Device for rapidly measuring grain size and magnetic domain wall width of oriented silicon steel sheet

A technology of oriented silicon steel and grain size, which is applied in the field of analysis and detection devices for oriented silicon steel sheets, can solve problems such as waste, complicated magnetic field conditions, and difficulty in characterizing the actual situation of large-sized samples, and achieve the effects of avoiding mutual pollution and rapid magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

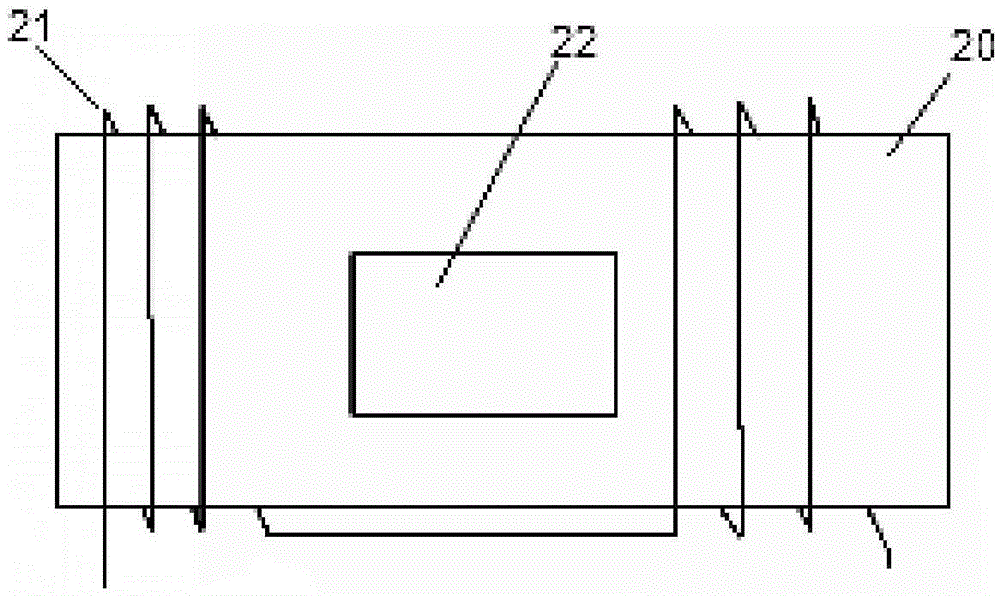

[0026] Such as figure 1 Shown is a device for measuring the grain size and magnetic domain wall width of grain-oriented silicon steel sheets in the prior art, and its structure has been described in detail in the background technology section, and will not be repeated here.

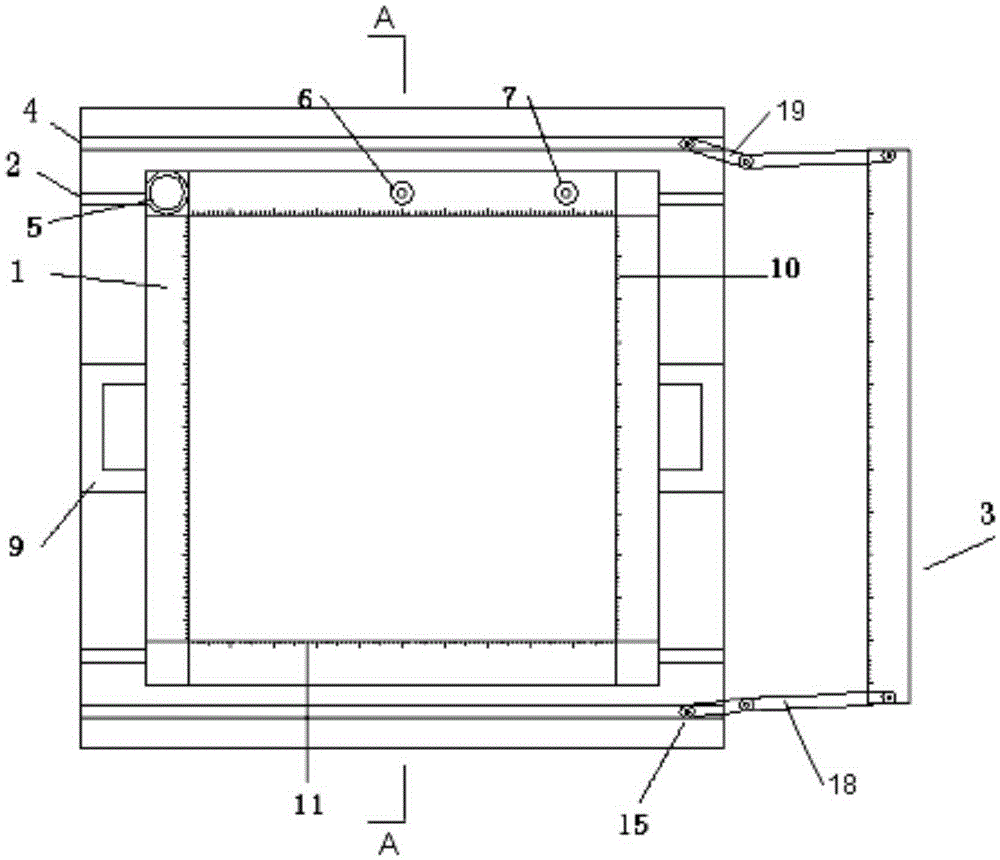

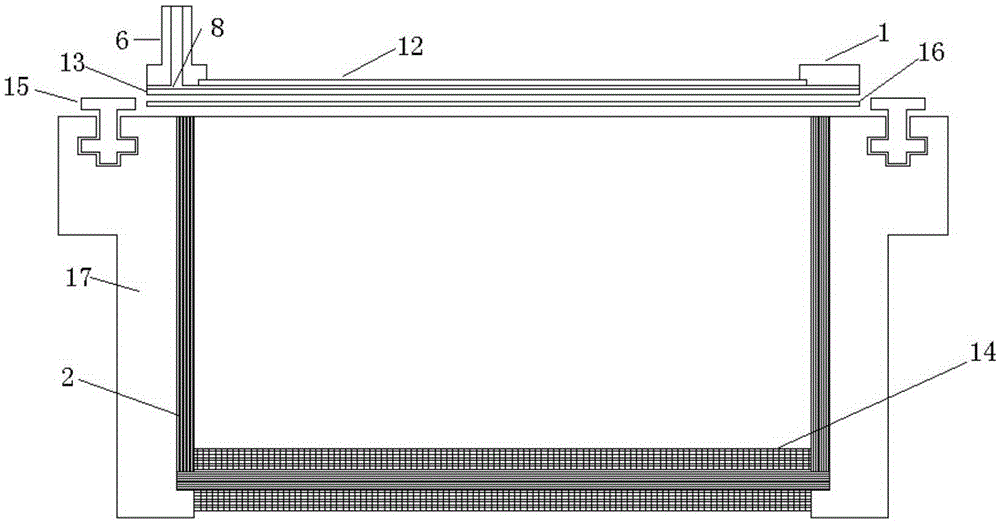

[0027] Such as Figure 2~4 As shown, the device designed by the present invention for quickly measuring the grain size and magnetic domain wall width of grain-oriented silicon steel sheets mainly includes two independent parts of the display part 1 and the sample stage 17, and the display part 1 includes a display window 12 and contact layer 13. The display window 12 is a rectangular transparent hard plastic plate, and a handle 9 is respectively arranged on both sides thereof. The contact layer 13 is a wear-resistant flexible plastic film, and its periphery is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com