 34 is provided with screw holes, and the two ends of the positioning connecting rod 34 are provided with threads. Screw holes, fixed with nuts. By adjusting the connection position between the positioning rod 32 and the positioning roller 33, the distance from which the positioning rod 32 protrudes from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com