Building board cutting machine

A technology for building boards and cutting machines, which is applied to stone processing tools, stone processing equipment, and work accessories. It can solve problems such as shaking of devices and building boards, high cutting costs, and low cutting precision, so as to prevent breakage and improve Cutting rate, effect of increasing torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

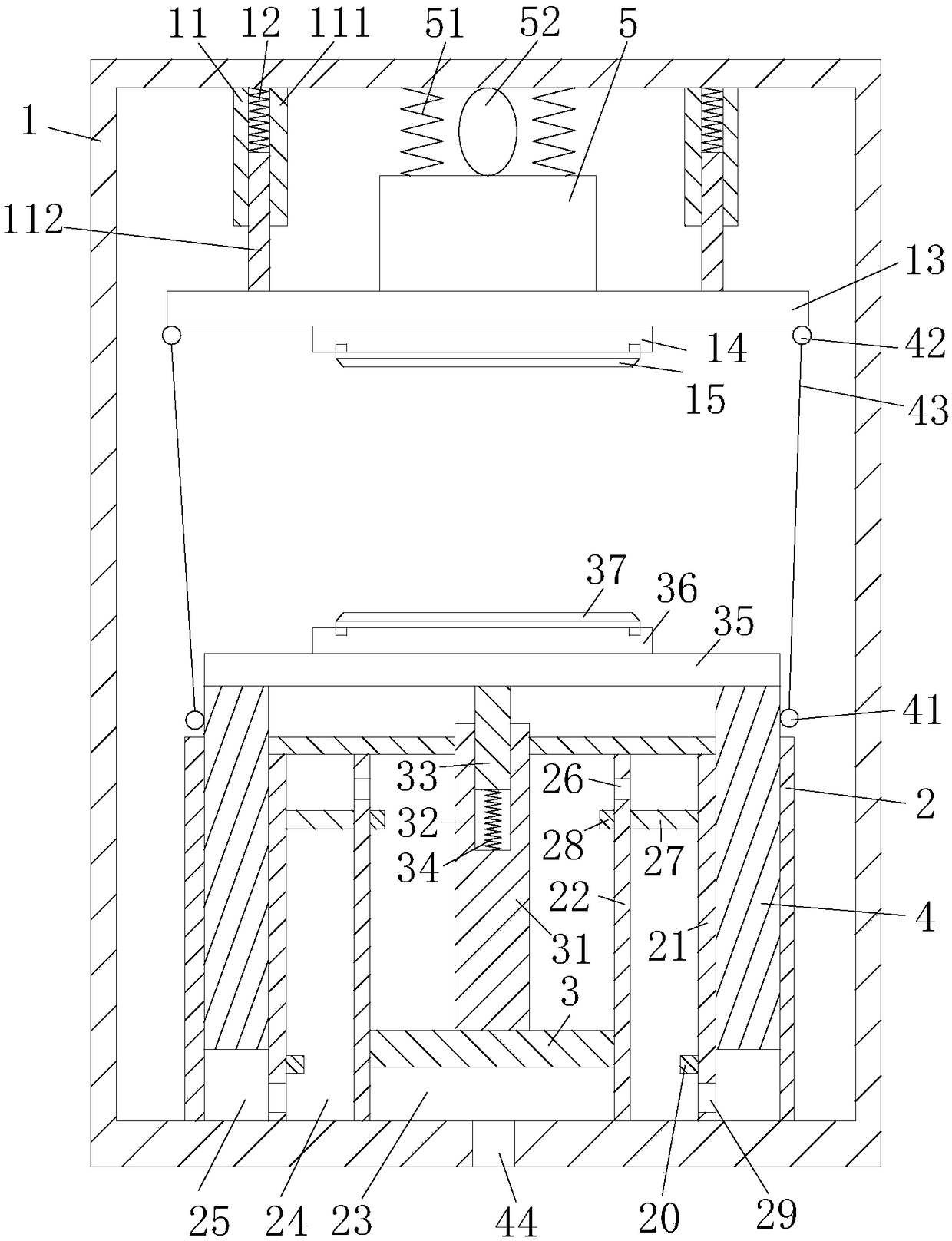

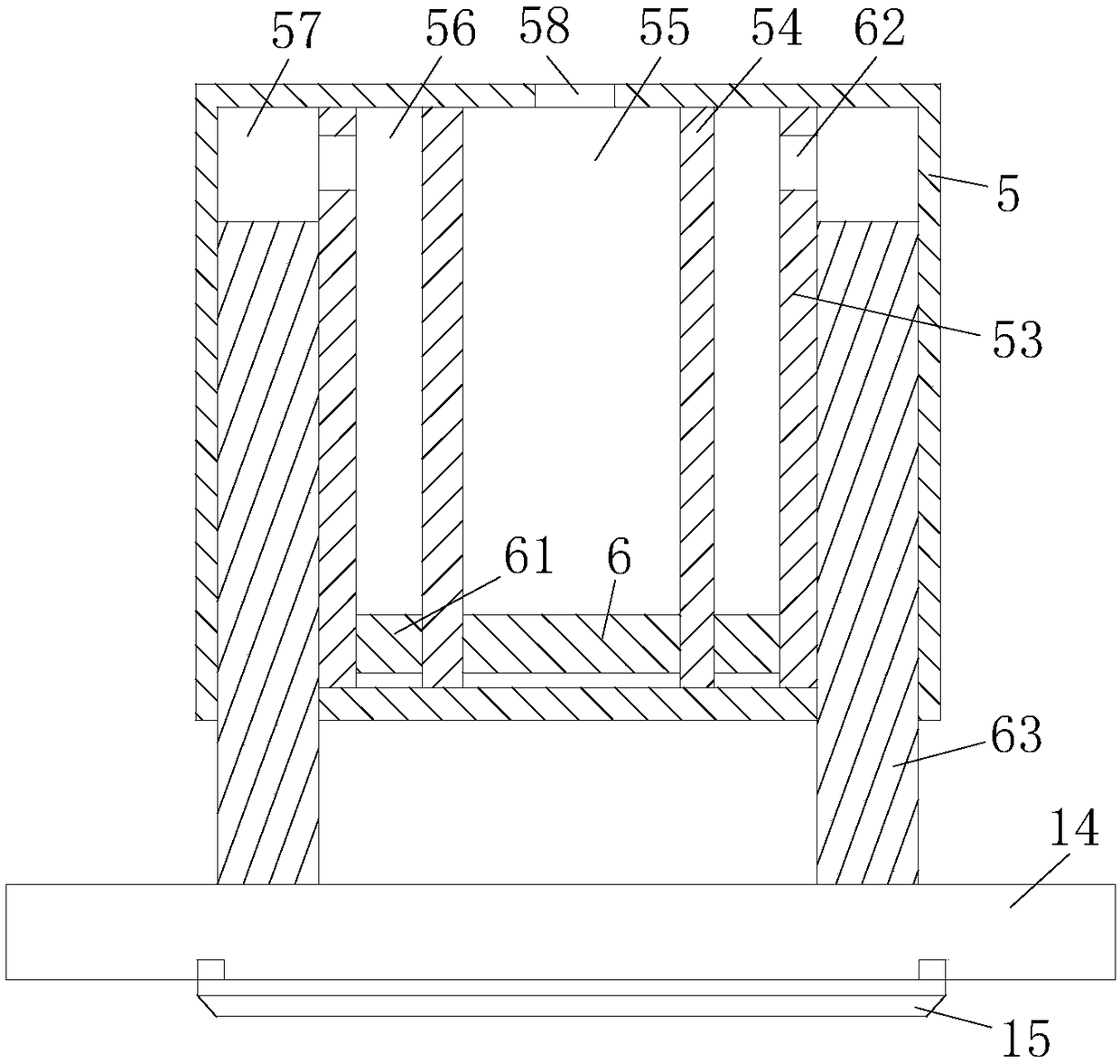

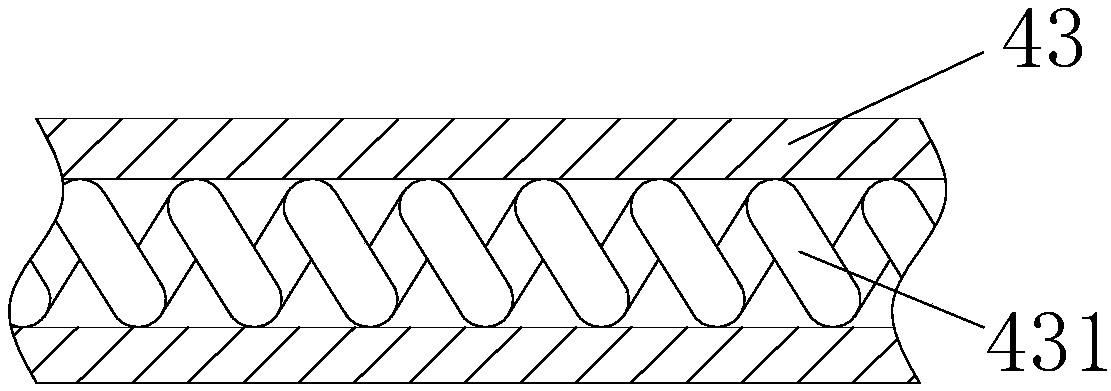

[0022] As an embodiment of the present invention, the upper surface of the first fixing plate 13 is fixedly connected with a second airtight barrel 5; the second airtight barrel 5 is located between two telescopic rods 11; the second airtight barrel 5 Two third springs 51 are fixedly connected between the upper surface and the inner wall of the frame body 1, and an air bag 52 is arranged between the two third springs 51; the air bag 52 is fixedly connected to the inner wall of the frame body 1 and the second airtight barrel 5 Between the surfaces; the second airtight barrel 5 is provided with a third isolation plate 53; the third isolation plate 53 is designed in a circular shape, and the third isolation plate 53 is vertically arranged, and the upper and lower ends are fixedly connected to the second The upper and lower inner walls of the airtight barrel 5; the third isolating plate 53 is provided with a fourth isolating plate 54; the fourth isolating plate 54 is circular in de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com