Electric palm picking machine

A technology of palm trees and picking machines, which is applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc. It can solve the problems of high failure rate of gasoline engines, difficult to use costs, and high maintenance costs, and achieves a simple, reasonable and compact structure, and reduces maintenance costs. , the effect of low implementation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

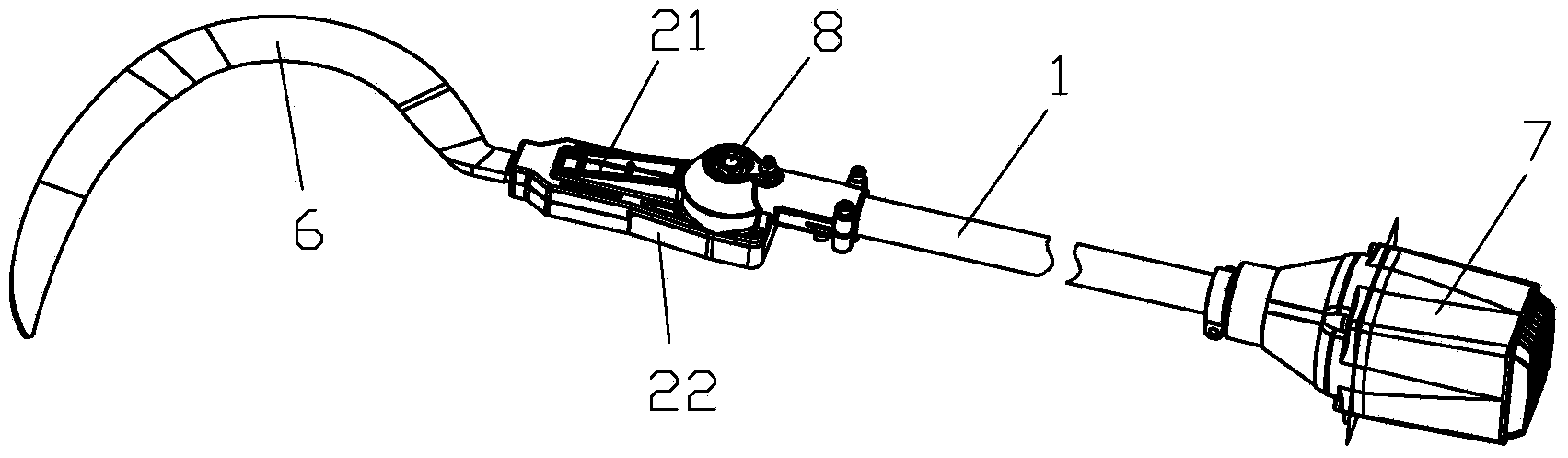

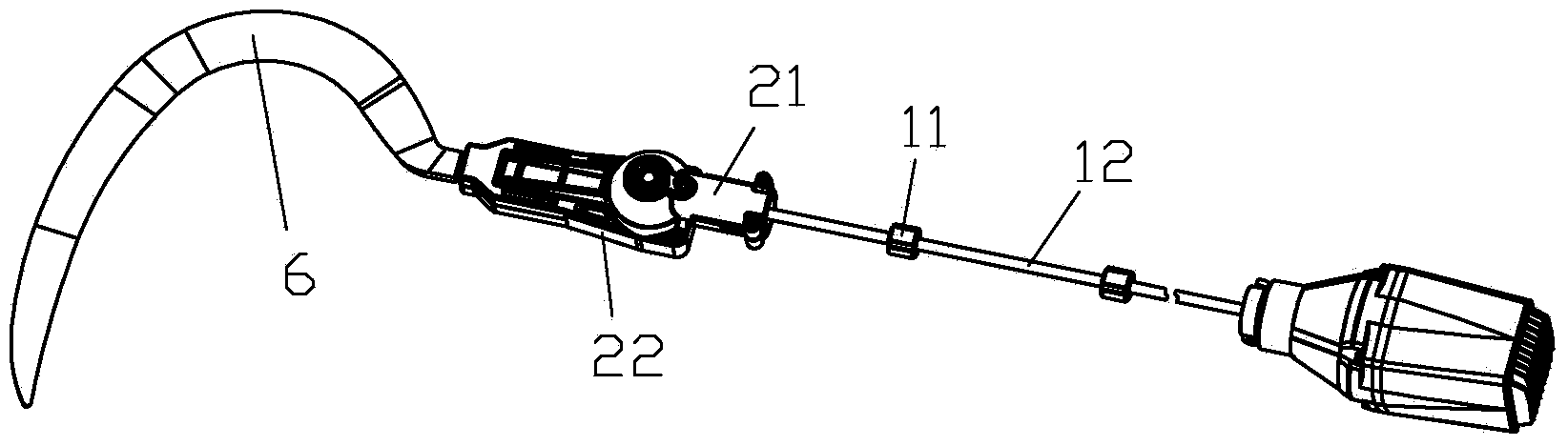

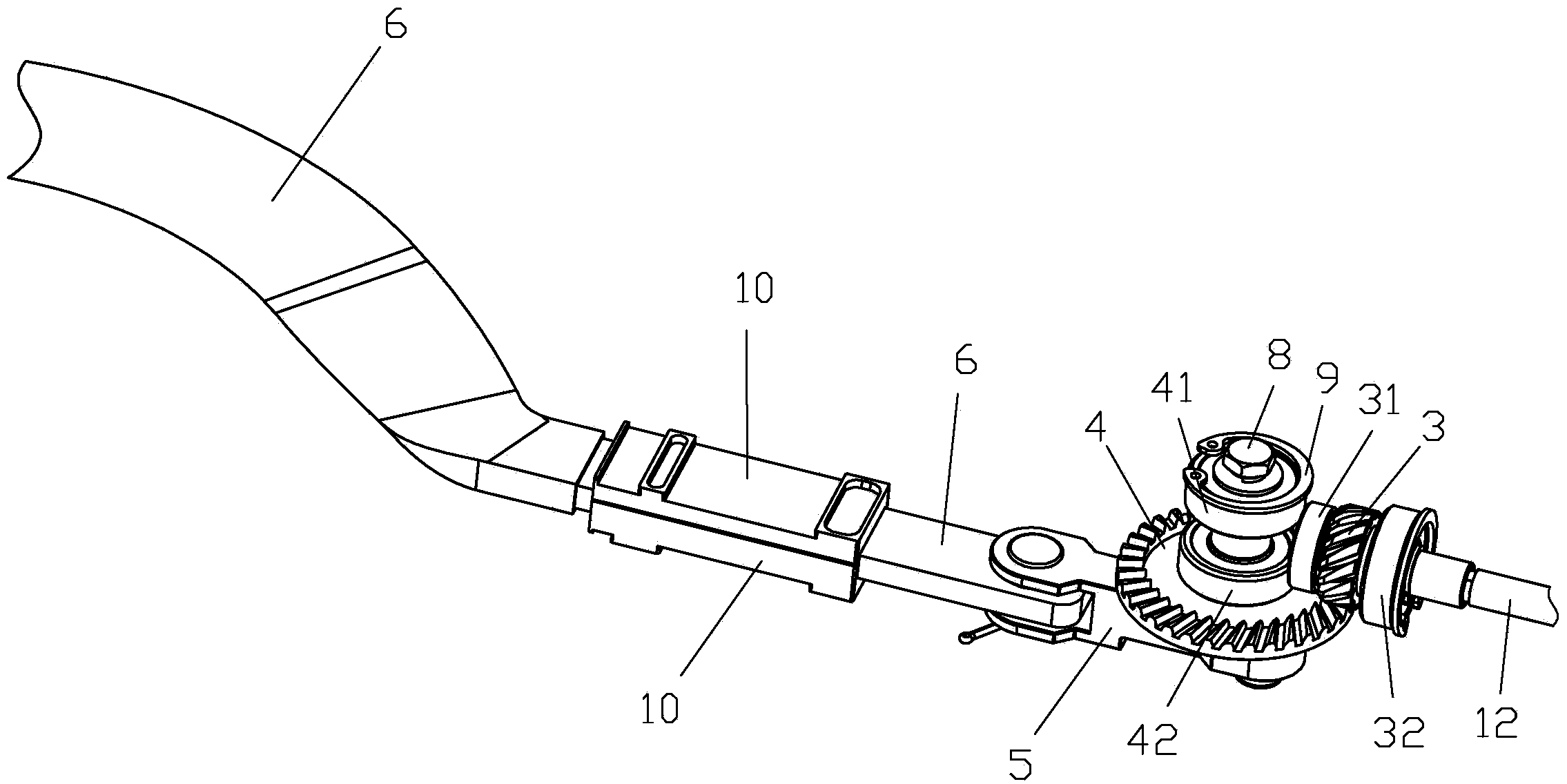

[0021] refer to Figure 1~Figure 9 , a kind of electric palm tree picker of the present invention, comprises high-branch pipe 1 and the main casing that is arranged on the front end of high-branch pipe 1, and described main casing is made up of upper casing 21 and lower casing 22, and described upper casing The rear end of 21 is provided with the horizontal tube part 23 that installs described high-branch pipe 1, and the driving bevel gear 3 and driven bevel gear 4 that intermesh are installed on the upper shell 21, wherein the axis of driving bevel gear 3 and high-branch pipe 1 Parallel, the axes of the active bevel gear 3 and the driven bevel gear 4 are vertically arranged, the bottom end of the driven bevel gear 4 is eccentrically connected with a connecting rod 5, the front end of the connecting rod 5 is hinged with the sickle 6, and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com