Combined type rib cutting convex mold

A combination and convex mold technology, which is applied in metal processing, electrical components, semiconductor/solid device manufacturing, etc., can solve the problems of high equipment and labor costs and low production efficiency, and achieve reduced mold investment, convenient processing and maintenance, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

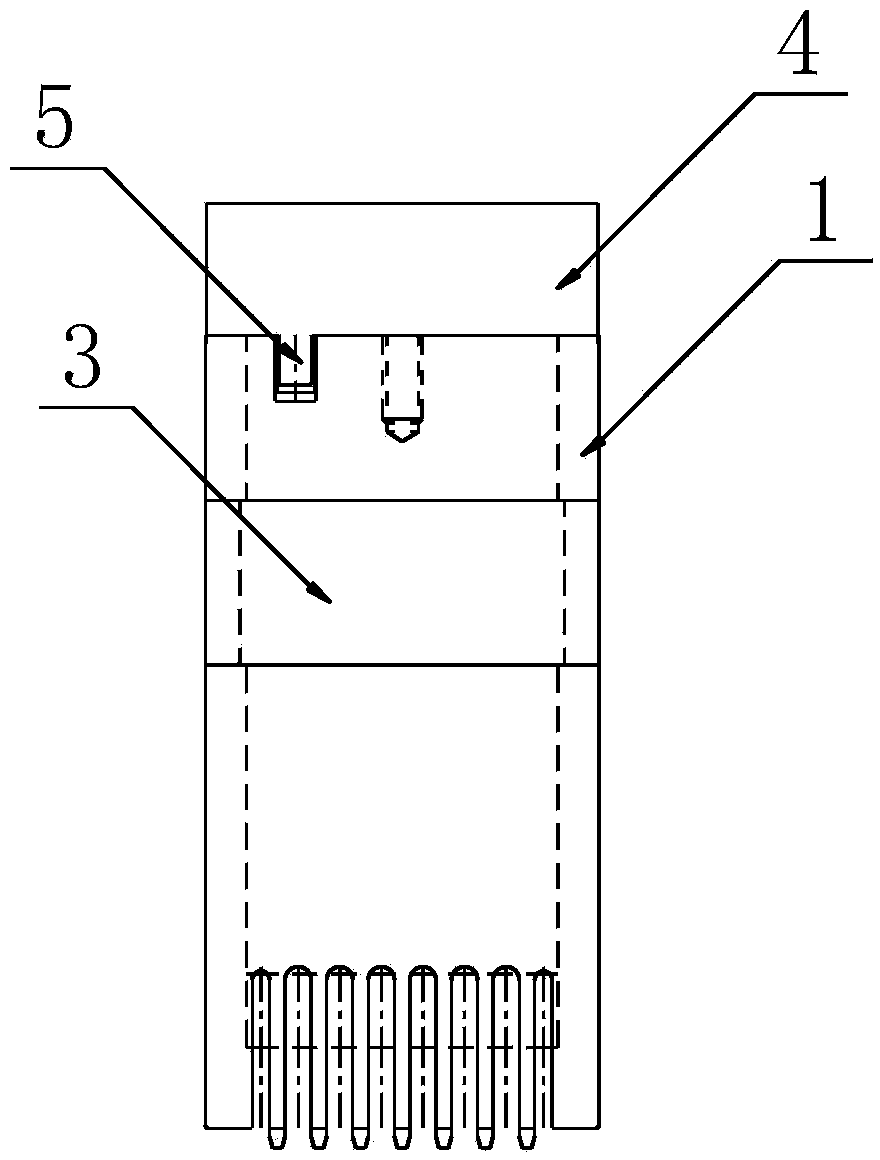

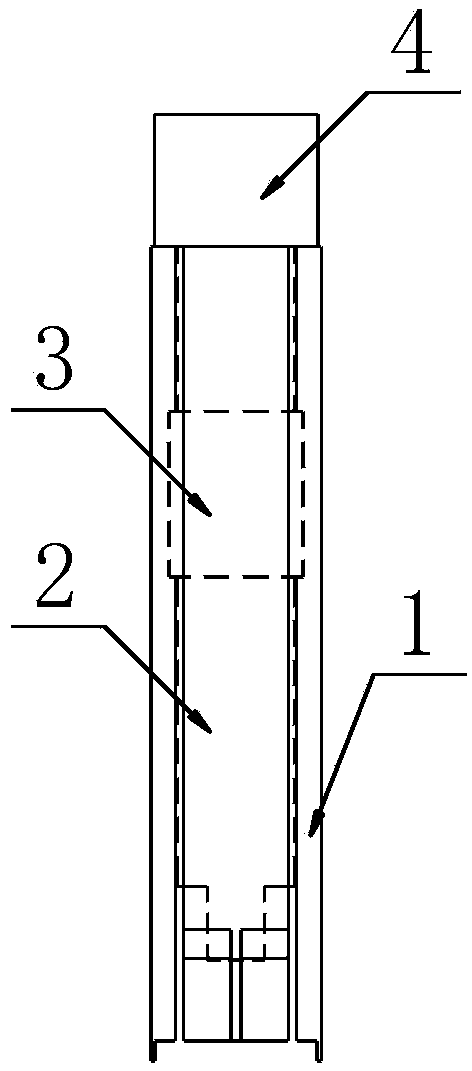

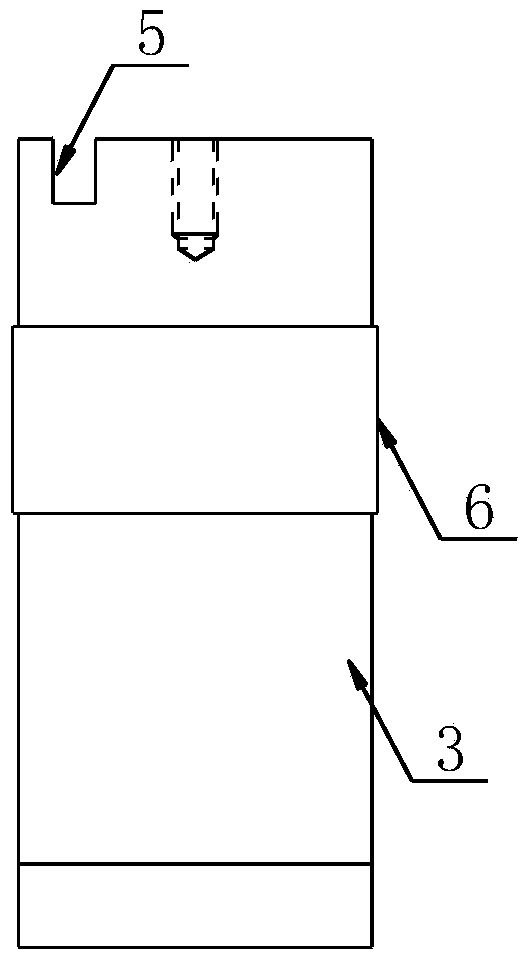

[0014] Embodiment: The present invention will be further described below. see figure 1 , figure 2 , image 3 , a combined rib-cutting punch die, comprising a rib-cutting punch group unit and a punch fixing plate, and the rib-cutting punch group unit is mainly composed of a vertically arranged middle rib-cutting punch 1 and a bottom rib-cutting punch 2 , punch pressing block 3 and rectangular punch cushion block 4, two rib-cutting punches 1 and bottom rib-cut punches 2 respectively, the rib-cutting punch 1 is located on the front and rear sides of the punch pad 4, and the ribs are cut The bottom rib punch 2 is located on the left and right sides of the punch pad 4, and the sides of the center rib punch 1 and the bottom rib punch 2 are sequentially connected to form a rectangular chamber, and the center rib punch 1 and the bottom rib The upper end of the punch 2 is fixedly connected with the lower edge of the punch pad 4 respectively, the punch press block 3 is located in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com