Press moving table rail cleaner

A technology for moving worktables and presses, applied in the field of cleaners, can solve the problems of poor cleaning effect, easy to scratch the guide rail surface, etc., and achieves the advantages of light structure, good economic effect, reduction of material adsorption and scratches on the guide rail surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

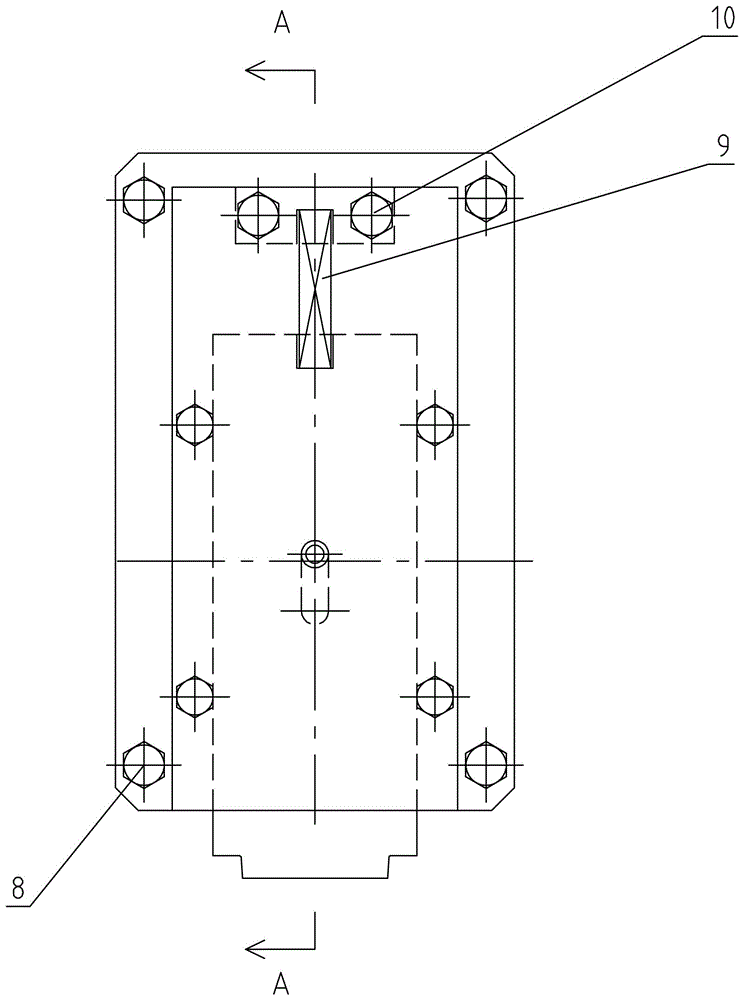

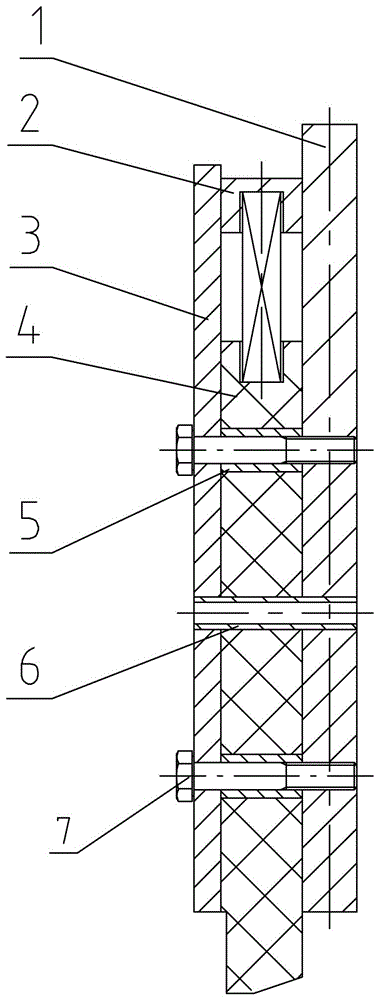

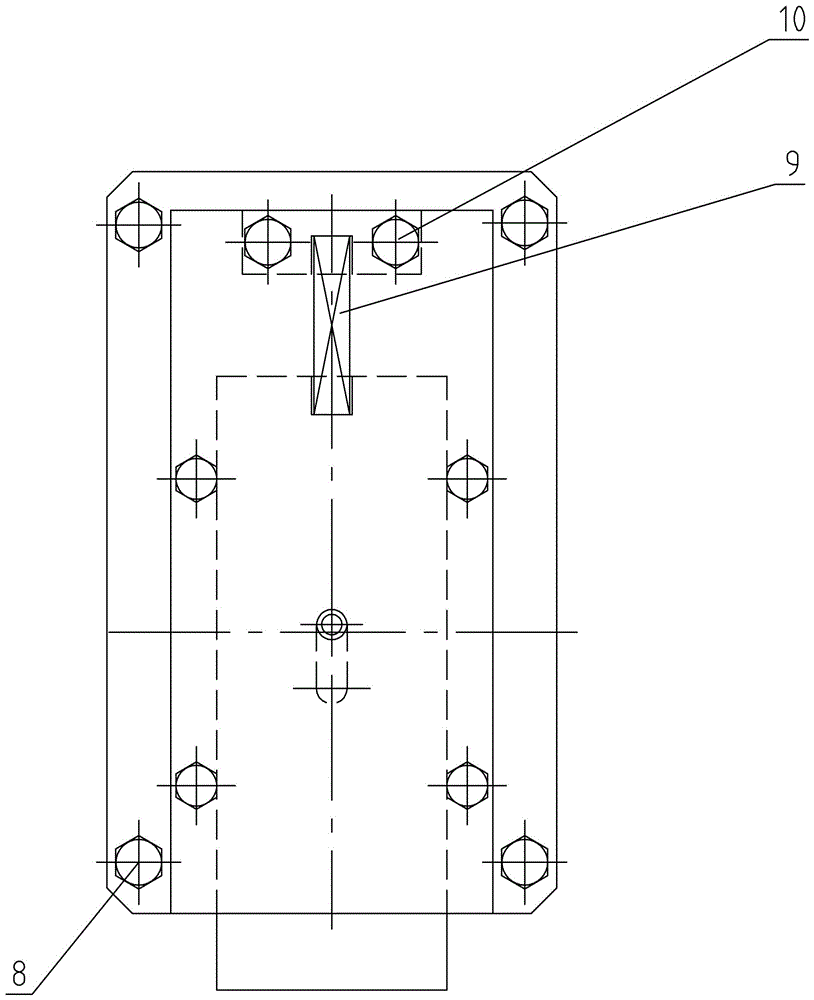

[0017] The present invention as Figure 1-3 As shown, a guide rail cleaner for a press mobile workbench includes a front platen 1 and a rear platen 3, and an upper support 2 is installed between the upper end of the front platen 1 and the upper end of the rear platen 3, and is characterized in that the scraper 4 is installed on Between the front pressure plate 1 and the rear pressure plate 3, the front pressure plate 1 is installed on the rear pressure plate 3 through the fixing bolt 10 and the guide bolt 7, the rear pressure plate 3 is installed on the mobile workbench through the installation bolt 8, and one end of the adjustment spring 9 is installed on the scraper On the plate 4, the other end of the adjustment spring 9 is installed on the upper support 2. According to the guide rail cleaner of the mobile workbench of the press, it is characteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com