Autonomous device for the magnetic handling of an electronic component

A technology for processing equipment and autonomous equipment, applied in the direction of electrical components, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention therefore relates to an autonomous device for processing elements, realizing permanent magnets, and a mechanical device that allows the magnets and elements to be separated with high precision without any manual contact with the latter.

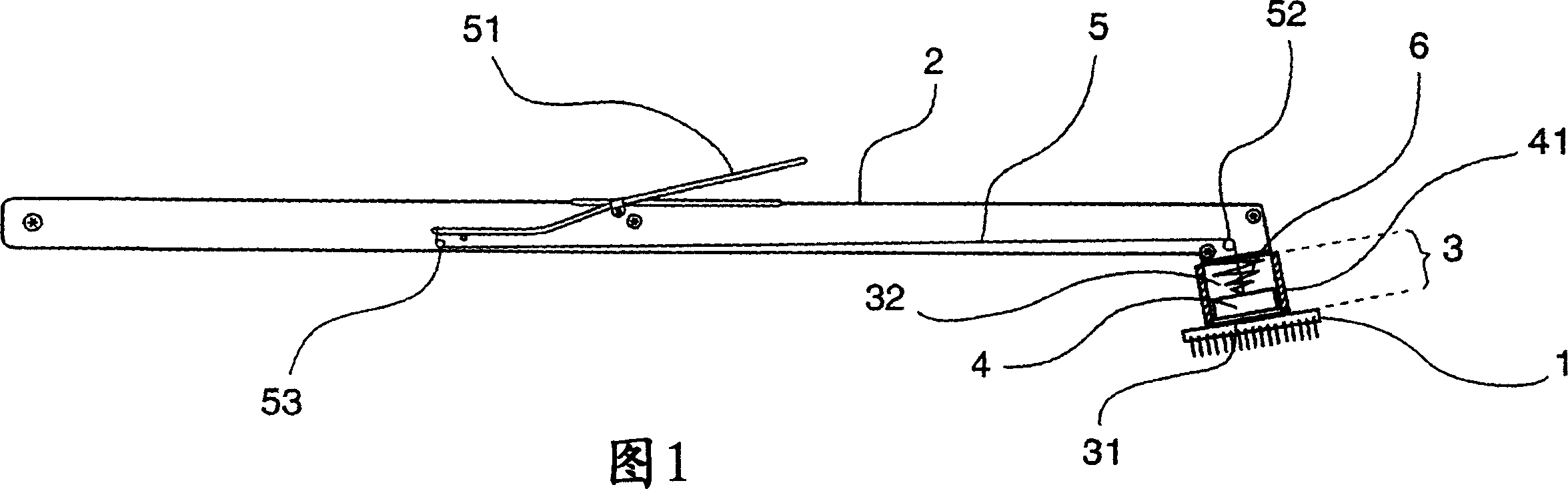

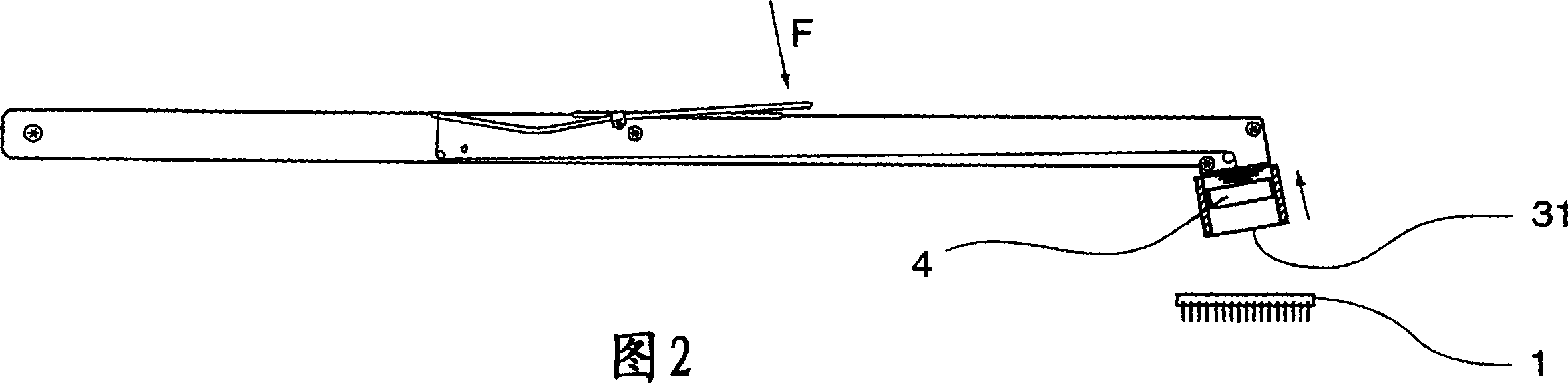

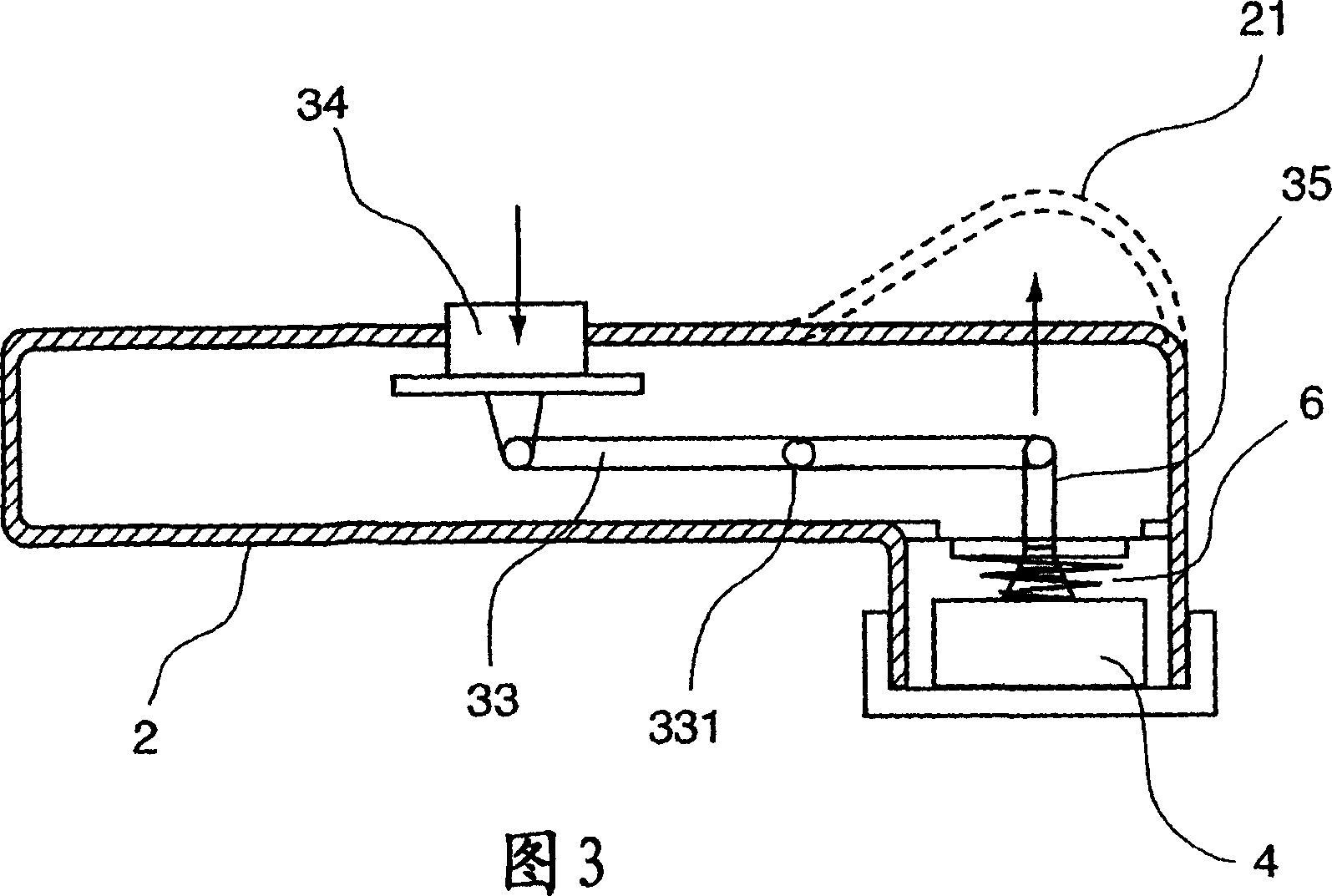

[0068] Figures 1 and 2 show an example of such a device in grip and release positions, respectively.

[0069] The autonomous device for processing the electronic component 1 includes a main body 2 and a gripping head 3 that are combined with each other.

[0070] In Figures 1 and 2, we notice that the main body 2 and the gripping head form an angled single unit, for example, composed of two separate plastic half-shells combined with each other. However, according to another possible embodiment, the head can be rotatably mounted on the device body.

[0071] It is also conceivable that the main body and the gripping head extend in an axial manner.

[0072] We also note that according to another way that can be conceived ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com