Compressor motor magnet magnetization method

A technology of compressors and magnets, which is applied in the direction of magnetic circuits, electromechanical devices, magnetic objects, etc., and can solve problems such as uneven arrangement of magnet polarity and incomplete magnetization of magnets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

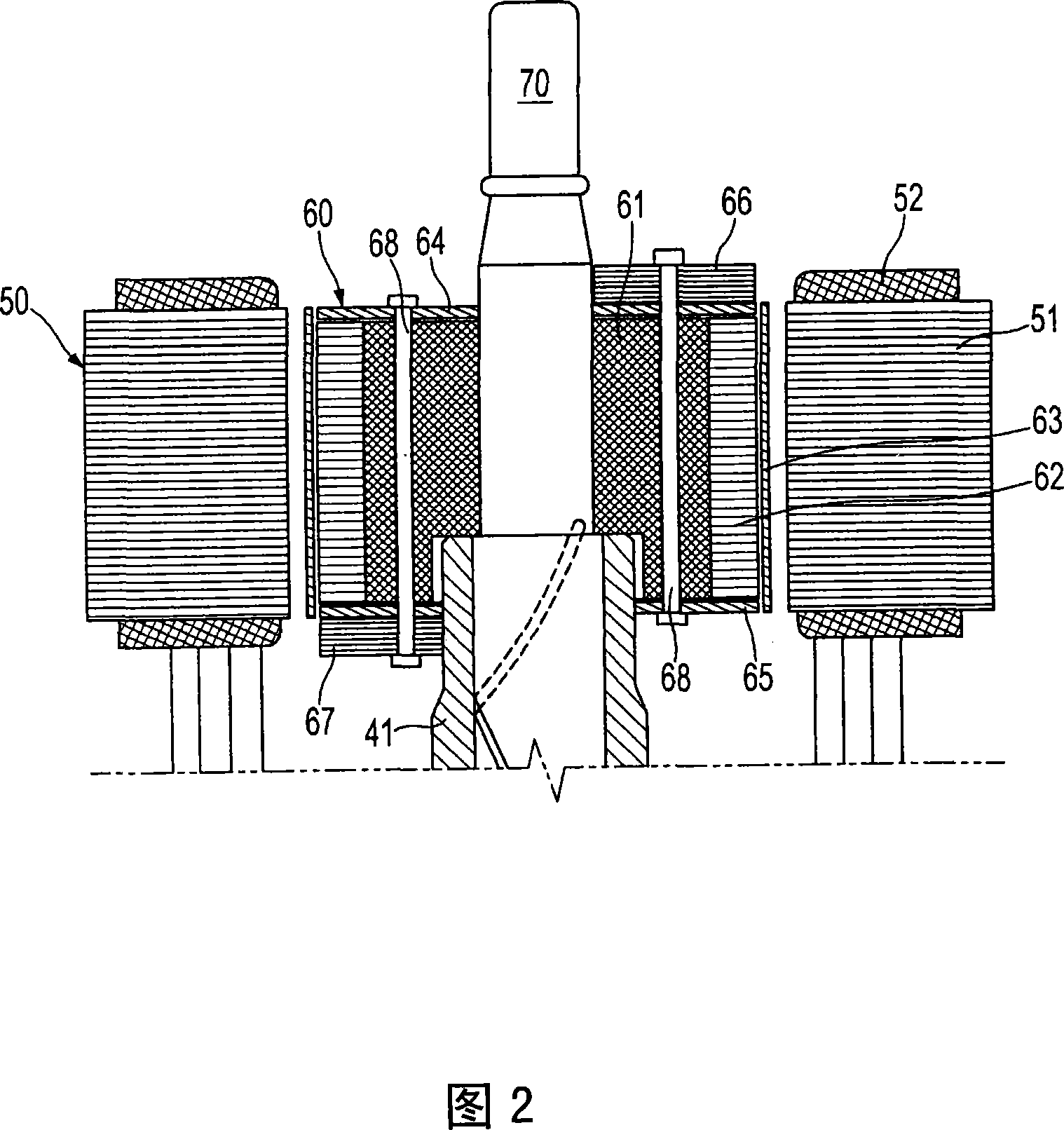

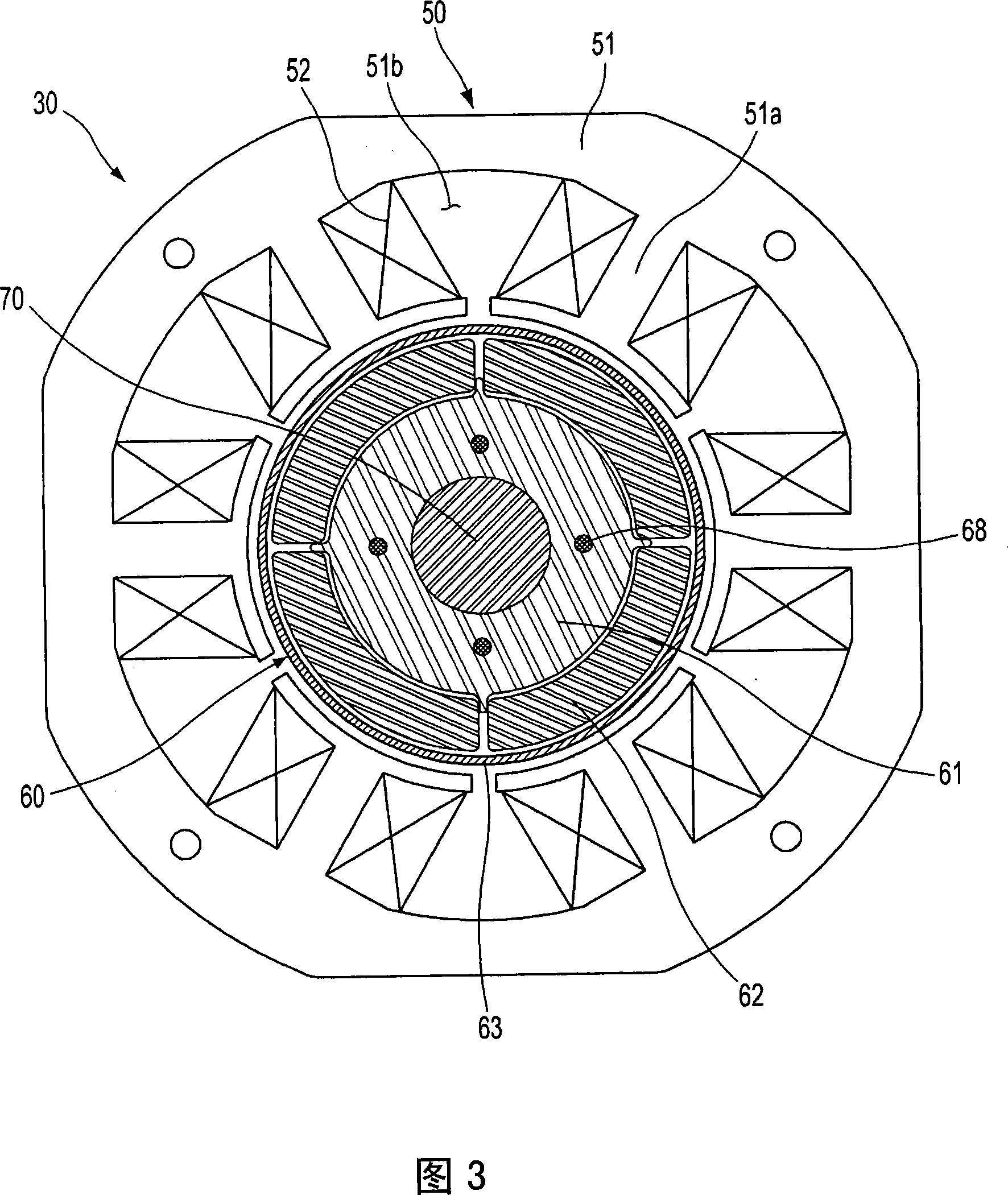

[0024] Hereinafter, a preferred embodiment according to the present invention will be described in detail with reference to the accompanying drawings.

