Movable type thin film packaging robot

A robotic and mobile technology, applied in packaging, wrapping objects, transportation packaging, etc., can solve the problems of complex cost of lifting mechanism, complex power transmission mechanism, low customer market acceptance, etc., and achieve high customer market acceptance and design layout. Reasonable, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

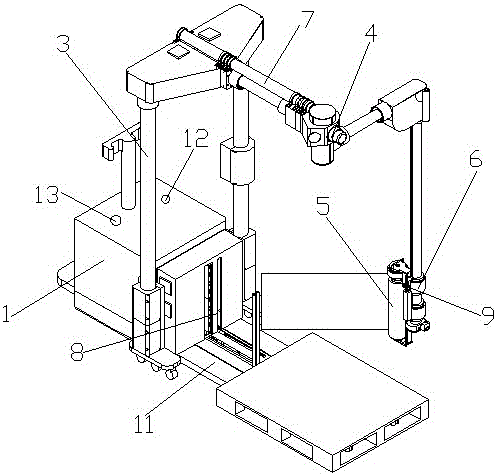

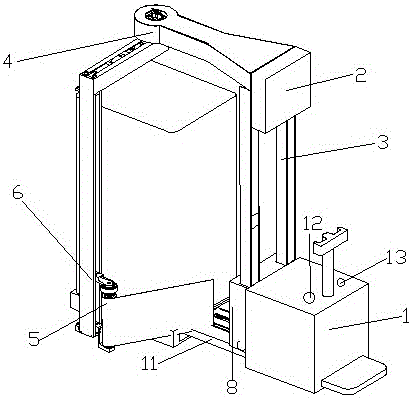

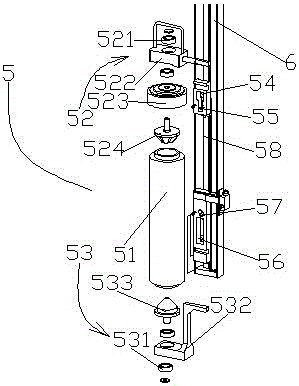

[0022] see figure 1 and figure 2 , a mobile film packaging robot, including a forklift body 1, an electric control box 2, a fixed support frame 3, a power transmission rotating mechanism 4, a film tension control mechanism 5, a film winding lifting mechanism 6, a stable balance bar 7 and a film cutting and pressing mechanism Mechanism 8, the front end of the forklift body 1 is provided with a pair of fork teeth 11, the forklift body 1 is provided with a power switch 12 and a start button 13, the fixed support frame 3 is arranged at the front end of the forklift body 1, the electric The control box 2 is fixedly arranged on the fixed support frame 3, the power transmission rotating mechanism 4 is arranged at the end of one side of the fixed support frame 3, and the film winding lifting mechanism 6 is movably connected to the end of the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com