Nondestructive testing device and method for steel wire rope

A non-destructive testing and wire rope technology, applied in the direction of material magnetic variables, etc., can solve the problems of large volume and inaccurate testing results, and achieve the effects of good wrapping, improved testing accuracy, and uniform magnetization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following, the present invention will be specifically described through exemplary embodiments. It should be understood, however, that elements, structures and characteristics of one embodiment may be beneficially incorporated in other embodiments without further recitation.

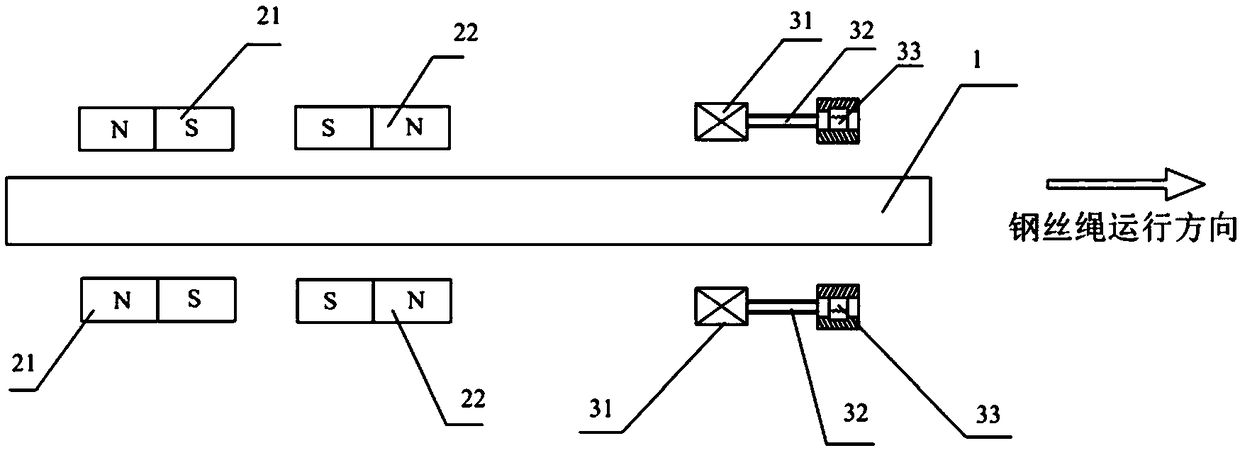

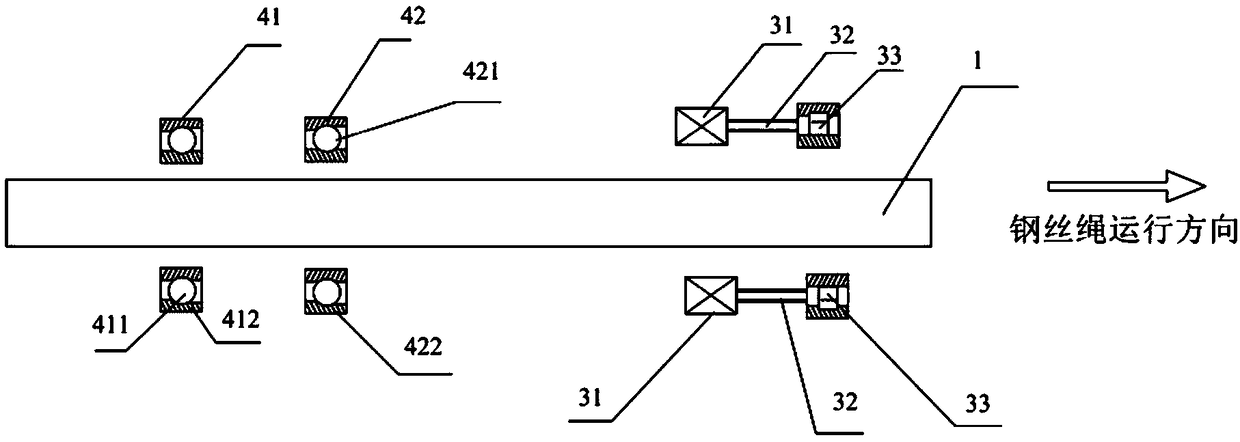

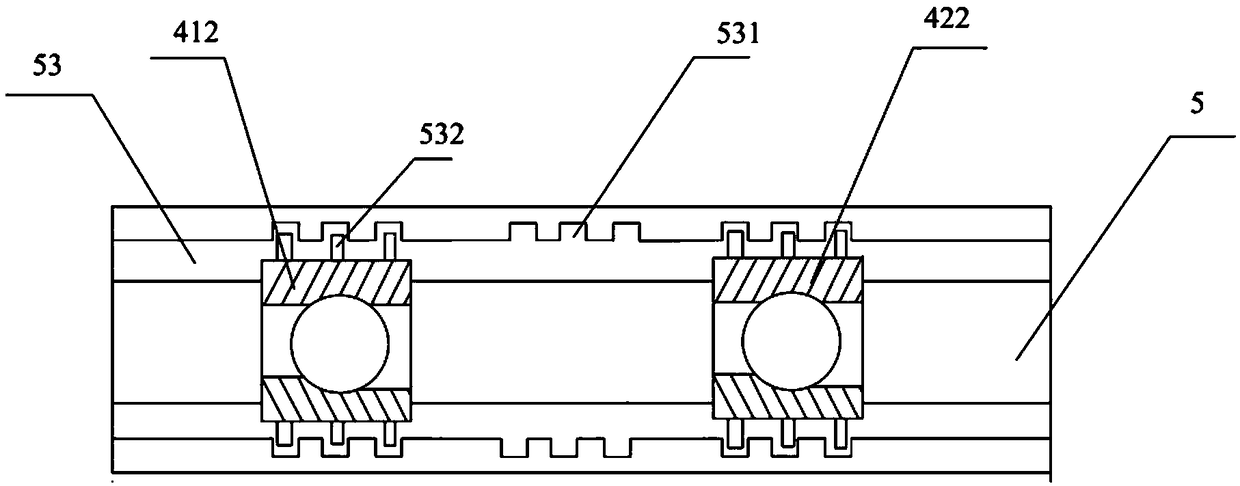

[0037] Such as figure 1 As shown, in the running direction of the steel wire rope 1, a group of permanent magnets 21 and permanent magnets 22 with completely opposite magnetic field directions are arranged. The excitation direction of the permanent magnets 21 is the same as the running direction of the steel wire rope 1. , will carry out forward saturation magnetization to the steel wire rope 1; the excitation direction of the permanent magnet 22 is opposite to the running direction of the steel wire rope 1, and when the steel wire rope 1 runs past the permanent magnet 22, it will carry out reverse saturation magnetization to the steel wire rope 1; A plurality of permanent magnets 21 and pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com