Assembly line type magnetic product magnetizing system and magnetizing method thereof

A pipeline-type, magnetic system technology, applied in the direction of magnetic objects, electrical components, circuits, etc., can solve problems such as low efficiency, magnetic product offset, and uneven magnetization of magnetic products, and achieve high magnetization efficiency and magnetization saturation uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

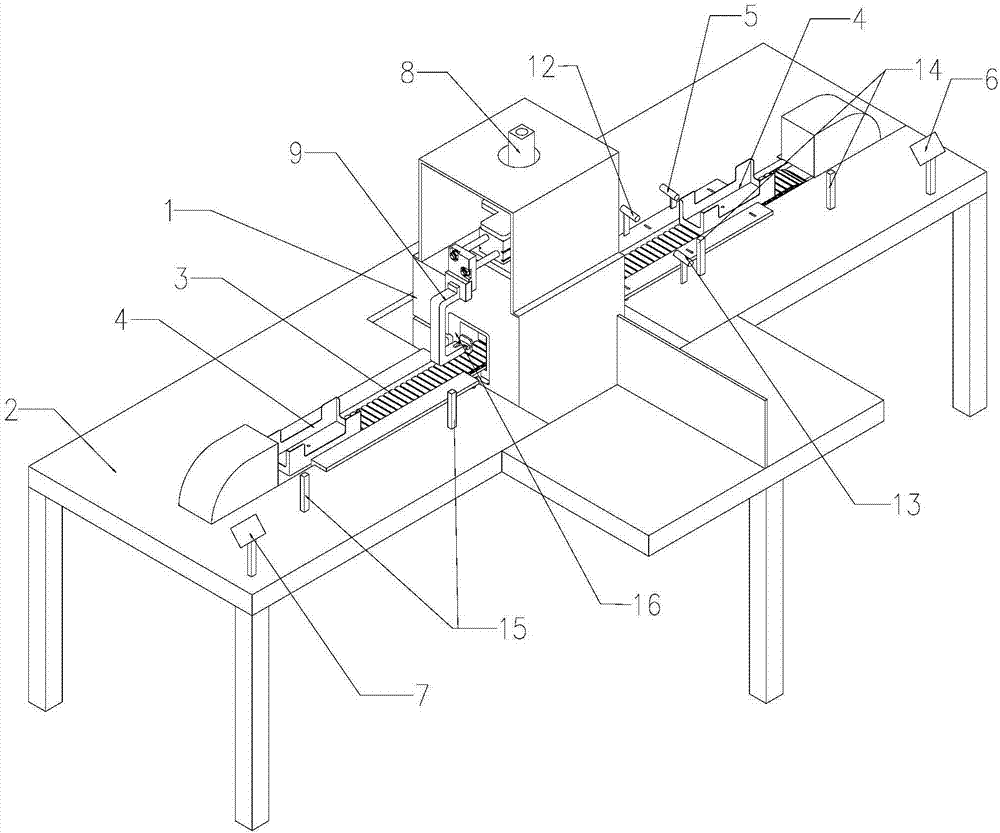

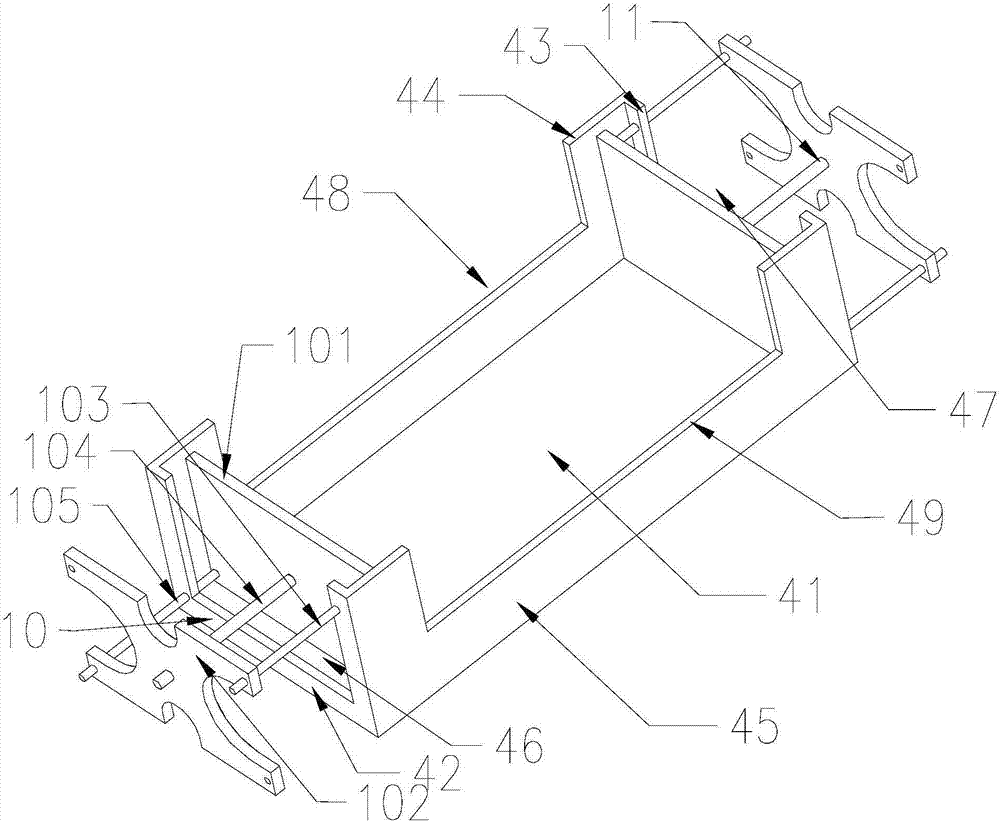

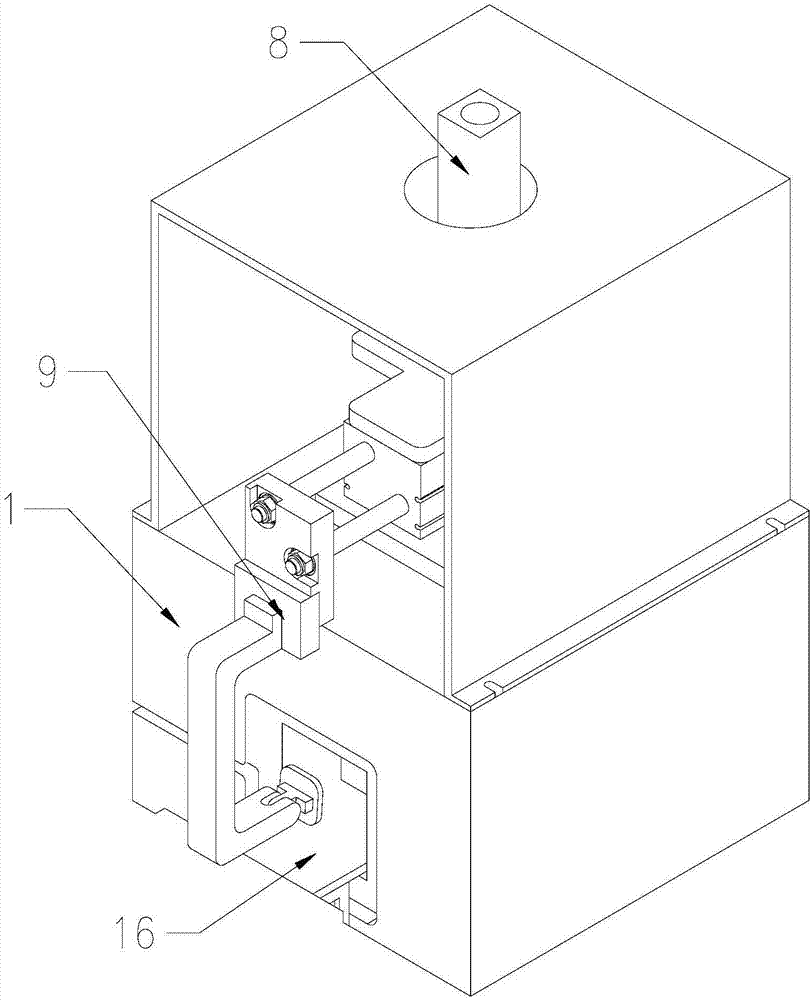

[0031]Embodiment 1: As shown in the figure, a pipelined magnetic product magnetization system includes a magnetizer (not shown in the figure) and a solenoid magnetization coil 1, and the magnetizer is connected to the solenoid magnetization coil 1 The front end of the solenoid magnetizing coil 1 has a front opening communicating with its interior. The assembly line magnetic product magnetizing system also includes a workbench 2, an endless conveyor belt 3 arranged on the workbench 2, and a device for driving the endless conveyor belt 3 to rotate. Driver, six feed boxes 4 evenly spaced on the endless conveyor belt 3, optical fiber sensor 5, controller, loading control input panel 6, unloading control input panel 7 and clamping mechanism, the controller is connected with the magnetizer, The optical fiber sensor 5, the feeding control input panel 6 and the unloading control input panel 7 are connected; The loading station of table 2 is used to send the first start signal to the c...

Embodiment 2

[0032] Embodiment 2: As shown in the figure, a pipelined magnetic product magnetization system includes a magnetizer (not shown in the figure) and a solenoid magnetization coil 1, and the magnetizer is connected to the solenoid magnetization coil 1 The front end of the solenoid magnetizing coil 1 has a front opening communicating with its interior. The assembly line magnetic product magnetizing system also includes a workbench 2, an endless conveyor belt 3 arranged on the workbench 2, and a device for driving the endless conveyor belt 3 to rotate. Driver, six feed boxes 4 evenly spaced on the endless conveyor belt 3, optical fiber sensor 5, controller, loading control input panel 6, unloading control input panel 7 and clamping mechanism, the controller is connected with the magnetizer, The optical fiber sensor 5, the feeding control input panel 6 and the unloading control input panel 7 are connected; The loading station of table 2 is used to send the first start signal to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com