Patents

Literature

35results about How to "Fast magnetization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

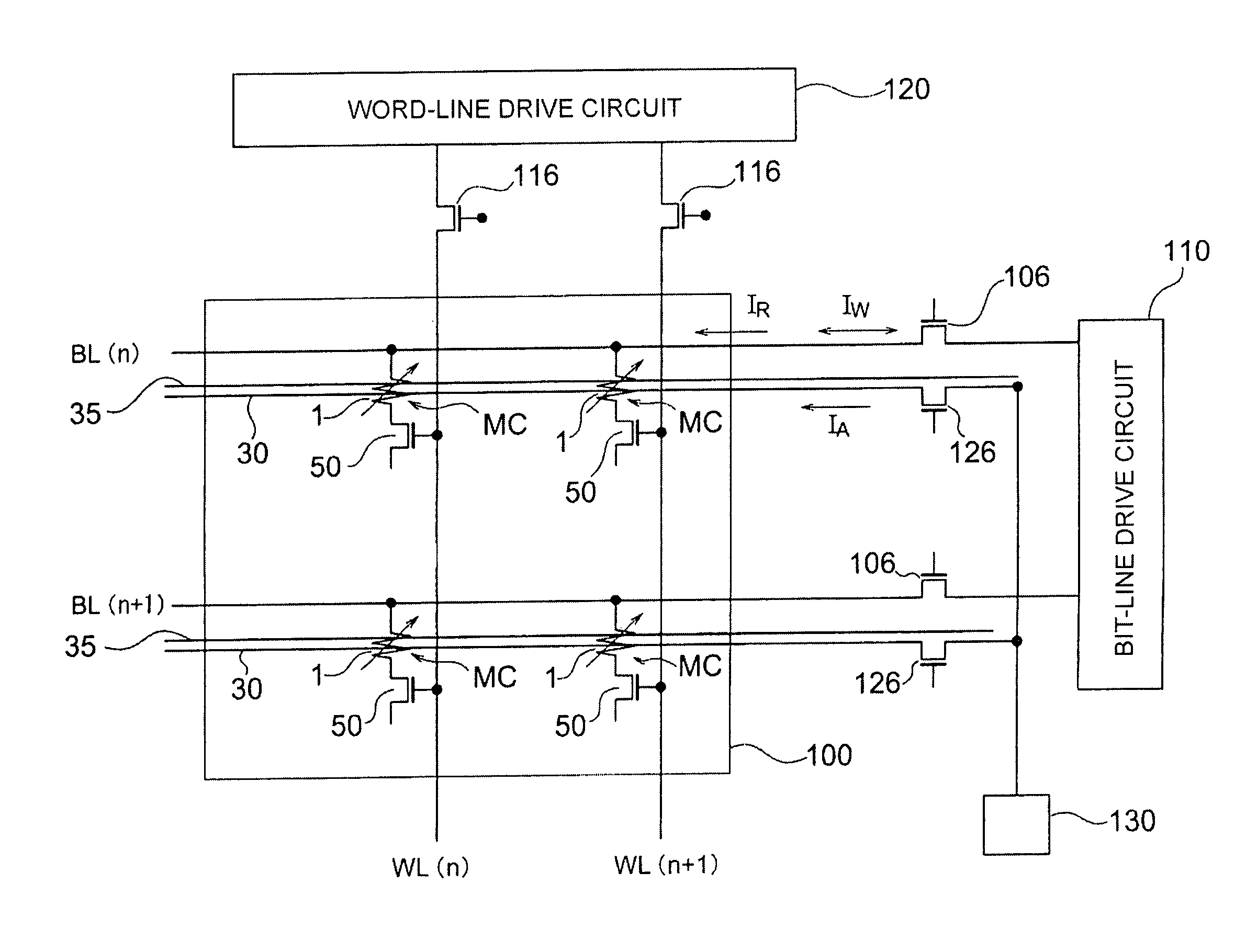

