Electronic back-pulling mechanism

An electronic and tensioning mechanism technology is applied in the field of sewing machines to achieve the effects of convenient maintenance and processing, improved production efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

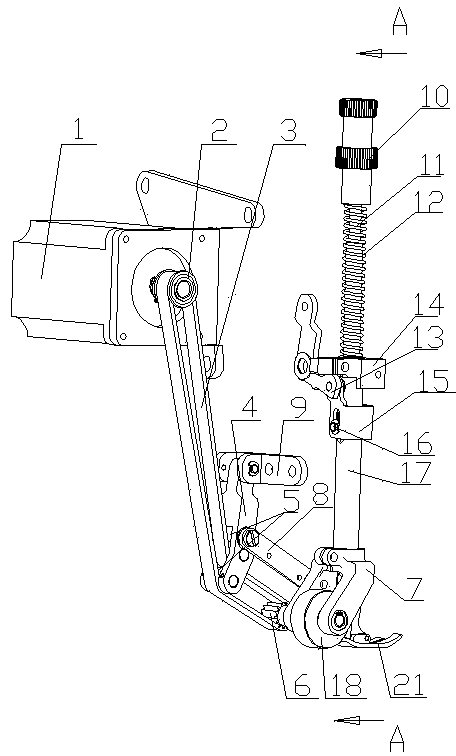

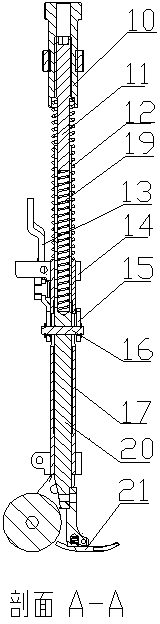

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] see figure 1 and figure 2 , an electronic dragging mechanism, including a motor 1, a first synchronous pulley 2, a synchronous belt 3, a second synchronous belt pulley 6, a synchronous belt tensioning mechanism, a mop wheel assembly 18 and a presser foot mechanism, and the mop wheel assembly 18 is Including the tug wheel frame 7, the presser foot mechanism includes an outer pressure adjusting screw assembly 10, an inner compression rod spring 19, an inner compression rod 20 and a presser foot assembly 21 arranged from top to bottom, and the timing belt tensioning mechanism includes A swing rod 4, a pair of needle roller bearing assemblies 5, a connecting rod 8 and a swing rod seat 9, one end of the swing rod 4 is a double-fork structure, and a pair of needle roller bearing assemblies 5 are arranged between the ends of the double-fork structure, A pair ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com