Circuit device of injection mold with single-side inlet and outlet cooling water

An injection mold and cooling water technology, which is applied in the field of a circuit device for the injection mold to enter and exit cooling water on one side, can solve the problems of poor cooling effect, high processing cost, complex waterway structure, etc., and achieves easy arrangement, simple structure, and convenient processing and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

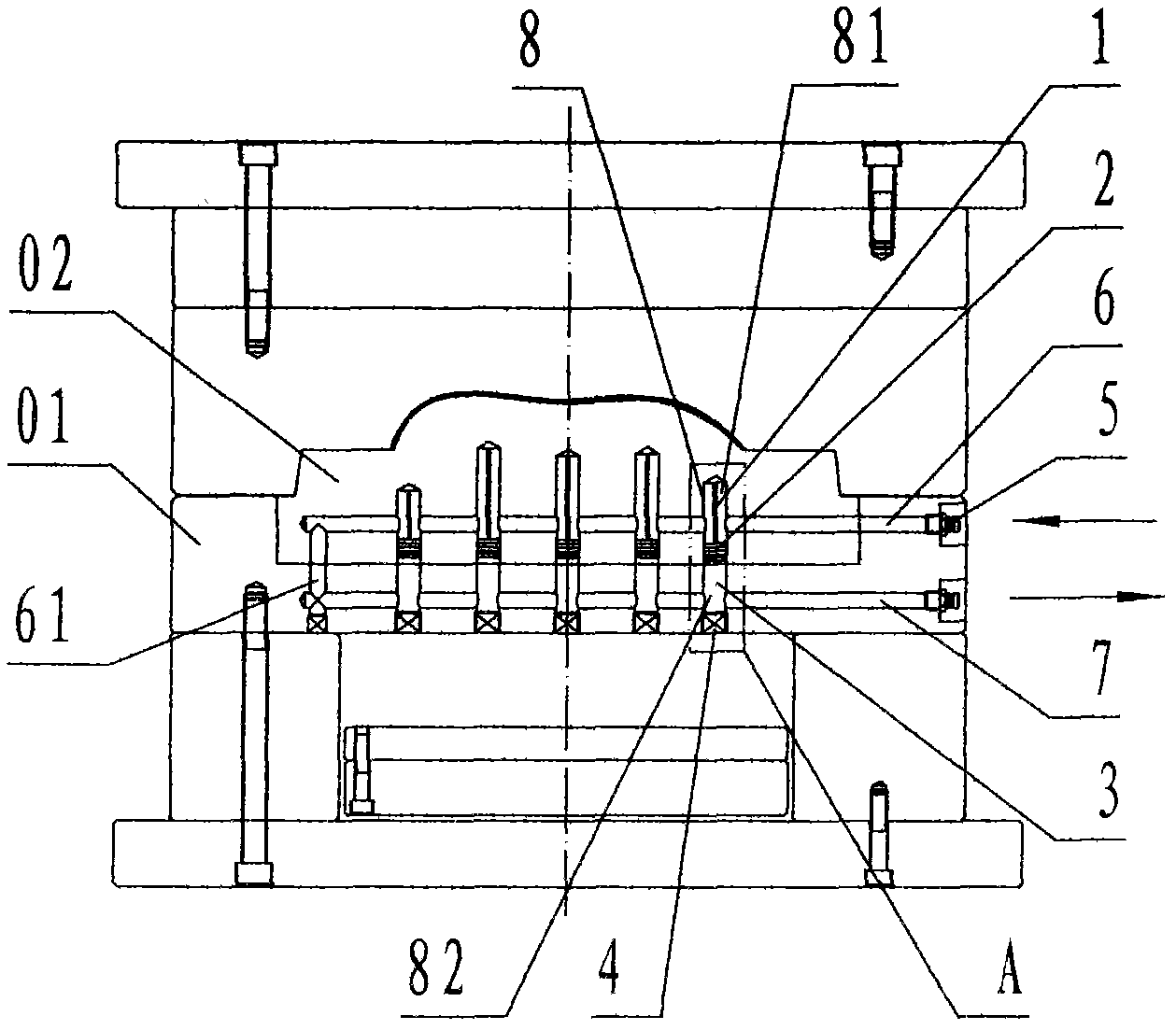

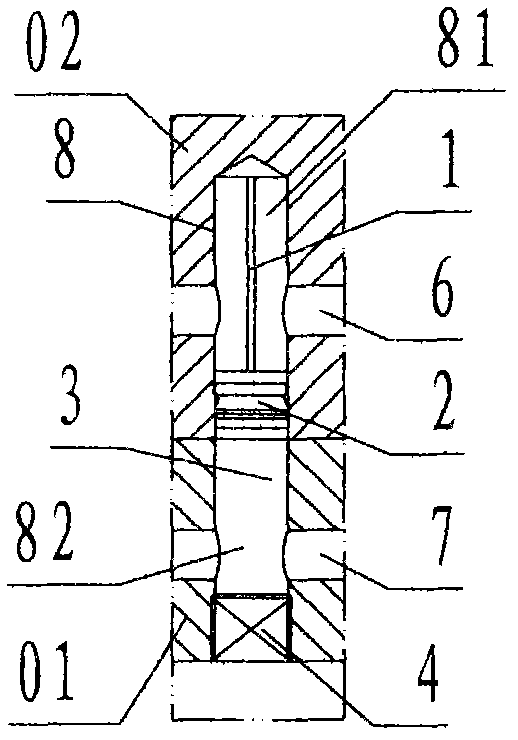

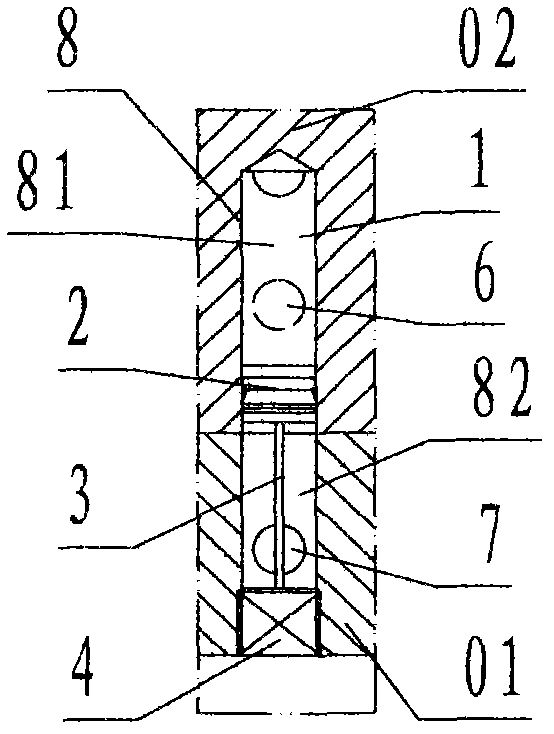

[0020] refer to Figure 1 ~ Figure 3 , a circuit device for cooling water in and out of an injection mold on one side of the present invention, comprising a water barrier 1, a water plug 2, a support plate 3, a plug 4, an inlet channel 6, a turning channel 61, an outlet channel 7, and a turning water cooling Holes 8, wherein: the water baffle 1 is a rectangular steel thin plate, and the upper end of the water baffle 1 is provided with a water turning gap formed by a semicircular groove;

[0021] The water plug 2 is a cylindrical copper plug;

[0022] The support plate 3 is a rectangular steel thin plate;

[0023] The plug 4 is a plug of cylindrical steel;

[0024] The water turning cooling hole 8 is a circular vertical blind hole arranged in the moving template 01 and the moving model core 02 from bottom to top; the water plug 2 is fixedly arranged in the turning water cooling hole 8, and the turning water cooling hole 8 is isolated The upper part is the water turning chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com