Low-noise valve rocker assembly of motorcycle engine

A valve rocker arm and engine technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., to achieve the effects of simple, reasonable and compact structure, stable rocker arm operation, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

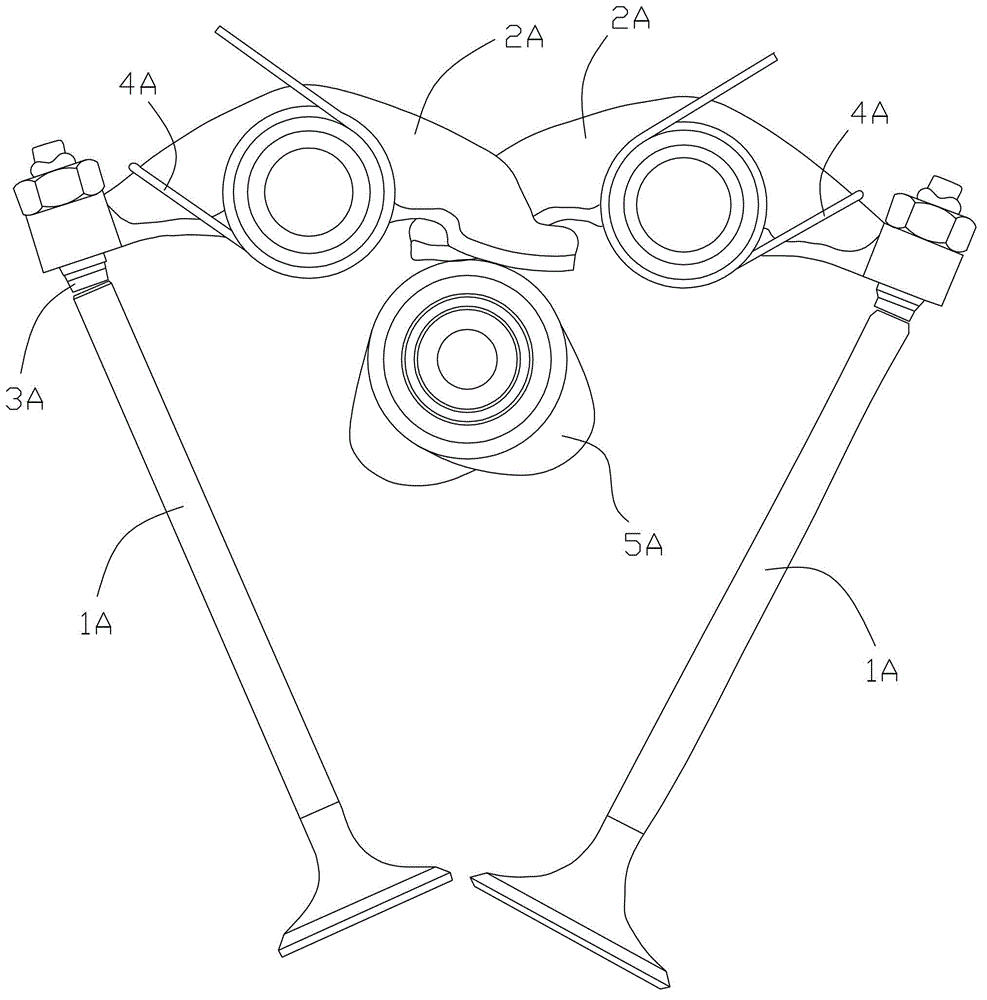

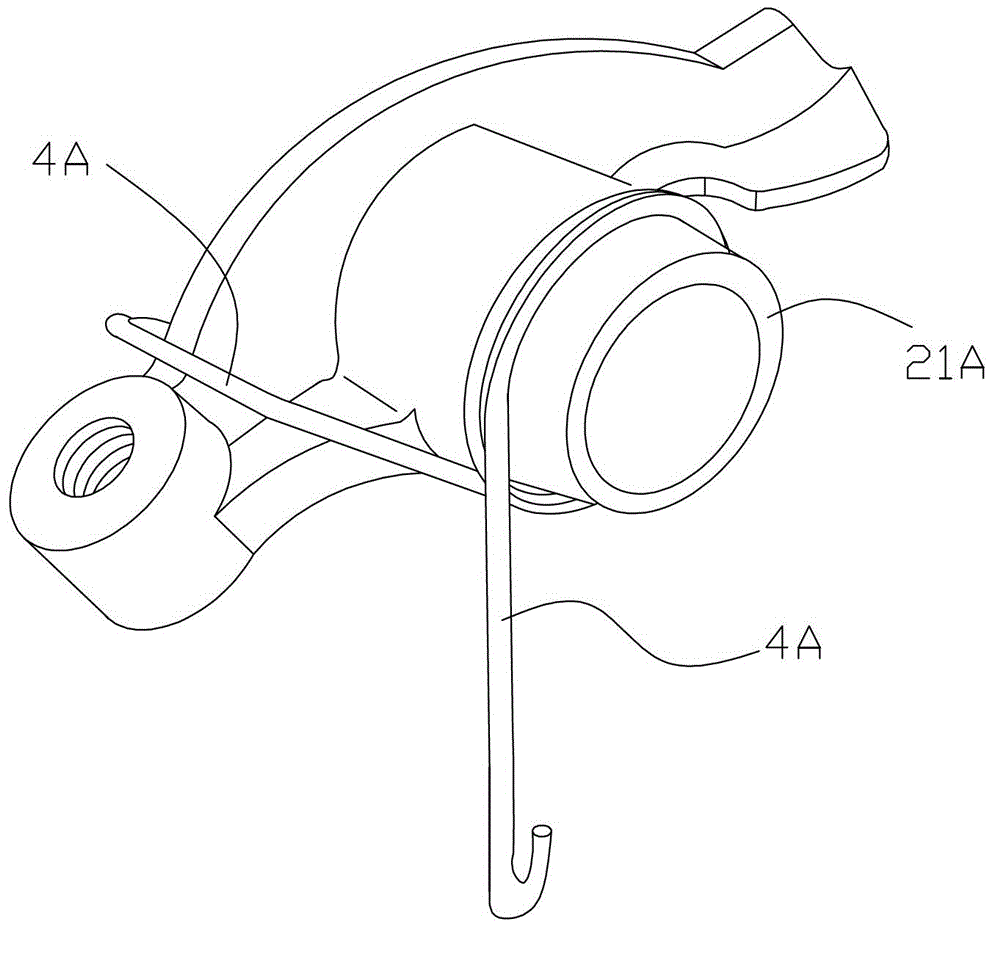

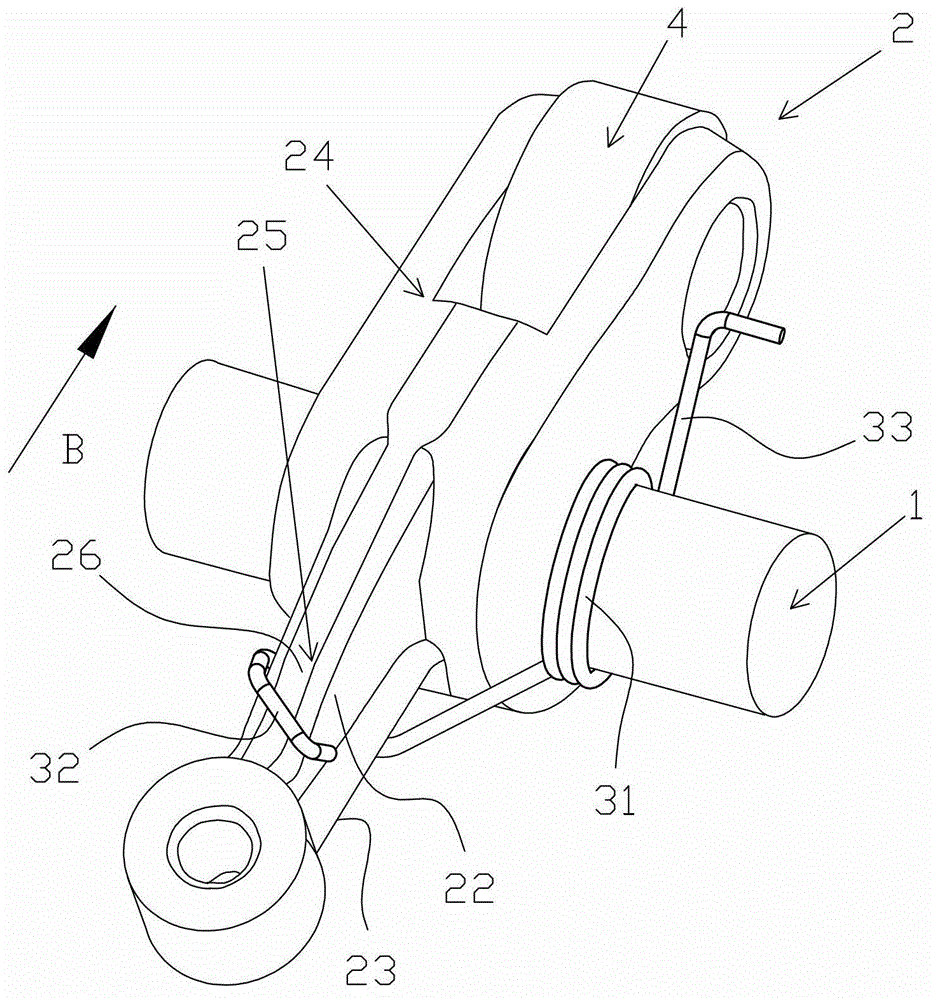

[0023] refer to Figure 3~Figure 7 , the motorcycle engine low-noise valve rocker arm assembly of the present invention, which includes the rocker arm 2 assembled on the rocker arm shaft 1 of the cylinder head and the torsion spring 3 for applying pretightening force to the rocker arm 2, and the rocker arm 2 is provided with corresponding The pivot hole of the rocker shaft 1, the pivot hole divides the rocker 2 into a front end 24 and a rear end 25, the front end 24 and the rear end 25 are arranged along the axial direction perpendicular to the rocker shaft 1, the front and rear ends "before" as image 3 Indicated by the middle arrow B; the rear end 25 is equipped with an adjusting nut (for details, please refer to figure 1 ), the adjusting nut is used to adjust the gap between the rocker arm 2 and the tappet, to ensure that the rocker arm 2 can accurately transmit the change of the cam profile, so as to correctly control the oil and gas entering the cylinder combustion cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com