Three-position four-way water pressure magnetic exchange valve used in deep sea

An electromagnetic reversing valve, three-position four-way technology, applied in the direction of fluid pressure actuating device, servo motor assembly, mechanical equipment, etc., can solve the problem that the two-position four-way reversing valve cannot complete the effective positioning of components and increase the amount of wear , low efficiency and other problems, to achieve the effect of reducing wire drawing erosion and corrosion problems, large flow capacity and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

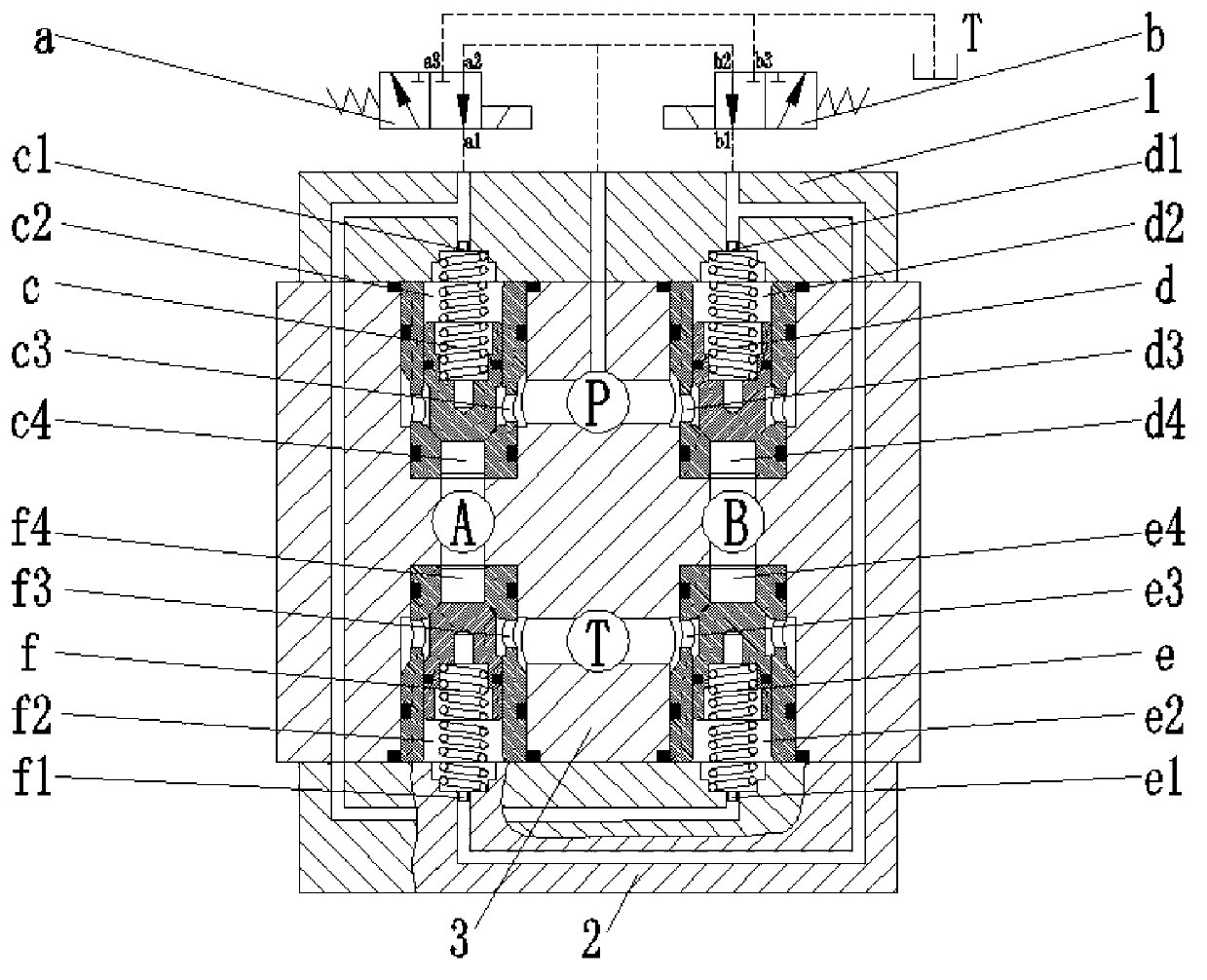

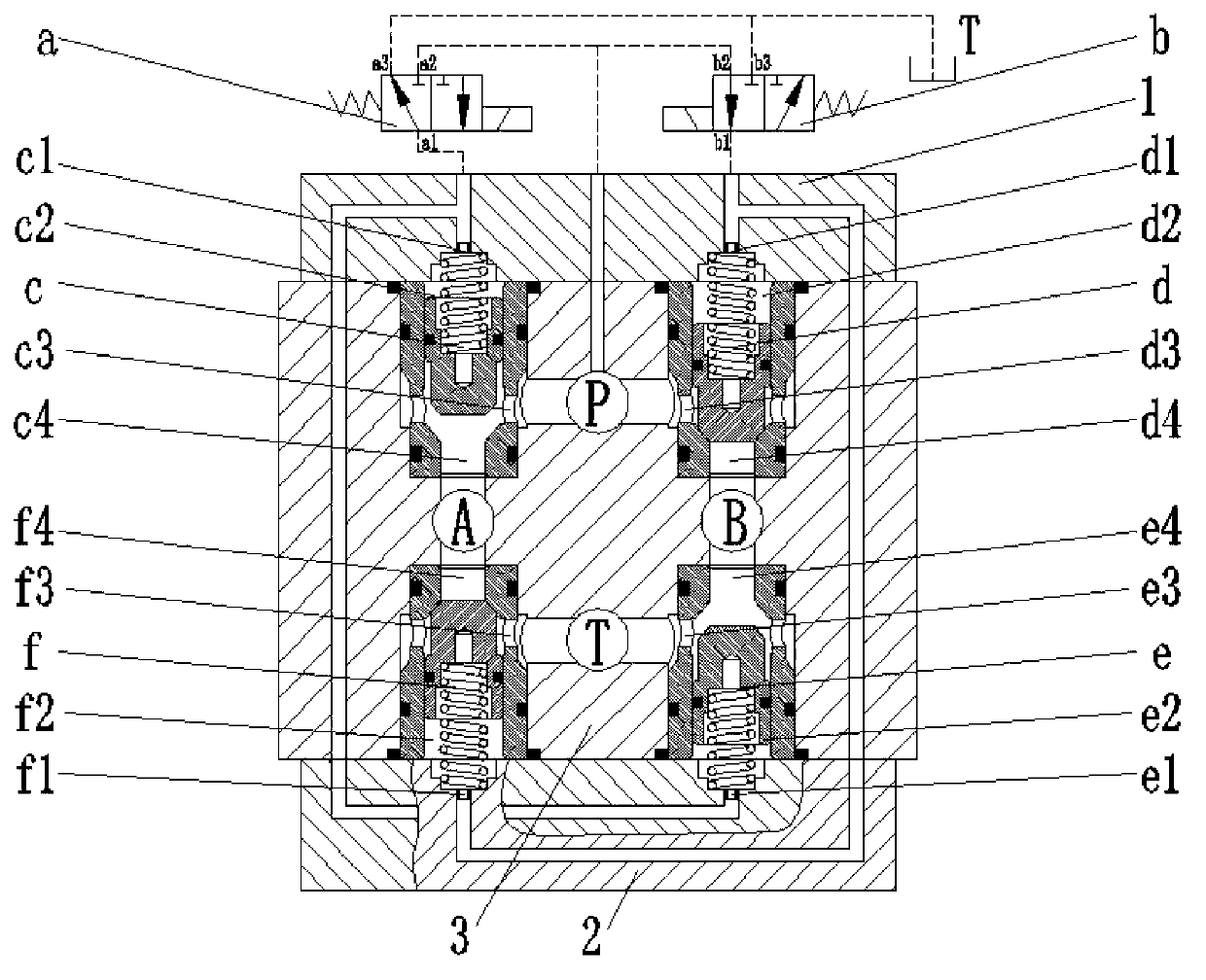

[0017] The present invention adopts two two-position three-way electromagnetic ball valves with small flow rate as pilot control valves, and adopts the method of inserting and adding a cover plate to connect four sets of cone valve-type two-way inserting assemblies with the same structure through holes opened inside the valve body. , the pilot control valve controls the opening or closing of the valve ports of each cartridge assembly, thereby changing the communication mode of the four valve ports P, A, B, and T of the three-position four-way electromagnetic reversing valve to realize the reversing function. The specific implementation will be further described below in conjunction with the accompanying drawings:

