Patents

Literature

53results about How to "No manual intervention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

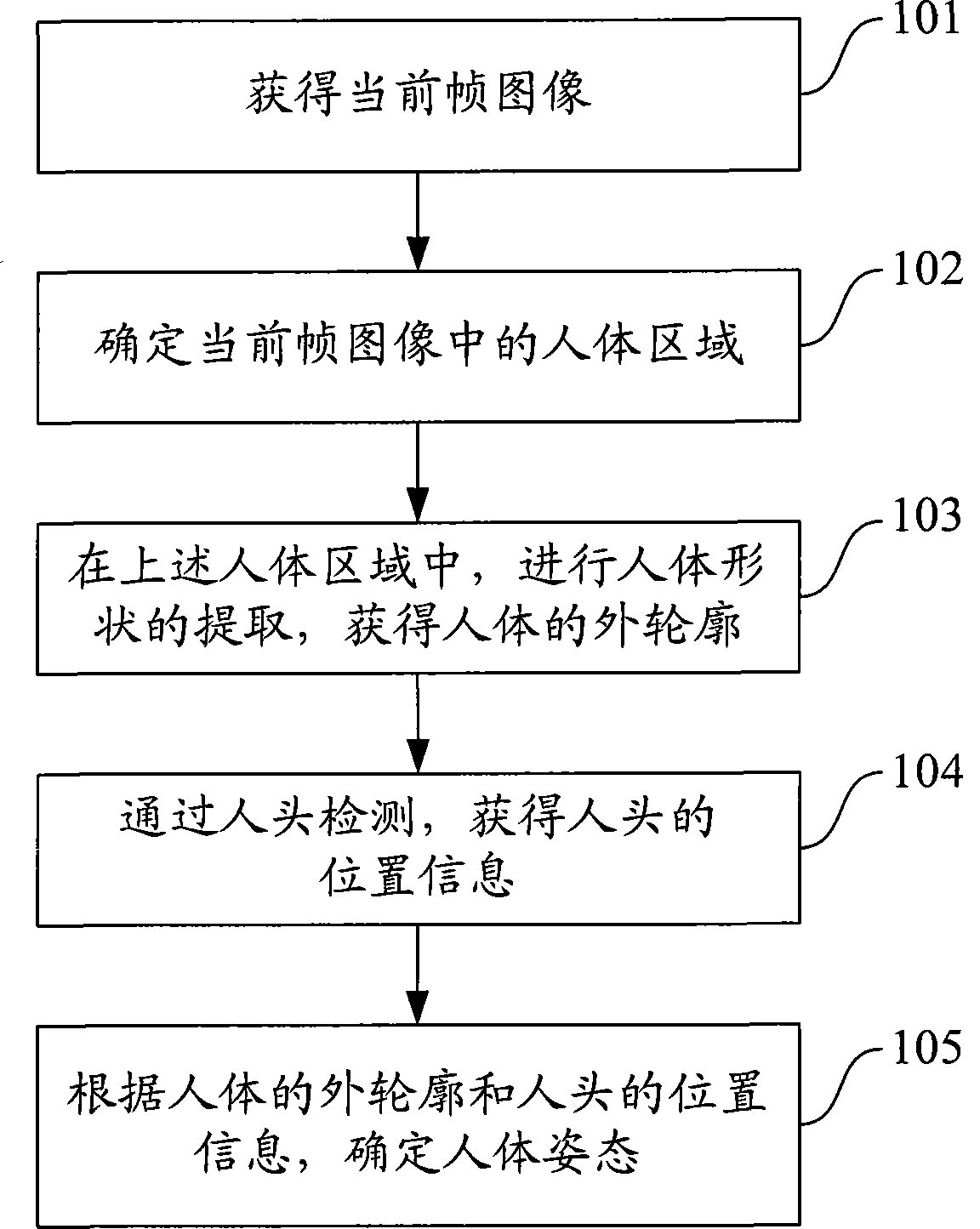

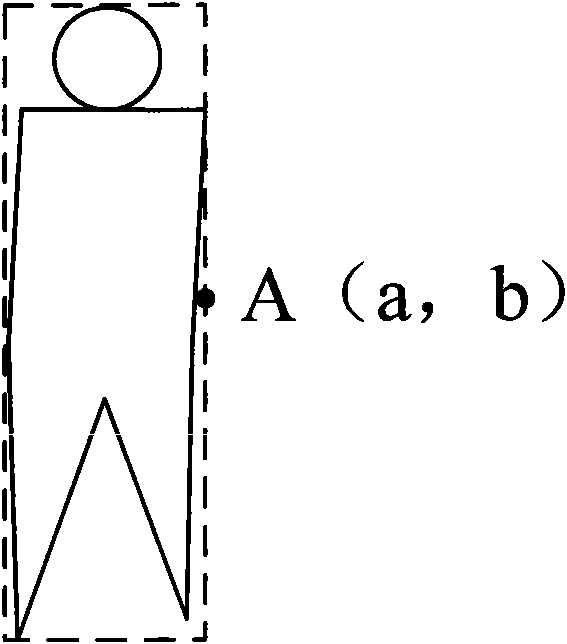

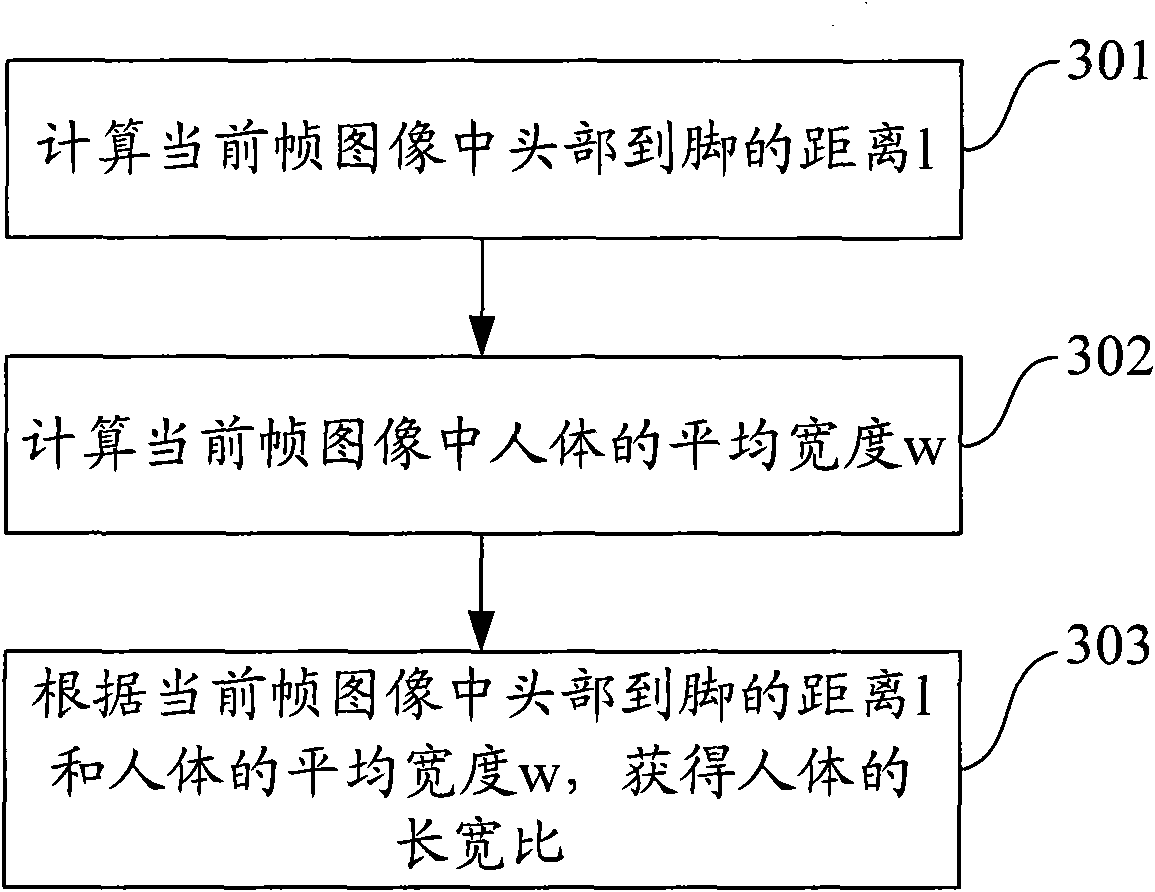

Classification method and device of human body posture

InactiveCN101576953AImplement classificationNo manual interventionCharacter and pattern recognitionState of artHuman body

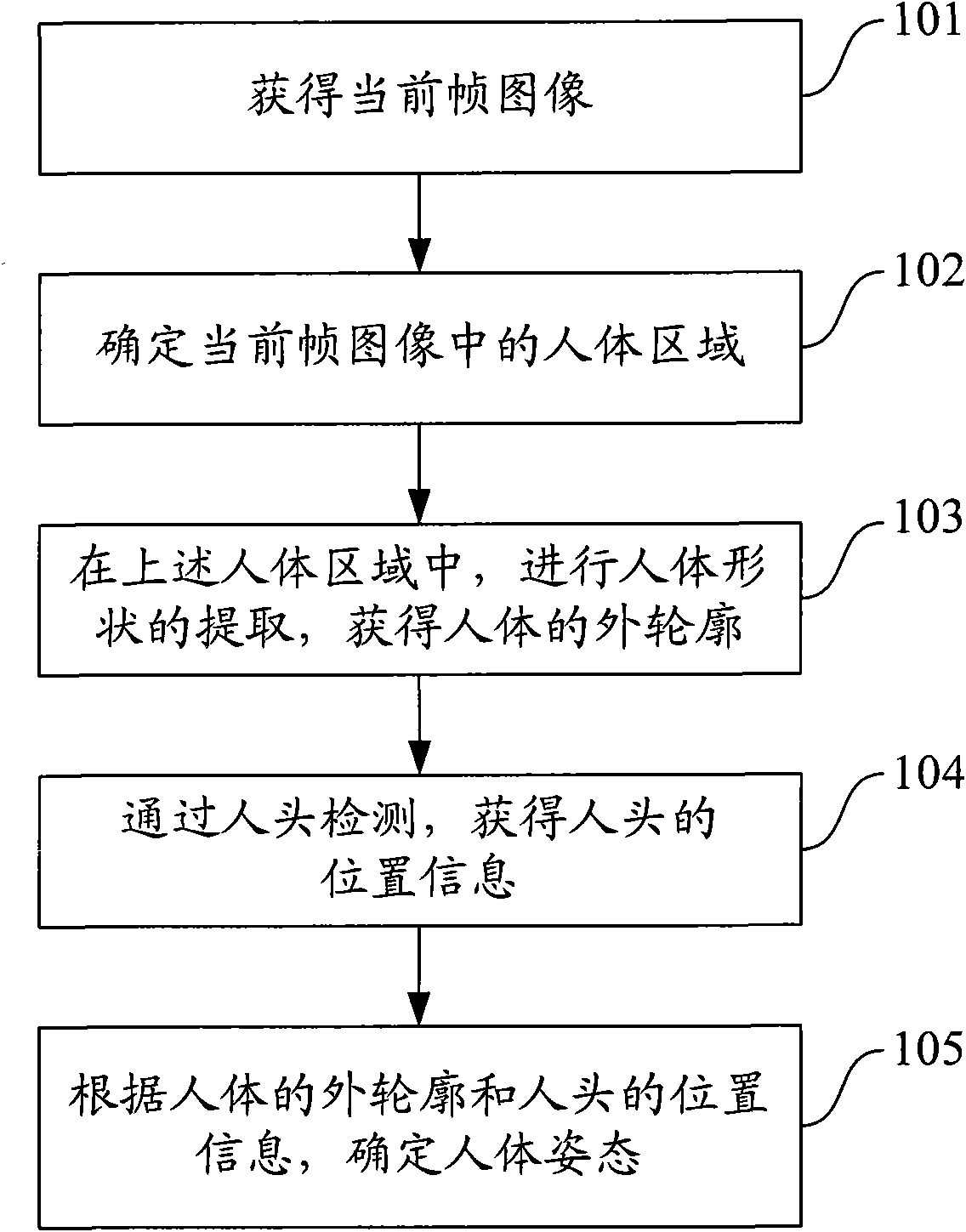

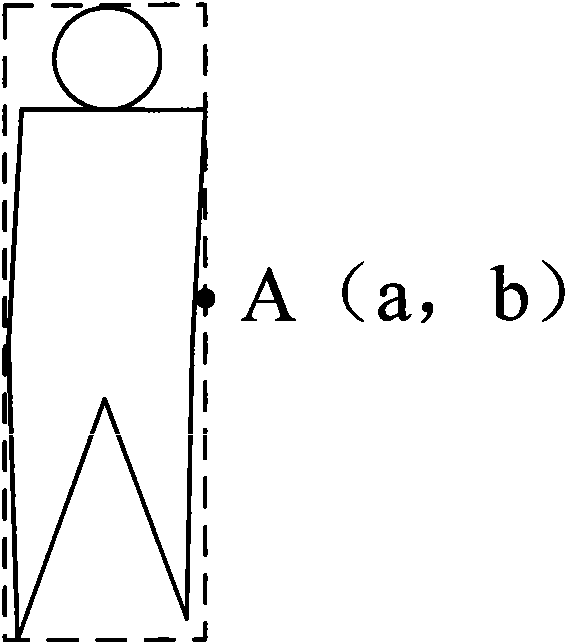

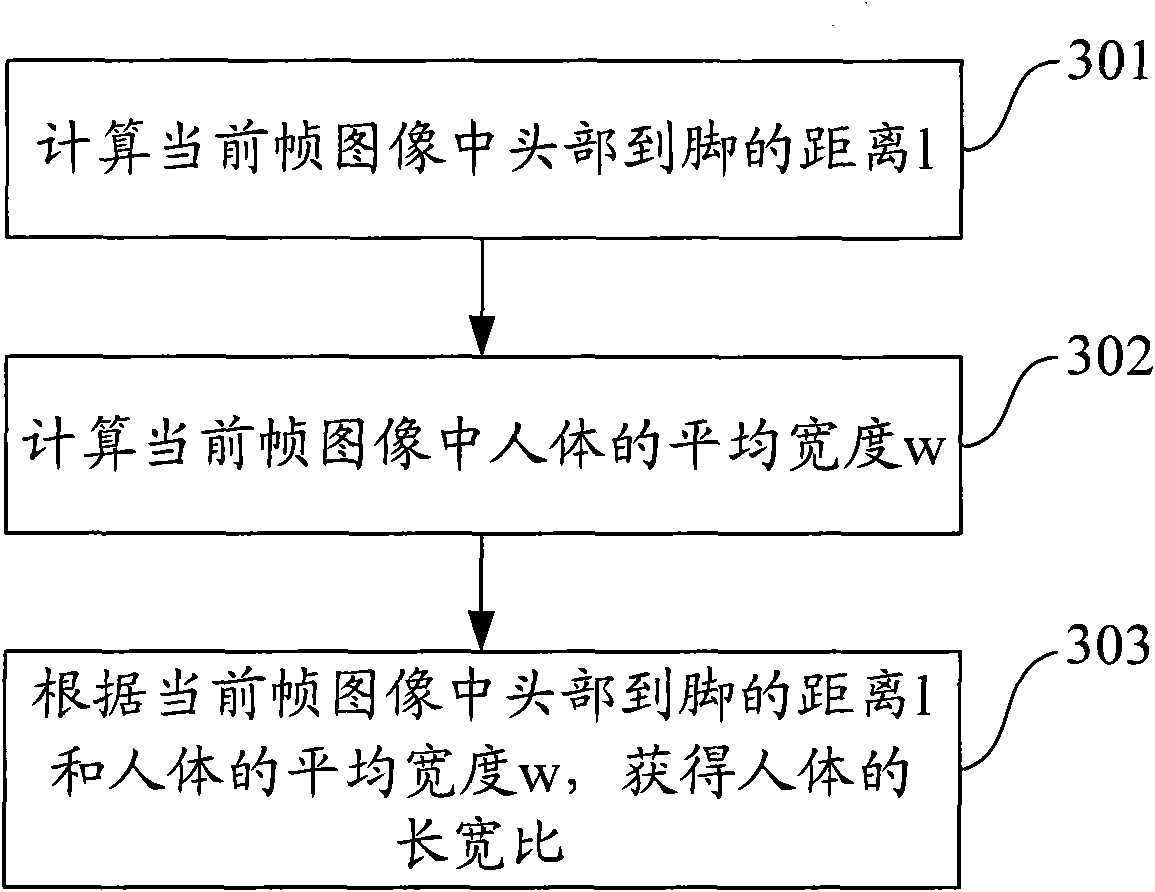

The invention discloses a classification method and a device of human body posture. The classification method of human body posture comprises the steps of: determining a human body region in an existing frame image; extracting the human body shape so as to obtain the external outline in the human body, then obtaining the information of the position of human head by human head detection; and then determining that the human body posture is in vertical standing-up status when the head part is right in the middle of the external outline of the human body; and further calculating the aspect ratio of the external outline of the human body when the head part is located at one side of the external outline of the human body, and then determining the types of human body posture according to the aspect ratio of the external outline of the human body, thereby achieving automatic identification and classification to the human body posture, without human intervention, thus making up the detects thatthe prior art does not provide a method for classifying the human body posture.

Owner:VIMICRO CORP

Fast object recognition algorithm

InactiveCN102222214AImprove robustnessEasy to divideImage analysisCharacter and pattern recognitionTime domainRecognition algorithm

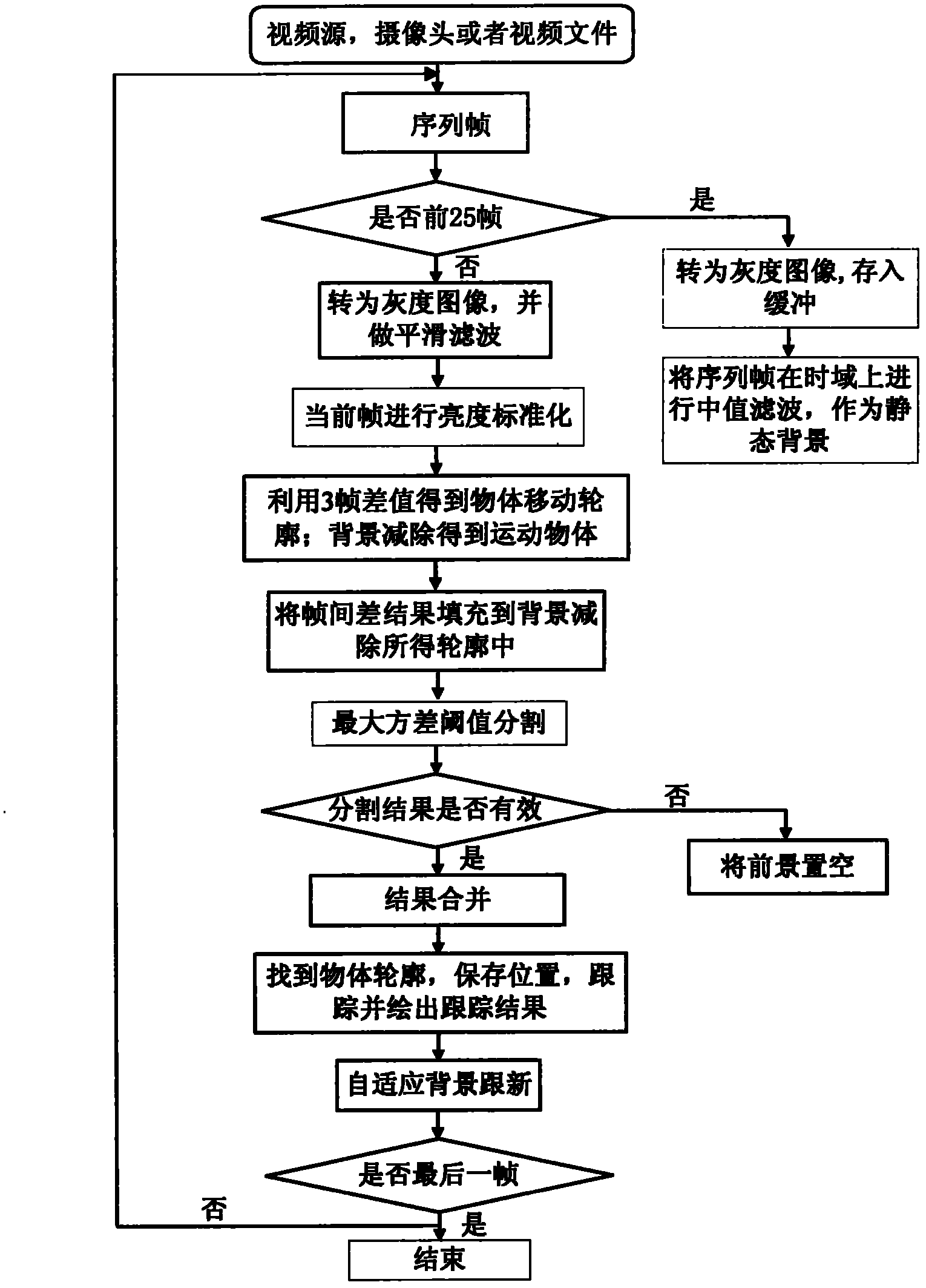

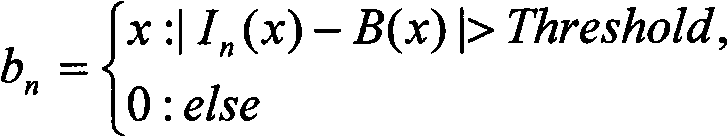

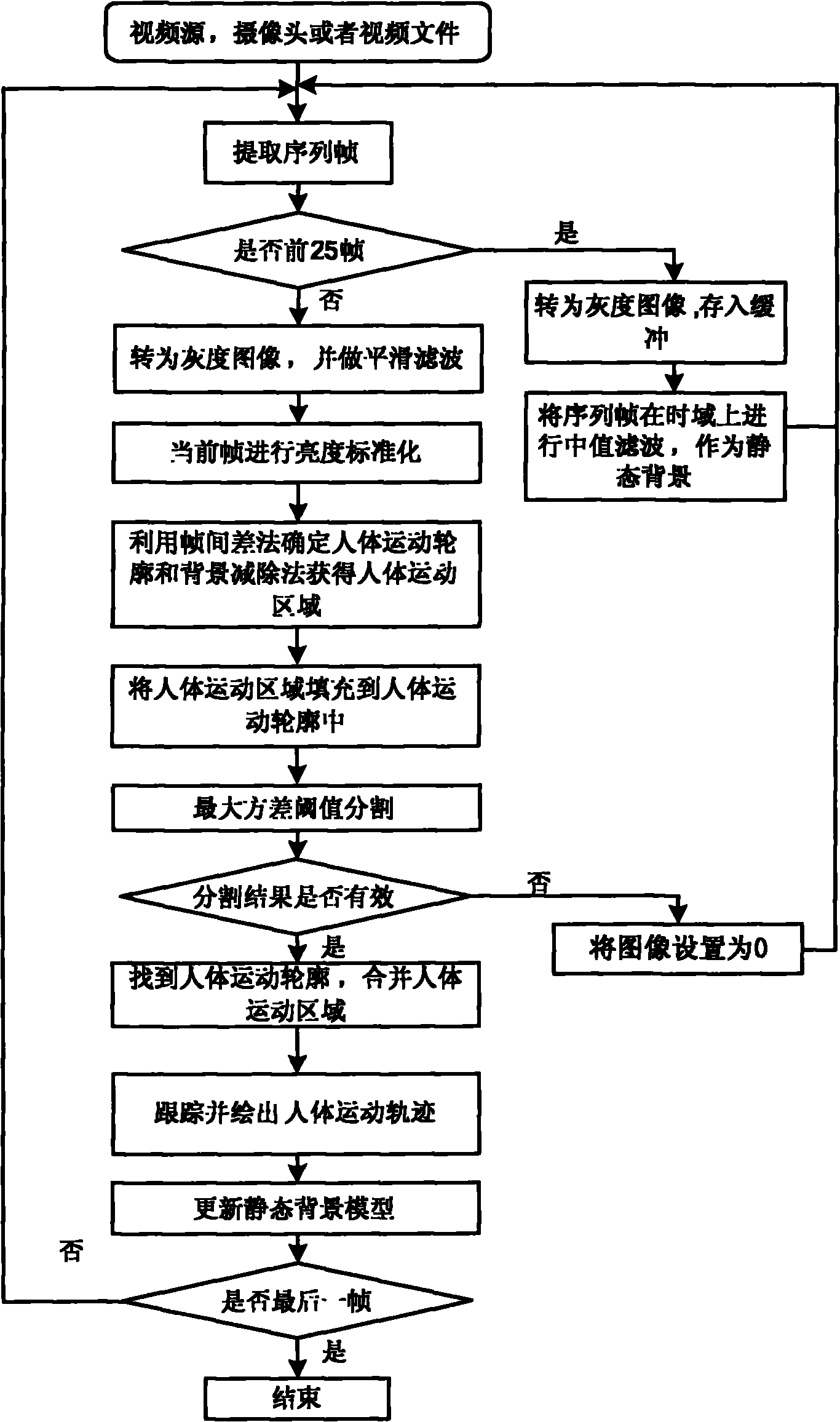

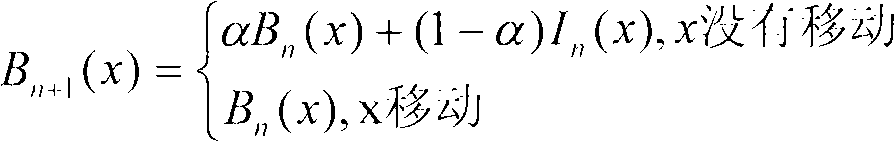

The invention relates to a fast object recognition algorithm comprising the following steps of: firstly, carrying out median filtering on approximately one second sequence frame in time domain so as to be taken as a static background; secondly, determining a moving object by utilizing the fusion algorithm of background subtraction and interframe difference; thirdly, carrying out binaryzation on the obtained result by utilizing maximum variance threshold segmentation, and simultaneously analyzing the effectiveness of the segmentation; and finally, merging the results of the effective segmentation, and tracking by utilizing Kalman filtering. The intelligent video object-tracking method has good tracking effect and high robustness, dispenses with manual intervention and effectively avoids the phenomena of tracking and alarming by mistake.

Owner:SUZHOU YISIKANG INFORMATION TECH

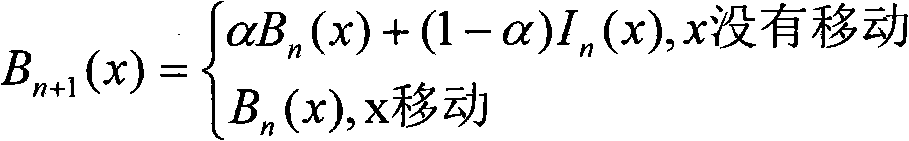

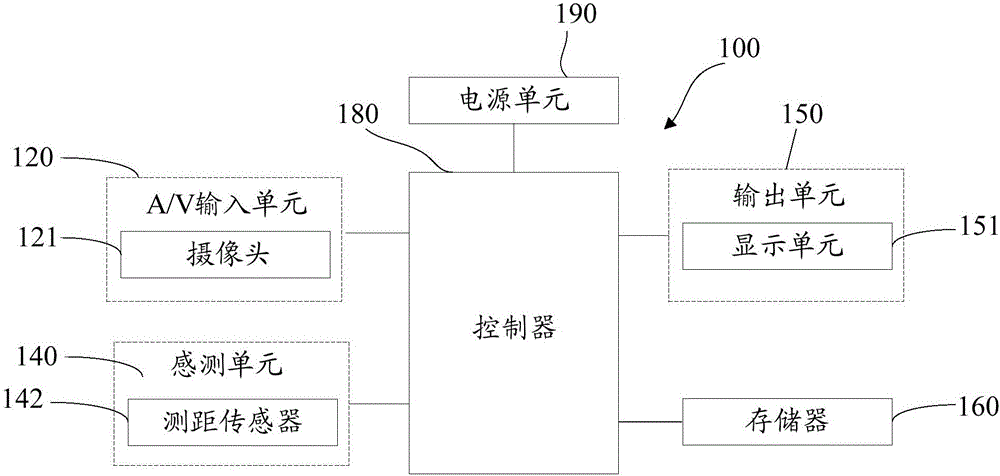

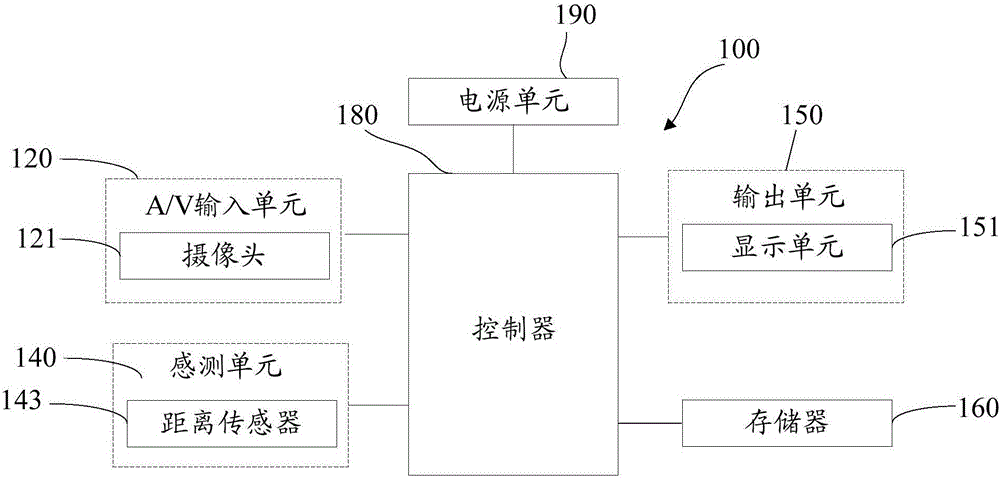

Mobile terminal and focusing method

InactiveCN105827961AImprove experienceStrong sense of hierarchyTelevision system detailsColor television detailsSensing dataImage plane

The present invention discloses a mobile terminal and a focusing method. The mobile terminal comprises a distance measuring sensor used for sensing an object in an environment and outputting the sensing data representing the position of the object in the environment; a controller used for determining an object distance parameter of the object formed relative to a camera based on the sensing data, and determining an image distance parameter used by the camera based on the object distance parameter; the camera used for adjusting the distance between a lens of the camera and an image plane corresponding to the camera under the control of the controller and based on the image distance parameter. According to the present invention, the automatic and rapid focusing of the camera can be realized.

