Three-cavity type three-position four-way air-control reversing hydraulic valve

A hydraulic valve and valve body technology, applied in the field of hydraulic components, can solve the problems of large volume, poor workmanship, and complex structure of the valve body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

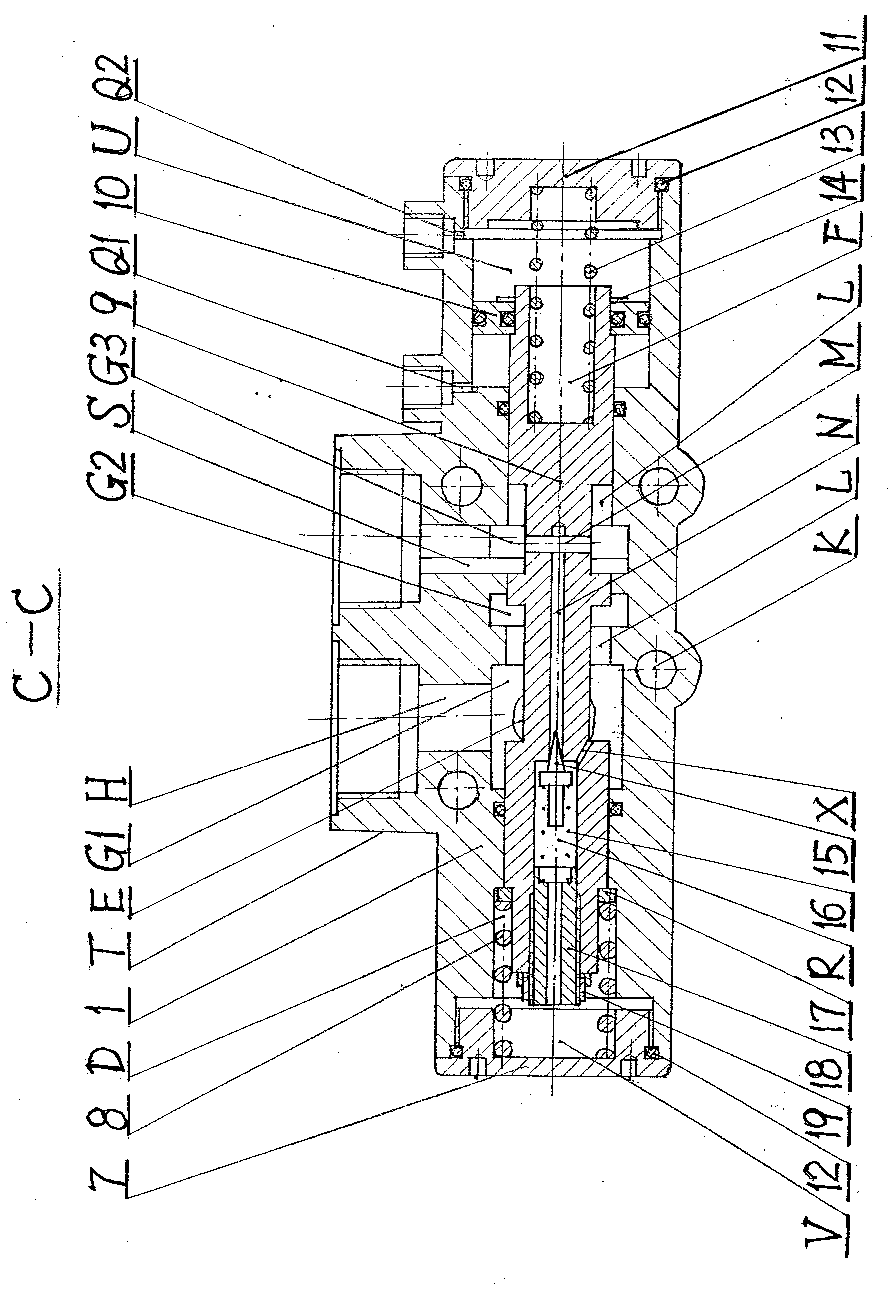

[0019] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

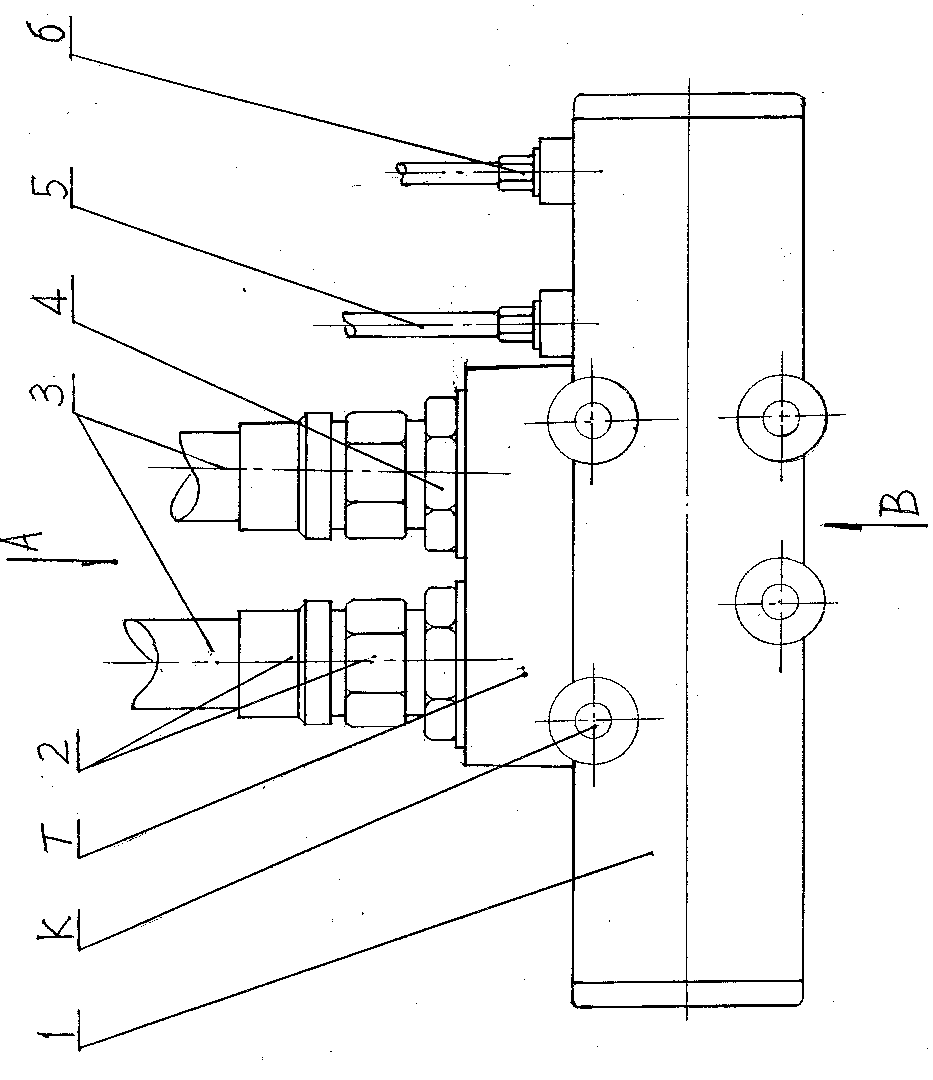

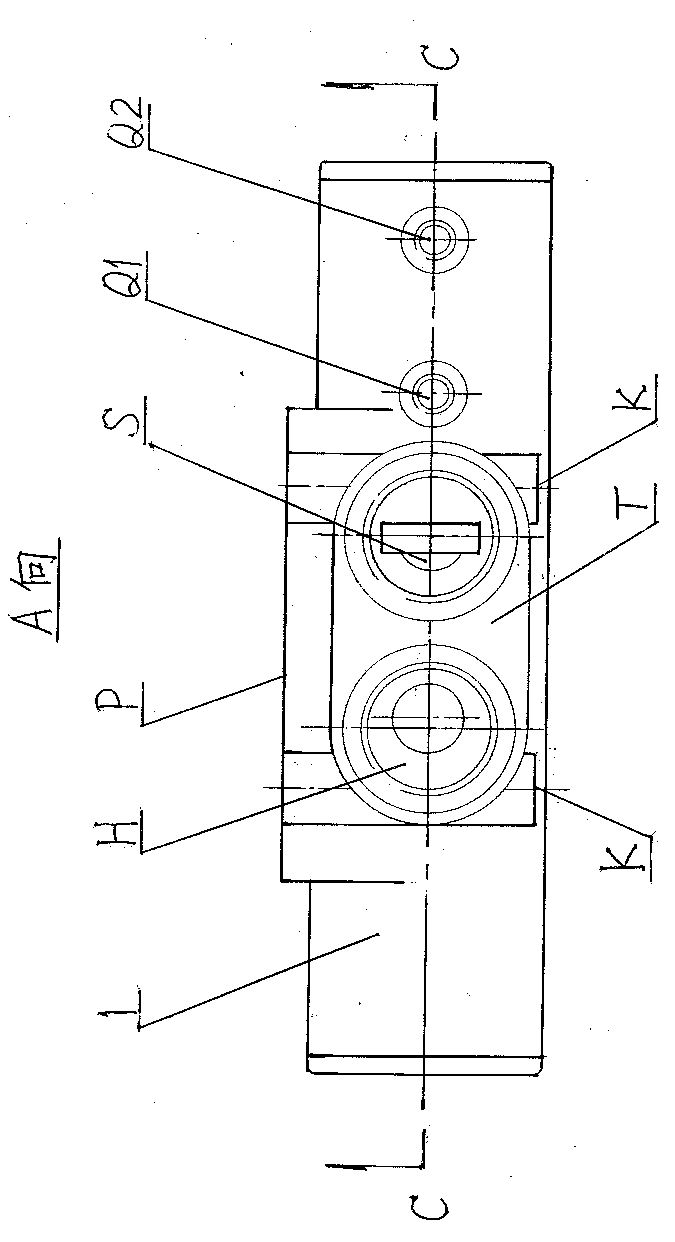

[0020] refer to figure 1 , figure 2 , The valve body 1 of the present invention is in the shape of a horizontal long cylinder, with a boss T on the top of the valve body 1, and a radial oil return hole H and an oil outlet hole S are opened on the boss T, each equipped with an oil pipe joint 2 Connect the oil pipe 3, respectively connect the hydraulic oil tank 21 and the oil cylinder 24, the top surface of the valve body 1 in front of the boss T is provided with a radial descending air hole Q1 and a lifting air hole Q2, each connected to the air pipe 5 through the air pipe joint 6, the connection ratio of the air pipe 5 Air valve 20. The vertical mounting surface P on the back of the valve body 1 is provided with four horizontal and horizontal mounting holes K penetrating through the valve body 1 for assembling bolts to install and fix the valve body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com