Wheel-rim electric axle

An electric vehicle and wheel edge technology, which is applied to electric power units, brakes, power units, etc., can solve the problems of in-wheel motor technical difficulty, reduced mechanical transmission efficiency, expansion and contraction of transmission shafts, etc., and achieves good application prospects and facilitates processing and maintenance. , the effect of increasing the door distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

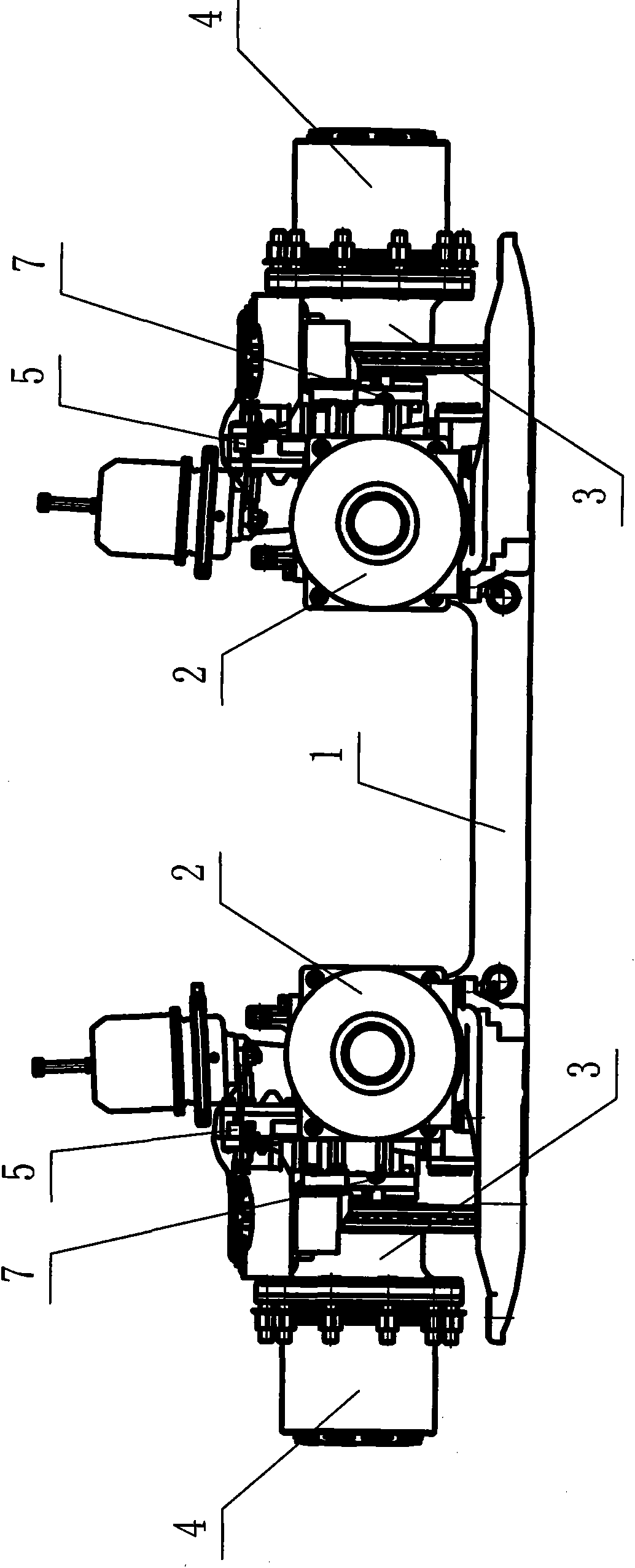

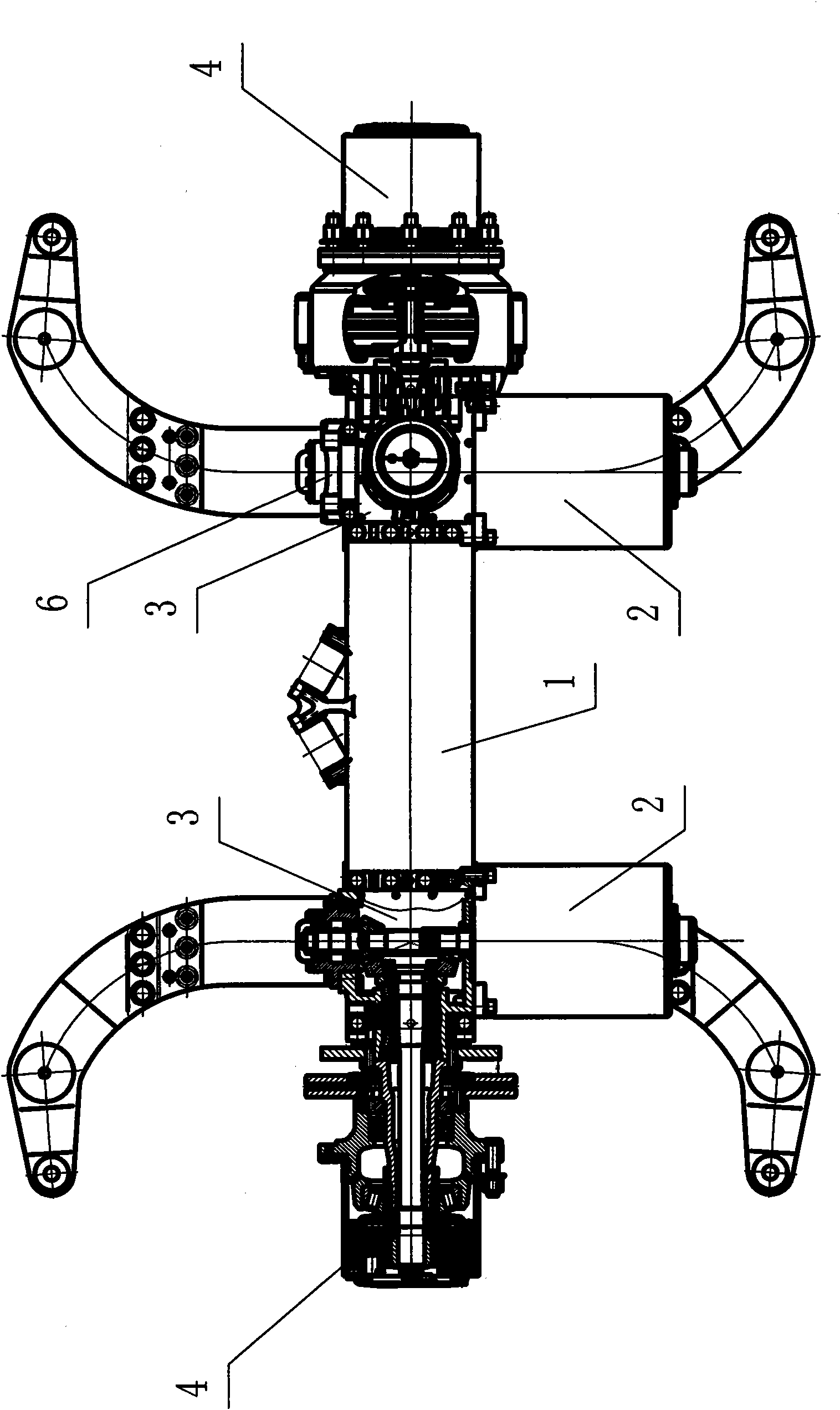

