Pneumatic mixer

A blender and air-passing technology, applied in blender accessories, mixers, dissolving and other directions, can solve the problems of labor-consuming, time-consuming and labor-intensive, and increase the burden on enterprises, so as to improve the stirring effect, reduce the difficulty of cleaning, and reduce the residual degree. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

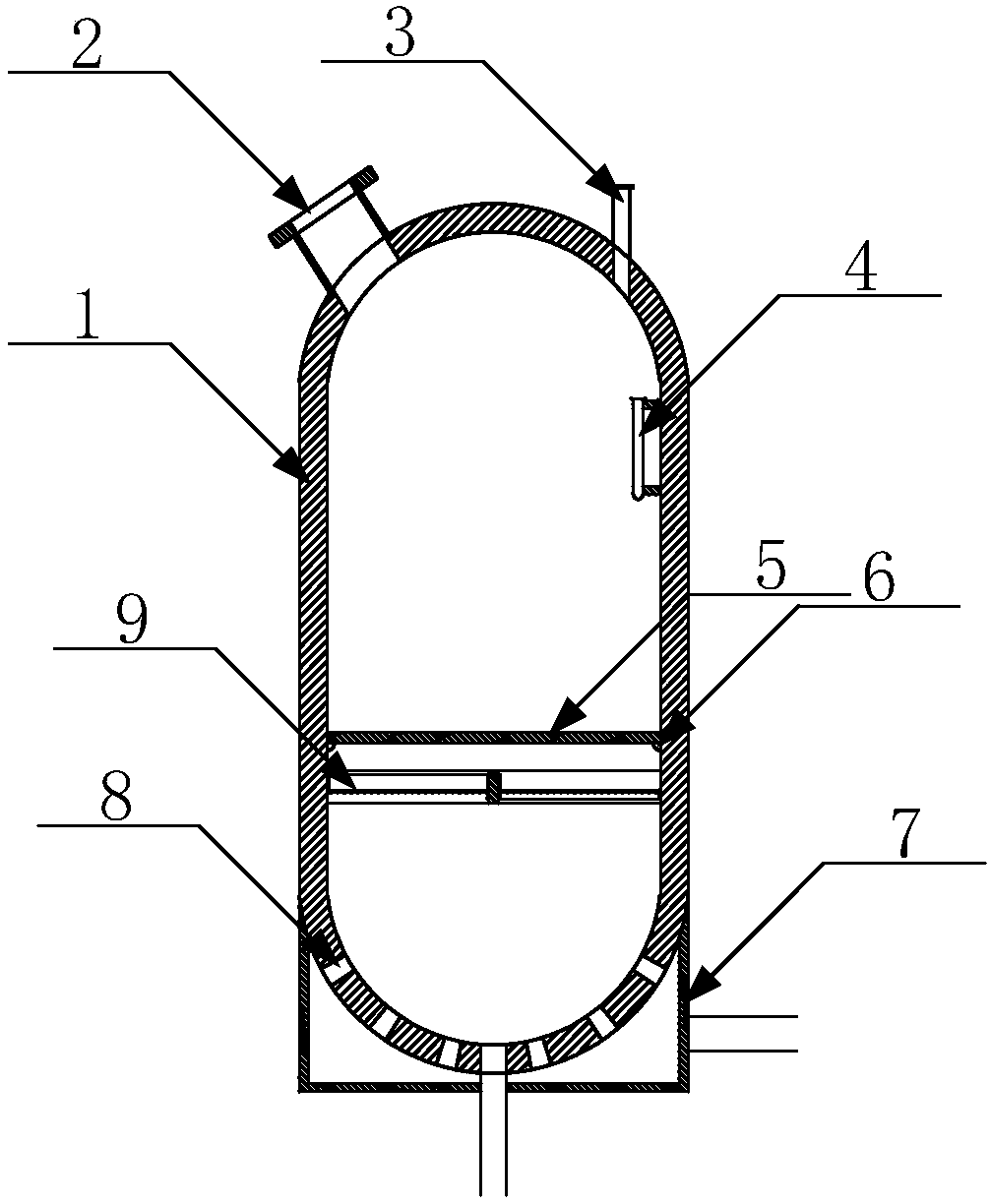

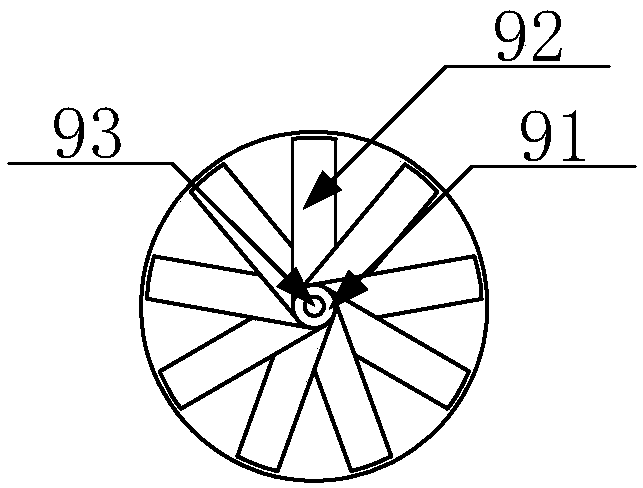

[0020] like figure 1 As shown, a pneumatic mixer includes a tank body 1, a material inlet 2 and an exhaust pipe 3 arranged on the upper end of the pipe body 1, and an impurity collection pipe 4 arranged on the inner wall of the tank body 1, which surrounds the inner wall of the pipe body 1 And the support ring 6 below the impurity collection pipe 4, the protective net 5 fixed on the support ring 6, the air passage chamber 7 arranged on the lower side of the tank body 1, penetrates the tank body 1 and connects the tank body 1 and the air passage chamber 7 The air inlet 8 that is connected, and the rotary fan 9 that is arranged on the protective net 5 lower sides.

[0021] A liquid discharge port is provided at the center of the bottom of the tank body 1 , and a liquid inlet port is provided at any position on the tank body 1 ; a gas inlet connected to the outside is also provided on the gas chamber 7 .

[0022] The bottom of the tank body is arranged in an arc shape, thereby e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com