Blank pipe fitting lateral surface punching die

A technology for empty pipe fittings and punching dies, applied in the field of side punching dies for empty pipe fittings, can solve the problems of side hole deformation, large side hole deformation, easy rupture of casing cores, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

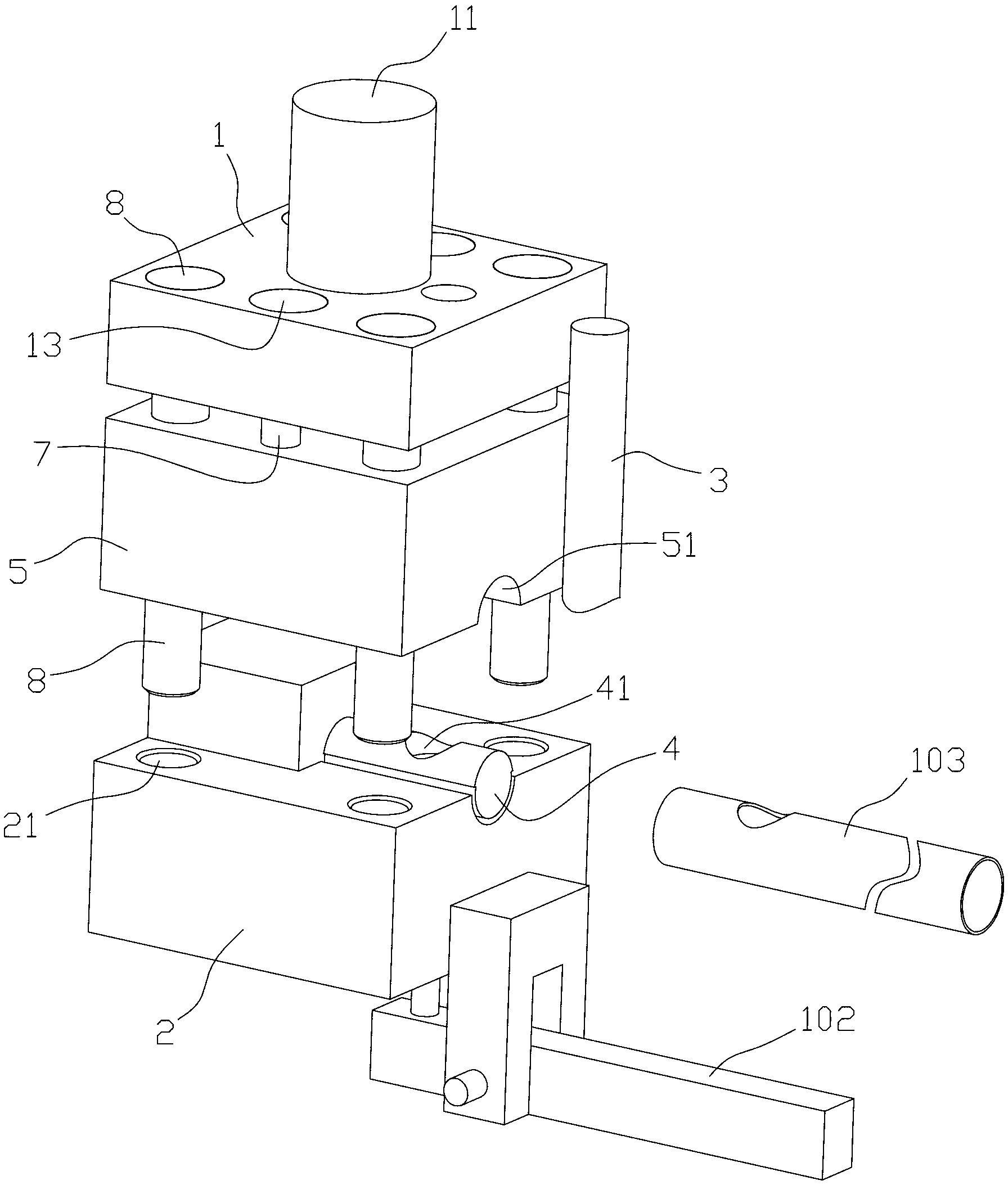

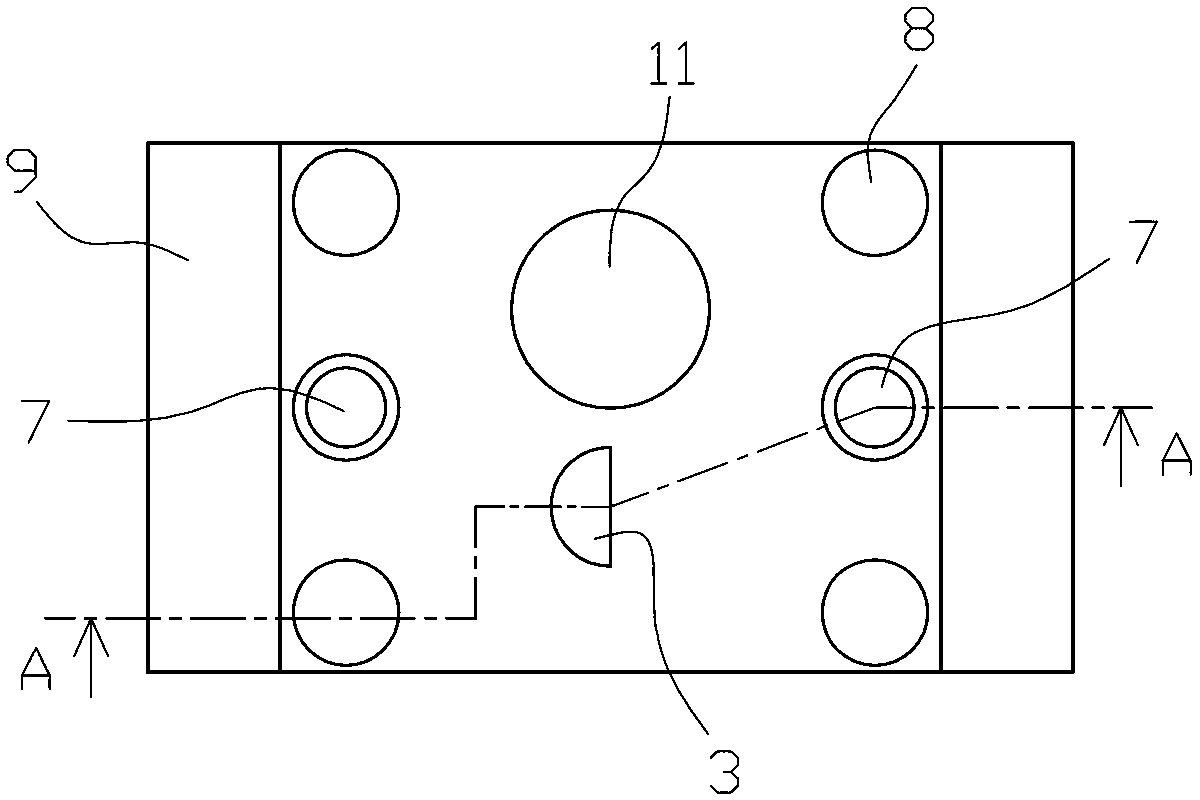

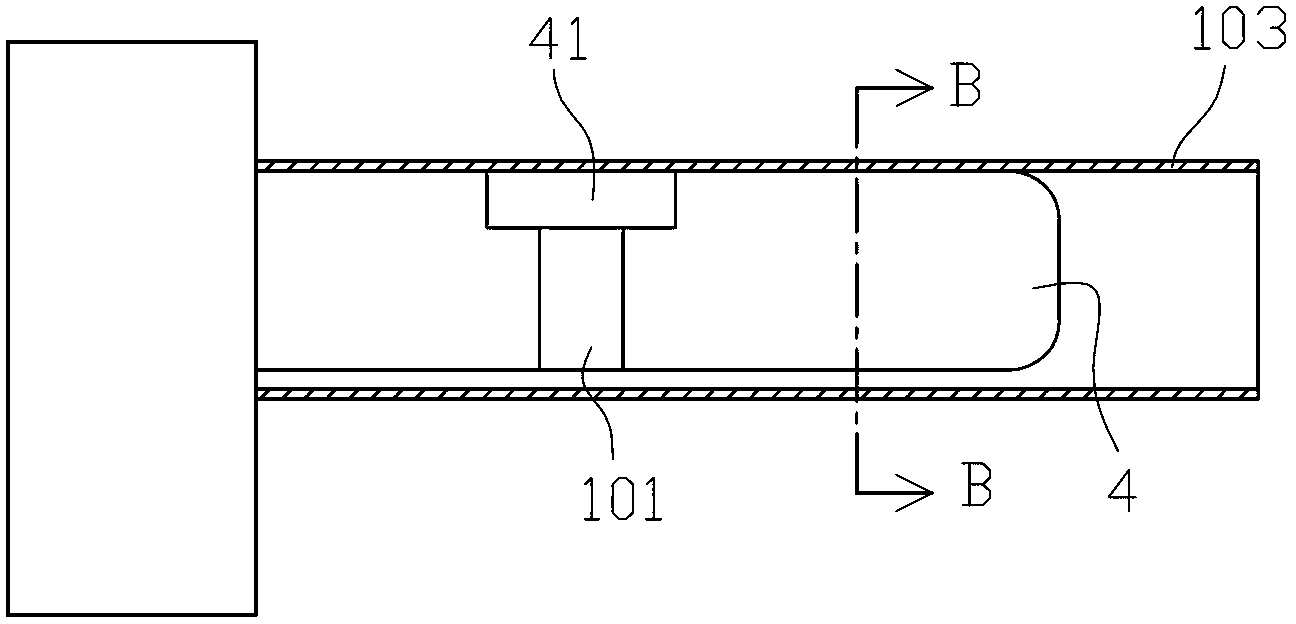

[0021] see Figure 1~Figure 7 , the hollow pipe side punching die of the present invention, it comprises upper mold 1 and lower mold 2, and the top of upper mold 1 is connected with mold handle 11 and is used for connecting and fixing with punching machine, and described upper mold 1 is fixedly connected with punching machine. Hole mold core 3, lower mold 2 is equipped with sleeve mold core 4 for sheathing empty pipe fittings 103, sleeve mold core 4 is provided with the punching hole 41 that gives way to described punching mold core 3, in punching At this time, the punching die core 3 breaks the cut part on the empty pipe fitting 103 and then extends into the punching hole 41, and also includes a movable pressure tube template 5, which is connected to the bottom of the upper die 1 end and can move up and down with the upper mold 1, the movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com