Waterproof structure of motorcycle rearview mirror

A technology of waterproof structure and rearview mirror, which is applied in bicycle mirrors, bicycle accessories, transportation and packaging, etc. It can solve problems such as easy to produce abnormal noise, the interference of waterproof rubber pad 16 should not be too large, and water residue, etc., to achieve structural Simple, reasonable and compact, good waterproof effect, good adjustment performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

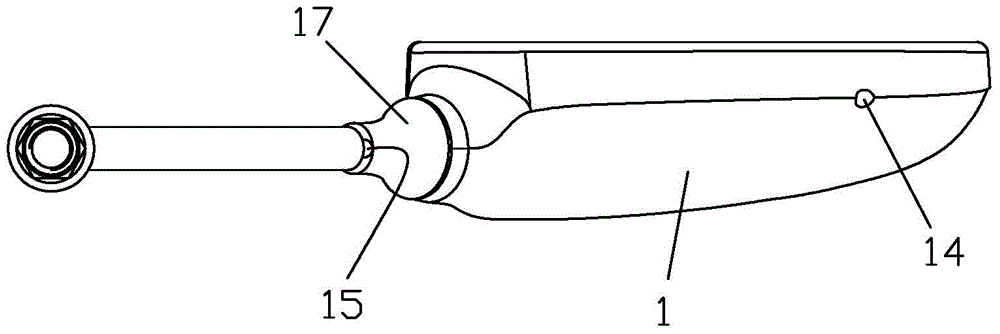

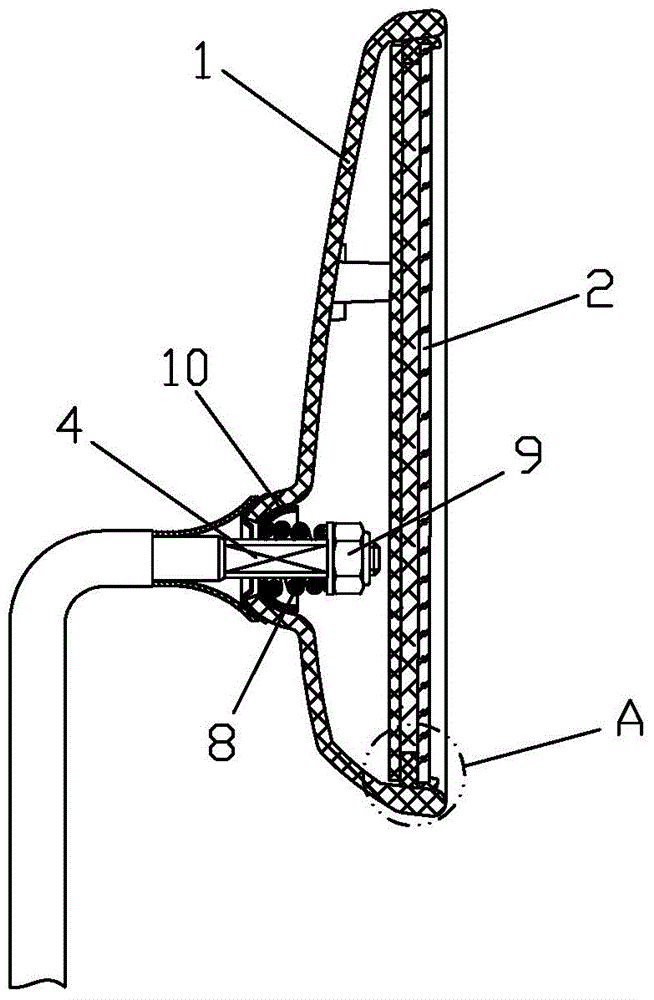

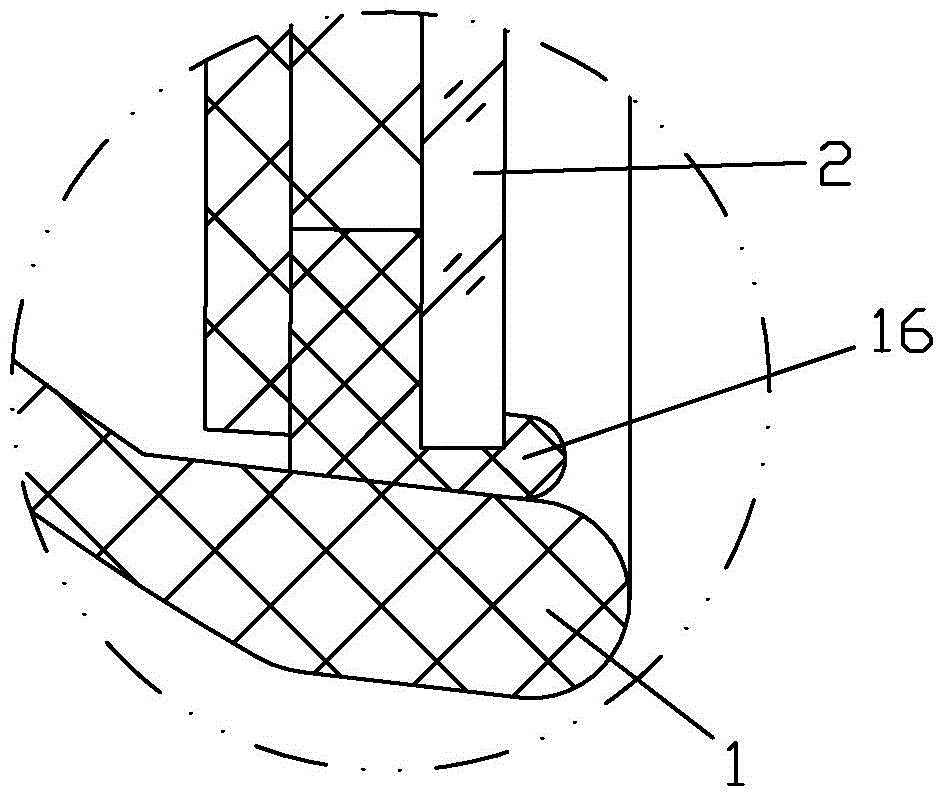

[0030] see Figure 5~Figure 12 , a kind of motorcycle rearview mirror waterproof structure of the present invention, comprises mirror case 1 and the eyeglass 2 that is installed in the mirror case 1, the back side of eyeglass 2 is provided with explosion-proof glue 3, and explosion-proof glue 3 is preferably EVA foam pad, so The mirror housing 1 is equipped with a mirror rod 4 for installing the mirror housing 1 on the handlebar. The inner bottom wall 11 of the mirror housing 1 protrudes with a ring-shaped waterproof rib 5, and the waterproof rib 5 Closely abutting against the explosion-proof glue 3, a waterproof space E is formed between the waterproof convex rib 5, the inner bottom wall 11 of the mirror case 1 and the explosion-proof glue 3, and the mirror rod 4 is located in the waterproof space E.

[0031] In this embodiment, preferably, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com