High-efficiency fluid electromagnetic magnetizer

A magnetizing device and fluid technology, which is applied to circuits, magnetic objects, electrical components, etc., can solve the problems of shortening the effective time of fluid particles, inconvenient use by users, inconvenient maintenance, and increased device manufacturing costs, and achieves extended effective time. Magnetization effect boost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

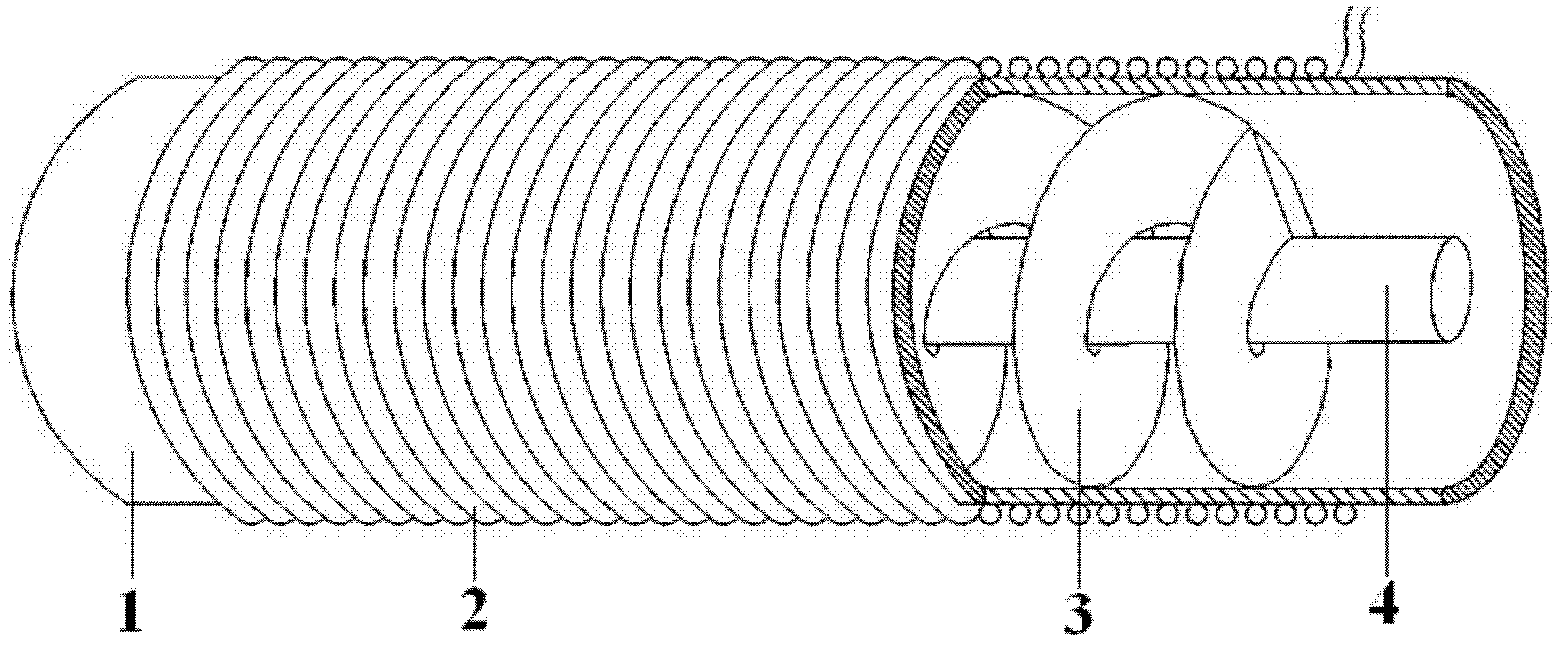

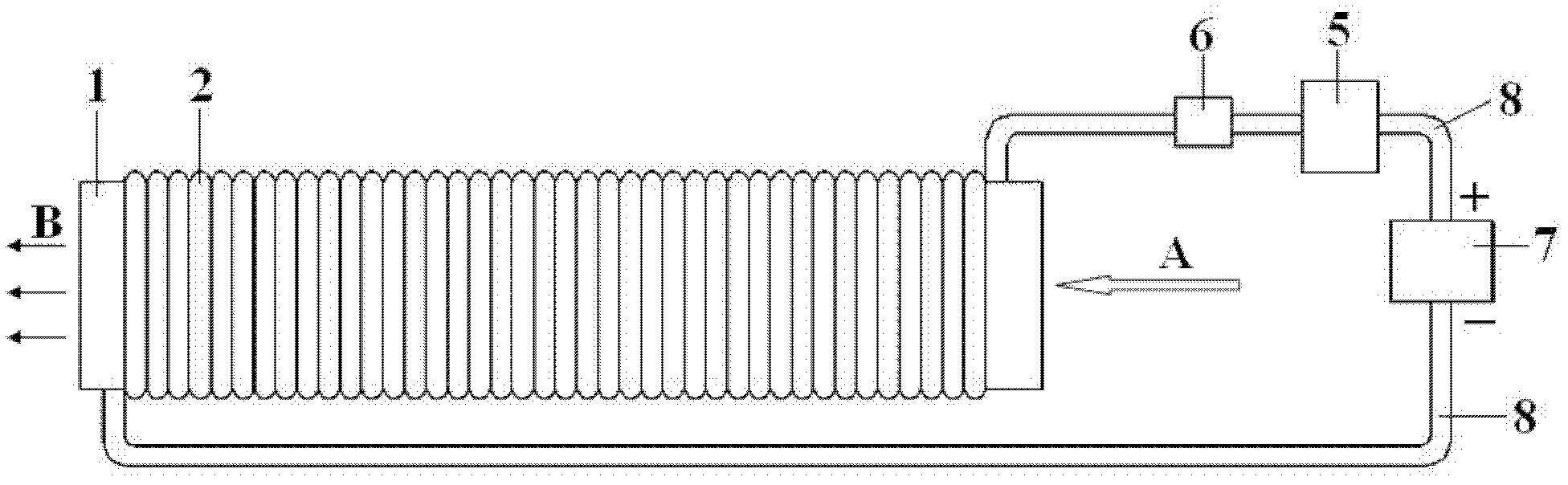

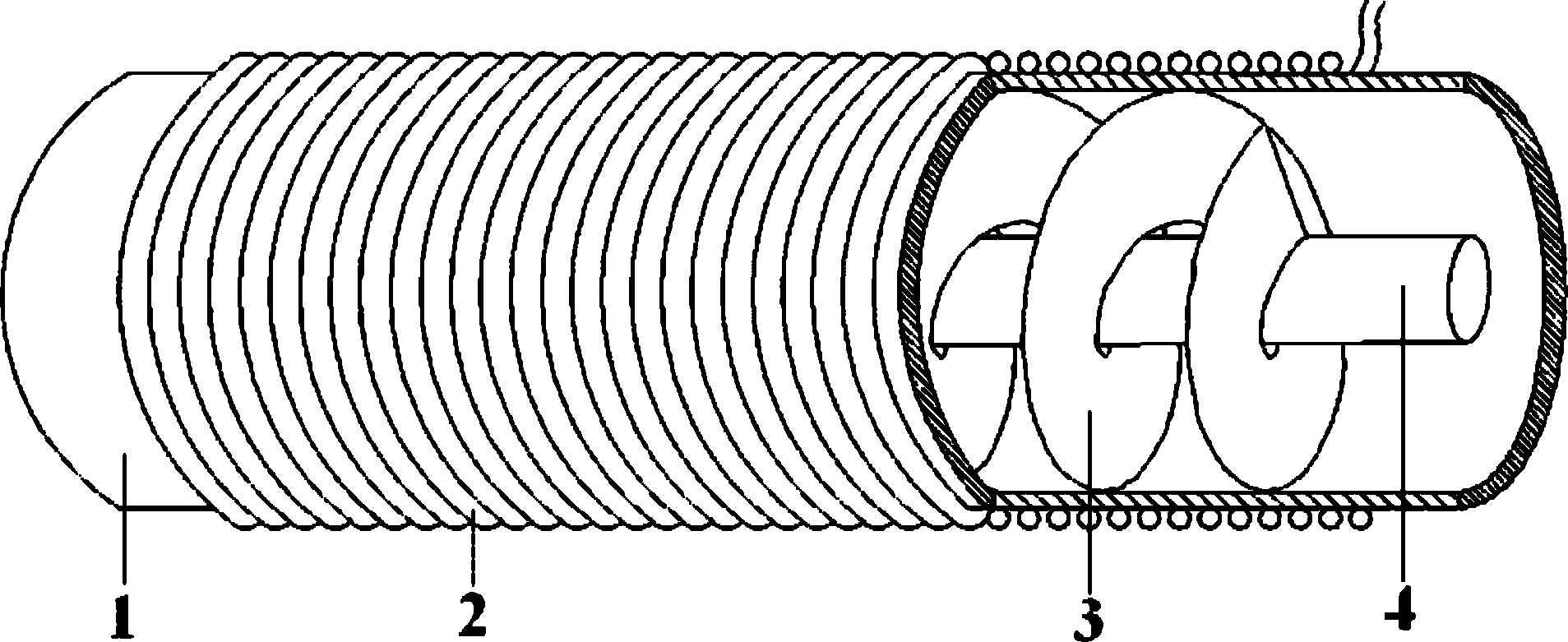

[0017] Such as figure 1 The high-efficiency fluid electromagnetic magnetization device shown includes a tube body 1, an electromagnetic winding 2, a flow guide screw 3 and a tube core 4. The outer circumference of the tube body 1 is wound with electromagnetic wire to form an electromagnetic winding 2, and the inside of the tube body 1 A tube core 4 is provided in the cavity, and a guide screw 3 is provided on the outside of the peripheral surface of the tube core 4, the axis of the tube core 4 coincides with the axis of the tube body 1, and the guide screw 3 is fixed on the tube body On the inner wall of the tube core 4, or fixed on the outer periphery of the tube core 4, and arranged continuously and evenly, one end of the electromagnetic winding 2 is connected with the current regulating device 5, which is used to adjust the magnitude of the current passed into the electromagnetic winding.

[0018] During use, the pipe body 1 of the high-efficiency fluid electromagnetic magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com