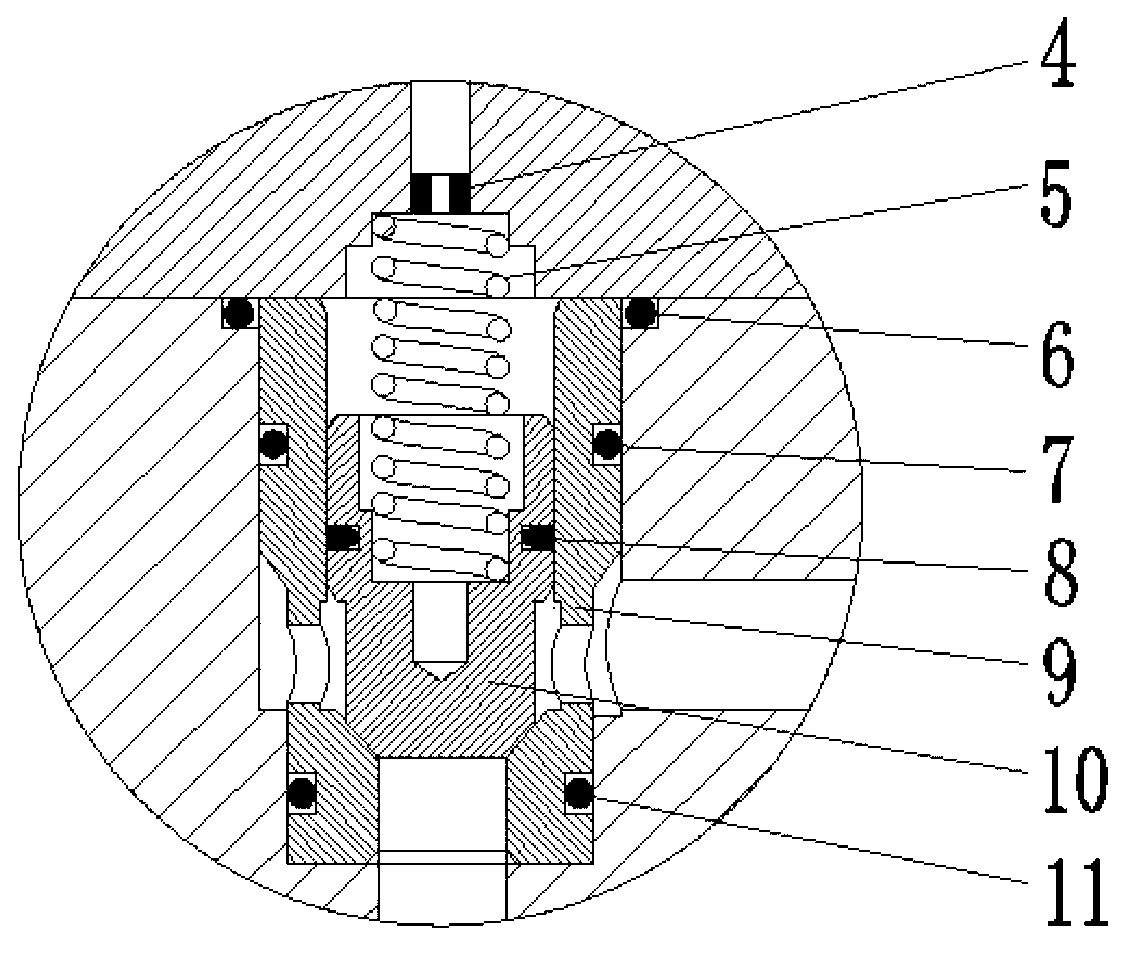

[0018]The present invention consists of two pilot control valves (a, b), four sets of plug-in components (c, d, e, f), two control cover plates (1, 2) and one plug-in block (3), each The plug-in assembly includes a valve core (10), a valve sleeve (9), a spring (5) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com