Owner:NUBIA TECHNOLOGY CO LTD

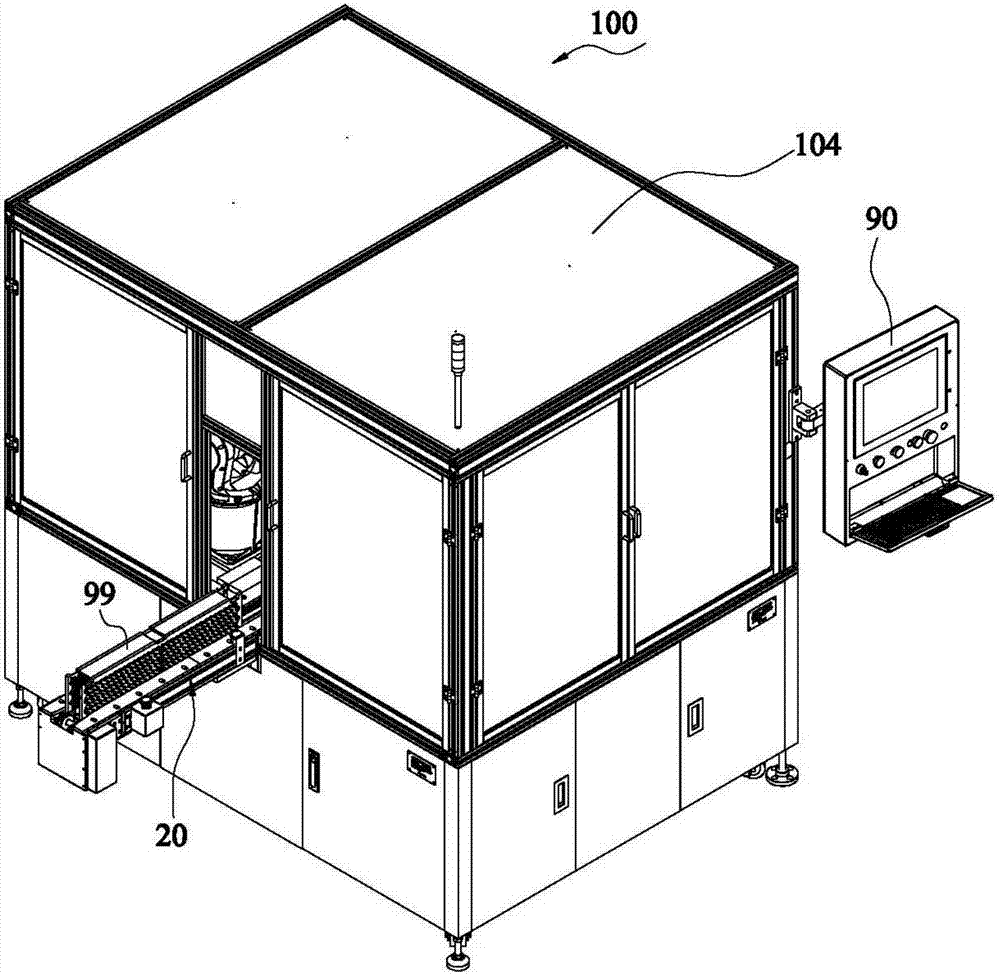

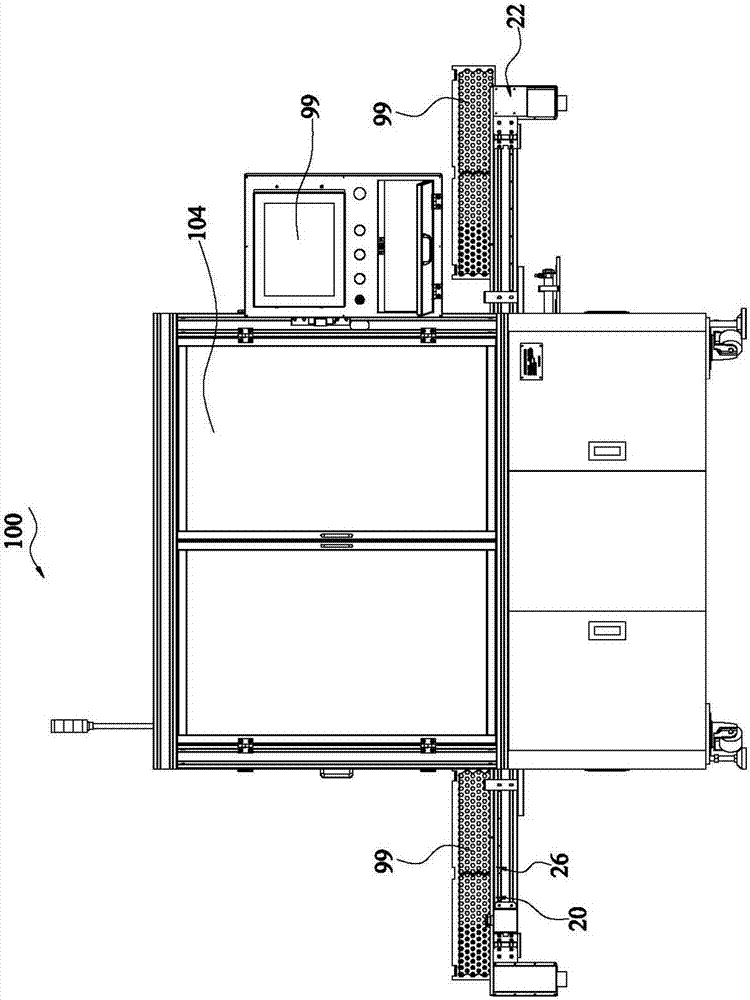

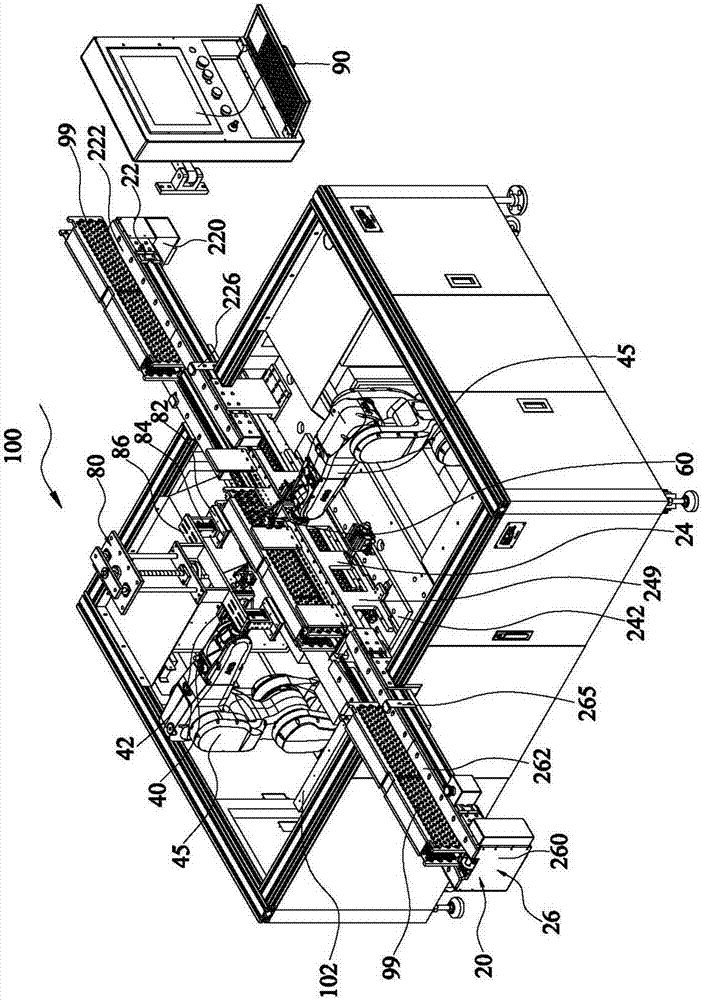

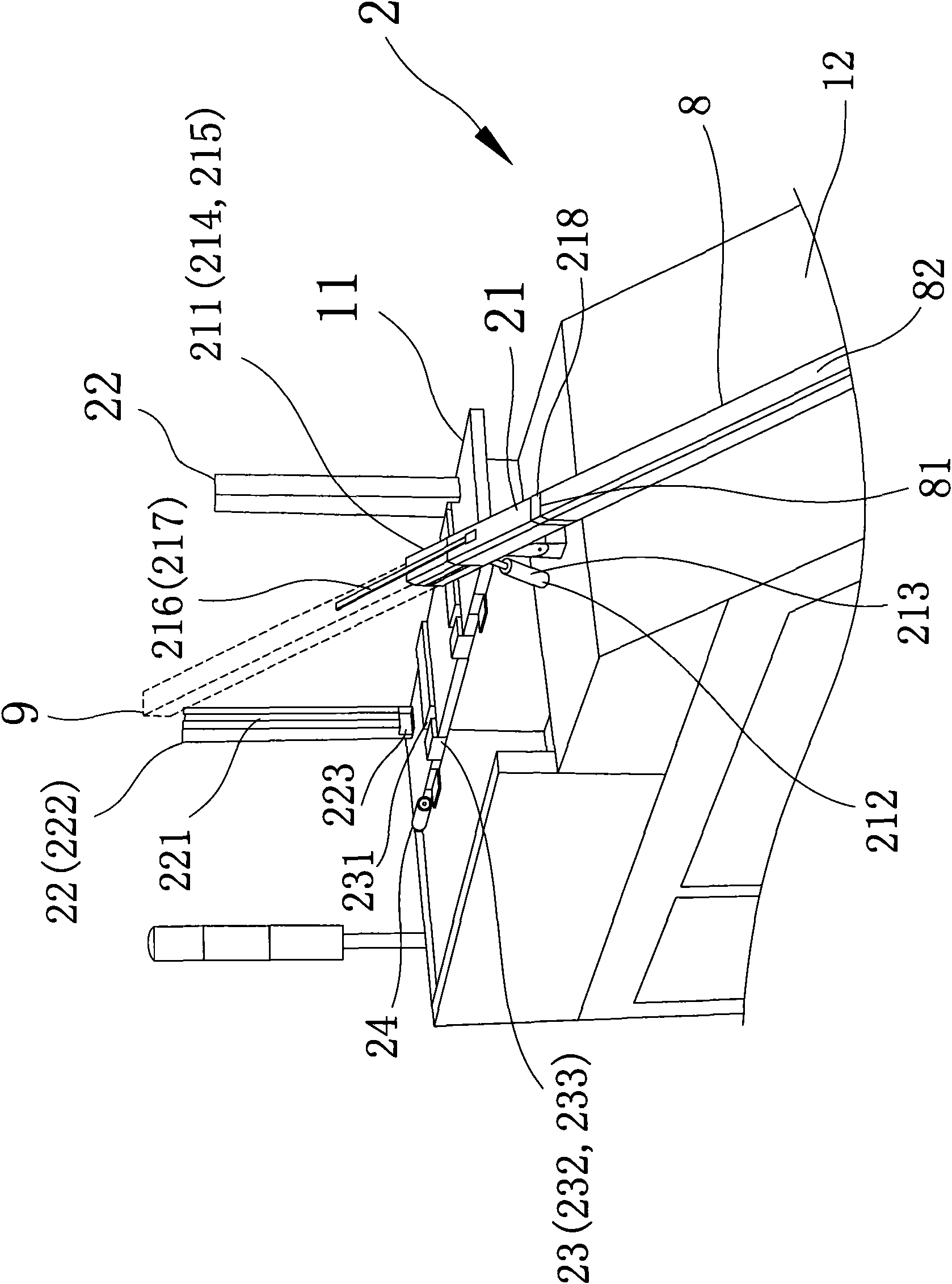

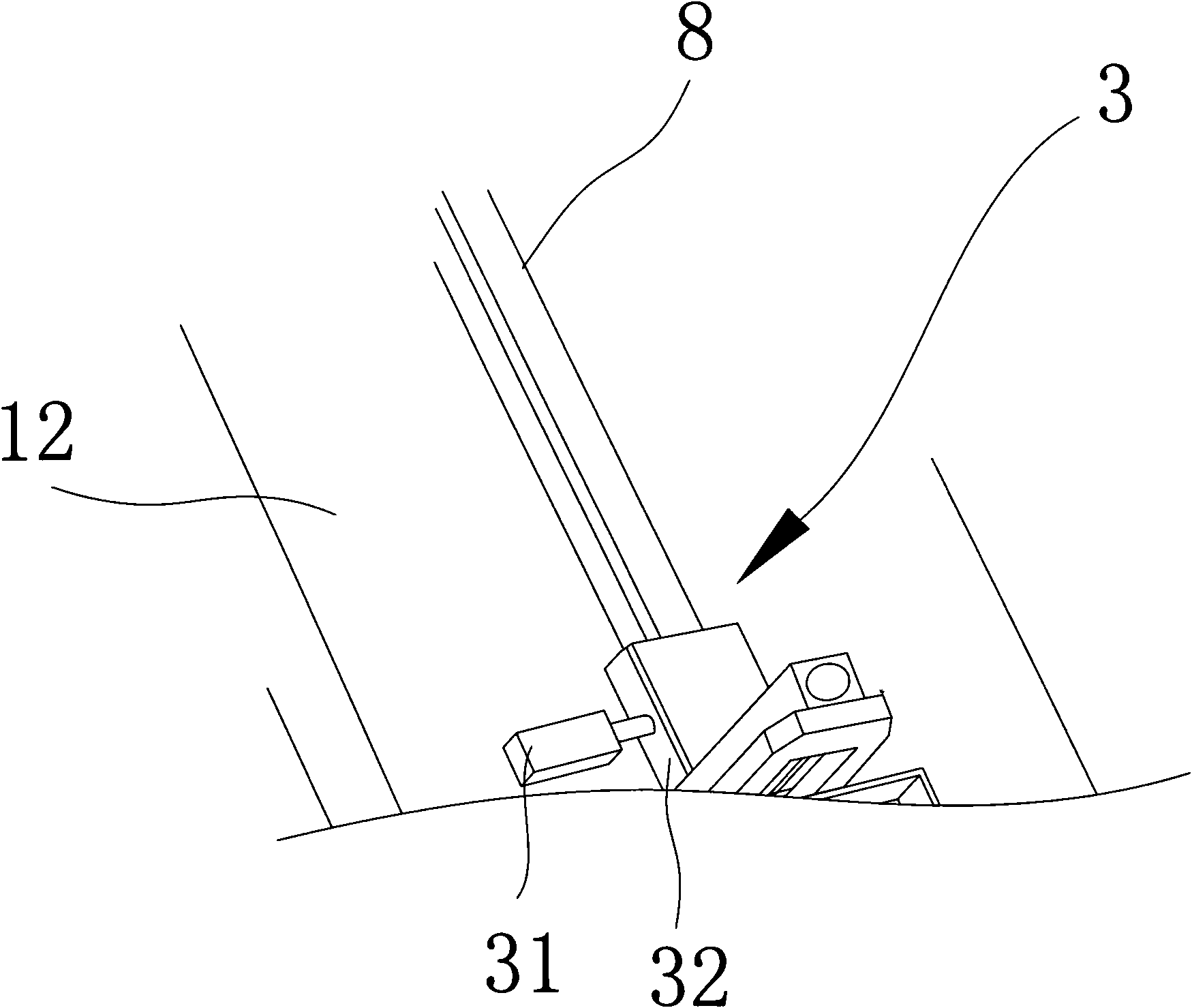

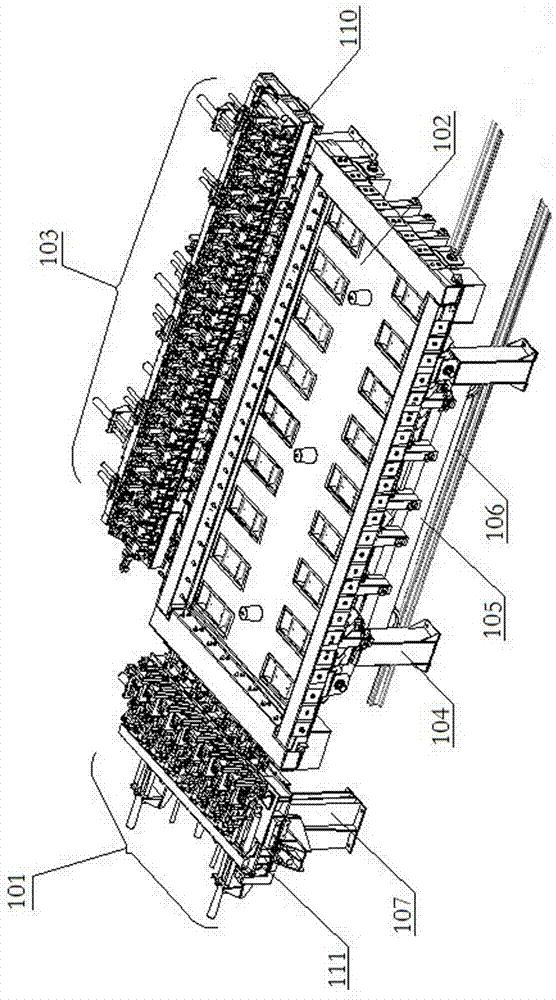

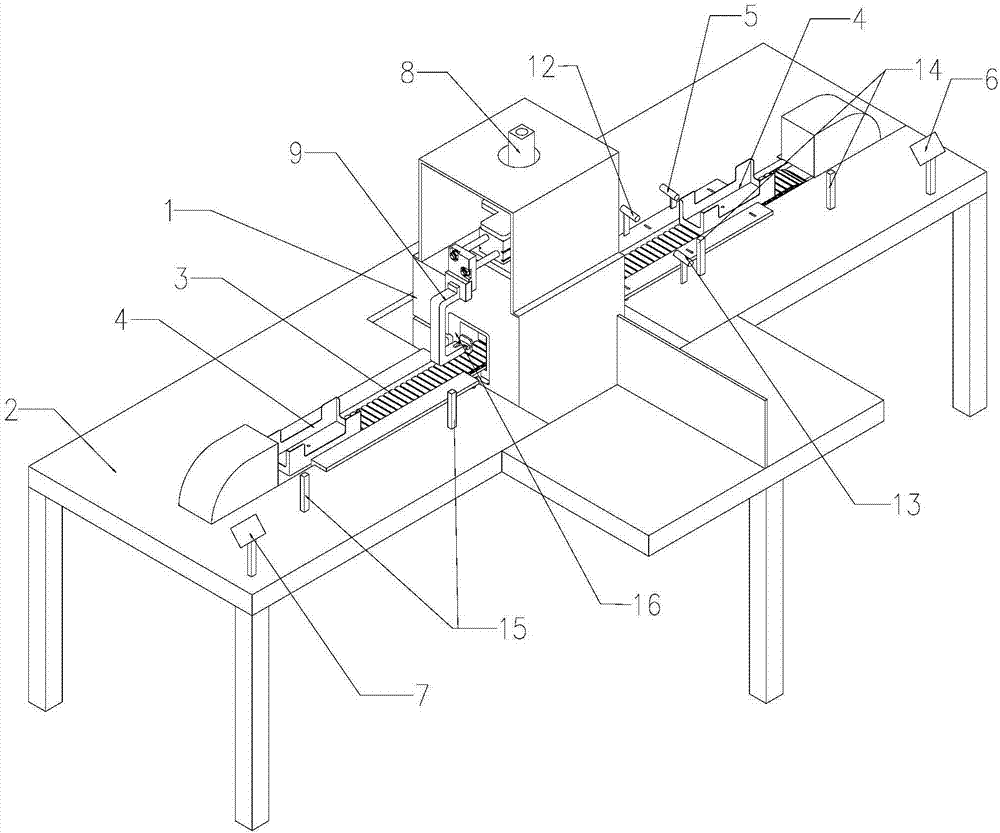

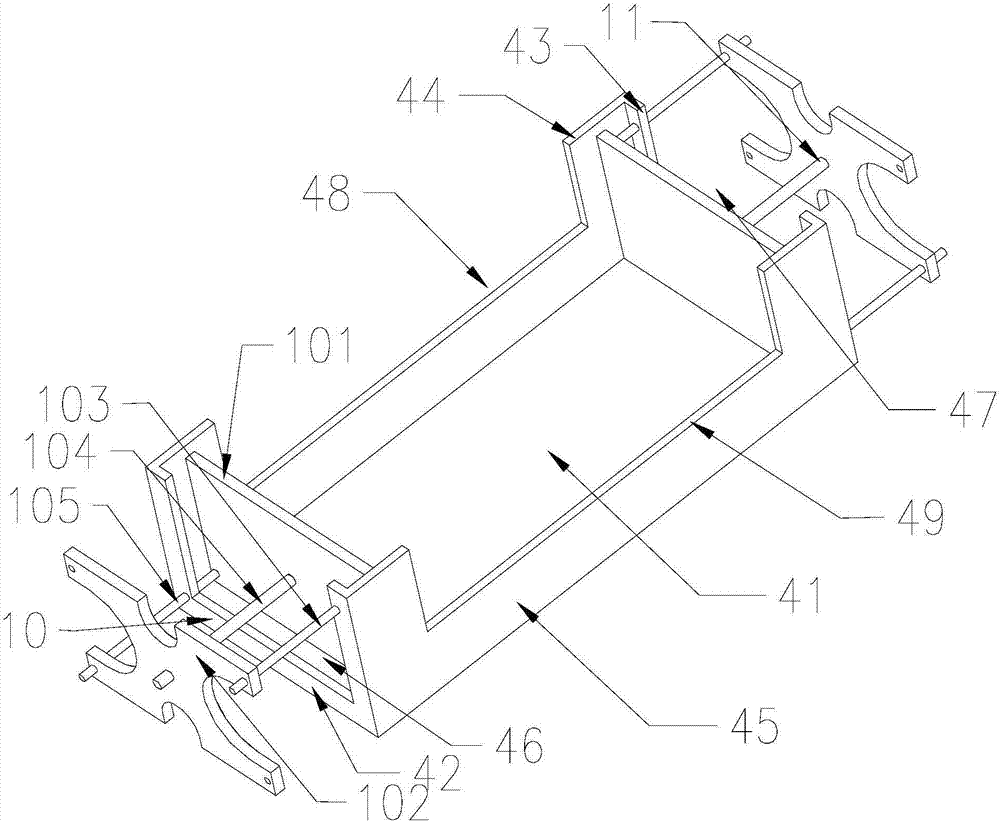

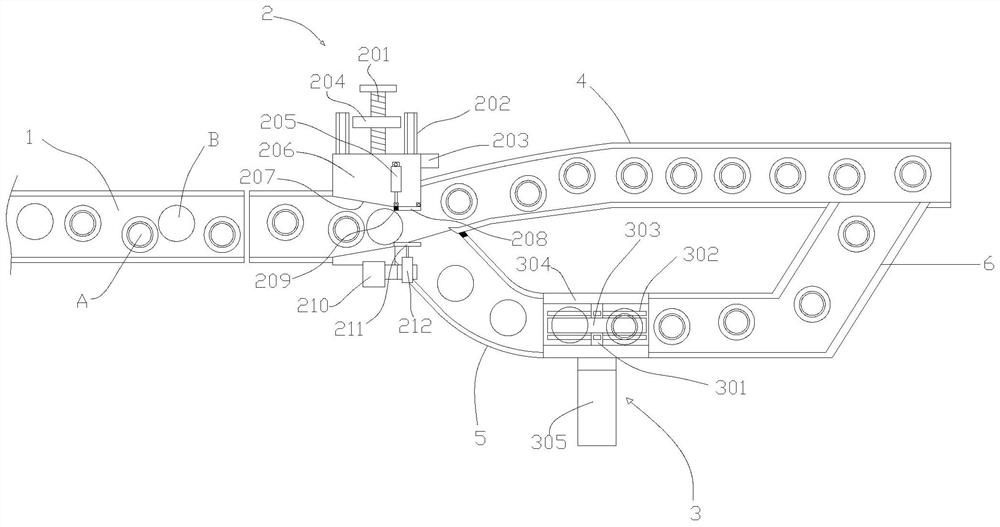

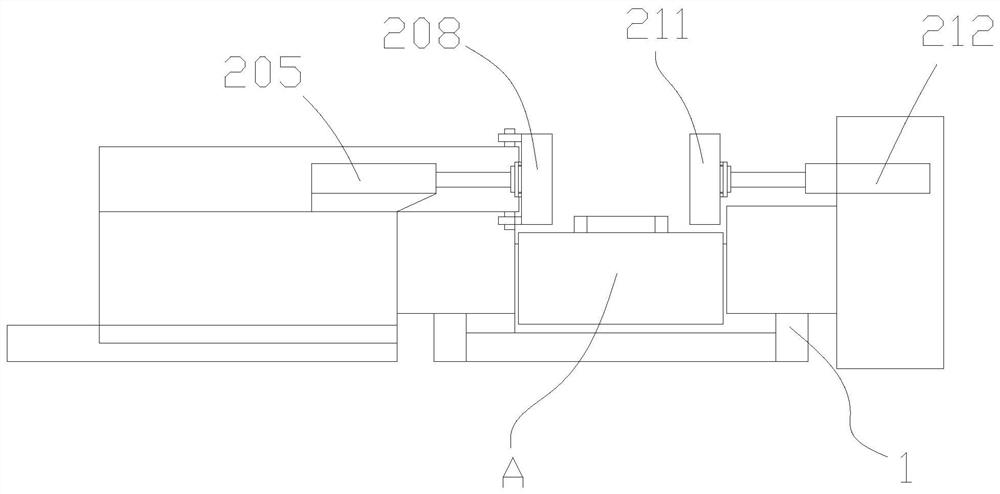

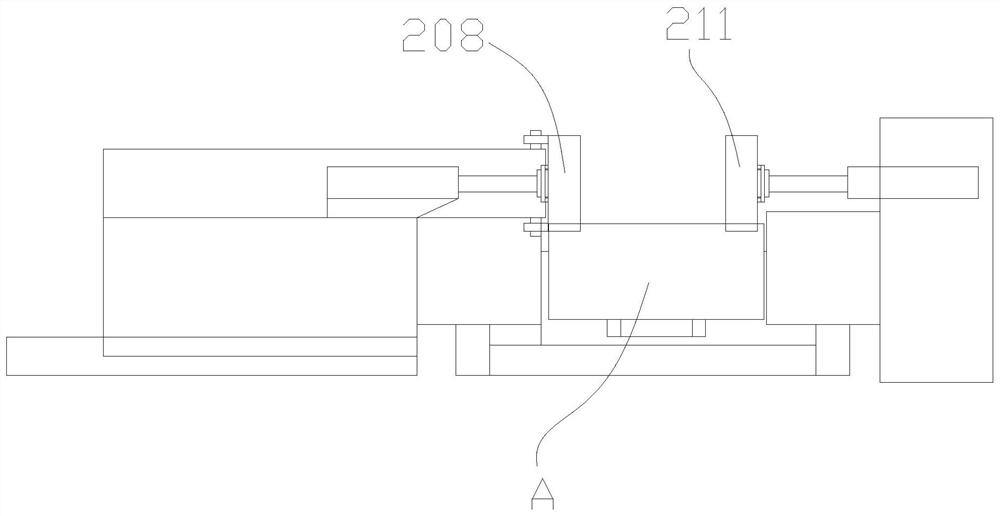

Welding equipment for cell modules

ActiveCN106964888AAvoid damageEasy to determineLine/current collector detailsFinal product manufactureControl systemEngineering

Welding equipment for cell modules comprises a rack, a conveying mechanism for conveying to-be-machined pieces, a welding mechanism, a visual positioning and detecting mechanism and a control system; the conveying mechanism comprises a feeding mechanism for conveying the to-be-machined pieces for feeding as well as a cell module positioning mechanism for positioning the to-be-machined pieces for positioning welding by the aid of the welding mechanism; the visual positioning and detecting mechanism positions and finds out first welding points on the to-be-machined pieces and determines relative coordinates of other welding points with the first welding points used as datum points; and the control system controls the welding mechanism to perform welding according to the relative coordinates. With the equipment, the first welding points of the workpieces are positioned and found out through the visual positioning and detecting mechanism and are used as the datum points for determining of the relative coordinates of other welding points, the welding mechanism is controlled to perform welding according to the relative coordinates, the coordinates of other welding points are convenient to determine for positioning welding, the feeding mechanism performs feeding automatically, and the cell module positioning mechanism positions the cell modules automatically, so that the positioning precision and the machining efficiency are improved.

