Ferromagnetic cable metal cross-sectional area loss detection method and device

A cross-sectional, ferromagnetic technology, applied in the field of non-destructive testing, can solve the problems of increasing the volume of the magnetization system, the influence of the detection speed is large, and the adjustment of the magnetic circuit is complicated, and achieves the effects of small size, reduced weight, and high magnetization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in more detail below by means of examples, but the following examples are only illustrative, and the protection scope of the present invention is not limited by these examples.

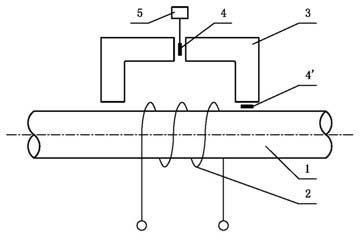

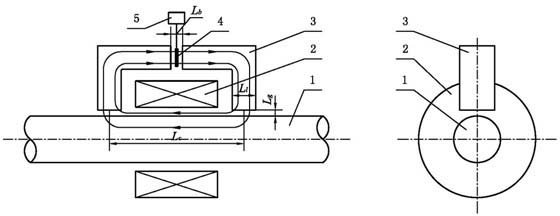

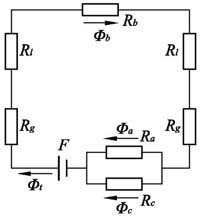

[0024] Such as figure 1 As shown, the cable connected to the DC power supply is wound on the tested cable 1 as a DC magnetizing coil 2, and one or more armature groups 3 are arranged along the circumferential direction of the cable 1 (the number of armature groups can be 1 to 32), Each armature group 3 consists of two symmetrically arranged Type armature blocks, each armature group 3 across the magnetized coil 2, two symmetrically arranged in each armature group 3 Arrange a magnetic sensitive element 4 in the gap reserved between the armature blocks or arrange a magnetic sensitive element 4' in the gap between the end of the armature group 3 and the cable 1; turn on the DC power supply, the cable 1 will be magnetized by the DC coil 2, A magnetic circuit is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com