Assembly guiding method and system

A technology of relationship and coordinate system, applied in the field of optical projection, can solve problems such as inability to fully simulate various objective situations, interactive operation of assembly parts, and lack of realism, so as to improve efficiency, realize automation, and improve efficiency and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

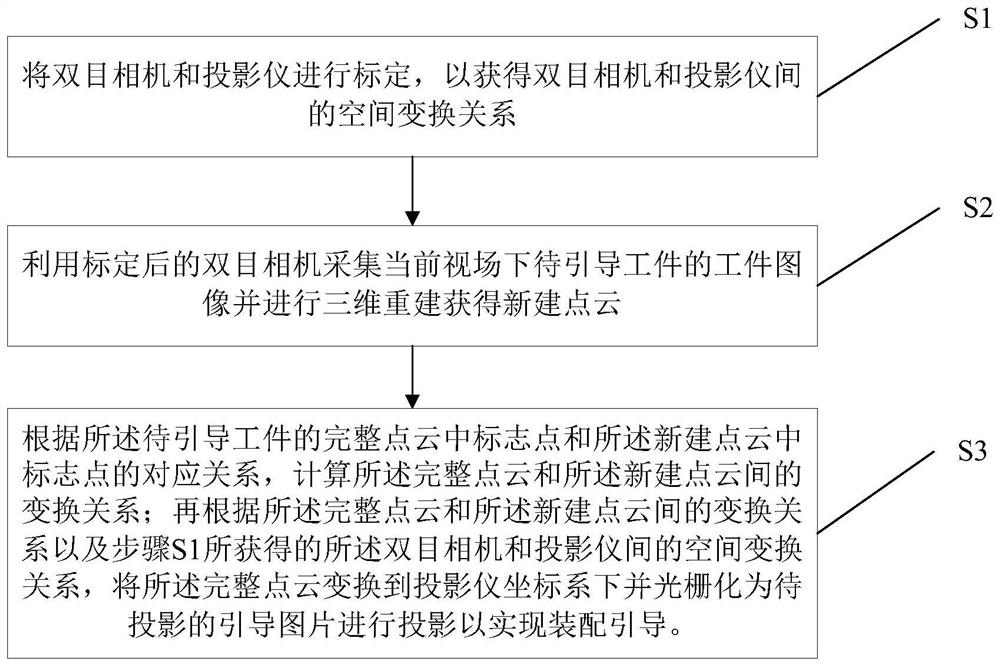

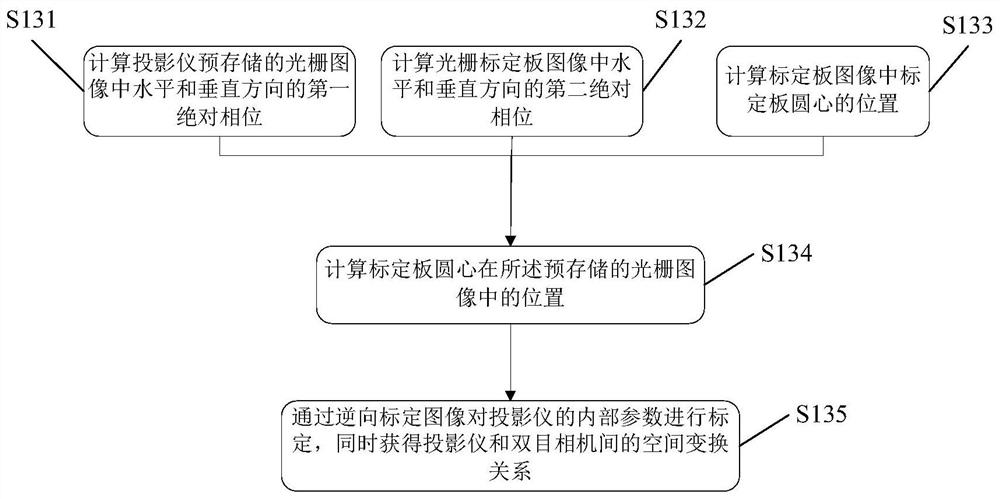

[0037] The present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. It should be emphasized that the following descriptions are only exemplary and not intended to limit the scope of the present invention and its application.

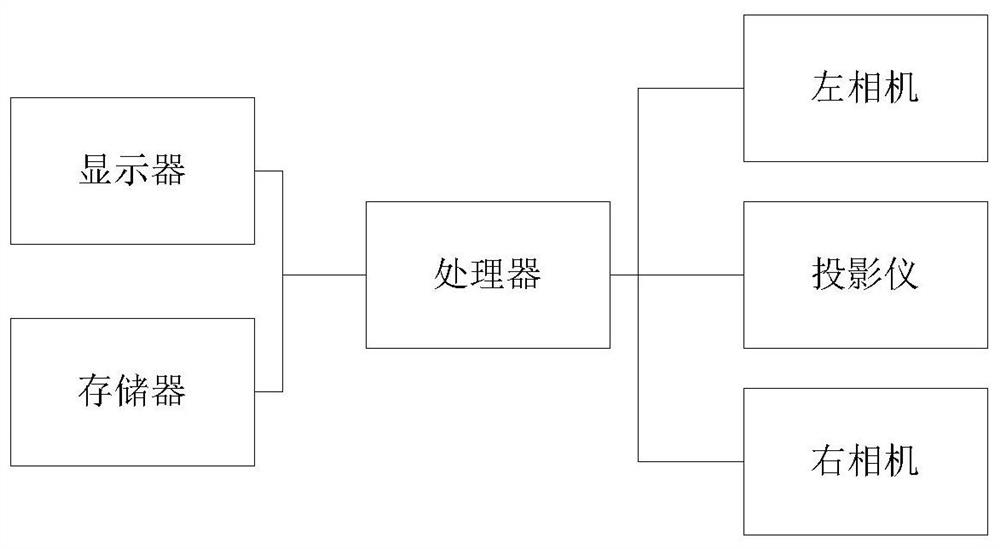

[0038] figure 1 It is a structural block diagram of an assembly guidance system according to an embodiment of the present invention. The system includes:

[0039]Projector: used to project structured light gratings and guiding pictures of workpieces to be guided;

[0040] Binocular camera: Two left and right cameras with high resolution of 2448×2048, used to collect the images of the grating calibration plate with grating stripes and the image of the calibration plate without grating, and capture the workpiece to be guided under the current field of view image;

[0041] Processor: connected to the projector and the binocular camera respectively, for calibratin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com