Production method of claw pole type permanent-magnet stable-voltage electric generator

A claw pole type, generator technology, applied in the field of claw pole type permanent magnet stabilized voltage generator, can solve the problems of unadjustable magnetic field, unstable output voltage, high output voltage, and ensure safety and reliability, output voltage The effect of maintaining stability and high material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

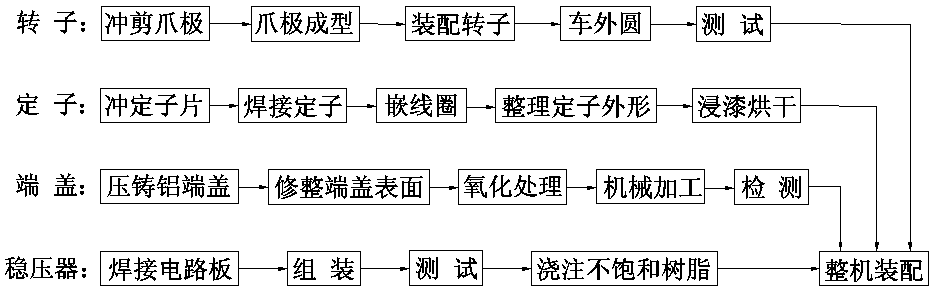

[0012] The present invention will be further explained below in conjunction with the drawings:

[0013] The production method of the claw-pole type permanent magnet stabilized voltage generator includes rotor assembly, stator assembly, end cover processing, voltage stabilizer assembly and complete machine assembly, and is characterized by:

[0014] The first step is to assemble the rotor: punch the steel plate into a claw pole flange, then bend the claw pole flange into a claw pole, and press the magnetic isolation bush with positioning groove on the shaft , The front claw poles are sleeved on the magnetic isolation bushing with positioning slots, the claws of the front claw poles are facing upwards, the axially magnetized ring-shaped permanent magnet steel is sleeved on the magnetic isolation bushing, and then the rear claw poles Sleeve on the magnetic isolation bush with positioning slot, the claws of the rear claw poles face downwards, the claws of the front claw poles and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com