Owner:深圳福源特新能源有限公司

Intelligent video human body identification method

InactiveCN101996307AEasy to identifyImprove robustnessImage analysisCharacter and pattern recognitionGraphicsHuman body

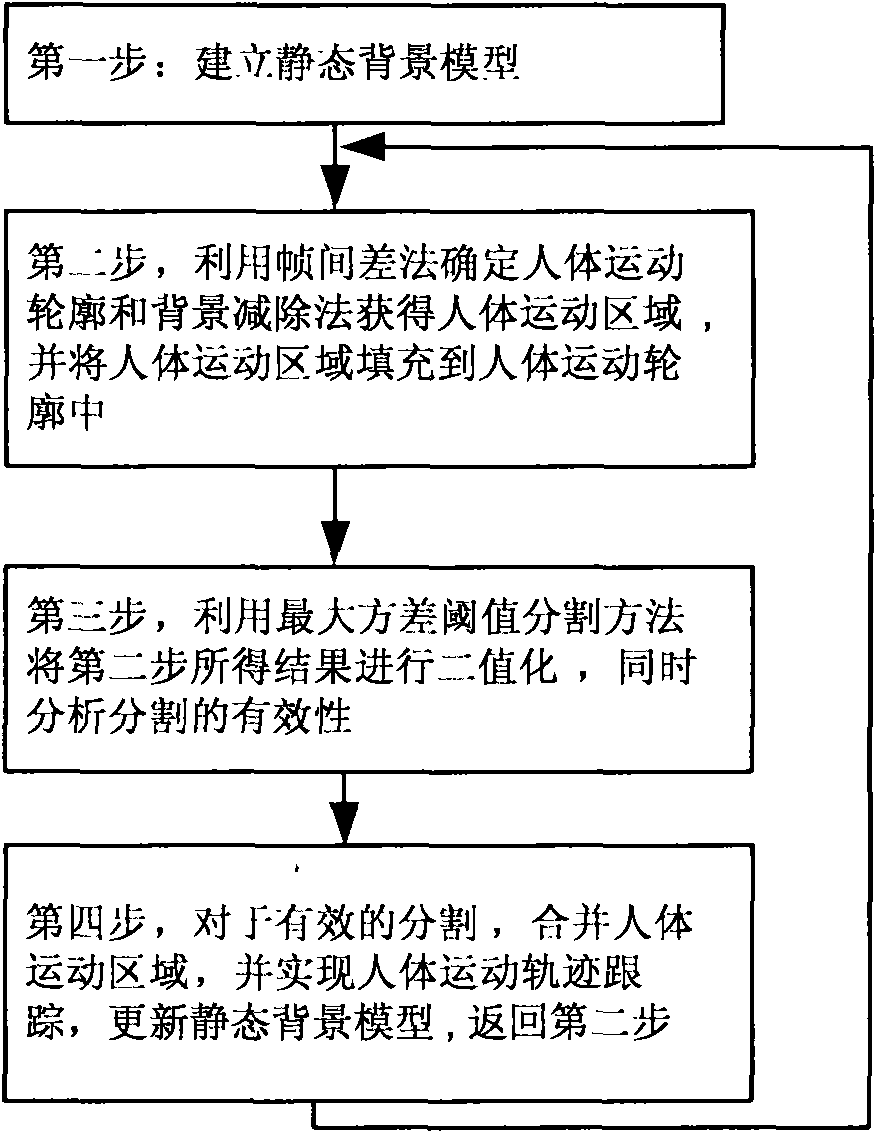

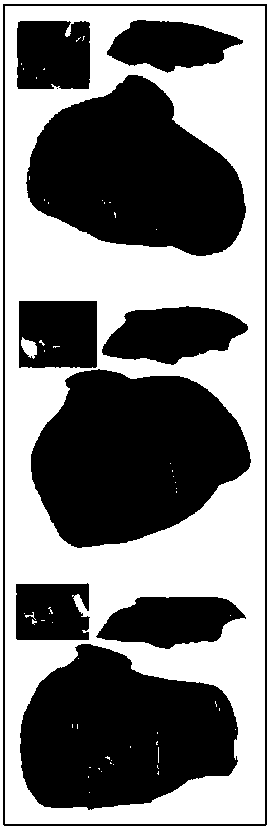

The invention provides an intelligent video human body identification method belonging to the technical field of computer graphics. The method comprises the following steps of: (1) establishing a static background model; (2) determining a human body movement outline and a background subtraction by utilizing interframe difference to obtain a human body movement areas, and filling the human body movement areas into the human body movement outline; (3) carrying out binaryzation on a filling result obtained in the step (2) by utilizing a maximum variance threshold segmentation method, and meanwhile analyzing the segmentation validity; and (4) for the valid segmentation, merging the human body movement areas, tracking the human body movement locus, updating the static background model and returning to the step (2). The invention has good identification effect and high robustness and does not need manual intervention. Moreover, the invention has strong interference resistance, can accurately eliminate the condition like the sudden change of the indoor light and can also filter off the interference of leaf swing and air flyers and the common outdoor environments like the sudden change of the weather, thereby reducing the false tracking phenomenon and false alarm phenomenon.

Owner:SHANGHAI LISHI MICROELECTRONICS

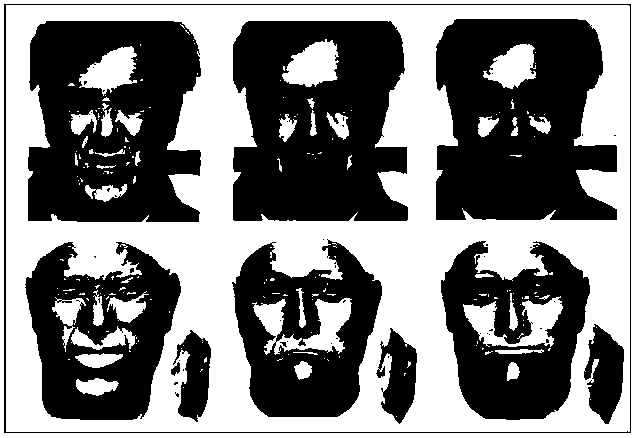

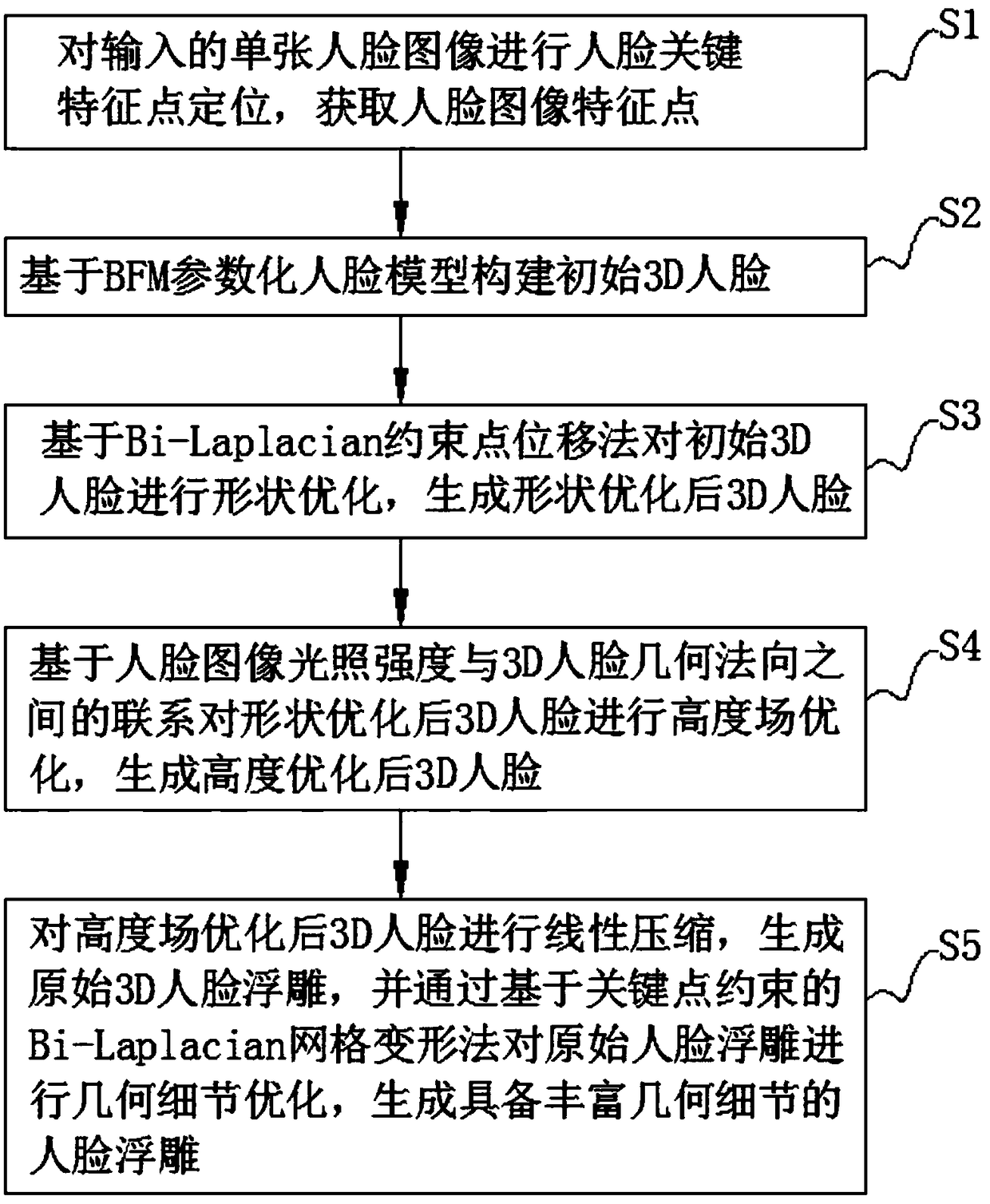

Face relief geometric modeling method

ActiveCN108492373ANo manual interventionImage enhancementImage analysisGrid deformationGeometric modeling

The present invention discloses a face relief geometric modeling method, and belongs to the field of relief modeling. The problems are solved that current portrait relief modeling is low in efficiencyand poor in automation. The method comprises the following steps of: performing face key feature point location for an input single face image, and obtaining face image feature points; based on a BFMparameter face model, constructing an initial 3D face; based on a Bi-Laplacian constrained point displacement method to perform shape optimization of the initial 3D face, and generating a 3D face after shape optimization; performing height field optimization of the 3D face after shape optimization based on a relation of the face image illumination intensity and the 3D face geometric normal, and generating a 3D face after height optimization; and performing linear compression of the 3D face after the height field optimization, generating an original 3D face relief, performing geometric detailoptimization of the original face relief through a Bi-Laplacian grid deformation method based on key point constraint, and generating a face relief with rich geometric details.

Owner:QILU UNIV OF TECH

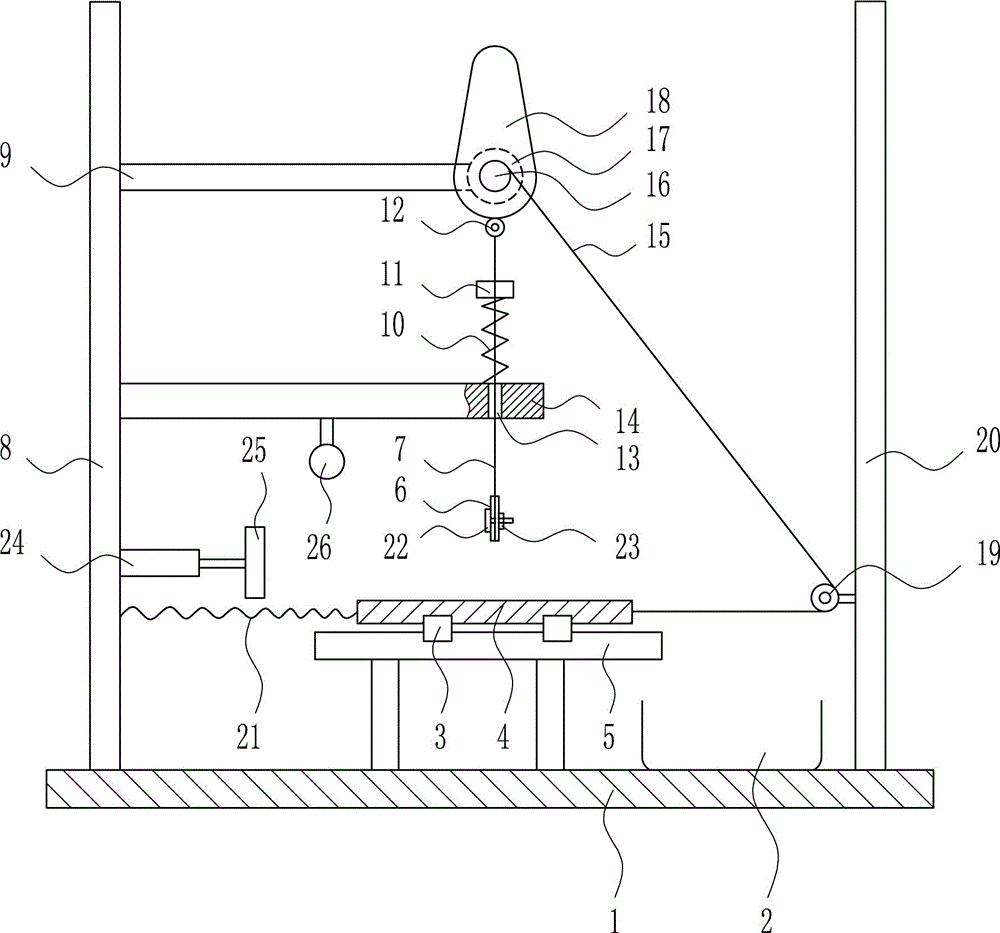

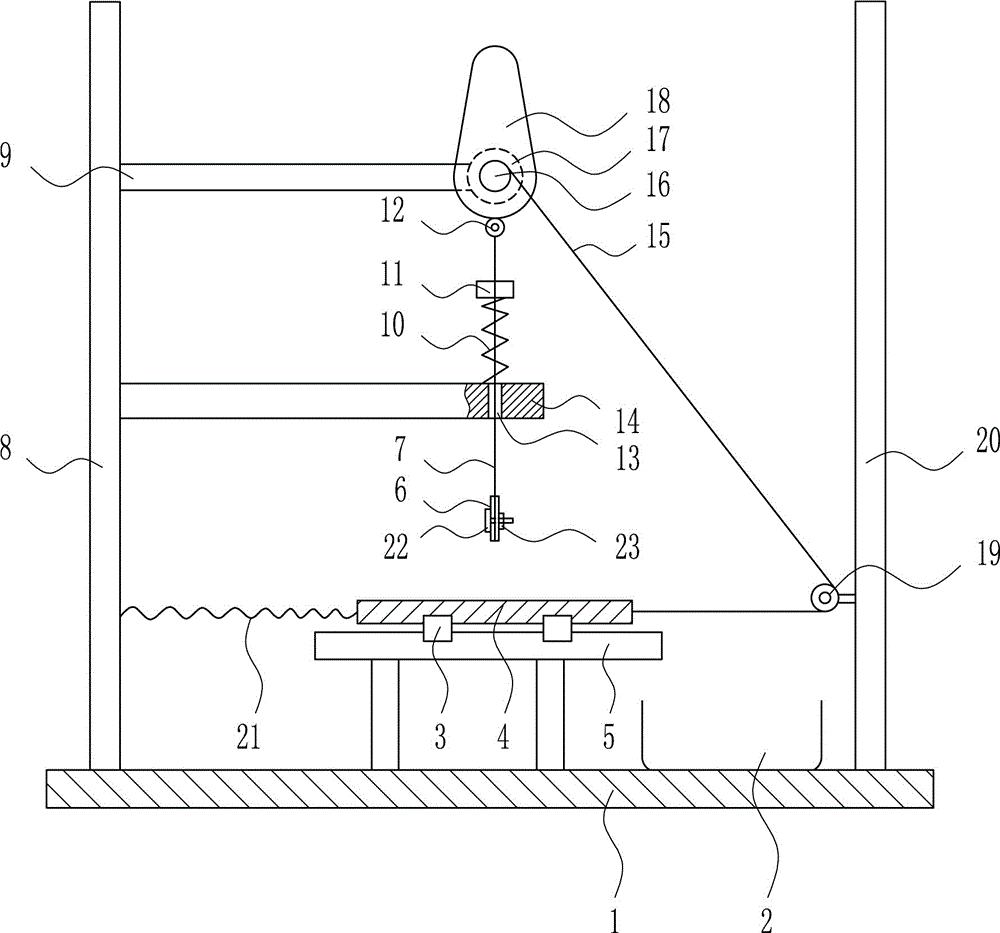

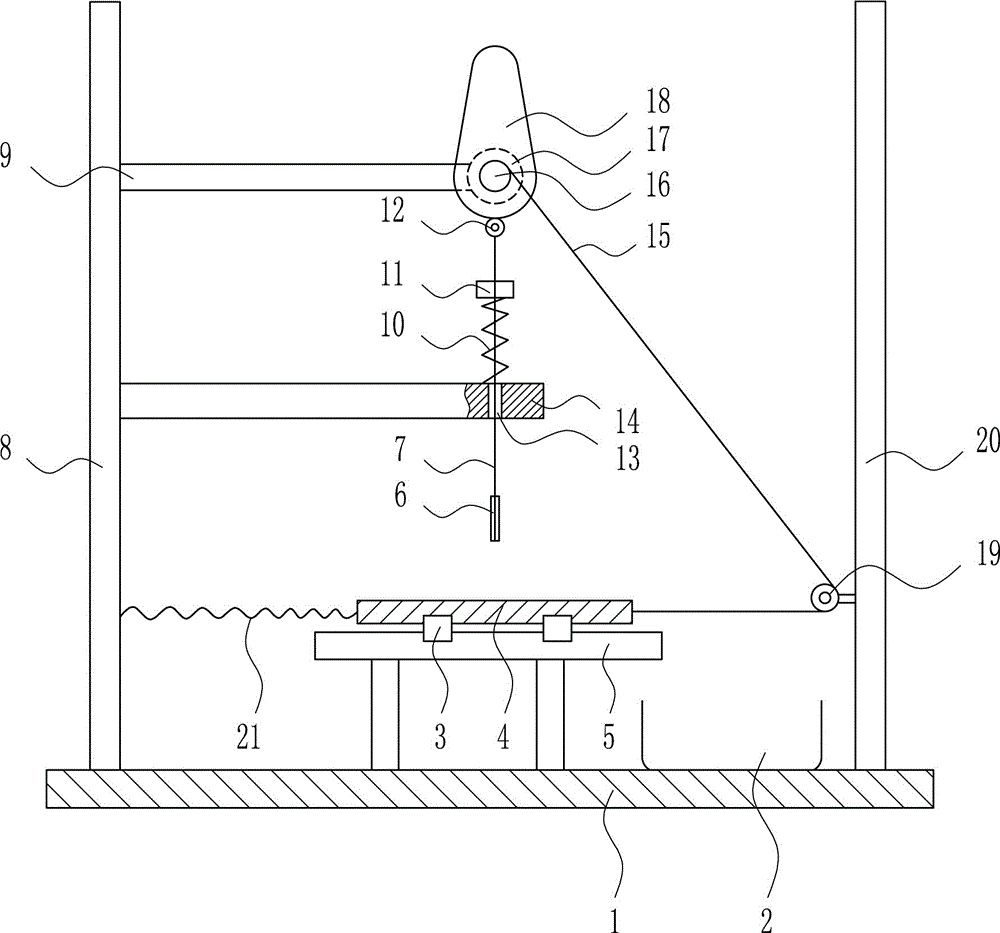

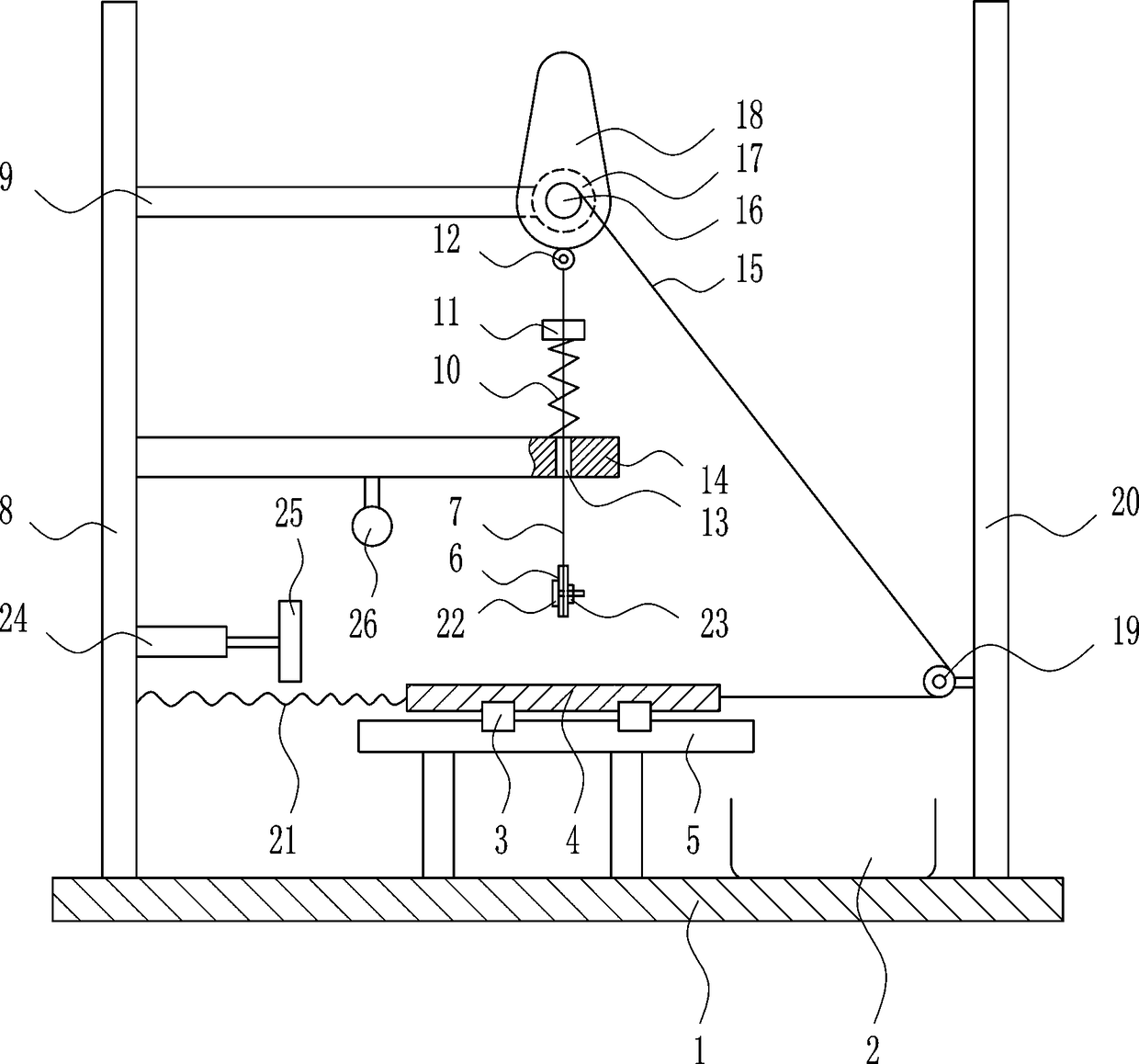

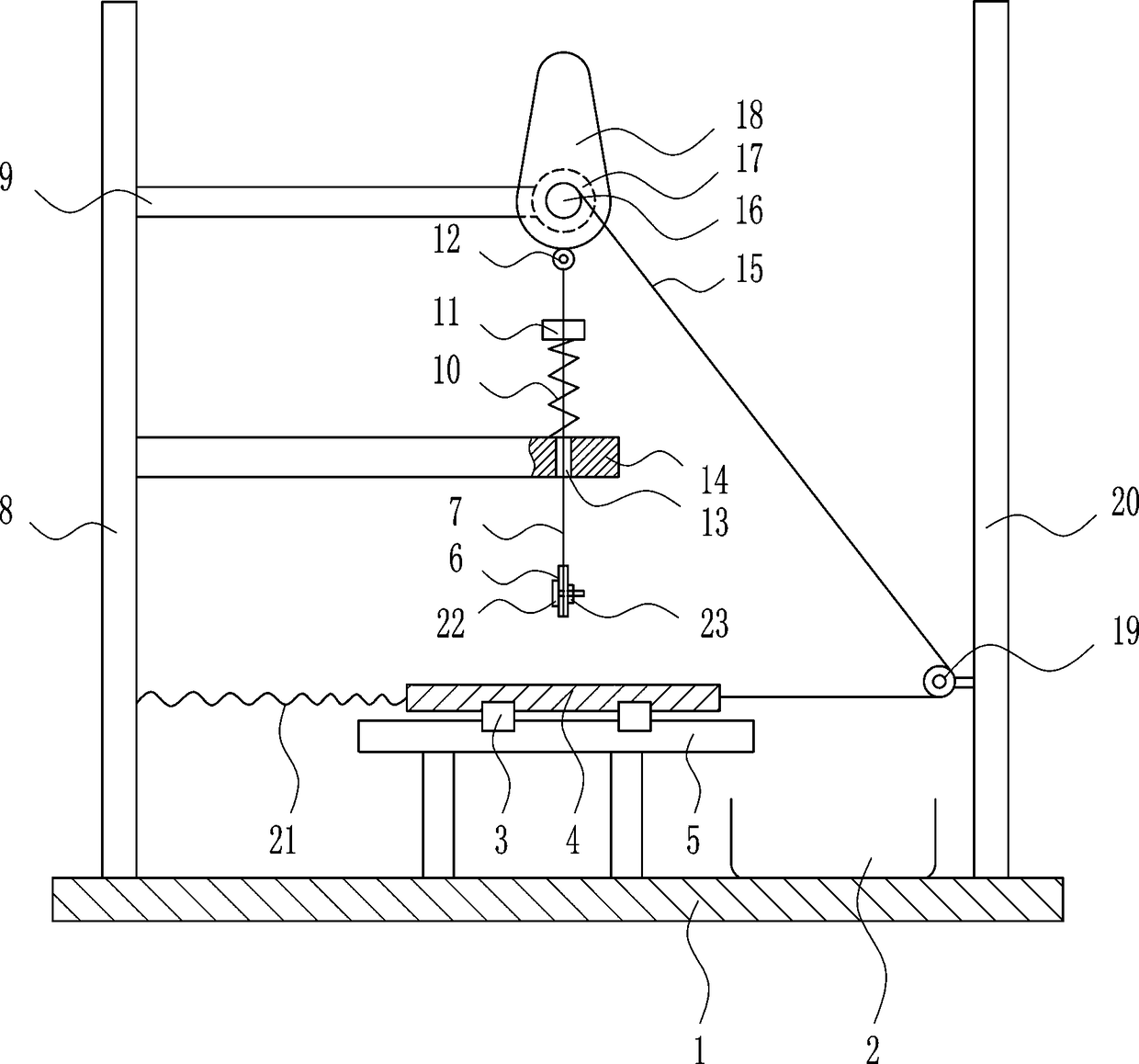

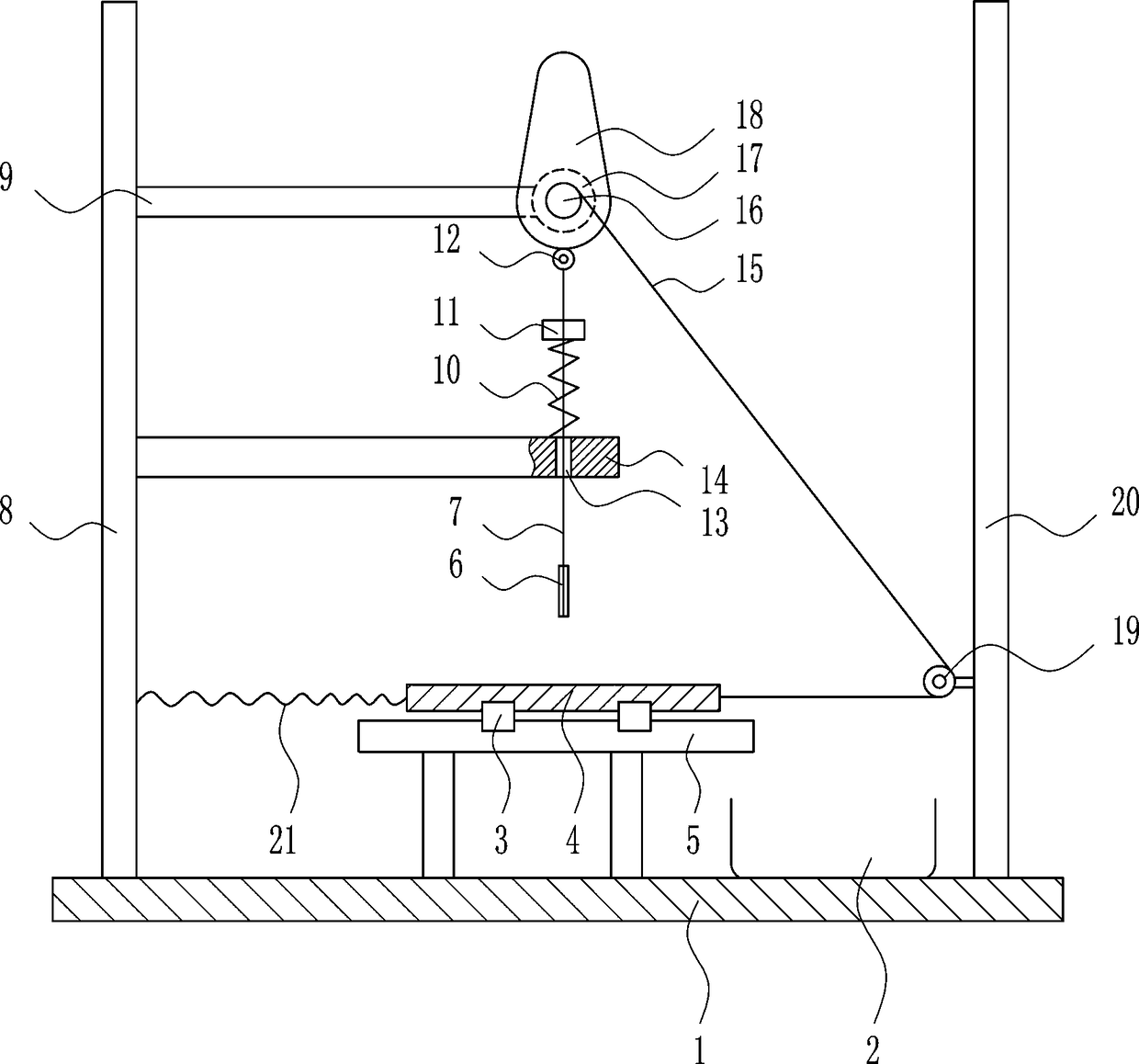

Industrial fast cavendish slicing device

ActiveCN106737926ASlicing is fastOperational securityMetal working apparatusSafe operationOperation safety

The invention relates to a slicing device, and in particular relates to an industrial fast cavendish slicing device. The invention aims at providing the industrial fast cavendish slicing device with high slicing speed. The industrial fast cavendish slicing device provided by the invention comprises a bottom plate, a collecting tank, a slide block, a cutting plate, a slide rail, a cutter, a lifting rod, a left bracket, a support rod, a first spring, a fixed stopper, a contact wheel, a guide plate and the like, wherein the left bracket, the slide rail and a right bracket are sequentially arranged at the top of the bottom plate from the left to the right, and the slide block is arranged on the slide rail; the top of the slide block is connected with the cutting plate, and the left end of the cutting plate is connected with a second spring; the left end of the second spring is connected with the right side of the left bracket. The industrial fast cavendish slicing device provided by the invention has the advantages of high slicing speed, safe operation and simple operation.

