3OZ thick copper plate one-time resistance welding process spraying method

A thick copper plate, one-off technology, applied in coating, spray booth, spray device and other directions, can solve the problems of long process flow, low efficiency and high production cost, and achieve the effect of cost reduction, efficiency improvement and good wrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

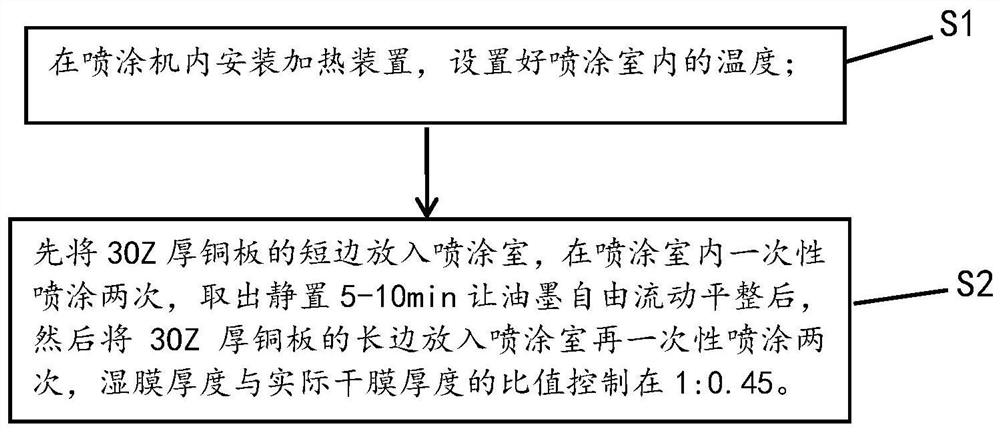

[0020] refer to figure 1 , a kind of 3OZ thick copper plate one-time solder resist process spraying method disclosed by the present invention, comprising:

[0021] S1: install a heating device in the spraying machine, and set the temperature in the spraying room;

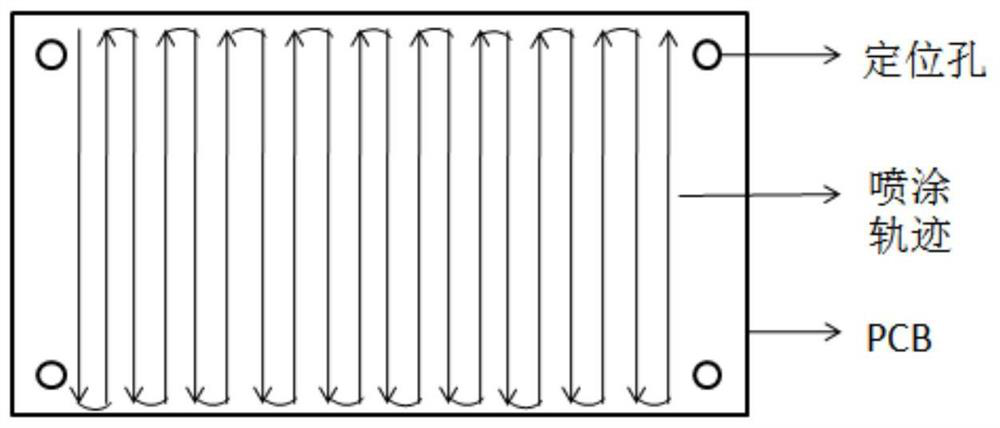

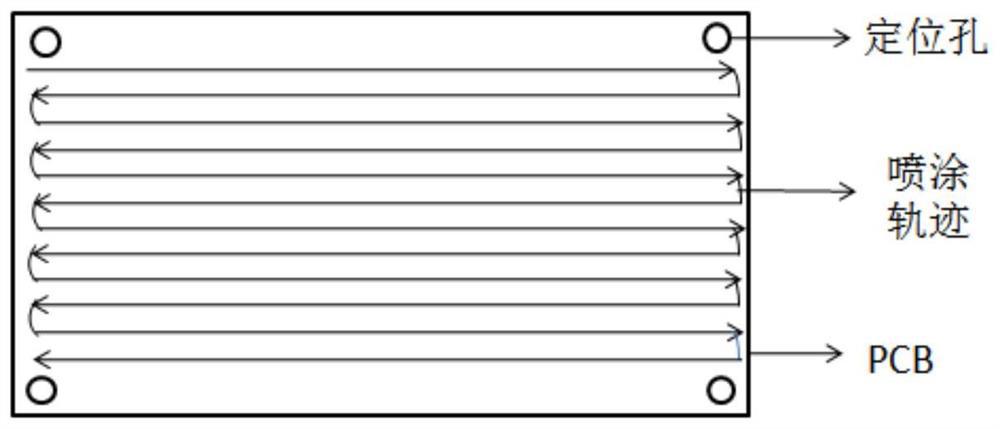

[0022] S2: First put the short side of the 3OZ thick copper plate into the spraying room, spray twice in the spraying room at one time, take it out and let it stand for 5-10 minutes, let the ink flow freely and level off, then put the long side of the 3OZ thick copper plate into the spraying room The chamber is sprayed twice at one time, and the ratio of wet film thickness to actual dry film thickness is controlled at 1:0.45.

[0023] Through step S1, the spray ink can be pre-cured du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com