Detachable magnetic type nozzle socket wrench and method for preventing nozzle from dropping

A socket wrench and oil nipple technology, which is applied to wrenches, manufacturing tools, wrenches, etc., can solve problems such as insecurity, affecting normal production of oil wells and staff operations, and achieves low cost, good safe operating environment, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

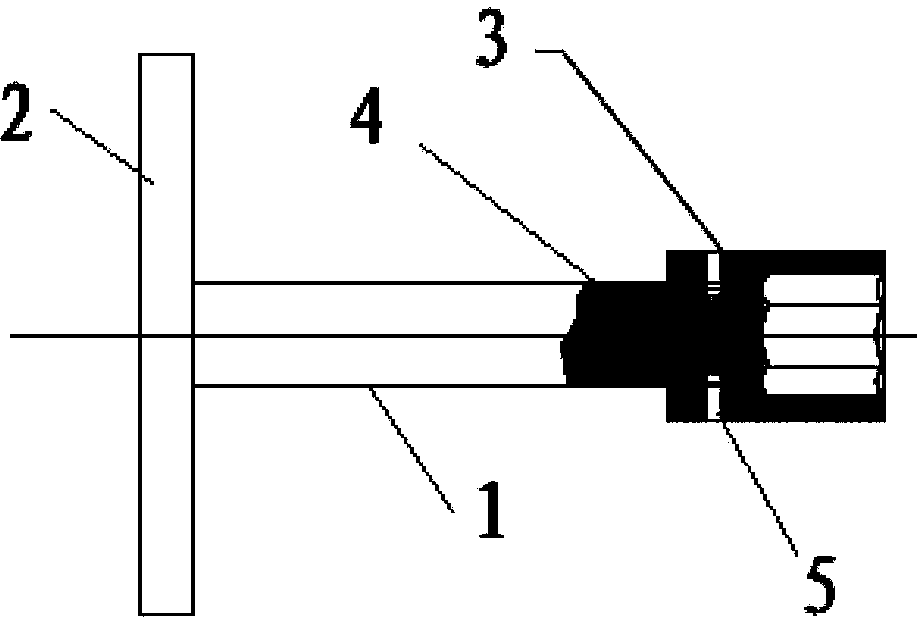

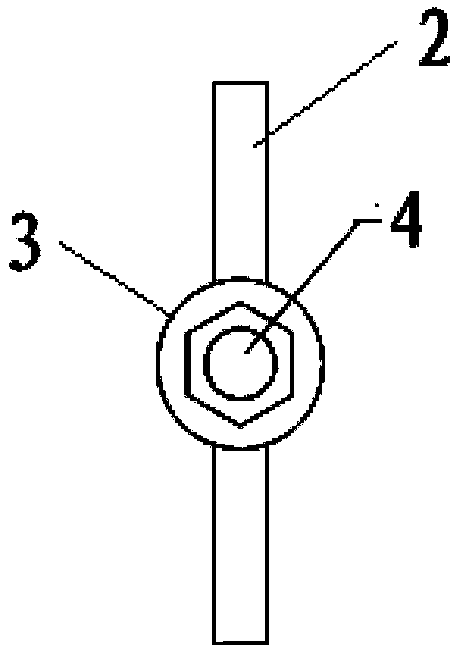

[0014] Embodiment 1: as figure 1 , figure 2 as shown,

[0015] A detachable magnetic oil nipple socket wrench of the present invention is composed of a rod body 1, a sleeve 3, a fixing pin 5, a magnet 4, and an operating handle 2;

[0016] The rod body 1 is connected with the operating handle 2, and the other end of the rod body 1 is connected with the sleeve 3, and a magnet 4 is placed at the position where the rod body 1 is connected with the sleeve 3, and the magnet 4 is connected in the sleeve through a fixing pin 5.

[0017] The technical solution of the invention is the fixed connection of the magnet 4—the specific implementation is to fix with bolts or welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com