Steel rail magnetic flux leakage detection device based on zero lift-off rolling magnetization

A technology for magnetic flux leakage detection and rails, which is applied in the directions of transportation and packaging, material magnetic variables, railway vehicle shape measuring instruments, etc. It can solve the problem of low magnetization efficiency, poor stability of magnetization state, and difficulty in achieving full coverage of the rail head surface and the side of the rail head Detection and other issues, to achieve the effect of improving magnetization efficiency, low manufacturing cost, and stable magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

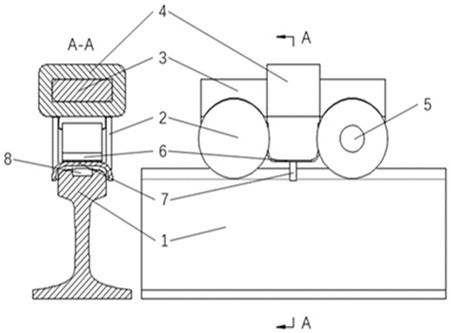

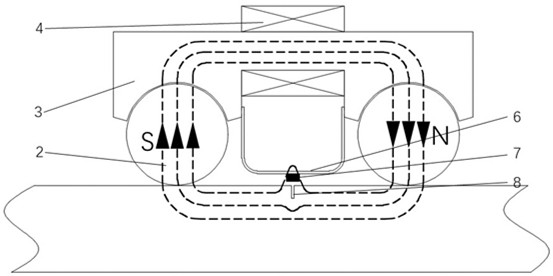

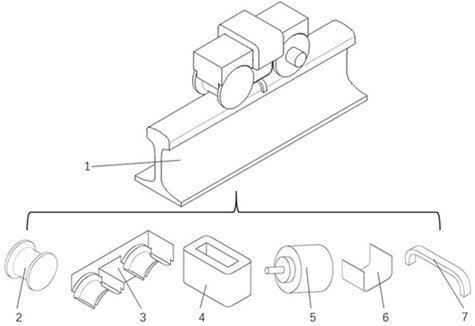

[0031] The specific embodiments of the present invention are given below in conjunction with the accompanying drawings, and a rail non-destructive testing zero lift-off magnetic leakage detection device of the present invention will be further described through the specific embodiments. It should be pointed out that the specific implementation of the present invention is not limited to the forms described in the examples.

[0032] The directional terms mentioned in the detailed description below, such as: up, down, left, right, front, back, etc., are only directions referring to the drawings. Therefore, the directional terms used are only for the convenience of explaining the present invention, and are not intended to limit the present invention.

[0033] A rail magnetic flux leakage detection device based on zero lift-off rolling magnetization in this embodiment has a structure such as figure 1 and figure 2As shown, the composition includes a magnetizing coil 4 for generat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com