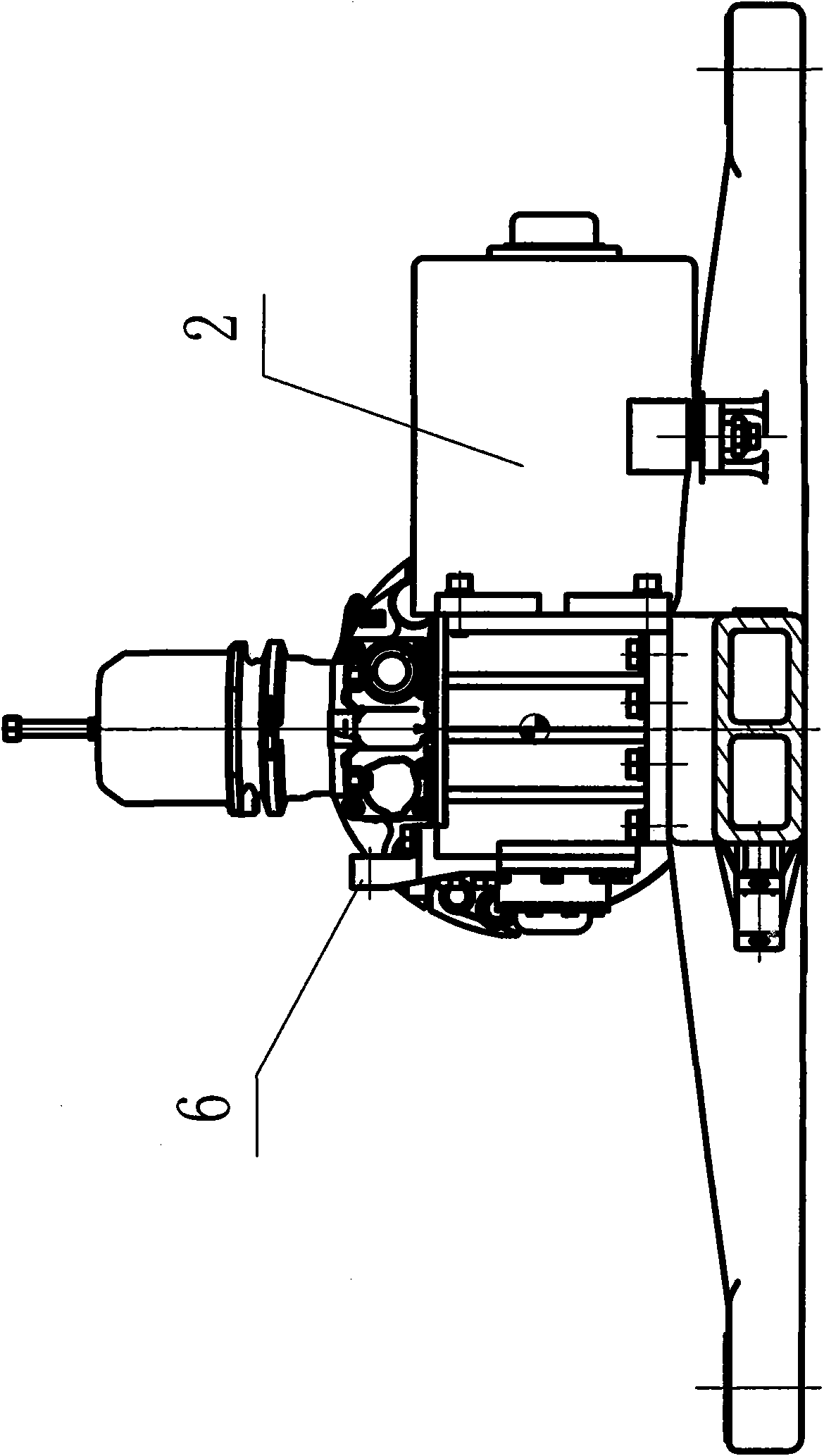

[0018] The wheelside electric axle consists of a rear axle housing assembly 1, two water-cooled brushless DC permanent magnet motors 2, two rear axle main reducer assemblies 3, two rear axle wheelside reducer assemblies 4, two Brake assembly 5, two thrust rod bearings 6 and two sensors 7 constitute. Two water-cooled brushless DC permanent magnet motors 2, two rear axle final reducer assemblies 3, two rear axle wheel side reducer assemblies 4, two brake assemblies 5, two thrust rod supports 6 and two Two sensors 7 are symmetrically arranged and installed on the left and right sides of the rear axle housing assembly 1 center. The water-cooled brushless DC permanent magnet motor 2 is installed on one side of the main reducer box 3-1 of the rear axle main reducer assembly 3, and the output shaft of the water-cooled brushless DC permanent magnet motor 2 is connected with the main reducer assembly of the rear axle. The spline sleeve 3-11 of 3 is connected; the rear axle wheel side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com