Owner:徐州宝美工程机械有限公司

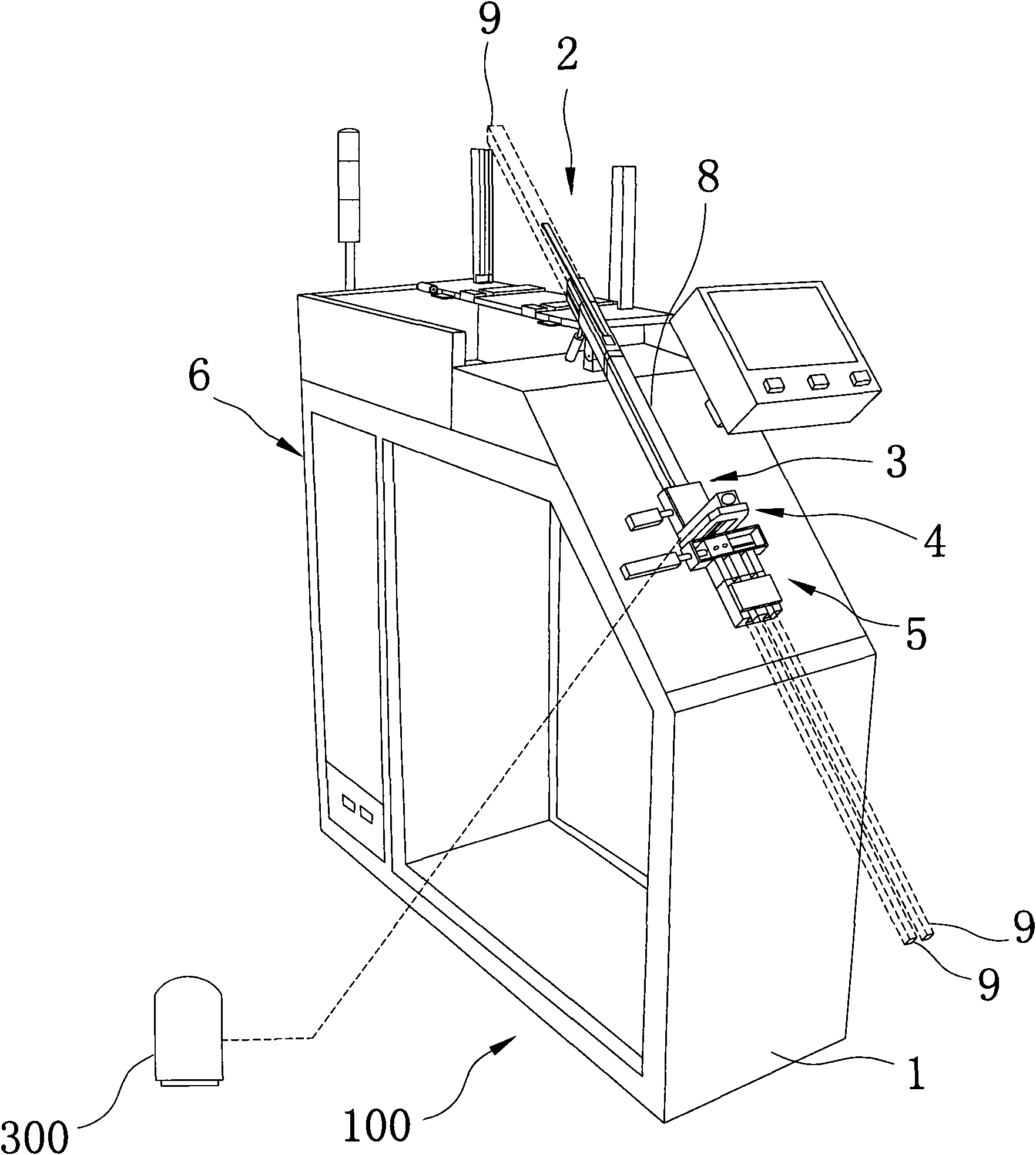

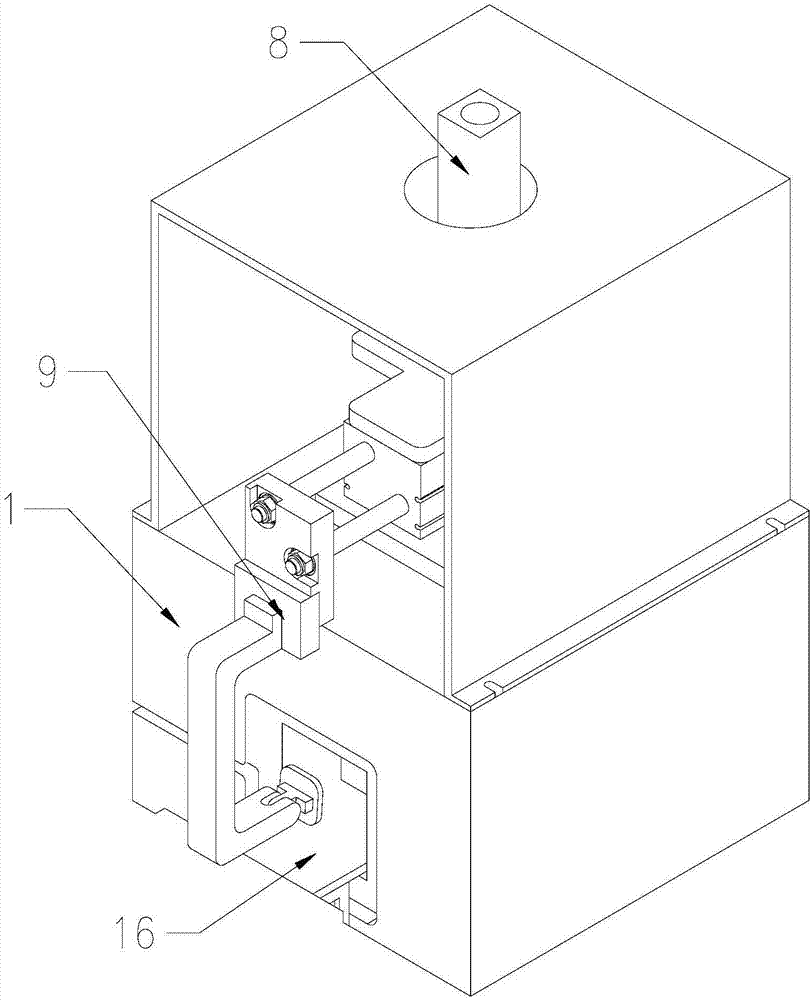

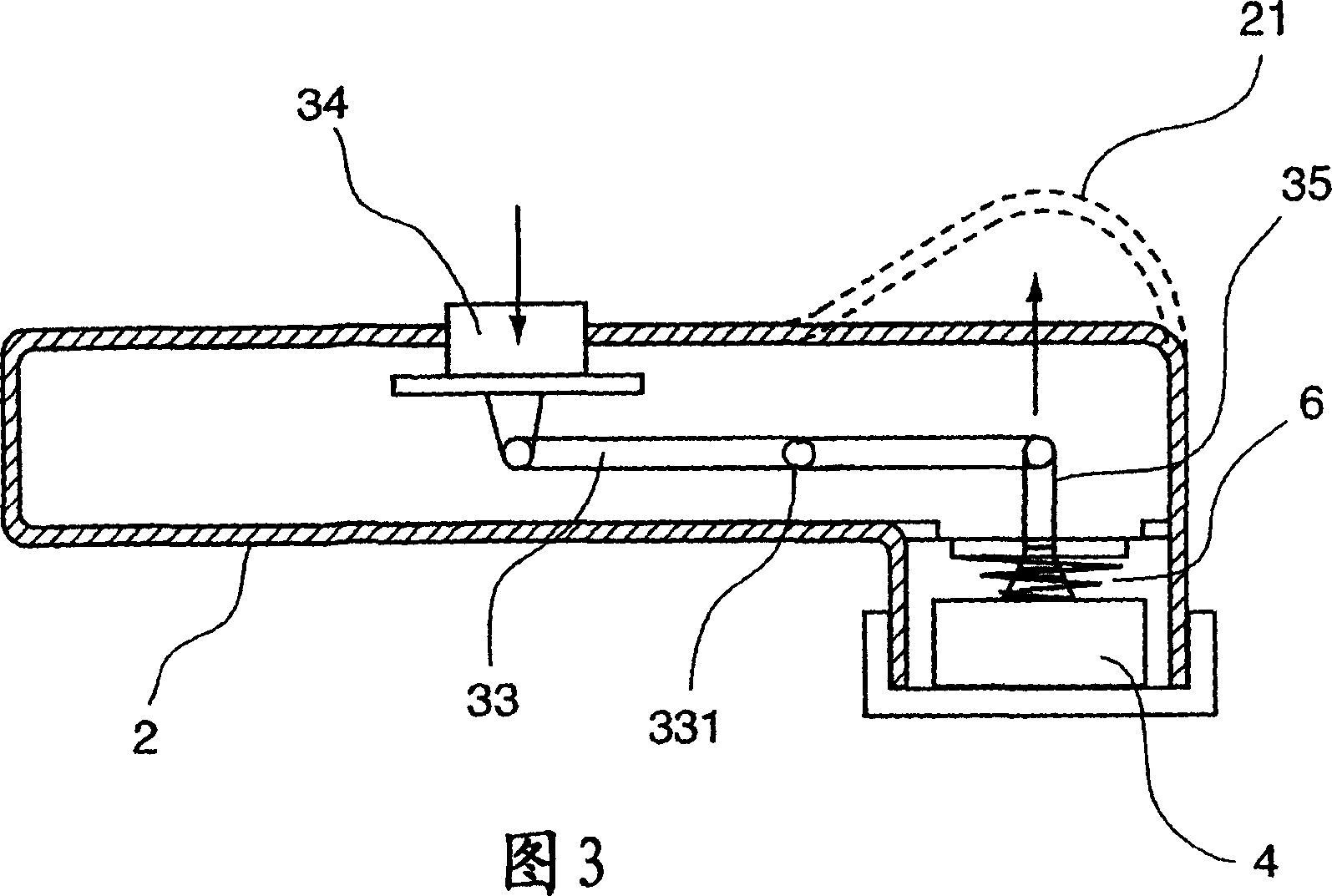

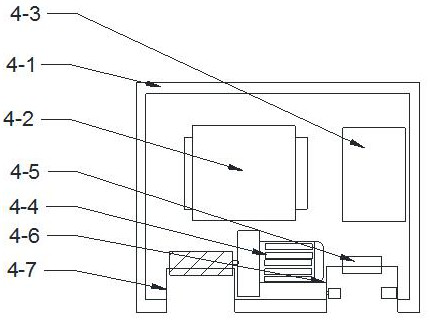

Chip issuing equipment and chip issuing system

ActiveCN102486835ARealize the whole process of automatic feedingFast releaseDigitally marking record carriersConveying record carriersComputer softwareEmbedded system

The invention discloses chip issuing equipment and a chip issuing system, wherein the chip issuing equipment comprises a chip loading device, a chip transmission passage, a chip writing device and a chip sorting device, wherein the chip loading device is used for loading chips to be issued into the chip transmission passage, the chip transmission passage is used for transmitting the chips to be issued to the chip writing device through the self weight of the chips to be issued, the chip writing device is used for writing issuing data into the chips to be issued, detecting issued chips and outputting detection results, and the chip sorting device is used for sliding the issued chips into successfully issued chip loading tubes or unsuccessfully issued chip loading tubes according to the detection results. The chip issuing equipment and the chip issuing system disclosed by the invention have the advantages that pneumatic transmission and infrared sensing detection modes are adopted, the computer software control is matched for completing the whole-process automatic feeding, the issuing, the detection and the loading of the chips, the issuing speed is high, and in addition, the issuing accuracy is high.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +2

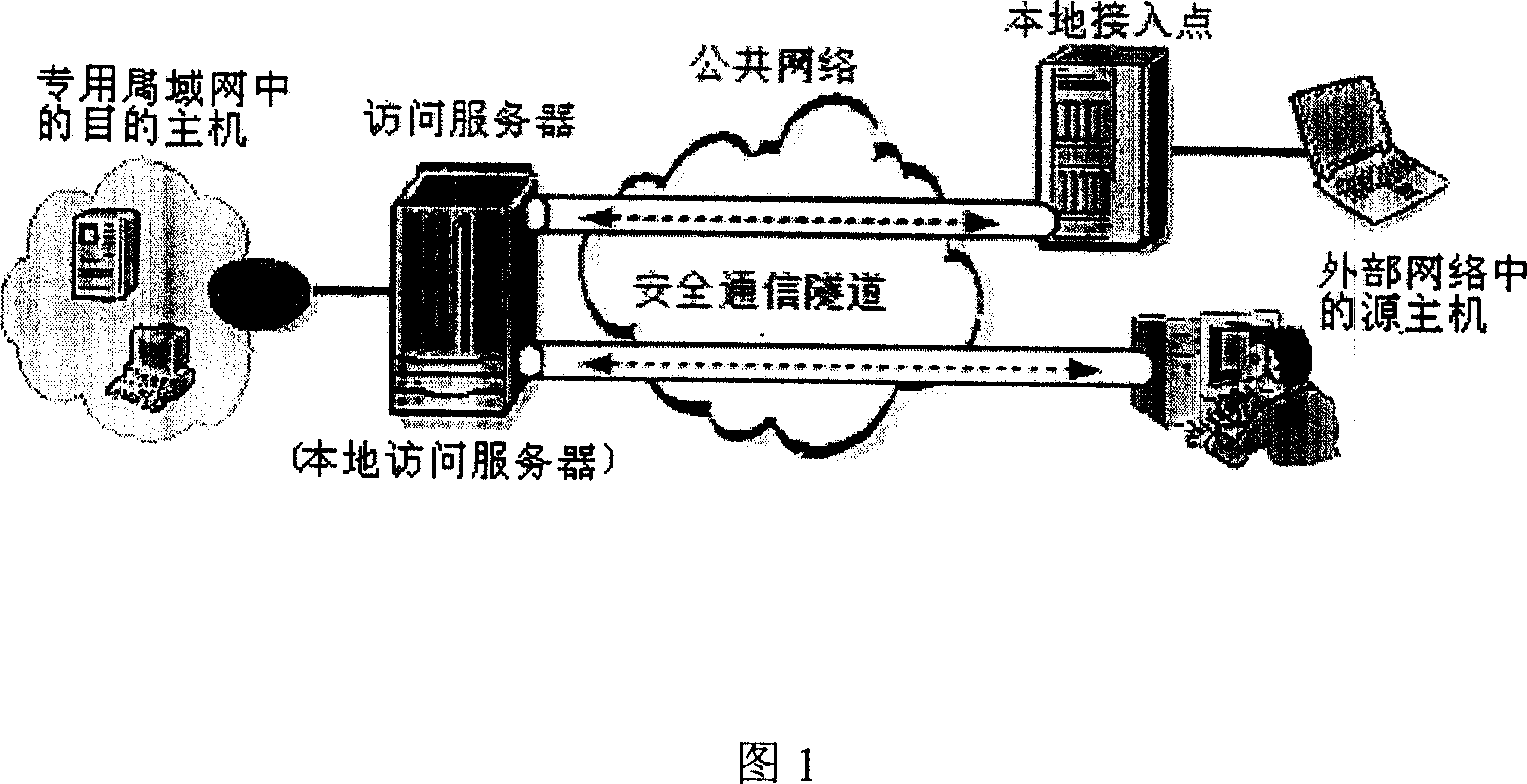

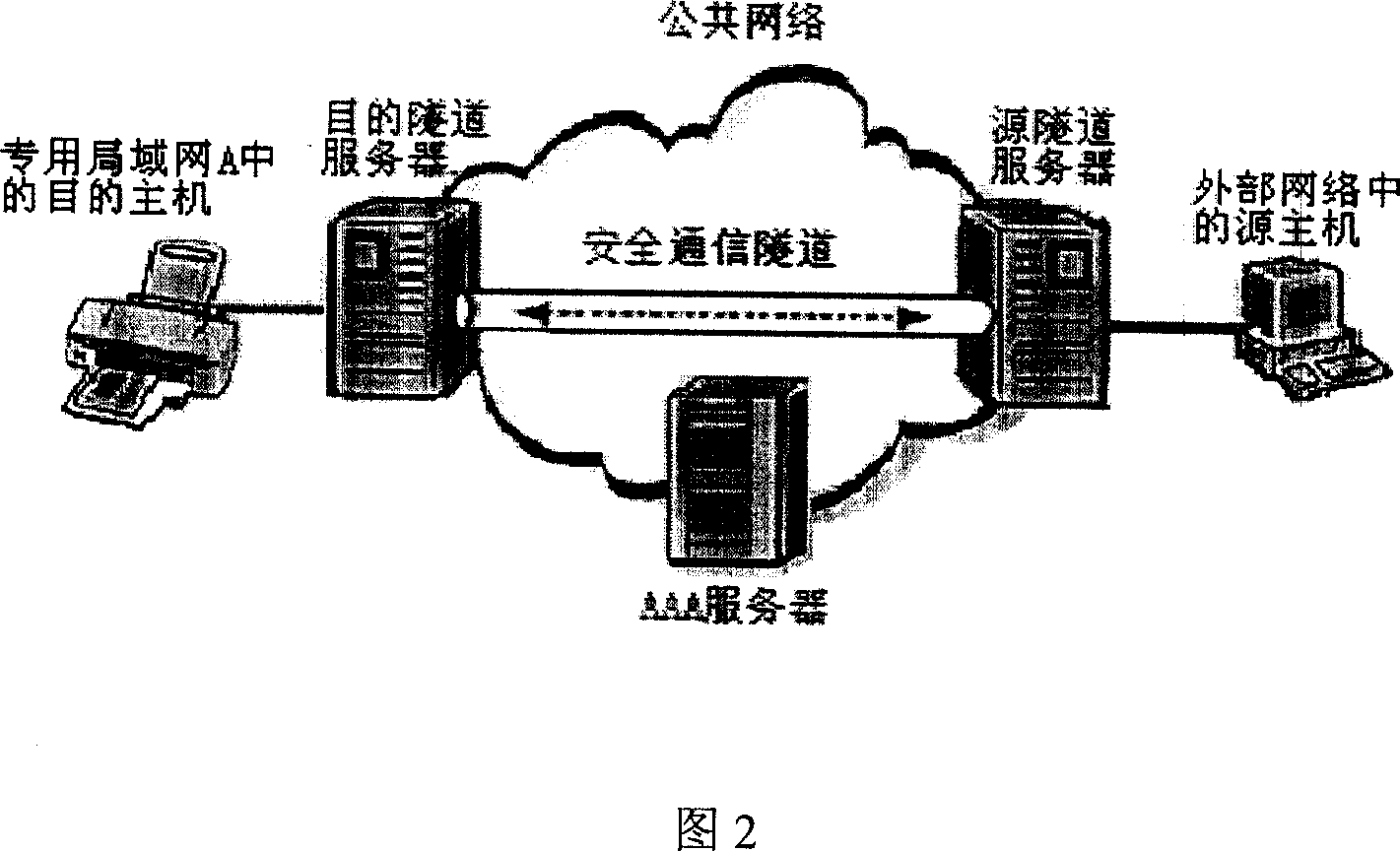

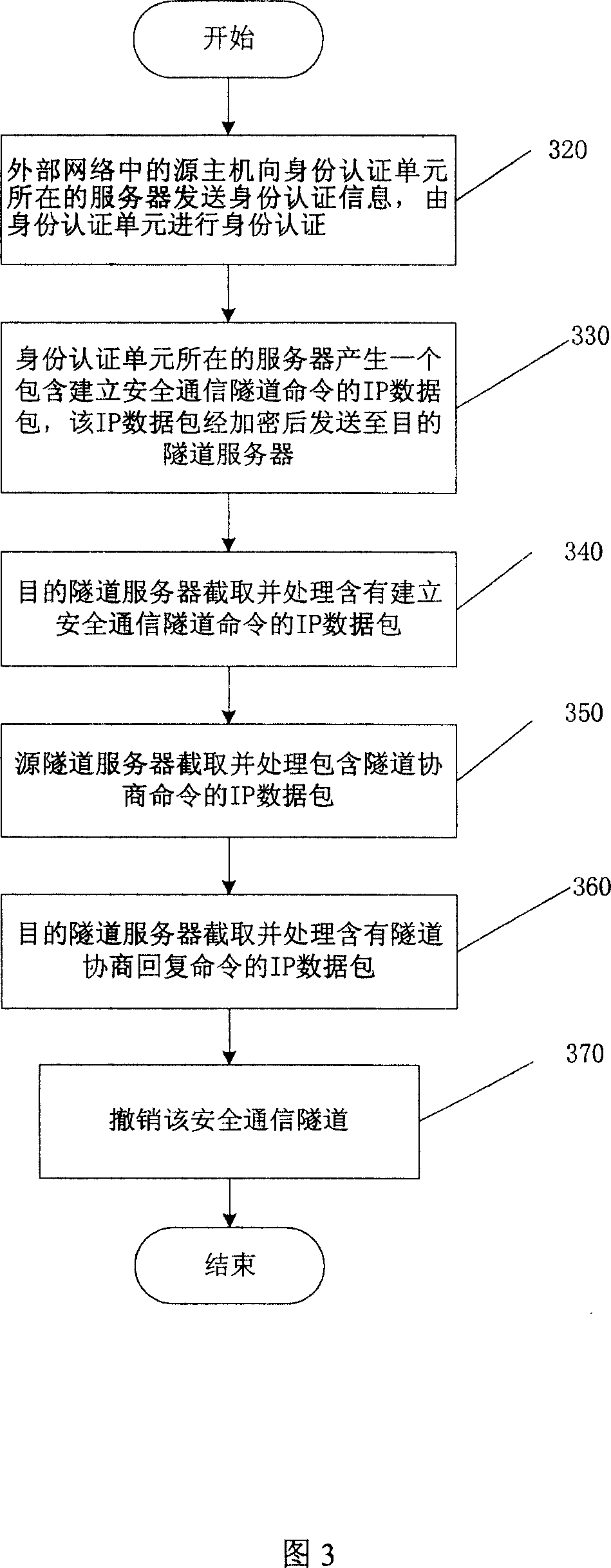

Dynamic tunnel construction method for safety access special LAN and apparatus therefor

ActiveCN1949705ADynamic constructionNo manual interventionUser identity/authority verificationData switching networksSecure communicationIp address

The invention advances a dynamic tunnel constructing method and device for safety access to private LAN. And the method arranges source tunnel server on a router where a source host computer need pass to receive and transmit IP data packets, arranges destination tunnel server on the other router where a destination host computer need pass to receive and tranmsmit IP data packets, and automatically constructs a safety communication tunnel between the two servers without manual tunnel configuration and providing corresponding IP address for private LAN to access server; and afer communication is completed, it can destroy the communication tunnel.

