Roller spinning device for steel tube pointing machine

A technology of rollers and bearing glands, applied in manufacturing tools, metal processing equipment, forming tools, etc., can solve the problems of complex structure, stabbing, large metal loss, etc., achieve simple, reasonable and compact structure, improve accuracy and efficiency, Easy to produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

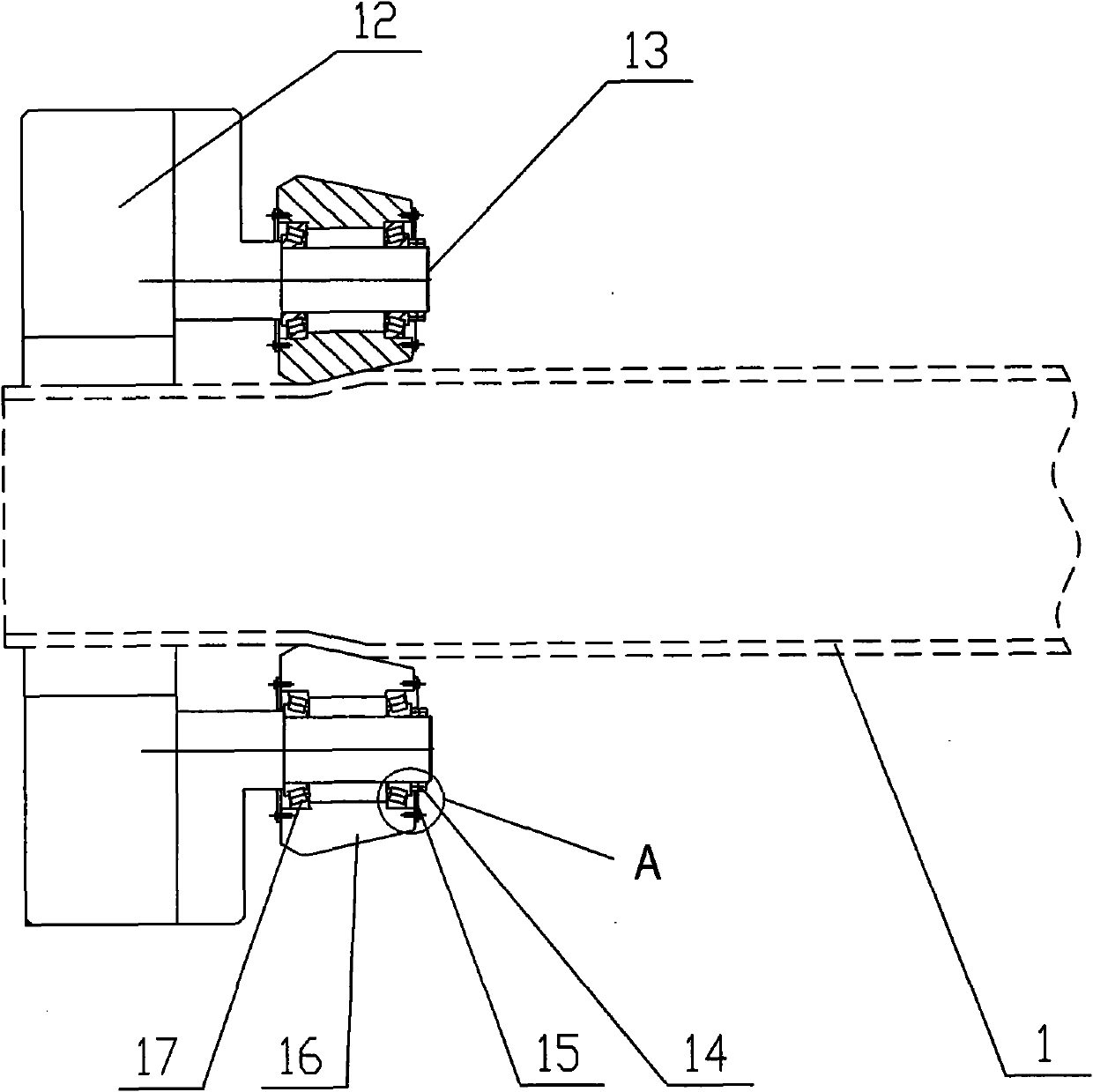

