Push plate clamping rod mechanism for garage carrier

A carrier and clamping rod technology, which is applied in the field of garage carriers, can solve the problems of high processing and maintenance costs and complex structures, and achieve the effects of easy processing and maintenance, simple structure, and reduced production and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

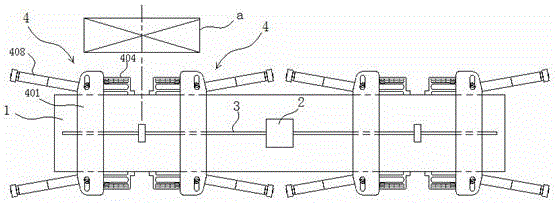

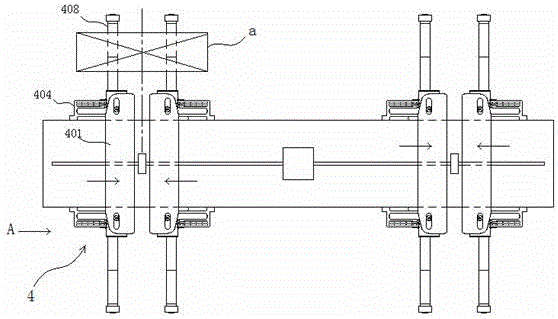

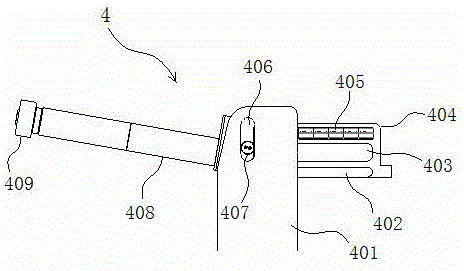

[0017] Holding a tire type carrier such as figure 1 Shown, comprise car body 1, be located at the front and rear two groups of push pedal clamping rod mechanisms on the car body 1 and the screw power mechanism that is made up of screw mandrel 3 and motor 2, every group of push pedal clamping rod mechanisms includes two relative The moving push plate clamp mechanism 4 is composed of each push plate clamp mechanism 4 including a thrust plate 401, a track seat 404 positioned at both sides of the car body 1, two upper and lower parts driven by the thrust plate 401 and matched with the track seat 404. A clamping rod 408, wherein the thrust plate 401 is connected with the screw mandrel 3, and two push pedal clamping rod mechanisms 4 that do relative motion in the two groups of push pedal clamping rod mechanisms are driven by the screw rod power mechanism.

[0018] Push plate clamp mechanism 4 such as Figure 3 to Figure 5 As shown, it includes a thrust plate 401, a clamping rod 408...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com