Owner:ALCATEL LUCENT SHANGHAI BELL CO LTD

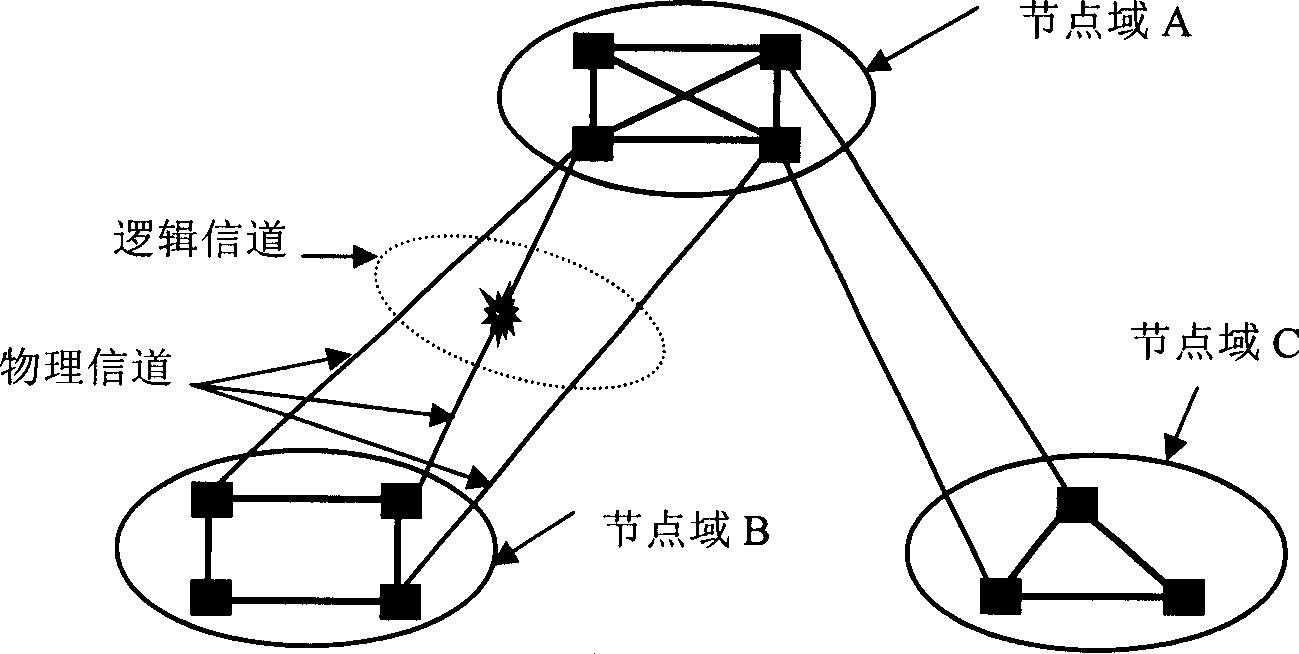

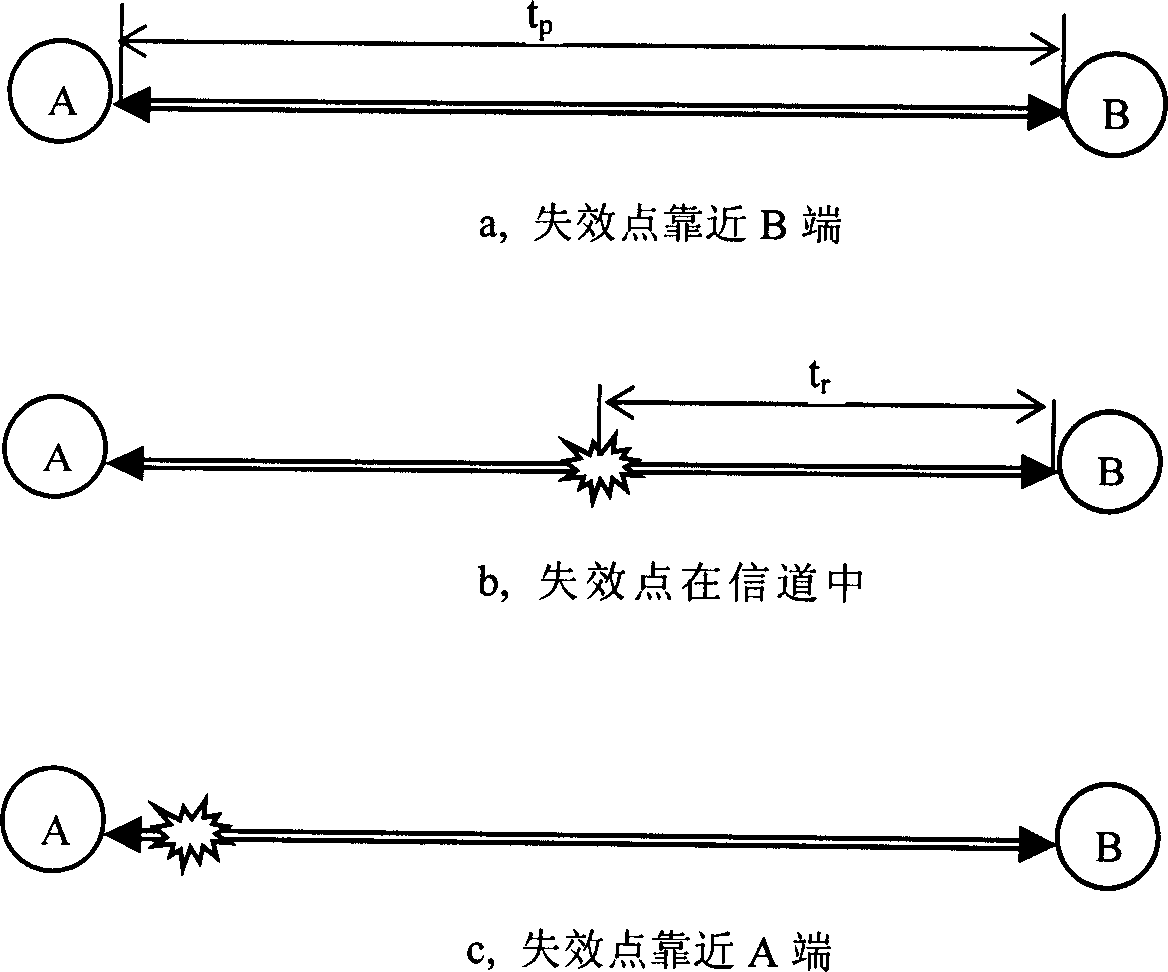

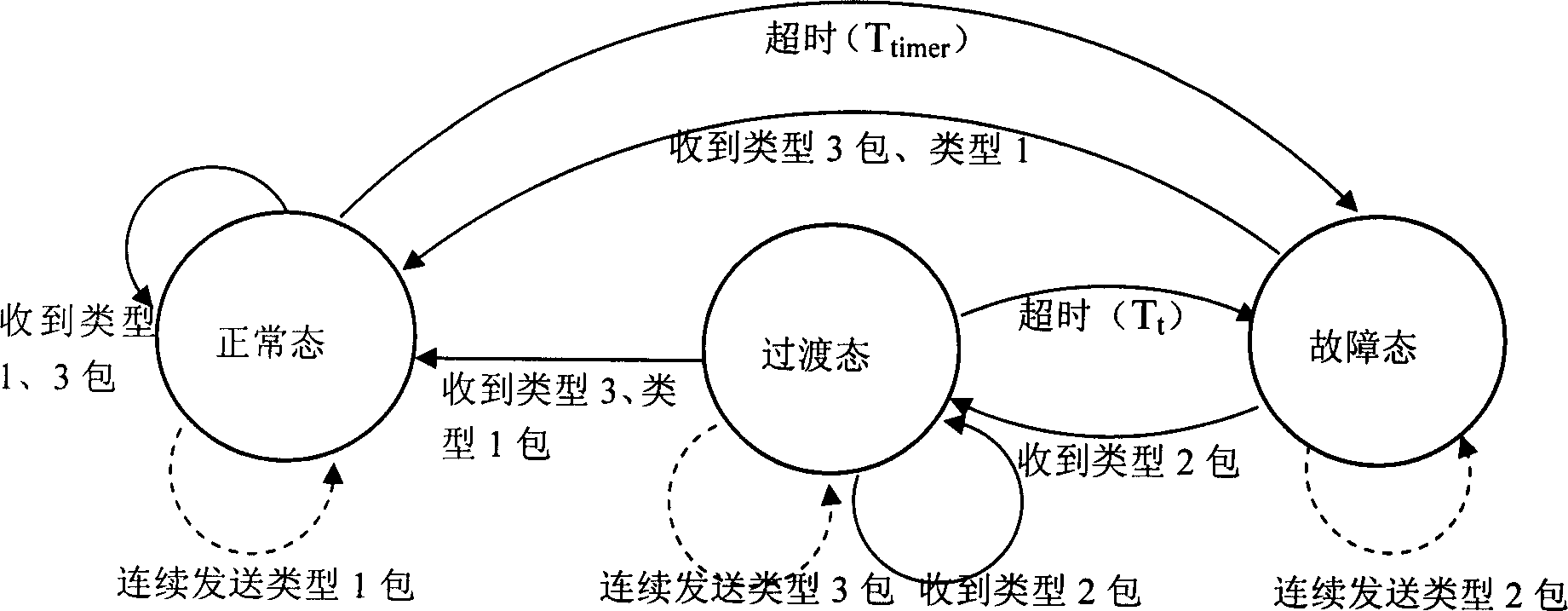

Hierarchical switched network logical channel self-healing method

InactiveCN1829163AGuarantee the quality of real-time communicationDoes not affect normal operationData switching by path configurationSelf-healingSelf recovery

The present invention relates to a hierarchy type switched network self-recovery method. Hierarchy type switched network logic channel is composed of multiple physics channels, when some physics channel or switchboard port occurring fault, the communication load distributed to said channel must be switched to other physics channel belonging to same logic channel. The present invention provides a fast zero channel fault detection method, after channel being fault, setting-up systematical fault state, transition state and normal state, using action, event and state conversion to realize channel recovering, at the same time utilizing interactive process in channel recovery process determining channel round-trip delay, being used as channel and port parameter for other protocol or software module to use. Said invention provided fast self-recovery method can overcame channel fault to user real-time communication infection. Said invention provided fault detection method can be used for other occasion possess of 1 1 or N: 1 spare channel spare channel.

Owner:COMP NETWORK INFORMATION CENT CHINESE ACADEMY OF SCI

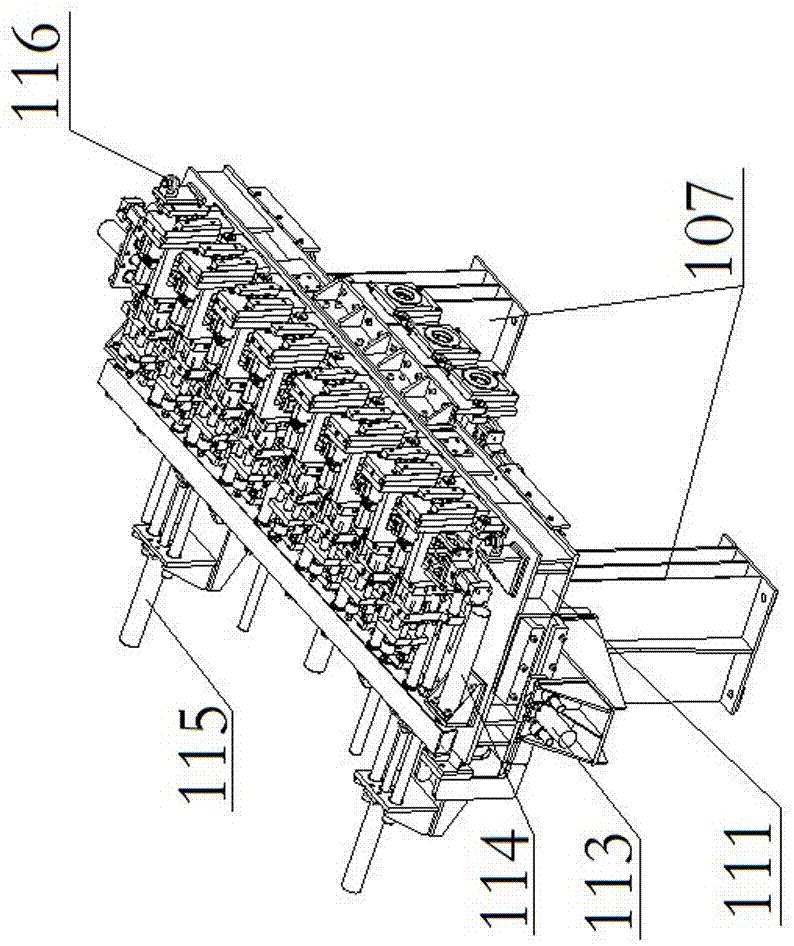

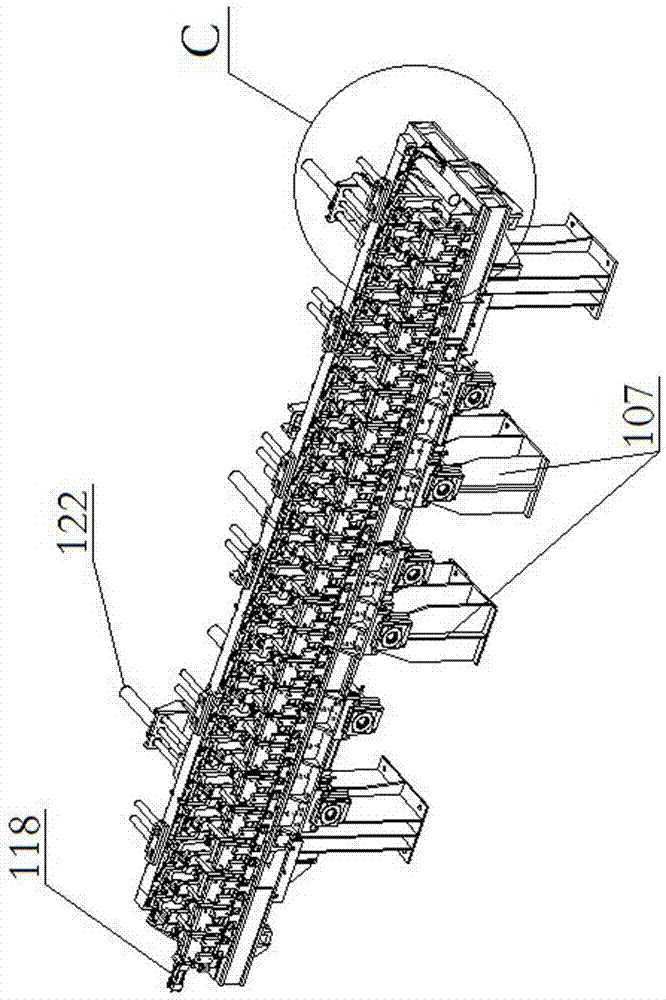

High-speed railway track plate pre-tensioning method flow assembling unit production line tensioning device

ActiveCN106945169AEasy to moveFlexible moving processCeramic shaping apparatusProduction lineEngineering

Provided is a high-speed railway track plate pre-tensioning method flow assembling unit production line tensioning device. A ground support seat with the fixed height supports a tensioning bed box through a universal bead. A tensioning power mechanism is fixed to the tensioning bed box. A track plate production line transferring track is arranged on the inner side of the ground surface of the ground support seat. Track plate locating support seats are arranged on the two sides of the transshipment track. According to the high-speed railway track plate pre-tensioning method flow assembling unit production line tensioning device, the height of the tensioning bed box is fixed, the height of a mold is corresponding to the height of the tensioning bed box at the time of operation and the operation height does not need to be adjusted. The high-speed railway track plate pre-tensioning method flow assembling unit production line tensioning device is simple, capable of saving time and effort. A traverse movement oil cylinder and a feed oil cylinder are arranged, the locating and taking place of the tensioning bed box are more flexible and accurate. The tensioning power mechanism adopts double oil cylinders or multiple oil cylinder combinations, the device size can be reduced, the tension power is more ample, and the tension process is simple and smooth.

Owner:SHANXI GAOHANG HYDRAULIC

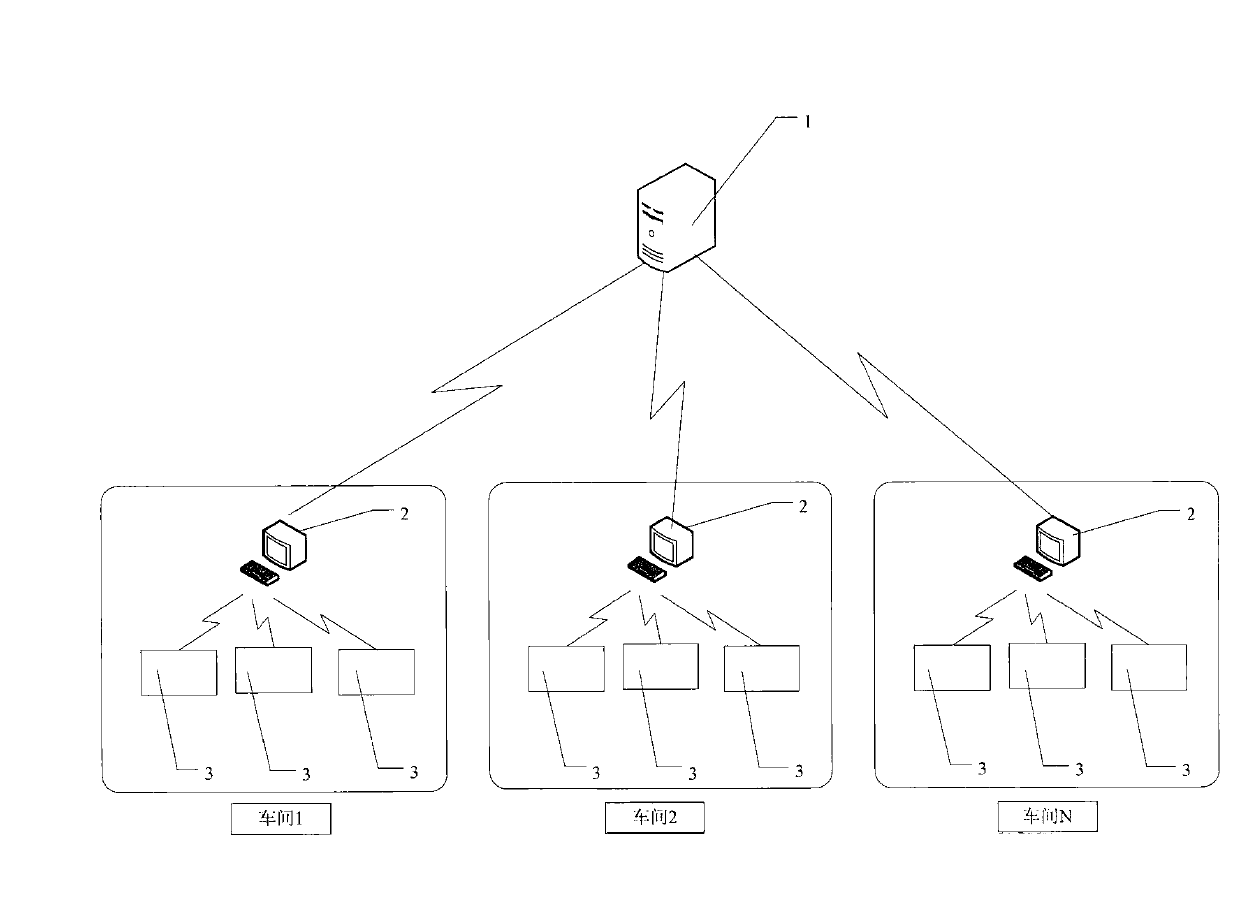

Production monitoring system of manufacturing plant of printed circuit board (PCB) or liquid crystal display (LCD) or solar cell

InactiveCN103135527AReal-time understanding of production statusKnow the actual production quantity in real timeTotal factory controlProgramme total factory controlAnalysis dataStatistical analysis

The invention relates to a production monitoring system of a manufacturing plant of a printed circuit board (PCB), a liquid crystal display (LCD) or a solar cell. The production monitoring system of the manufacturing plant of the PCB, the LCD or the solar cell is characterized by comprising a monitoring center and at least one data collection transmission device, wherein the monitoring center is arranged at a remote end. Each workshop of the PCB, the LCD or the solar cell manufacturing plant is provided with one data collection transmission device, or at least two workshops sharing one data collection transmission device. The data collection transmission device is connected with a data interface device, and production equipment in the workshop is connected with one data interface device. By means of the production monitoring system, an administer of the manufacturing plant of the PCB, the LCD or the solar cell can visit the monitoring center any time anywhere through a terminal (for example, a mobile intelligent terminal) and know the state of a production line, the actual production amount and statistic analysis data in real time. The production monitoring system of the manufacturing plant of the PCB, the LCD or the solar cell has the advantages of being free from space and time intervals, completely intelligent, free from need of manual intervention, and capable of improving efficiencies of production and management and reducing labor cost.

Owner:上海飞为智能系统股份有限公司

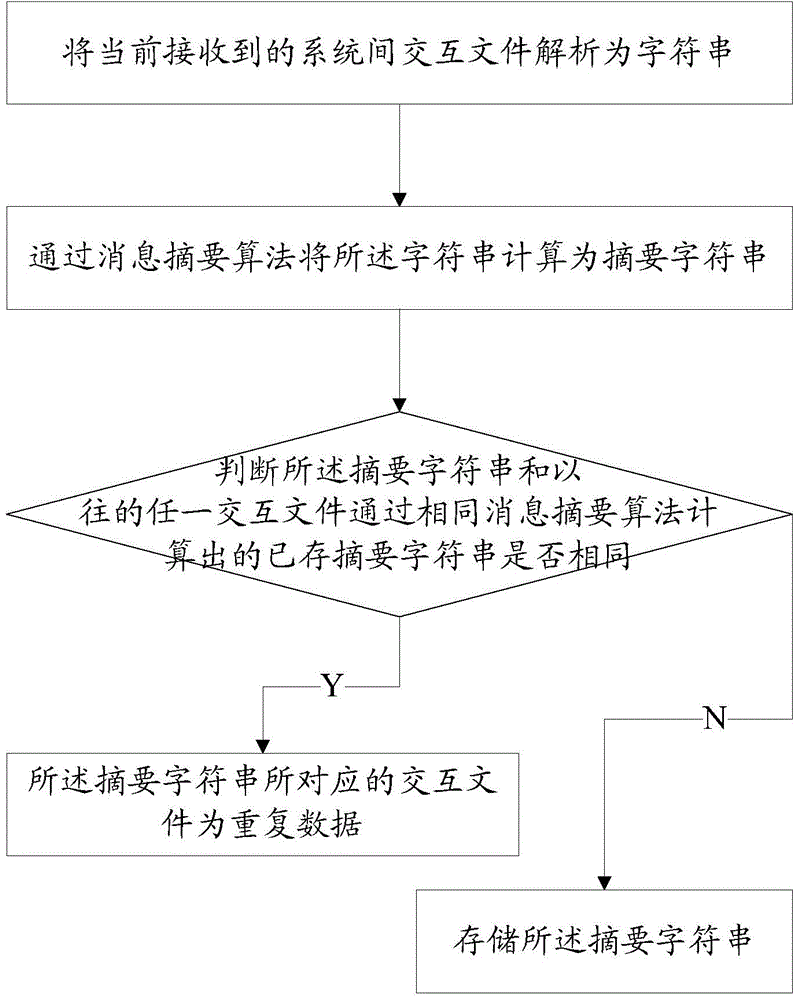

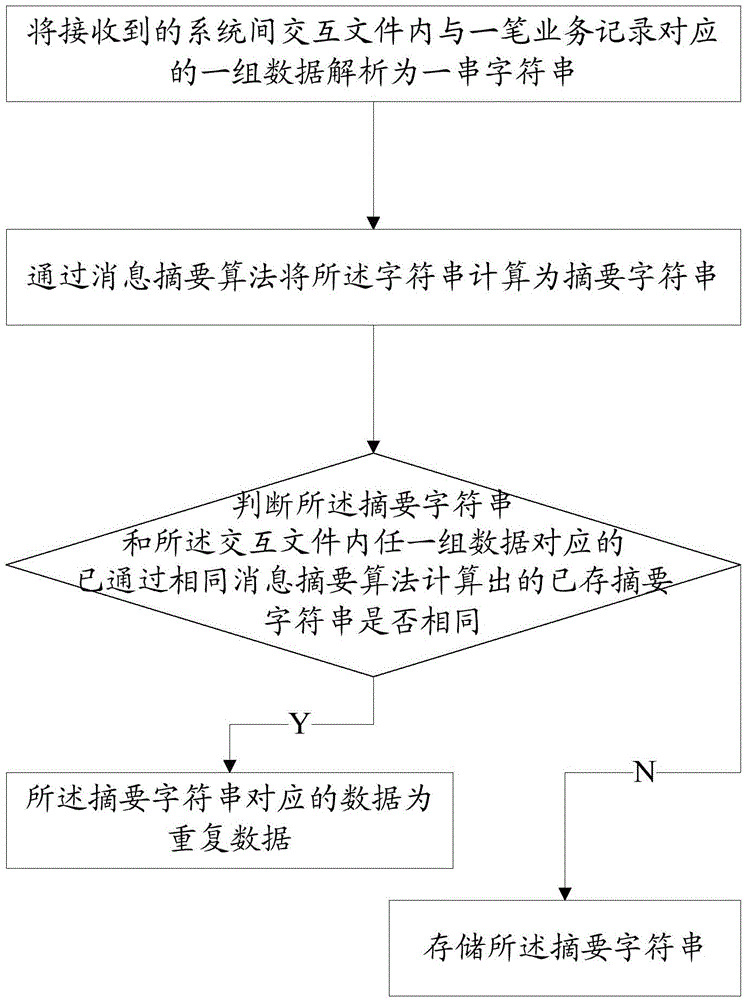

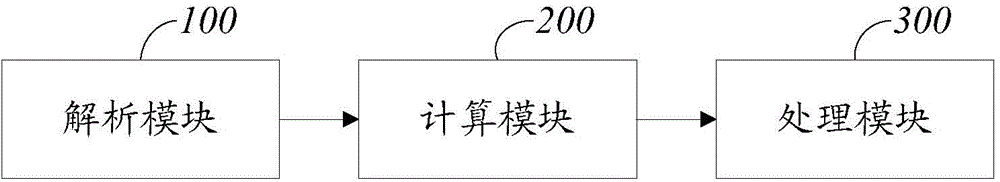

Data processing method and device

InactiveCN105989532ASave resourcesAvoid follow-up business processingFinanceComputer resourcesAlgorithm

The invention discloses a data processing method and device. The method comprises the following steps: analyzing an intersystem interaction file which is received at present into a character string; calculating the character string into a digest character string through a message digest algorithm; judging whether the digest character string is the same with a stored digest character string calculated by any interaction file through the same message digest algorithm or not; if the digest character string is the same with the stored digest character string, considering that the interaction file corresponding to the digest character string is repeated data; and otherwise, storing the digest character string. Through the message digest algorithm, the data is calculated into the digest character string, the digest character string can be compared to identity whether different pieces of data are repeated or not to avoid the subsequent transaction processing of the same data, so that computer resources are saved, manual intervention is omitted, and time and labor are saved.