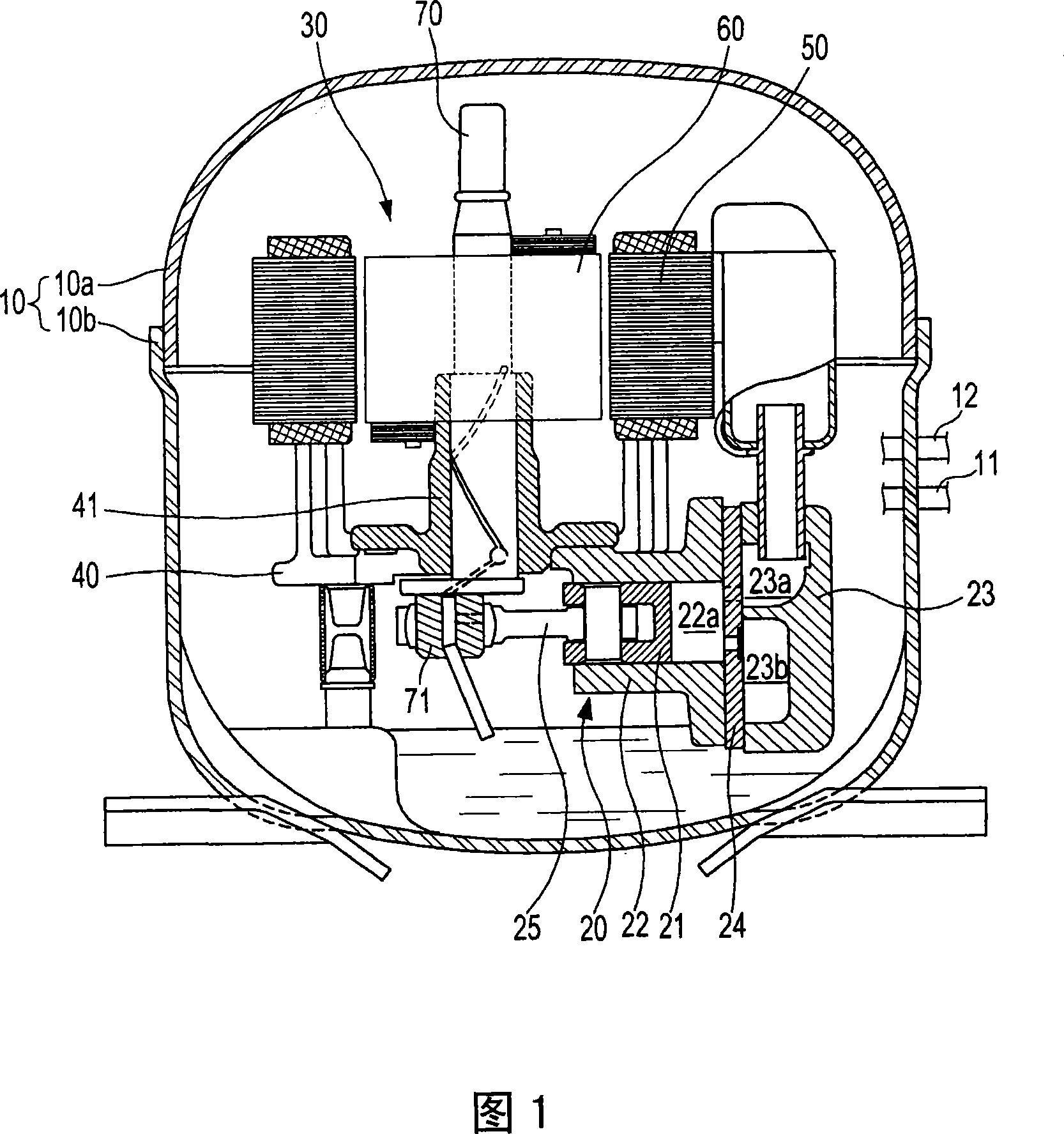

[0025] First, as shown in FIG. 1, the compressor according to this embodiment forms an appearance by combining an upper container 10a and a lower container 10b with each other to form a hermetic container 10, and one side and the other side of the airtight container 10 are provided with A suction pipe 11 that guides refrigerant to the inside of the sealed container 10 and a discharge pipe 12 that guides refrigerant compressed inside the sealed container 10 to the outside of the sealed container 10 .

[0026] In addition, a compression unit 20 for performing a compression action of the refrigerant and a motor 30 for providing a driving force based on the compression action of the refrigerant are provided inside the sealed container 10 .

[0027] Among them, the above-mentioned compression unit 20 is first provided with: a pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com