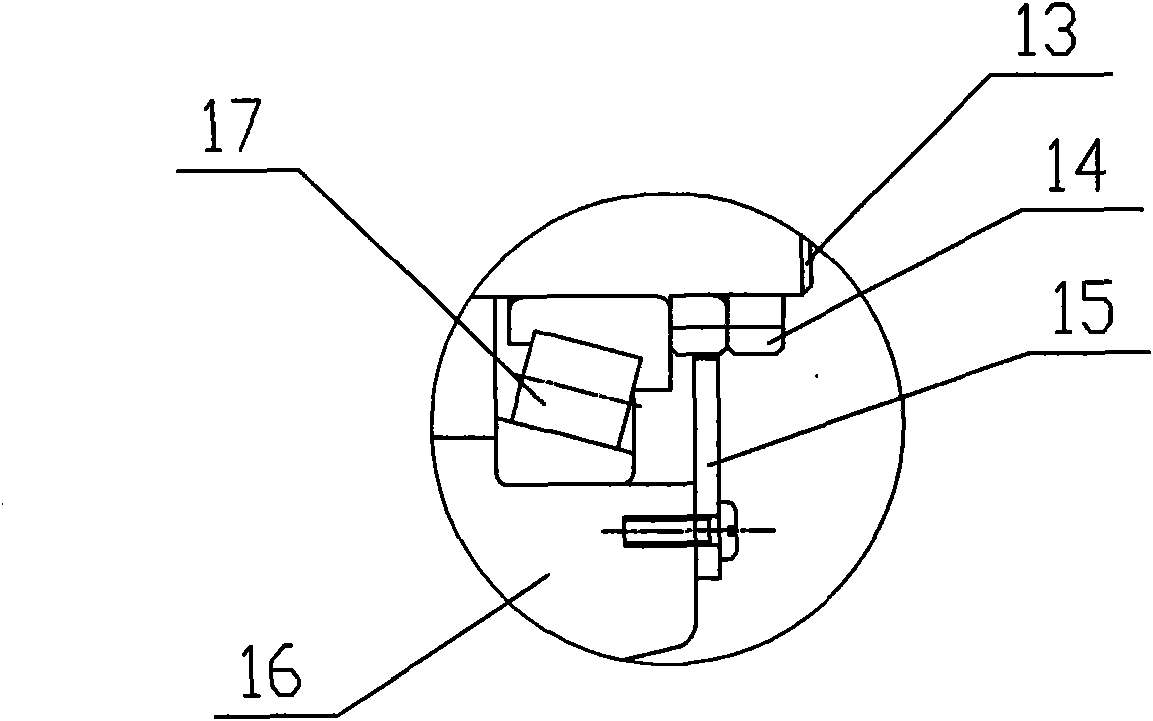

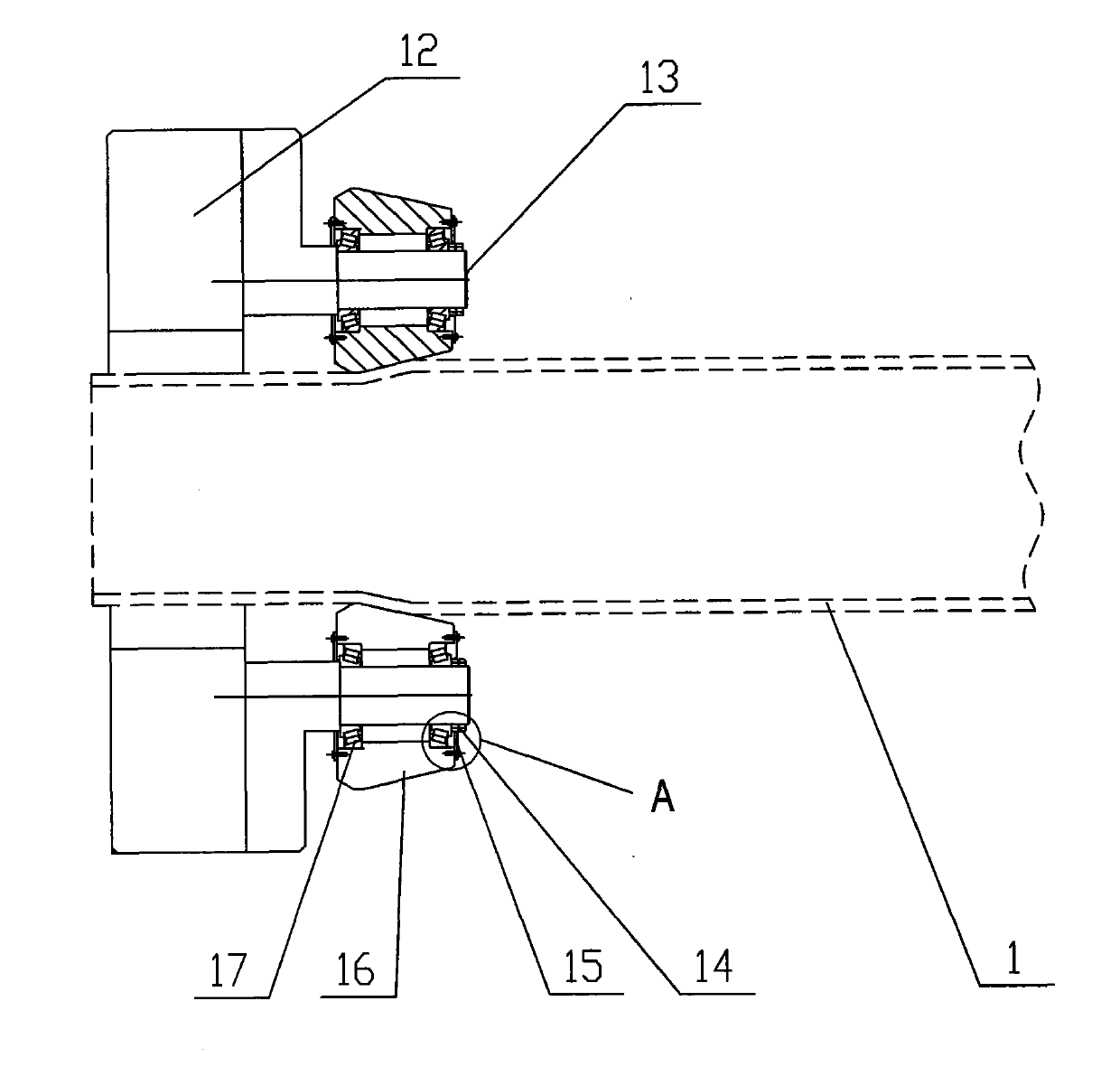

[0010] Such as figure 1 , 2 As shown, it is a roller spinning device of a steel pipe head making machine, which includes a self-centering three-jaw chuck 12, and one side of the self-centering three-jaw chuck 12 is connected with three jaws 13, and each jaw 13 is respectively The roller 16 is connected by a round nut 14 , a bearing gland 15 , and a third single row tapered roller bearing 17 . The three rollers can be configured in different positions to form different pass patterns (replacing the rollers can realize the wide group spacing of steel pipes).

[0011] The other side of the self-centering three-jaw chuck 12 is connected to the driving device through a flange, and the steel pipe 1 to be made is inserted into the self-centering three-jaw chuck 12 through an oil cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com