Owner:ALIBABA GRP HLDG LTD

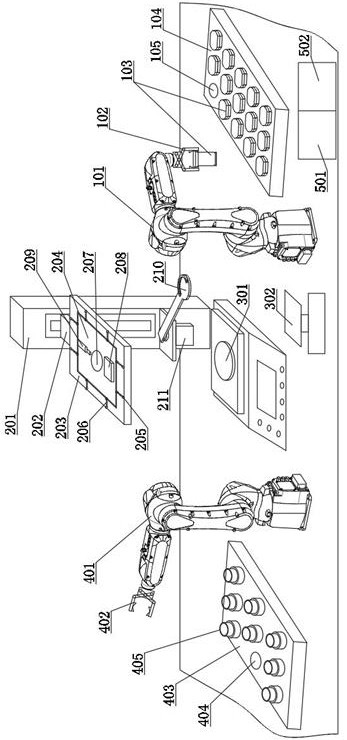

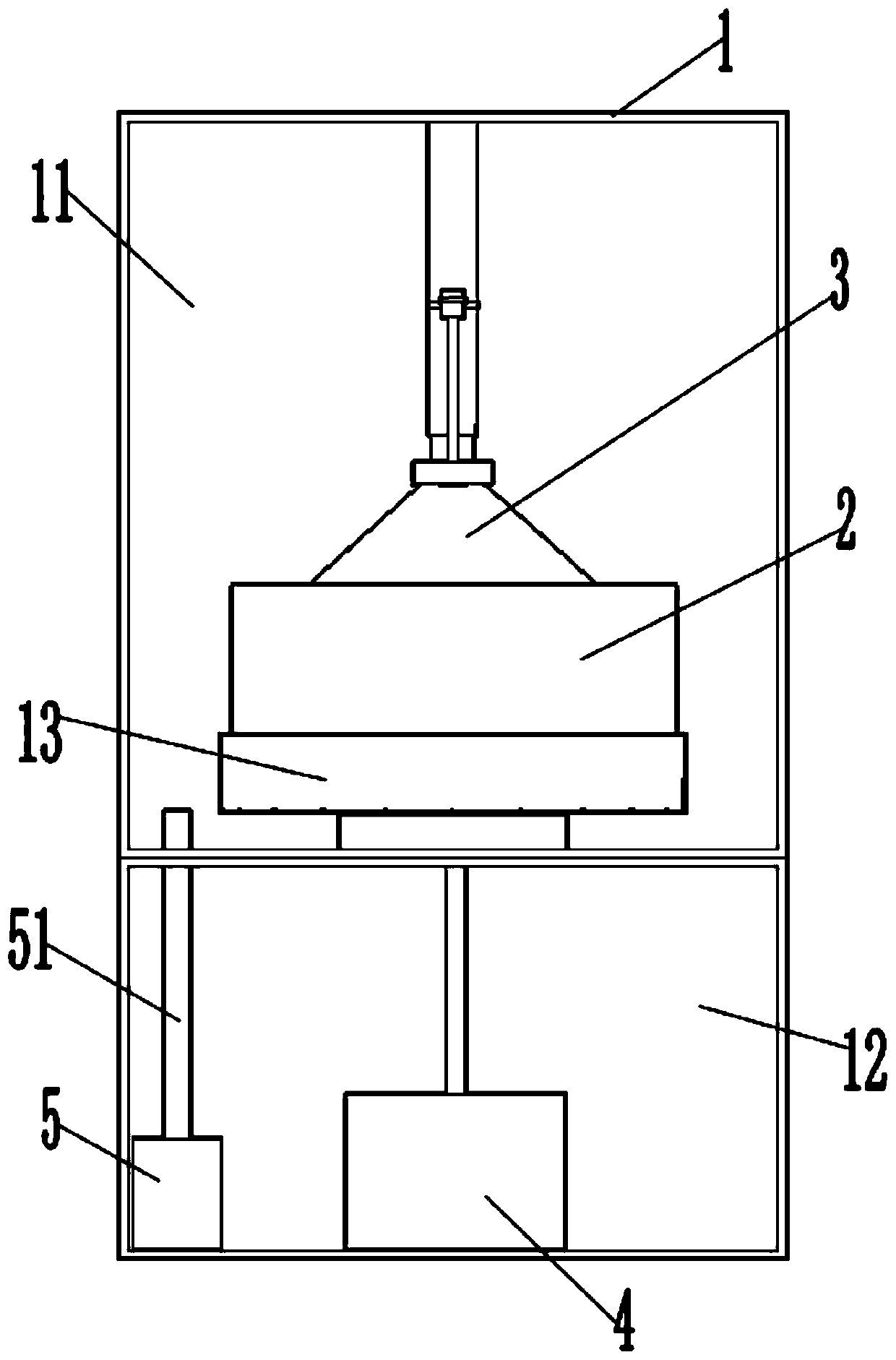

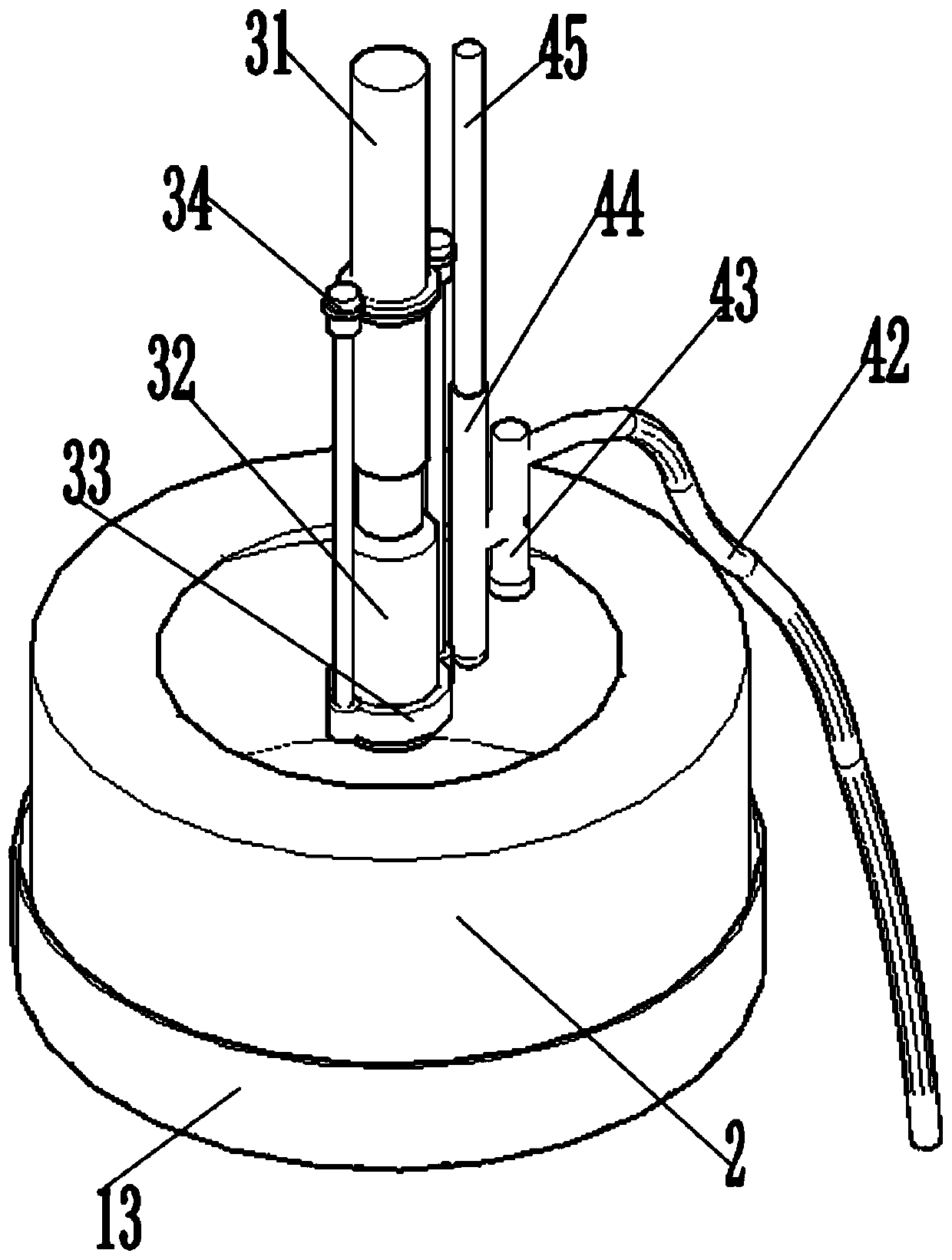

Full-automatic intelligent sample weighing instrument and use method thereof

PendingCN112212953AAvoid cross-contaminationGuaranteed Analytical Test QualityWeighing apparatus for materials with special property/formControl engineeringProcess engineering

The invention relates to the technical field of sample inspection and detection equipment, in particular to a full-automatic intelligent sample weighing instrument and a use method thereof, the full-automatic intelligent sample weighing instrument comprises: a sampling part for grabbing a sample storage tank containing a sample and putting the sample storage tank into a sample vibration part; a sample vibrating part which is used for fixing the sample storage tank conveyed by the sampling part and vibrating the sample storage tank to realize sample discharging; a sample weighing part which ispositioned below the sample vibration part and is used for weighing the sample vibrated by the sample storage tank in real time; and a control part which is connected with the sampling part, the sample vibration part and the sample weighing part, wherein the sample vibration part comprises a supporting stand column and a vibration platform which is used for fixing the sample storage tank and can ascend and descend along the supporting stand column, wherein the vibration platform is provided with a sample storage tank sleeving hole for installing the sample storage tank, an electric clamping mechanism for fixing the sample storage tank and a vibrator, the instrument is operated by virtue of two robots through a controller, manual operation is replaced, continuous production is realized, theproduction efficiency is improved, the production cost is reduced, and sample weighing weight data is automatically and instantly stored; and therefore, recording data accuracy is ensured.

Owner:SHANDONG INST OF GEOPHYSICAL & GEOCHEM EXPLORATION

Assembly line type magnetic product magnetizing system and magnetizing method thereof

ActiveCN107978417AUniform magnetization saturationImprove securityMagnetic bodiesMagnetizationEngineering

The invention discloses an assembly line type magnetic product magnetizing system, comprising a magnetizer and a solenoid magnetization coil, wherein the magnetizer is connected with the solenoid magnetization coil, and the front end of the solenoid magnetization coil is provided with a front opening that internally communicates with the solenoid magnetization coil; the assembly line type magneticproduct magnetizing system further comprises a worktable, an annular conveyor belt arranged on the worktable, a driver for driving the annular conveyor belt to rotate, six material boxes uniformly distributed on the annular conveyor belt at intervals, an optical fiber sensor, a controller, a feeding control input panel, a discharging control input panel and a clamping mechanism, wherein the controller is respectively connected with the magnetizer, the optical fiber sensor, the feeding control input panel and the discharging control input panel. The scheme of the invention has the advantages of high magnetization efficiency and saturated and uniform magnetization.

Owner:NINGBO YUNSHENG +2

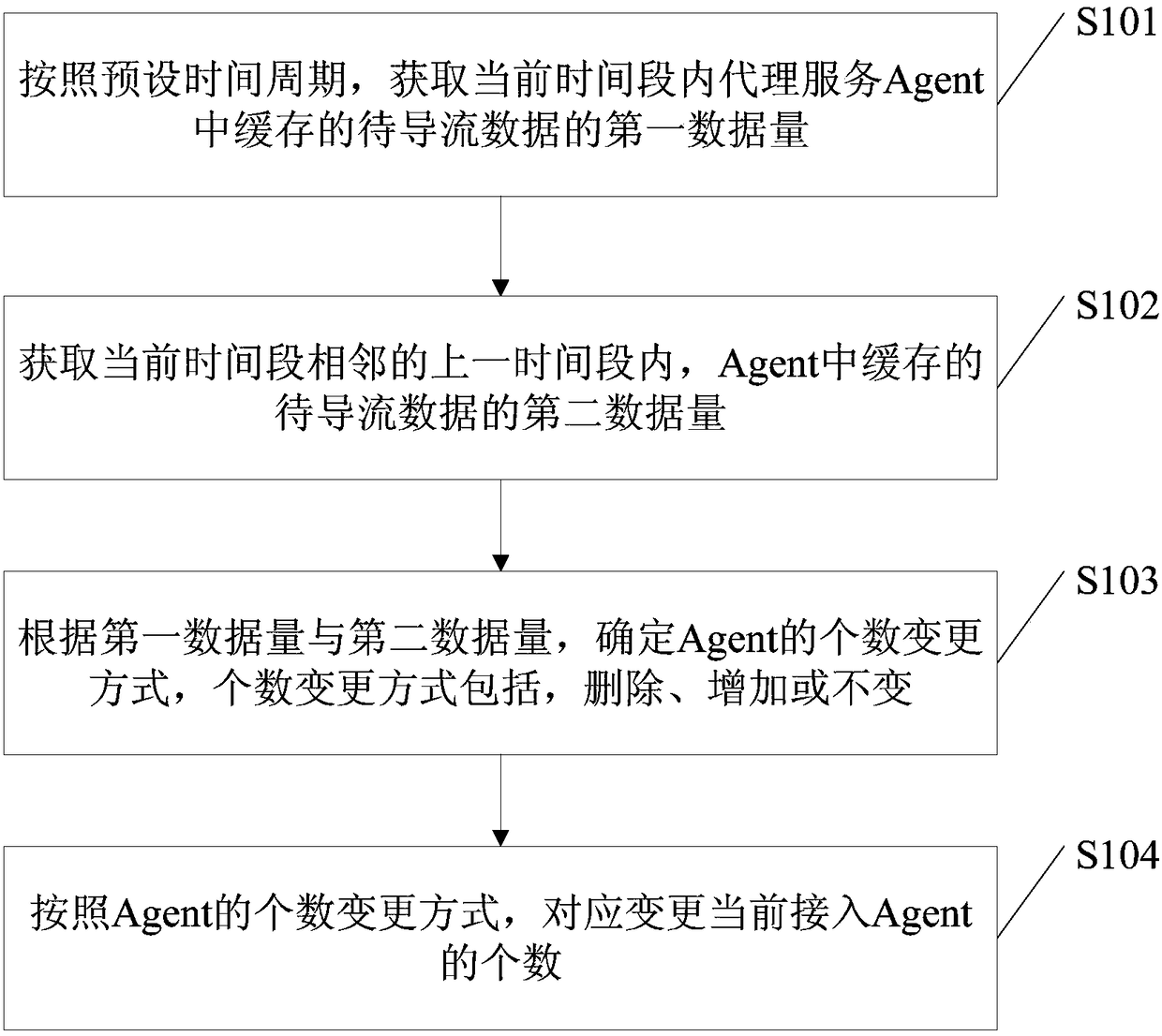

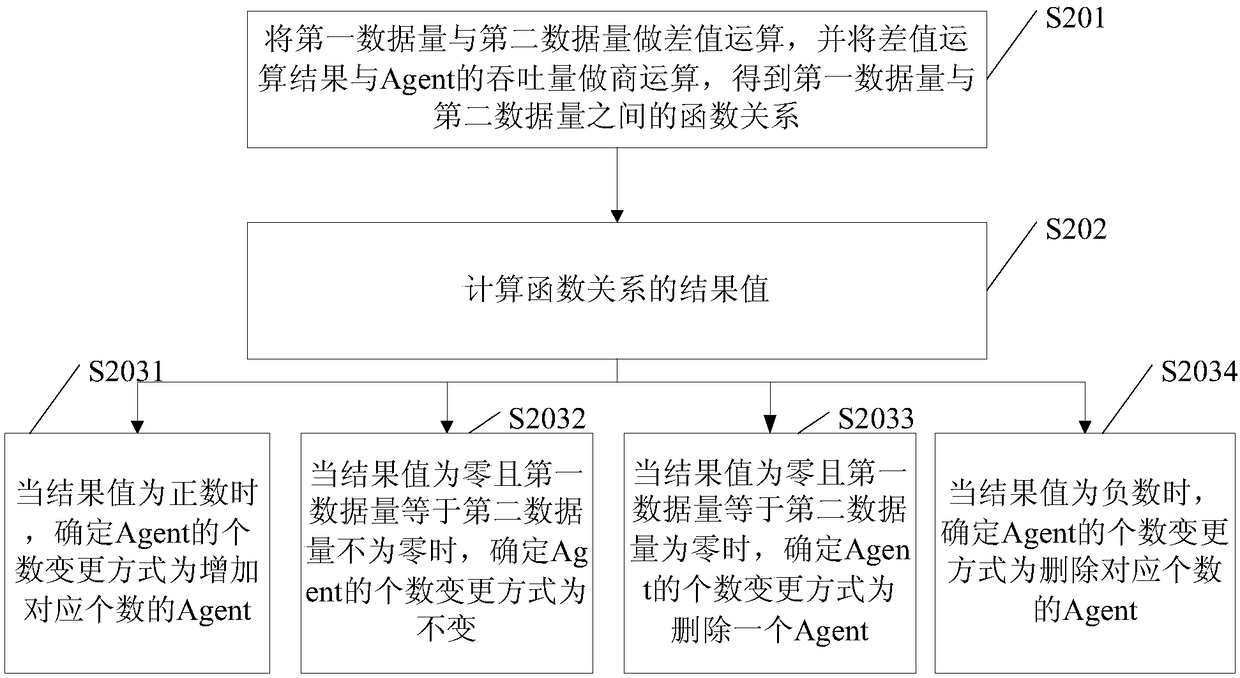

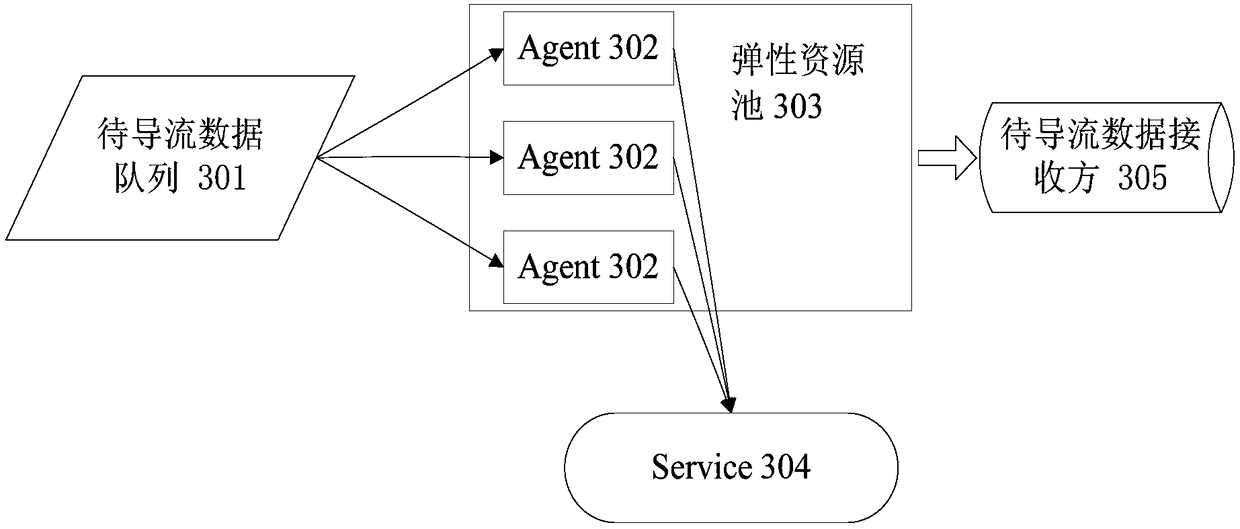

Data processing method and apparatus, and electronic device

ActiveCN108121507AReduce wasteAvoid wastingInput/output to record carriersProxy serviceReal-time computing

The embodiment of the invention provides a data processing method and apparatus, and an electronic device, wherein the data processing method includes: acquiring, according to a preset time period, first a first data volume of to-be-diverted data buffered in a proxy service agent in a current time period; obtaining a second data volume of the to-be-diverted data cached in the agent in the previoustime period adjacent to the current time period; determining, according to the first data volume and the second data volume, methods of changing the number of agents, wherein the methods include deletion, addition or invariance; and according to the number of changes of the number of the agents, changing the number of currently accessed agents correspondingly. According to the data processing method and apparatus, the agents are reasonably used to perform data diversion, and resource waste is reduced.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

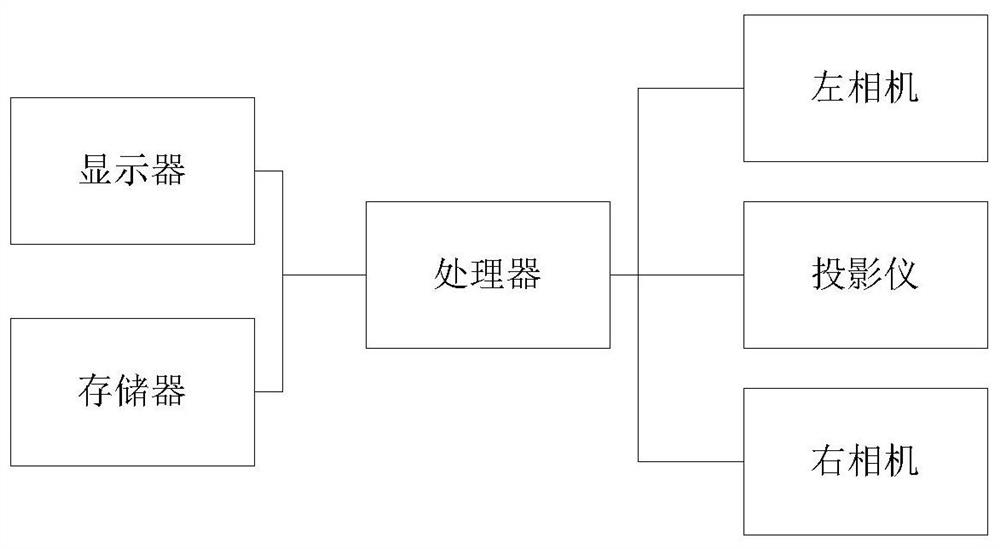

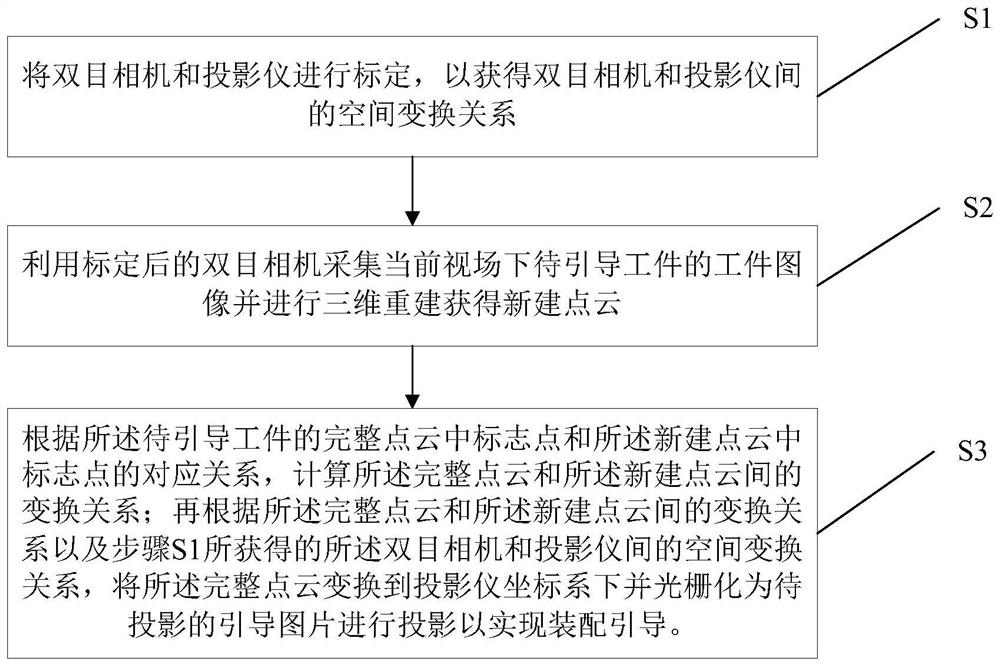

Assembly guiding method and system

PendingCN112785685AImprove accuracy and efficiencyReduce damage ratePicture reproducers using projection devicesAdvertisingEngineeringComputer graphics (images)

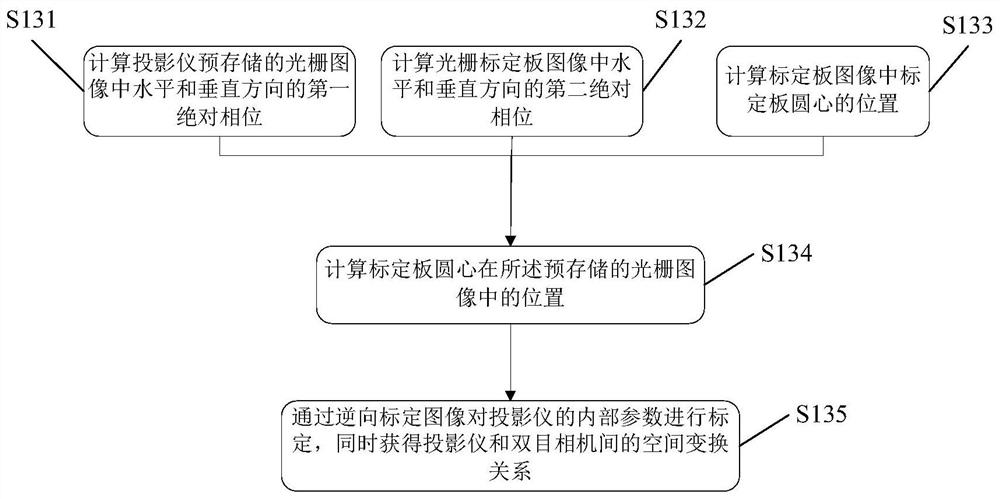

The invention provides an assembly guiding method and system. The method comprises the steps: S1, calibrating a binocular camera and a projector so as to obtain a spatial transformation relation between the binocular camera and the projector; S2, using the calibrated binocular camera to collect a workpiece image of a to-be-guided workpiece in the current field of view, and performing three-dimensional reconstruction to obtain a new point cloud; and S3, calculating a transformation relation between the complete point cloud and the new point cloud according to a corresponding relation between the mark points in the complete point cloud of the to-be-guided workpiece and the mark points in the new point cloud, according to the transformation relationship between the complete point cloud and the new point cloud and the spatial transformation relationship between the binocular camera and the projector obtained in the S1, transforming the complete point cloud to a projector coordinate system, and rasterizing the complete point cloud into a to-be-projected guide picture for projection so as to realize assembly guidance. According to the method and system, real-time scanning reconstruction and guided assembly of the workpiece can be achieved, and the efficiency and precision of the assembly process are improved.

Owner:新拓三维技术(深圳)有限公司

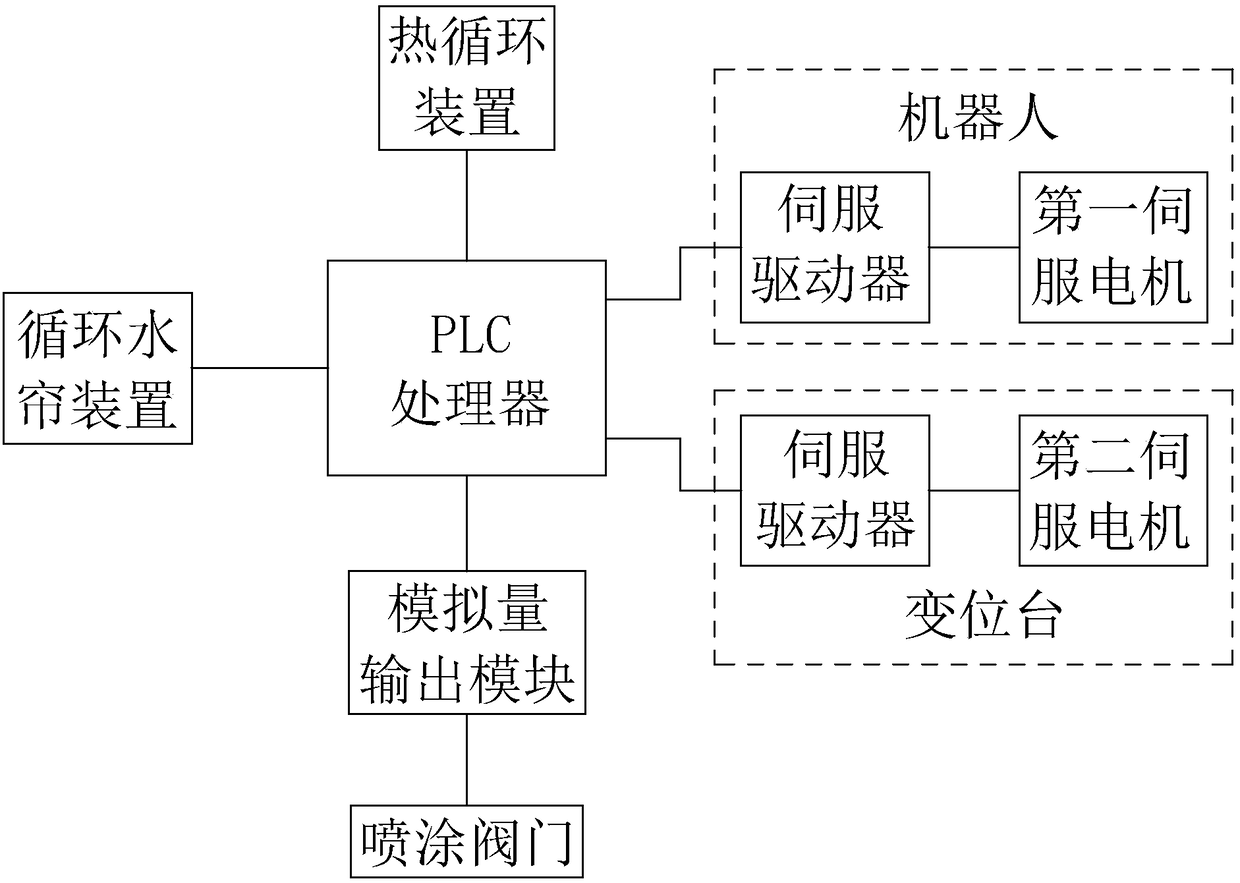

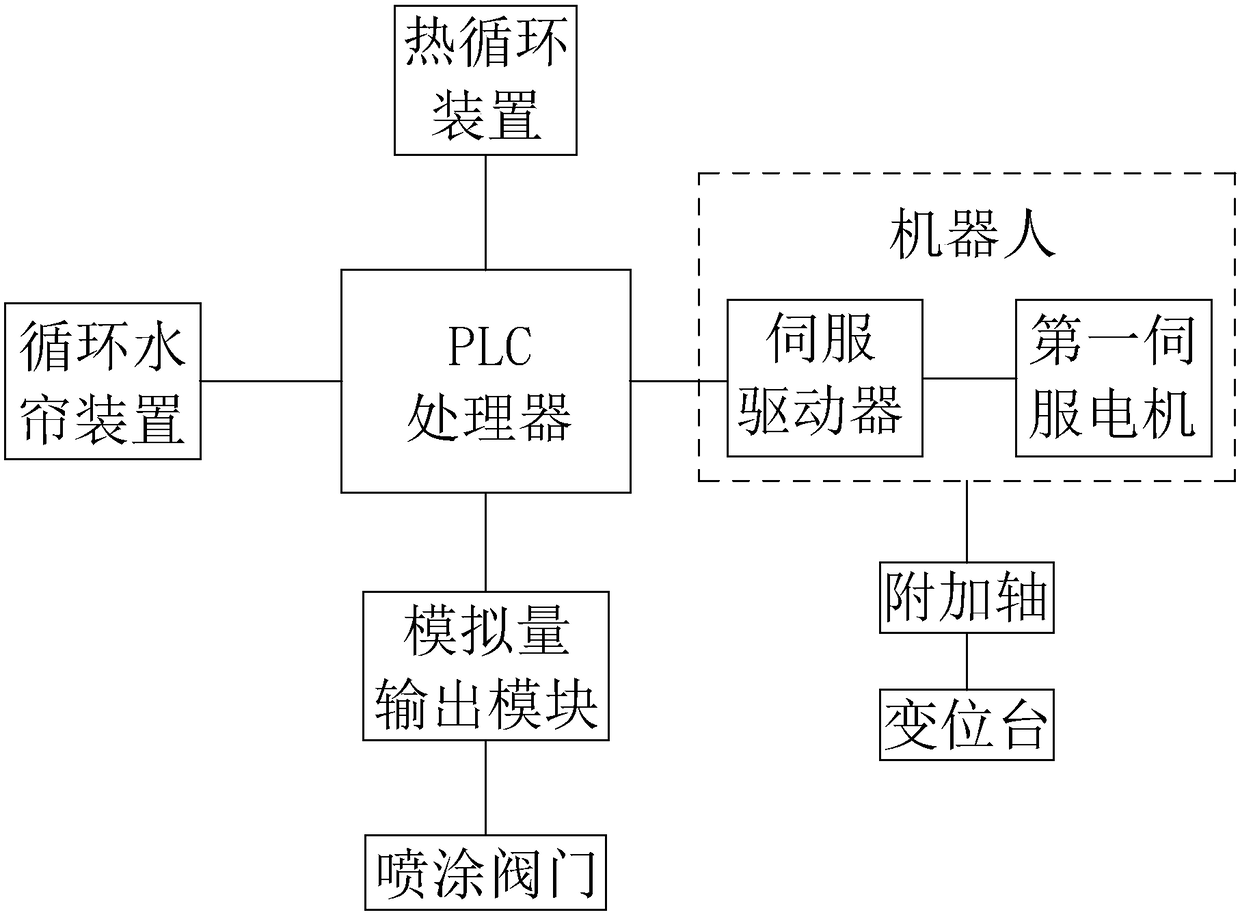

Robot spraying control system

The invention discloses a robot spraying control system which comprises a nozzle, a displacement table, a robot, an analog output module and a processor. A spraying valve is arranged on the nozzle; afirst servo motor for driving the nozzle to move is arranged on the robot; a second servo motor for driving the displacement table to move is arranged on the displacement table; the first servo motorand the second servo motor are each provided with a servo driver; an output end of the processor is connected with the first servo motor and the second servo motor through the servo drivers; and the processor is connected with the spraying valve through the analog output module. According to the robot spraying control system provided by the invention, the first servo motor and the second servo motor are used for controlling the nozzle and the displacement table to move, and the analog output module is used for controlling an opening degree of the spraying valve, so that a product can be automatically, all-dimensionally and accurately sprayed without the need for manpower intervention. The robot spraying control system provided by the invention is used for controlling spraying operation.

Owner:FOSHAN HUASHU ROBOTICS CO LTD

Classification method and device of human body posture

InactiveCN101576953BImplement classificationNo manual interventionCharacter and pattern recognitionHuman bodyClassification methods

The invention discloses a classification method and a device of human body posture. The classification method of human body posture comprises the steps of: determining a human body region in an existing frame image; extracting the human body shape so as to obtain the external outline in the human body, then obtaining the information of the position of human head by human head detection; and then determining that the human body posture is in vertical standing-up status when the head part is right in the middle of the external outline of the human body; and further calculating the aspect ratio of the external outline of the human body when the head part is located at one side of the external outline of the human body, and then determining the types of human body posture according to the aspect ratio of the external outline of the human body, thereby achieving automatic identification and classification to the human body posture, without human intervention, thus making up the detects thatthe prior art does not provide a method for classifying the human body posture.

Owner:VIMICRO CORP

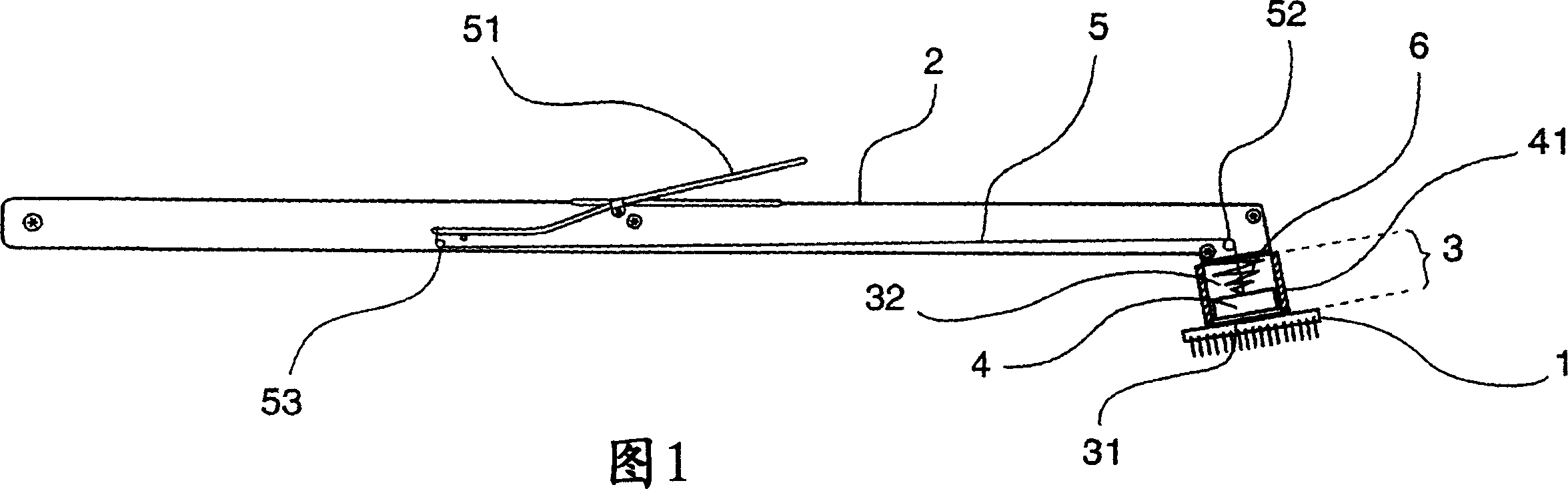

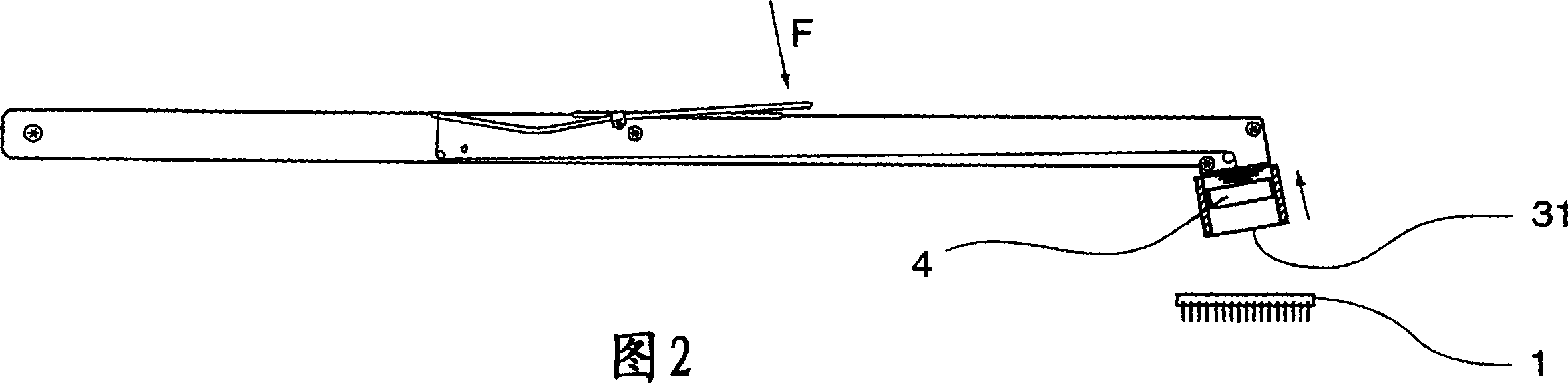

Autonomous device for the magnetic handling of an electronic component

InactiveCN1659947ANo manual interventionElectrical componentsElectronic componentMagnetic interaction

The invention relates to an autonomous device that is used to handle an electronic component (1), comprising a body (2) and a head (3) for picking up said component (1) magnetically. Moreover, the aforementioned pick-up head (3) comprises a permanent magnet (4) and mechanical separation means which can move in relation to one another such that the device can occupy at least two positions, namely: a pick-up position, in which the magnet (4) interacts with the component (1) so as to keep said component in contact with a contact surface of the head (3); and a release position, in which the magnet (4) is moved away from the component (1) such as to stop the magnetic interaction.

Owner:WAVECOM SA

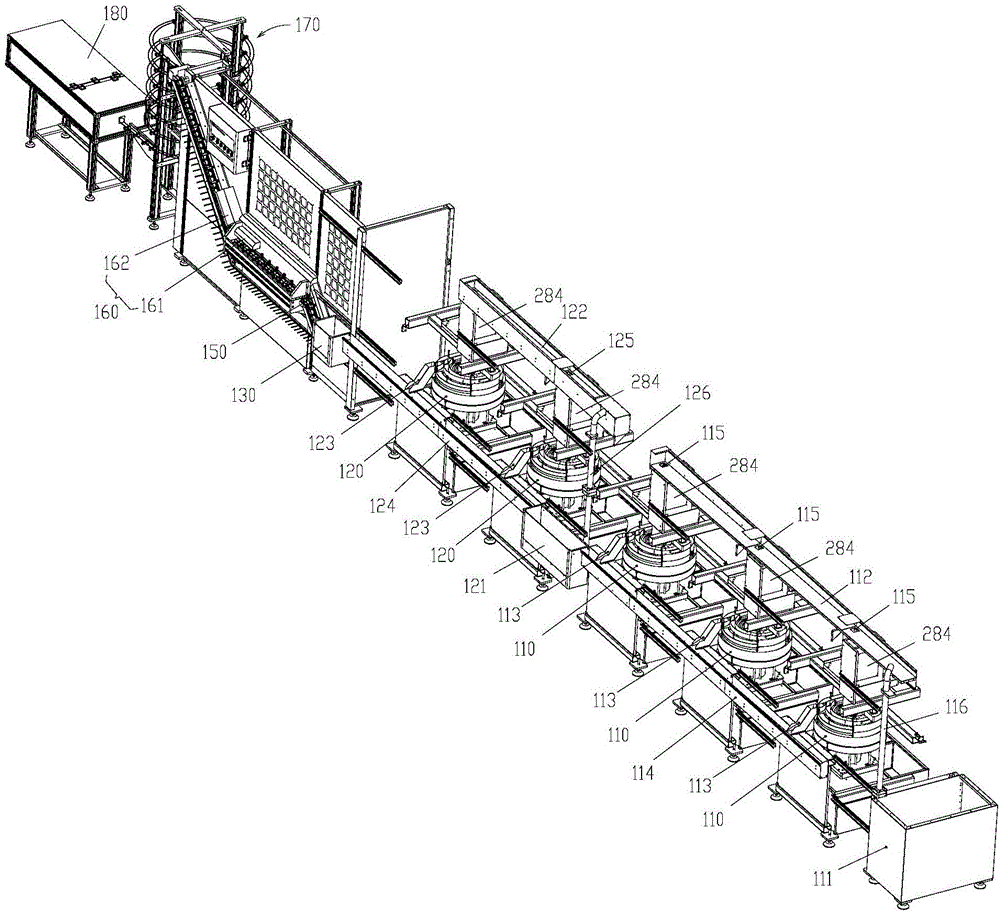

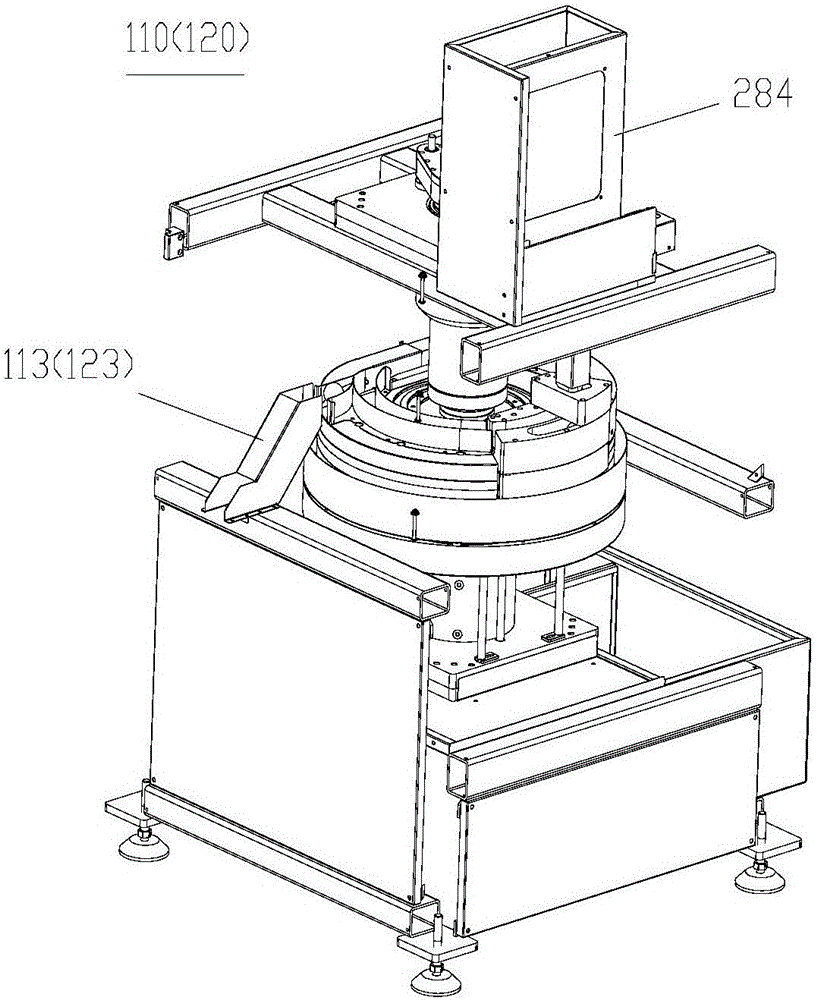

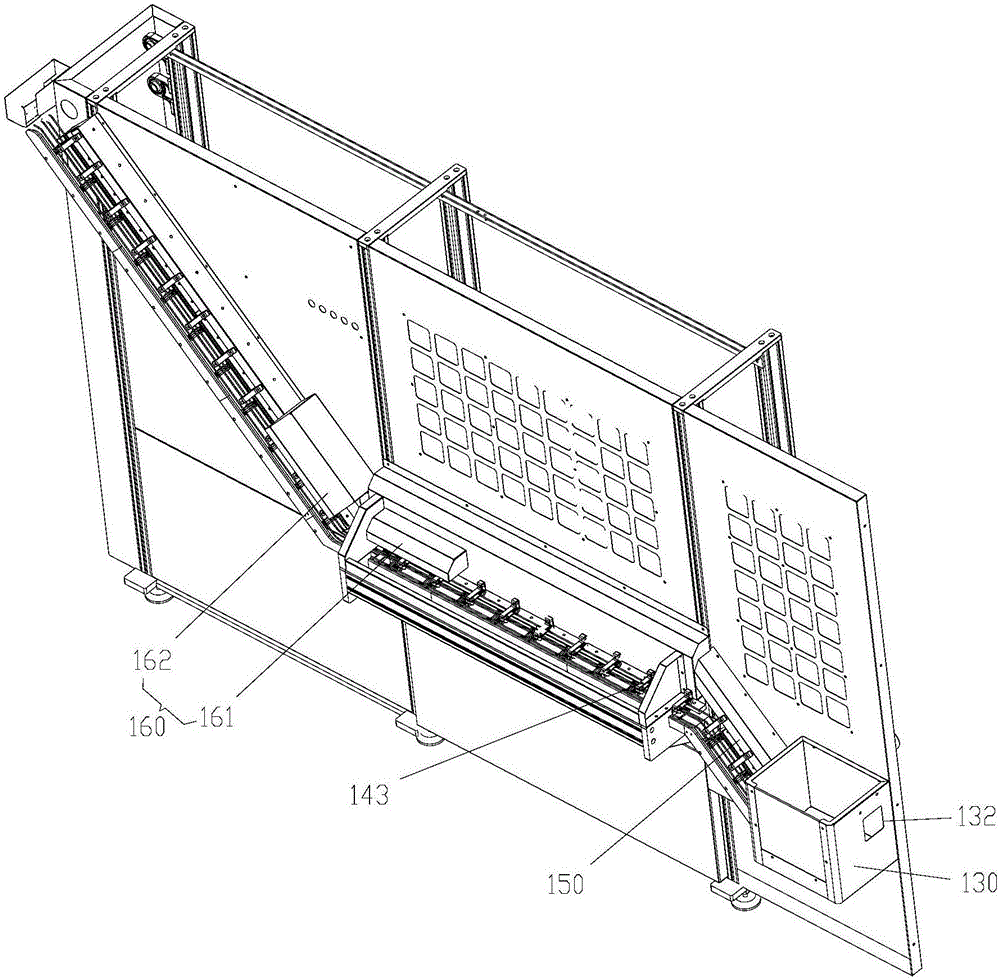

Full-automatic table tennis ball grinding, shaping, classifying and sieving equipment

ActiveCN106823310ANo skill levelLower skill levelHollow non-inflatable ballsCleaning using liquidsEngineeringSmall footprint

The invention relates to full-automatic table tennis ball grinding, shaping, classifying and sieving equipment. The full-automatic table tennis ball grinding, shaping, classifying and sieving equipment comprises an initial grinding ball accumulation box (111), m initial grinding machines (110), a fine grinding ball accumulation box (121), n fine grinding machines (120), a water washing ball accumulation box (130), a conveying chain (140), a flushing machine (150), a dehydration dryer (160), a slide rail frame (170) and a measuring sieving machine (180), wherein the initial grinding ball accumulation box (111) can be used for pumping table tennis balls into the m initial grinding machines (110) through cooperation of a vacuum pump and an initial grinding conveying inclined pipe; the fine grinding ball accumulation box can be used for pumping table tennis balls into the n fine grinding machines through cooperation of a vacuum pump and a fine grinding conveying inclined pipe. By adopting the equipment, initial grinding, fine grinding, flushing, drying and sieving are performed instead of a manual process, the stability of product quality is ensured, and simple and labor-saving procedures are adopted; through cooperation of the conveying chain, the initial grinding conveying inclined pipe, the fine grinding conveying inclined pipe, a discharge pipe and the like, the production efficiency is increased greatly; the equipment is simple in structure, and small in floor area.

Owner:李桂兰

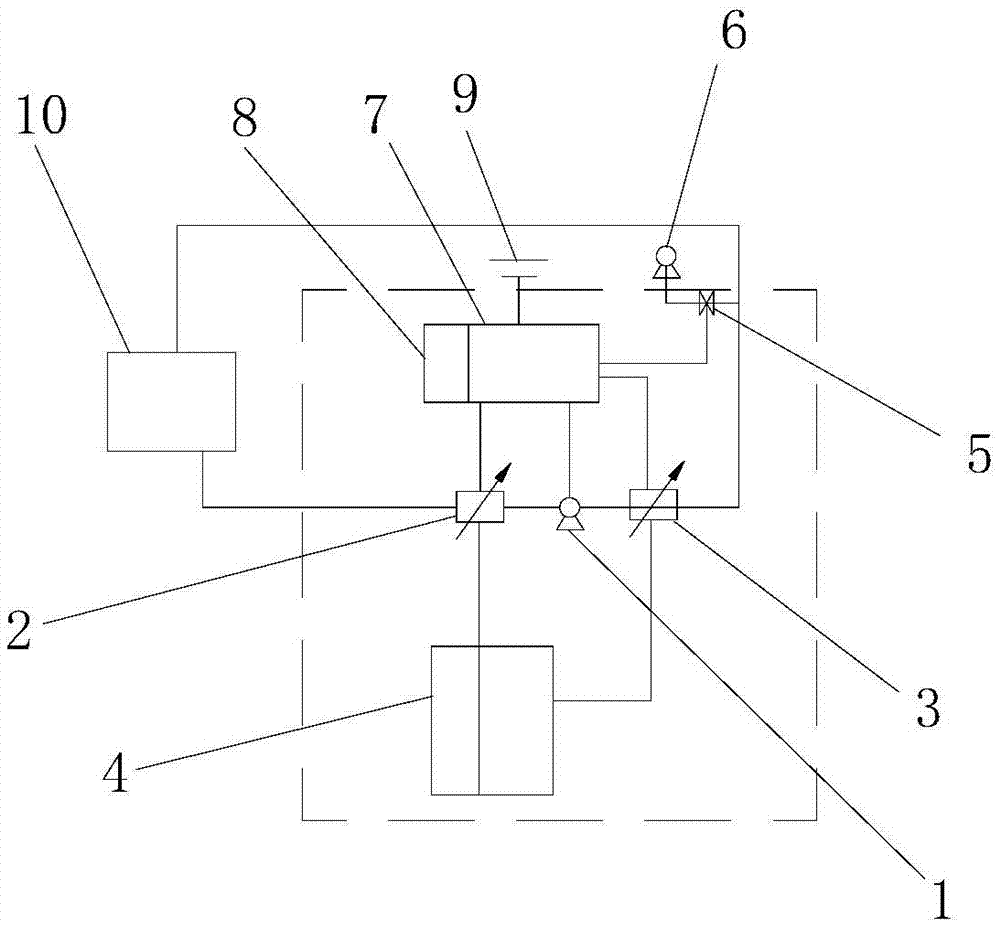

Intelligent lubricating oil way cleaning system and working method thereof

PendingCN107199220AEfficient and thorough cleaningClean up thoroughlyHollow article cleaningSolenoid valveOil intake

The invention relates to an intelligent lubricating oil way cleaning system and a working method thereof. The intelligent lubricating oil way cleaning system comprises a circulating tank, an oil pump, a first three-way solenoid valve and a second three-way solenoid valve; a first port of the first three-way solenoid valve is in sealed connection with an oil outlet of an oil tank through an oil pipe; a second port of the first three-way solenoid valve is in sealed connection with the circulating tank through an oil pipe; a third port of the first three-way solenoid valve is in sealed connection with an oil inlet of the oil pump through an oil pipe; an oil outlet of the oil pump is in sealed connection with a first port of the second three-way solenoid valve through an oil pipe; a second port of the second three-way solenoid valve is in sealed connection with an oil inlet of the oil tank through an oil pipe; and a third port of the second three-way solenoid valve is in sealed connection with the circulating tank through an oil pipe. The intelligent lubricating oil way cleaning system further comprises a control circuit; output ends of the control circuit are electrically connected with the first three-way solenoid valve, the oil pump and the second three-way solenoid valve; and the control circuit is used for controlling the first three-way solenoid valve, the oil pump and the second three-way solenoid valve to be opened and closed.

Owner:CHANGZHOU ZHONGJIE NEW MATERIAL TECH CO LTD

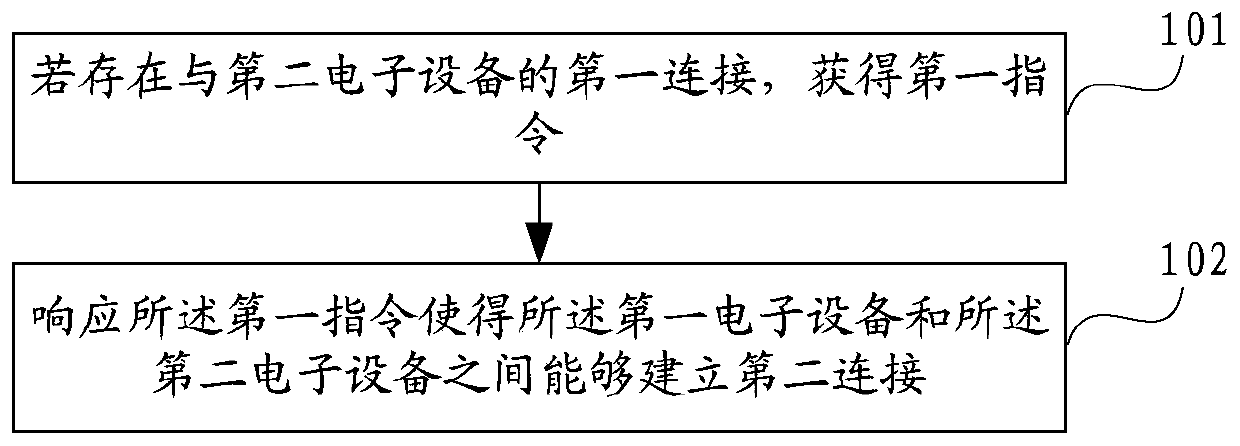

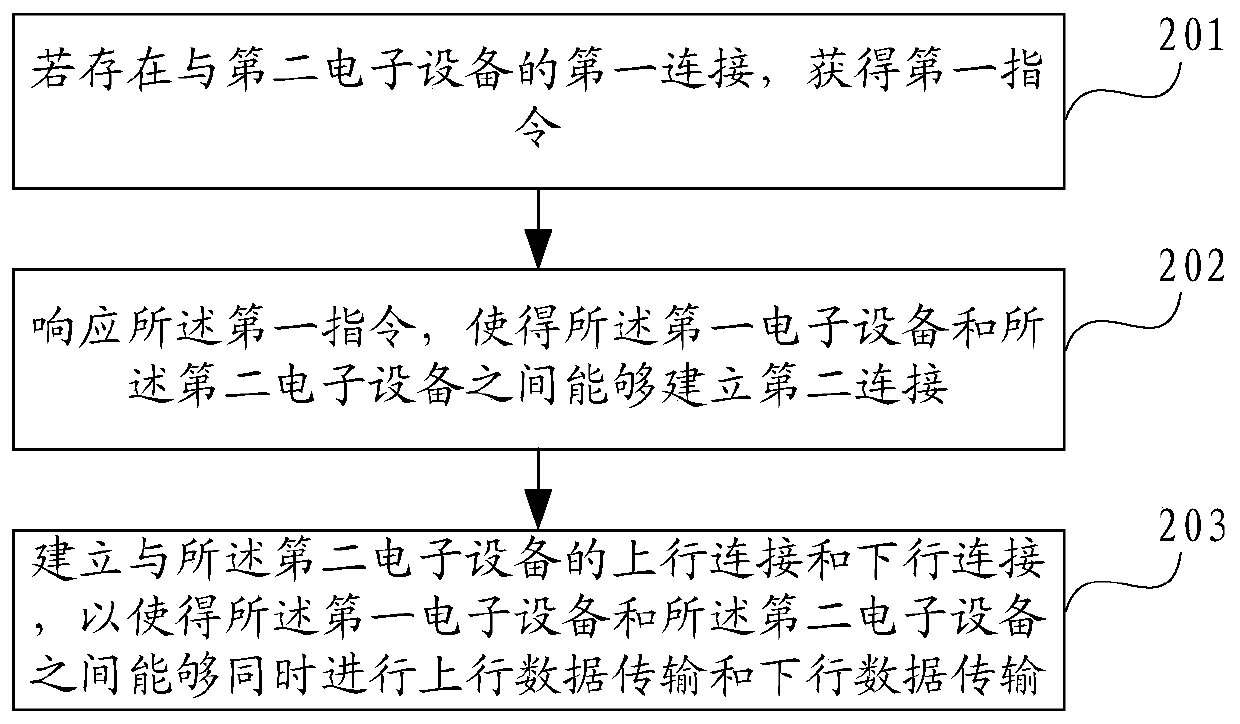

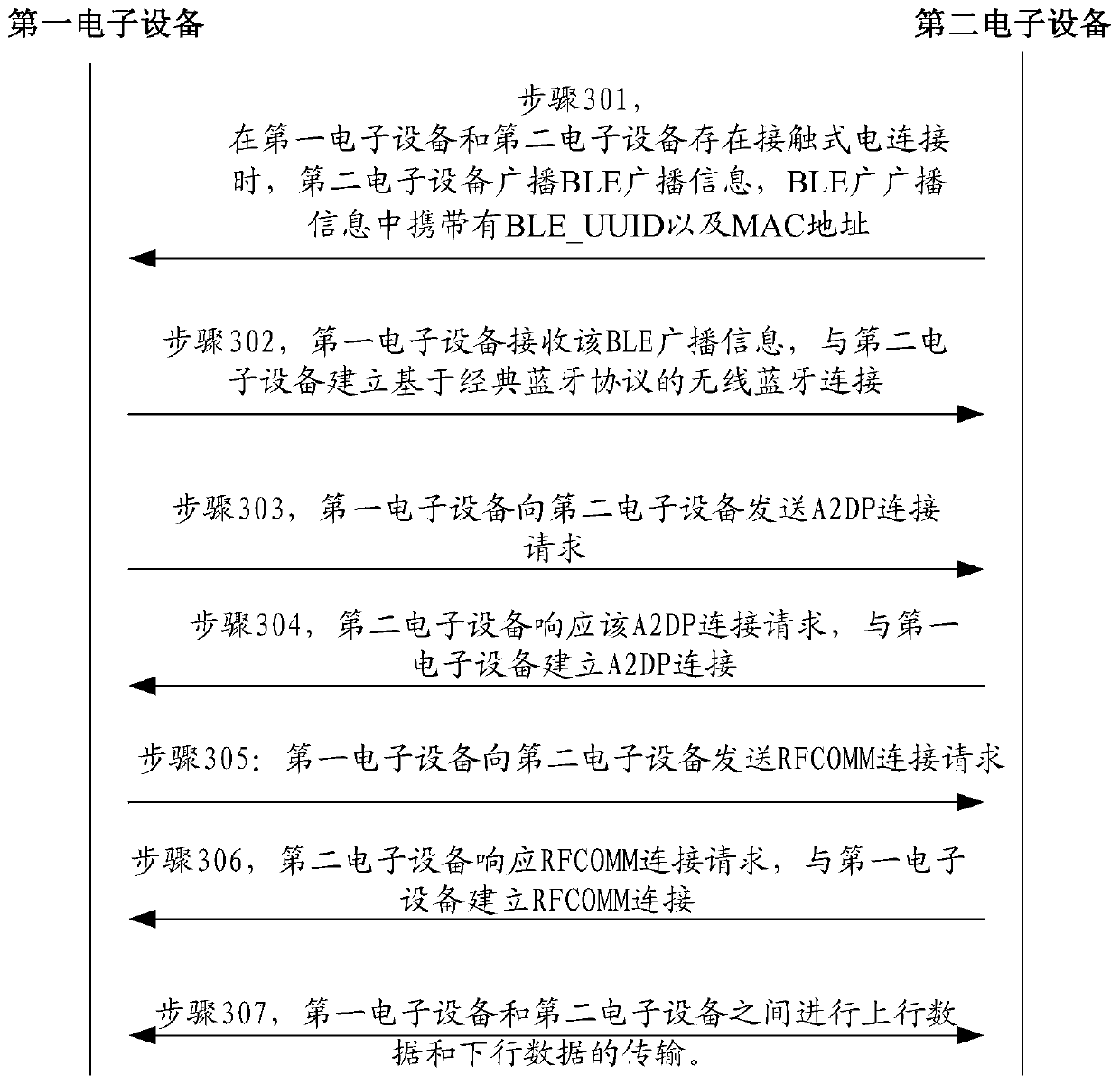

Processing method and system and electronic equipment

ActiveCN109743715ANo manual interventionImprove experienceNear-field transmissionAssess restrictionElectricityContact type

The invention provides a processing method and system and electronic equipment, and the method is applied to first electronic equipment, and comprises the steps: obtaining a first instruction if firstconnection with second electronic equipment exists; Responding to the first instruction, so that second connection can be established between the first electronic equipment and the second electronicequipment; Wherein after the second connection is established, the first electronic equipment and the second electronic equipment can simultaneously maintain the connection state of the first connection and the second connection; The first connection is contact type electric connection, and the second connection is non-contact type connection; Therefore, the first electronic device and the secondelectronic device can have the first connection and the second connection at the same time, the diversity of the connection is achieved, manual intervention of a user is not needed, and the user experience is improved.

Owner:LENOVO (BEIJING) LTD

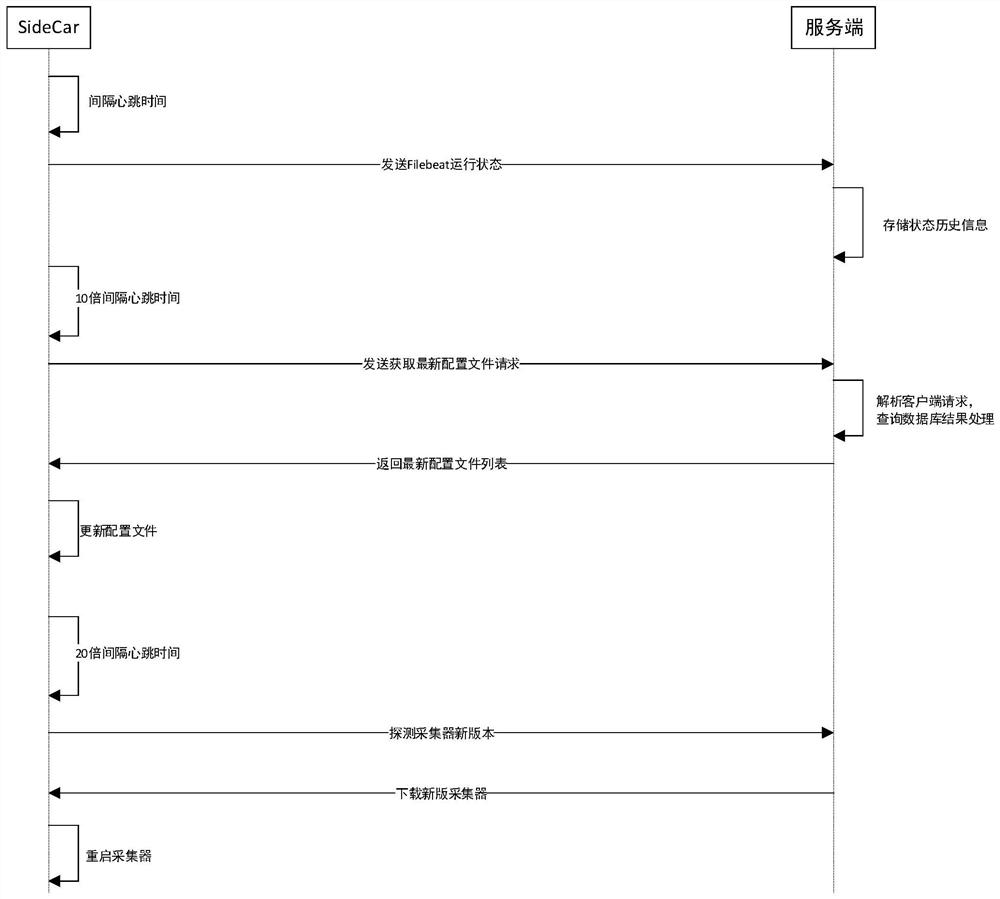

Cloud platform full-automatic management log collection method and terminal

The invention provides a full-automatic management log collection method for a cloud platform. The method comprises the following steps of judging whether Filebeat is started or not, reading a SideCar configuration file, updating log collection configuration according to heartbeat interval time during operation, adding a configuration file to be newly added to a file beat configuration file directory, and closing a module. According to the cloud platform full-automatic management log collection method and the terminal, the collection configuration is automatically pulled from the server side, the latest configuration file is dynamically loaded, and restarting is not needed in the period. Meanwhile, the log collection terminal sends the operation state to the server side, and whether the log collection terminal operates normally or not can be found in a state monitoring mode. The new version of the terminal is automatically detected and collected, and is automatically downloaded, updated and restarted, and the process does not need manual intervention of a user.

Owner:SHANDONG LANGCHAO YUNTOU INFORMATION TECH CO LTD

Automatic bearing turn-over transportation production line

ActiveCN111776688AGood efficiencyNo manual interventionConveyorsControl devices for conveyorsManufacturing lineManufacturing engineering

The invention discloses an automatic bearing turn-over transportation production line. The automatic bearing turn-over transportation production line structurally comprises a main line; a forward bearing and a reverse bearing are placed on the main line, the main line is further connected with a first branch line and a second branch line in a communicating mode, a detection device is further arranged between the first branch line and the main line, and the detection device is used for detecting and classifying the forward bearing and the reverse bearing and used for conveying the forward bearing to first branch line and conveying the reverse bearing to the second branch line; a turnover device is further arranged on the second branch line and turns over the reverse bearing into the forwardbearing, the other side of the turnover device is connected with a third branch line, and the turned-over forward bearing is conveyed into the third branch line and then conveyed into the first branch line. The bearings on the front side and the back face can be automatically detected and classified through the detection device and conveyed to different conveying belts, the turnover device can turn over the bearings on the reverse side into the front side, manual intervention is not needed, and efficiency is high.

Owner:临清市汇金轴承有限公司

A quick slicing device for industrial tobacco

ActiveCN106737926BSlicing is fastOperational securityMetal working apparatusEngineeringSafe operation

The invention relates to a slicing device, and in particular relates to an industrial fast cavendish slicing device. The invention aims at providing the industrial fast cavendish slicing device with high slicing speed. The industrial fast cavendish slicing device provided by the invention comprises a bottom plate, a collecting tank, a slide block, a cutting plate, a slide rail, a cutter, a lifting rod, a left bracket, a support rod, a first spring, a fixed stopper, a contact wheel, a guide plate and the like, wherein the left bracket, the slide rail and a right bracket are sequentially arranged at the top of the bottom plate from the left to the right, and the slide block is arranged on the slide rail; the top of the slide block is connected with the cutting plate, and the left end of the cutting plate is connected with a second spring; the left end of the second spring is connected with the right side of the left bracket. The industrial fast cavendish slicing device provided by the invention has the advantages of high slicing speed, safe operation and simple operation.

Owner:徐州宝美工程机械有限公司

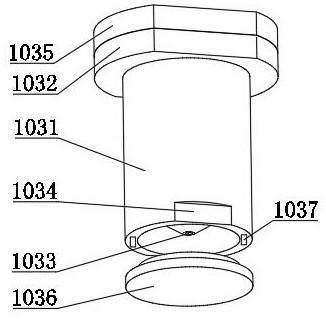

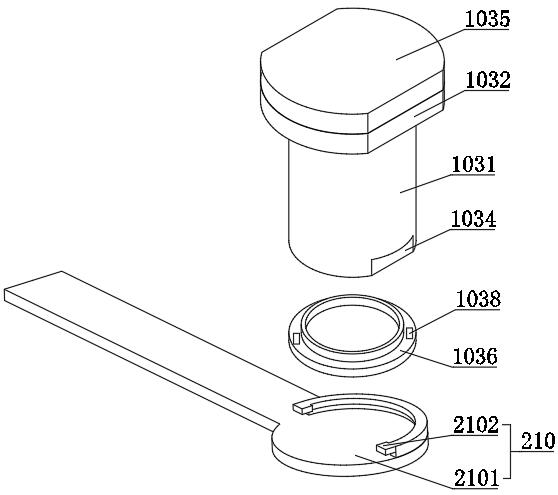

Vacuum biological sample storage device and biological sample storage method

ActiveCN110063328ANo splash pollutionNo manual interventionDead animal preservationMedical equipmentEngineering

The invention relates to the technical field of medical equipment, in particular to a vacuum biological sample storage device and a biological sample storage method. The vacuum biological sample storage device comprises a storage box, a containing box, a sealing device, an infusion device and a vacuumizing pump. The storage box comprises an upper layer storage space and a lower layer storage space, and an electronic scale is arranged inside the upper layer storage space; the containing box is arranged on a tray of the electronic scale; the sealing device is arranged above the containing box; the infusion device comprises an infusion pump, a communicating pipe, an infusion tube, a movable rod and a second fixing rod; the vacuumizing pump is arranged inside the lower layer storage space. Theproblem that when a traditional medical worker manually processes a sample, the risk that formaldehyde or other stimulus substance steam is absorbed is caused is solved.

Owner:未来模式(苏州)生物科技有限公司

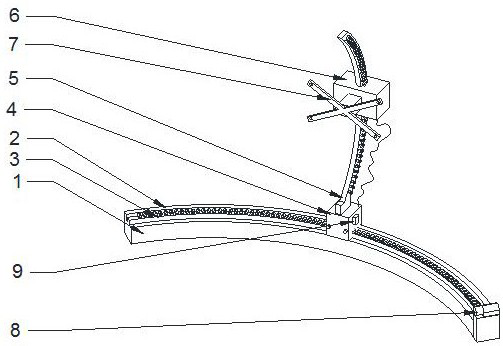

Inductive display screen motion induction support

The invention relates to an inductive display screen motion induction support. The support comprises an arc-shaped horizontal track base, an arc-shaped toothed belt track, a horizontal auxiliary track of a horizontal moving machine, a horizontal moving machine of the display screen motion induction support, a vertical arc-shaped track of the display screen motion induction support, a display screen vertical moving machine, a display screen backboard fixing frame, a motion induction camera and an equipment power switch, wherein the arc-shaped toothed belt track and the horizontal auxiliary track of the horizontal moving machine are arranged at the upper part of the arc-shaped horizontal track base; and two grooves are formed in the lower part of the horizontal moving machine of the display screen motion induction support and movably connected with the arc-shaped toothed belt track and the horizontal auxiliary track of the horizontal moving machine separately. After the condition that a person starts to use the inductive display screen motion induction support is induced, the horizontal and vertical positions of the display screen are automatically and continuously adjusted, and passive movement of the head and eyes of an audience is induced, so that fatigue of cervical vertebra and eyes caused by watching the screen in a fixed posture for a long time is reduced or avoided.

Owner:张晓萍

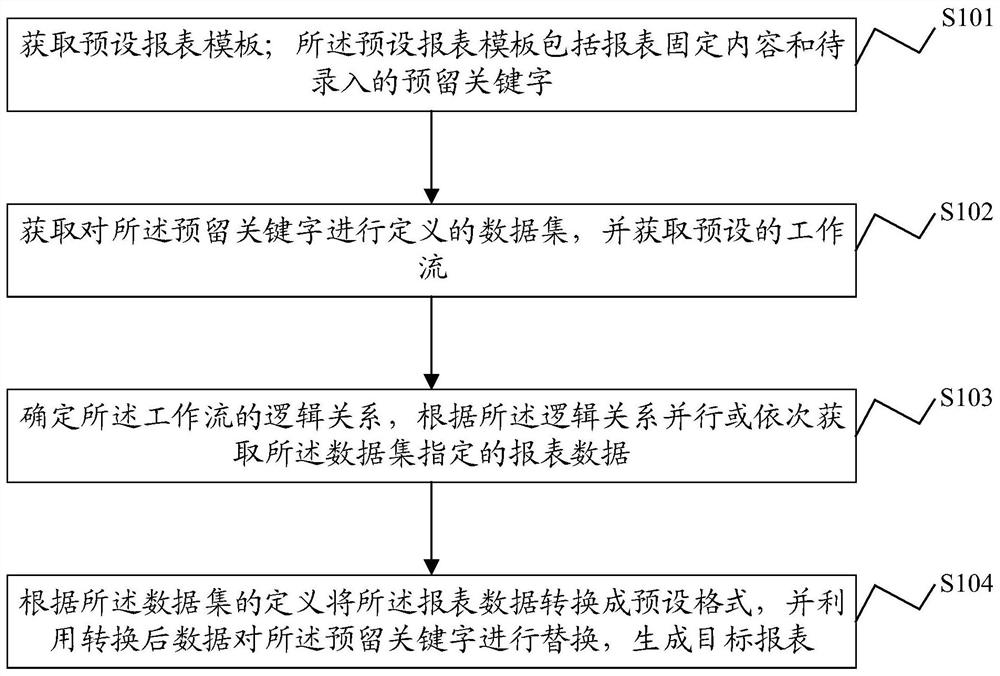

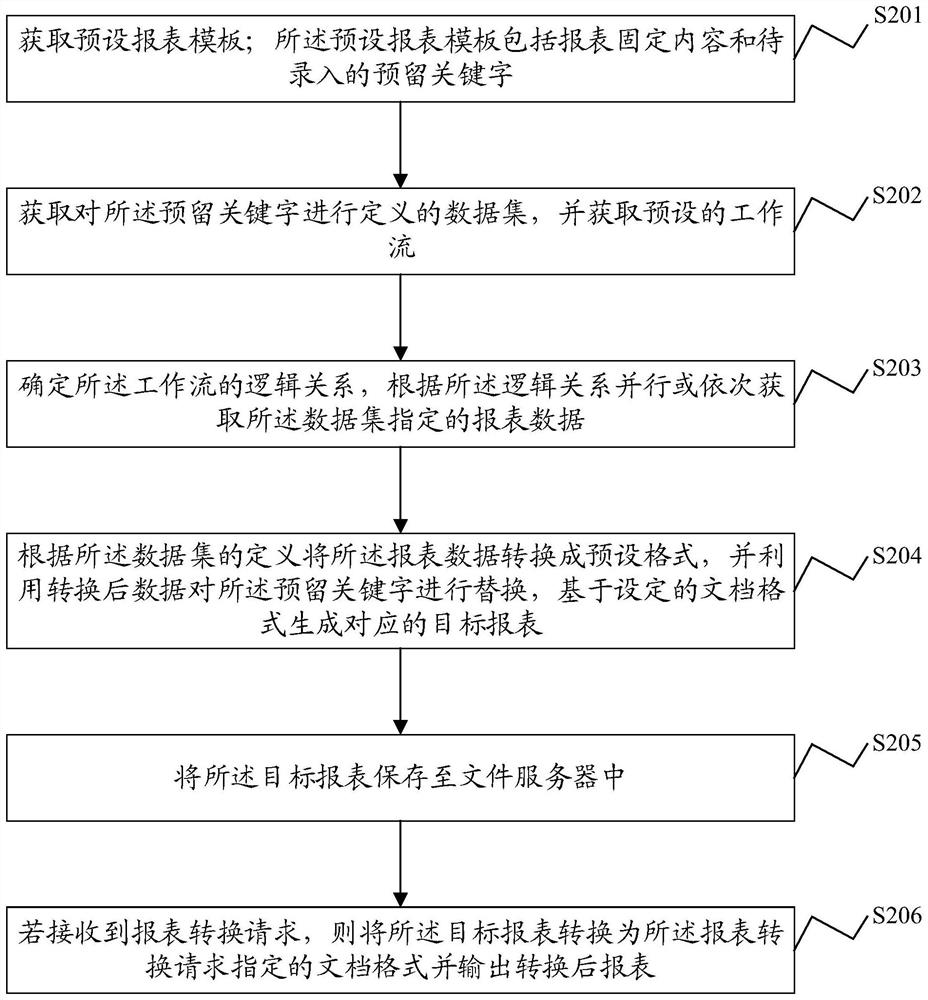

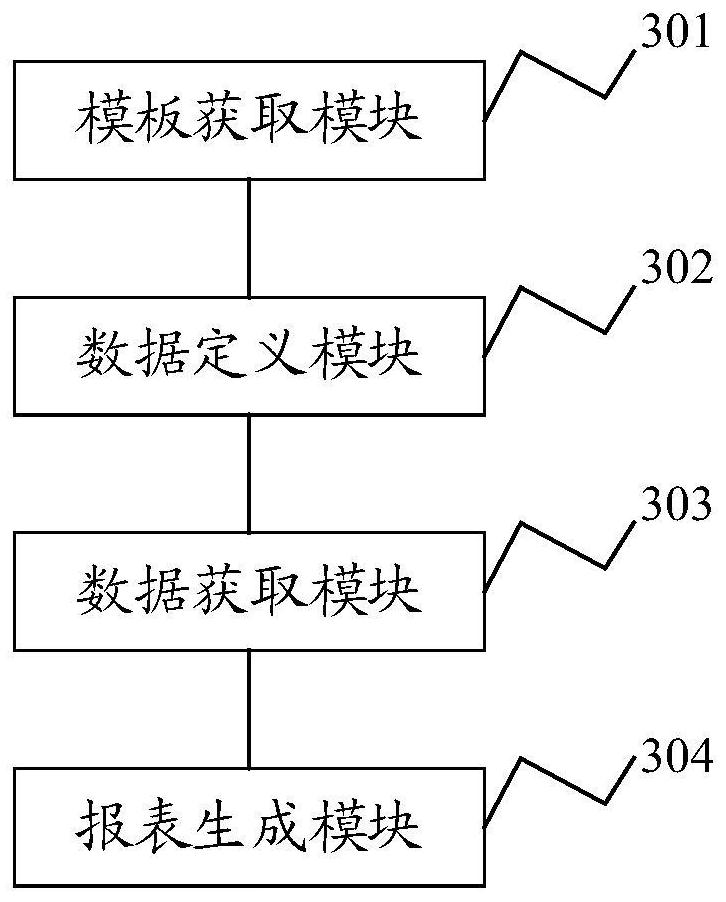

A workflow-based report generation method, system, device and storage medium

ActiveCN110807002BGenerate efficientlyGuaranteed accuracyNatural language data processingFile system administrationData setData transformation

The present application discloses a workflow-based report generation method and system, an electronic device and a computer-readable storage medium. The method includes: acquiring a preset report template including fixed content of the report and reserved keywords to be entered; Obtain the data set that defines the reserved keywords, and obtain the preset workflow; obtain the report data specified by the data set in parallel or sequentially according to the logical relationship of the workflow; convert the report data into a preset format according to the definition of the data set, And use the converted data to replace the reserved keywords to generate the target report. As can be seen from the above, the present application can automatically generate reports based on preset report templates and data sets, and can sequentially or concurrently obtain report data specified by the data sets based on the logic of the workflow, which improves data acquisition efficiency while ensuring data accuracy. , so as to achieve efficient report generation, and the report generation process does not require user manual intervention, which improves user experience.

Owner:HANGZHOU ANHENG INFORMATION TECH CO LTD

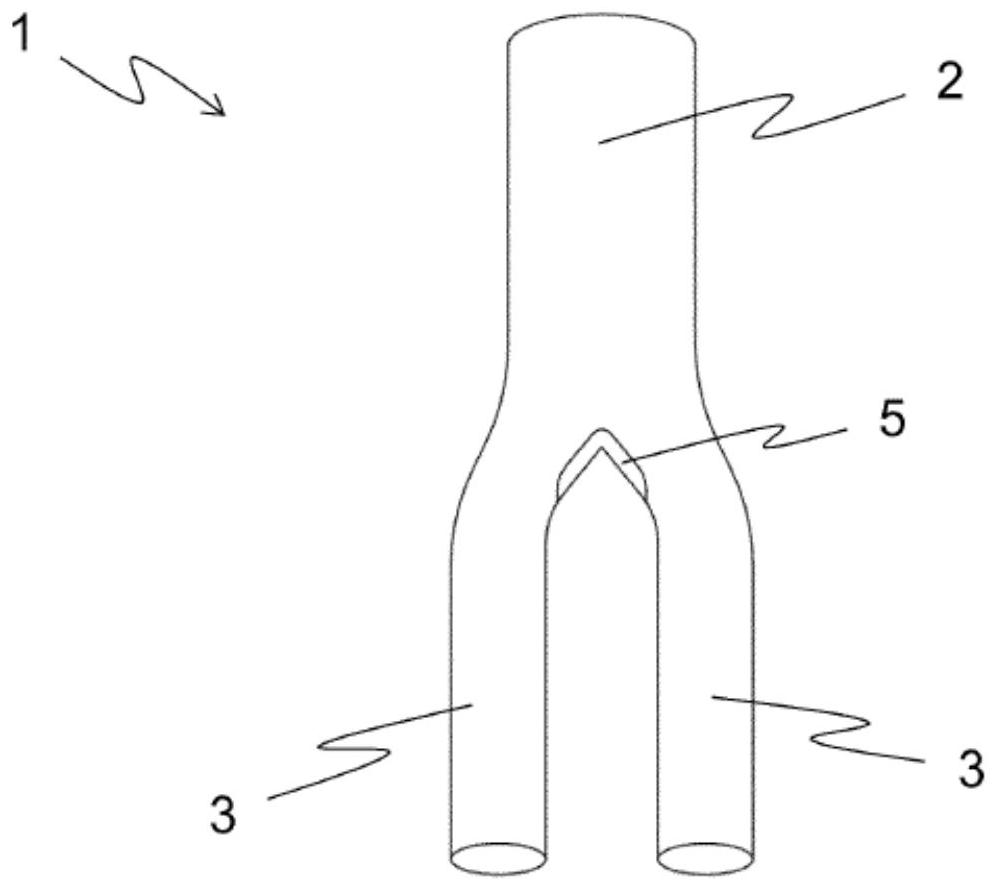

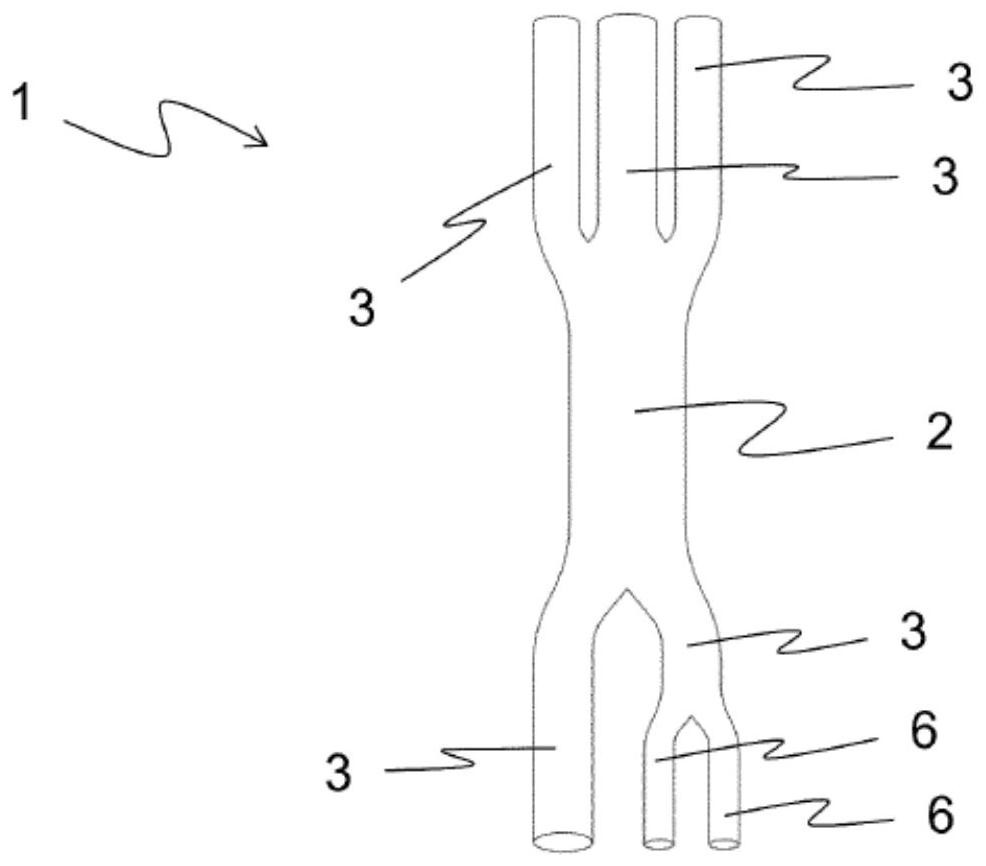

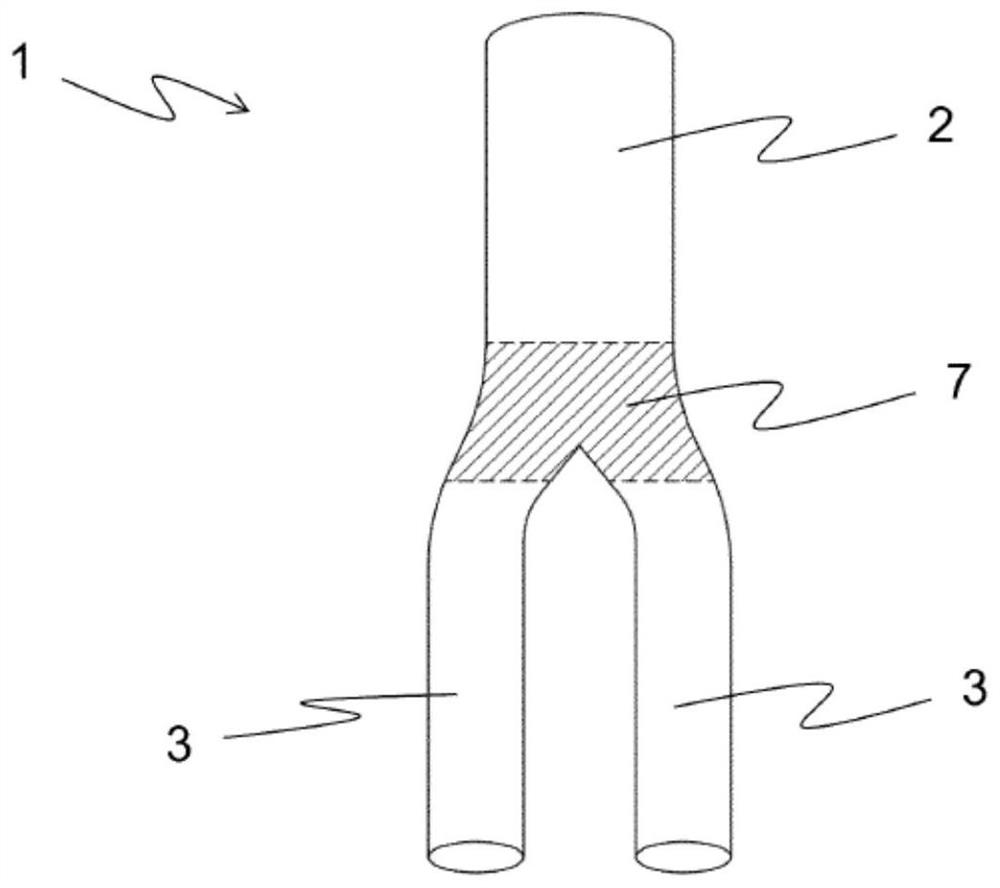

Braided structure, in particular stent, and method for braiding braided structure

PendingCN111970998AGood braided structureNo manual interventionStentsBlood vesselsBiomedical engineeringAnatomy

The present invention relates to a braided structure (1) having a primary limb (2) and at least two secondary limbs (3), wherein the primary limb (2) is braided from a group of filaments (4), in particular threads or wires, and the secondary limbs (3) are braided from filaments (4) such that the totality of the filaments (4) associated with the secondary limbs (3) is the same as the group of filaments (4) of the primary limb (2). The invention proposes that a transitional region (7) braided from the group of filaments (4) of the primary limb (2) is arranged between the primary limb (2) and thesecondary limbs (3). The invention further relates to a method for braiding a braided structure (1), in particular a stent, having a primary limb (2) and at least two secondary limbs (3), wherein theprimary limb (2) is first braided from a group of filaments (4), a substantially hole-free transitional region (7) is then braided from the group of filaments (4) of the primary limb (2), and the secondary limbs (3) are then braided, or the method steps are carried out in the reverse order.

Owner:巴伐利亚州公立霍夫应用科学大学材料科学研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com