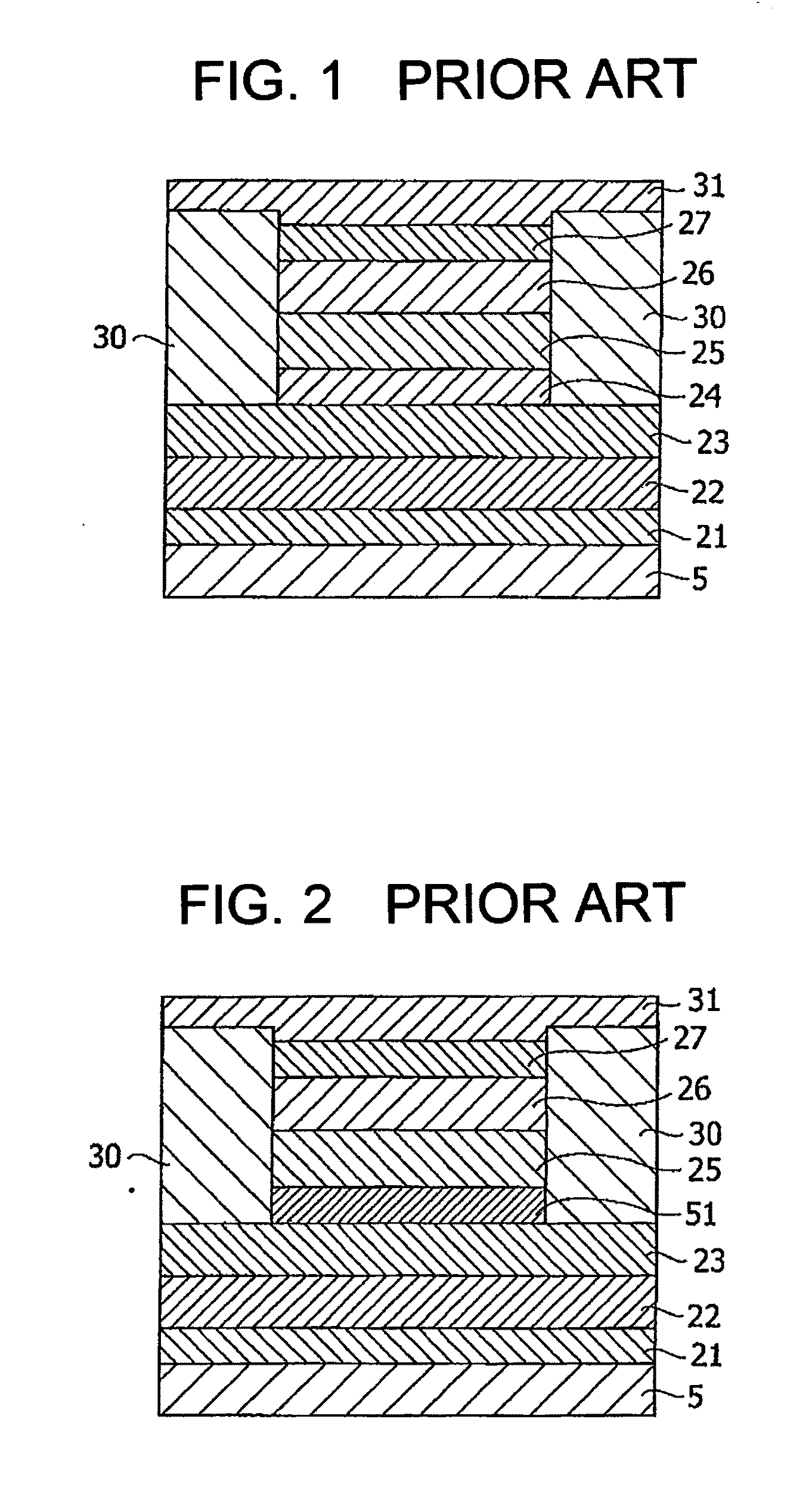

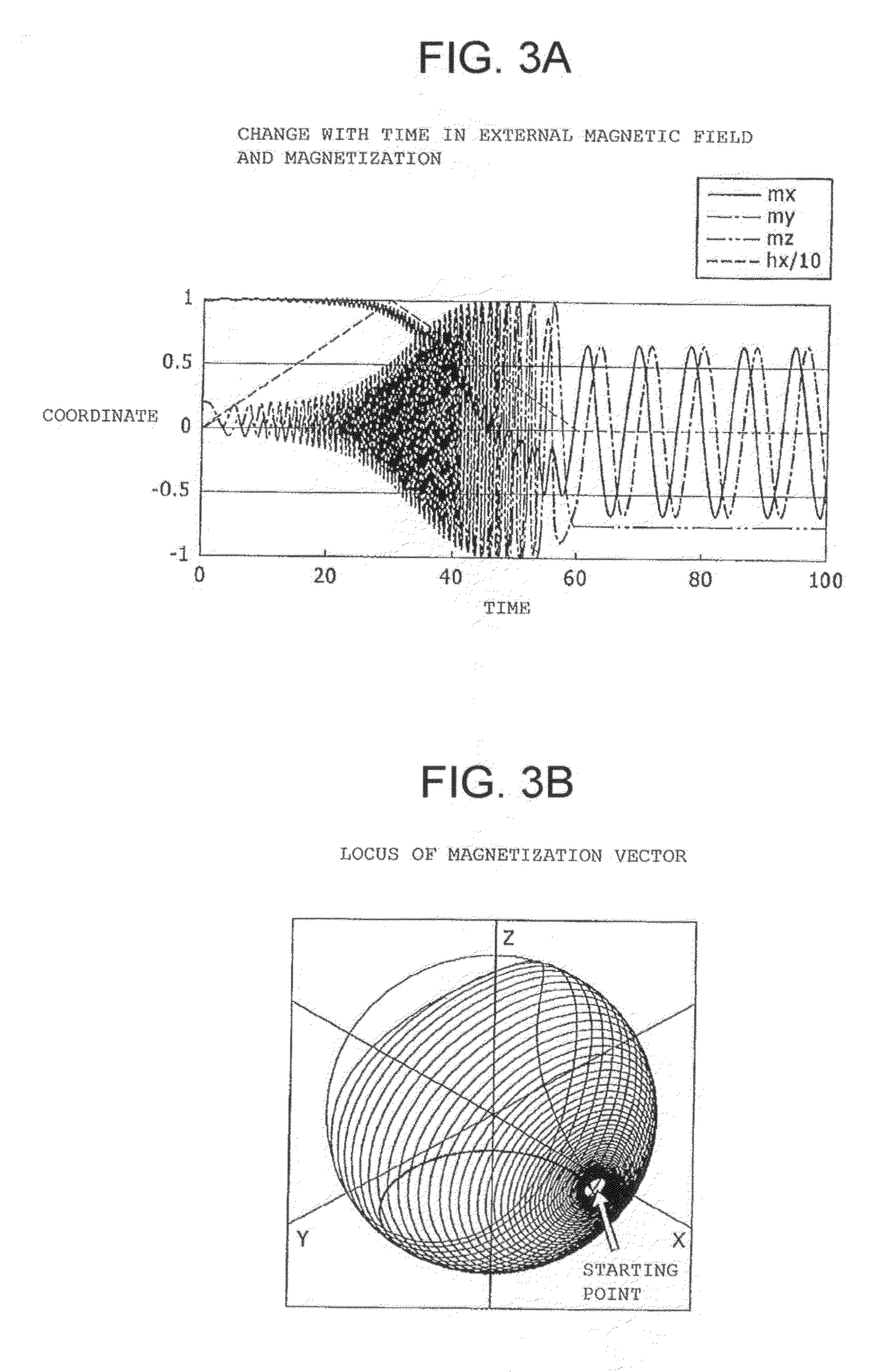

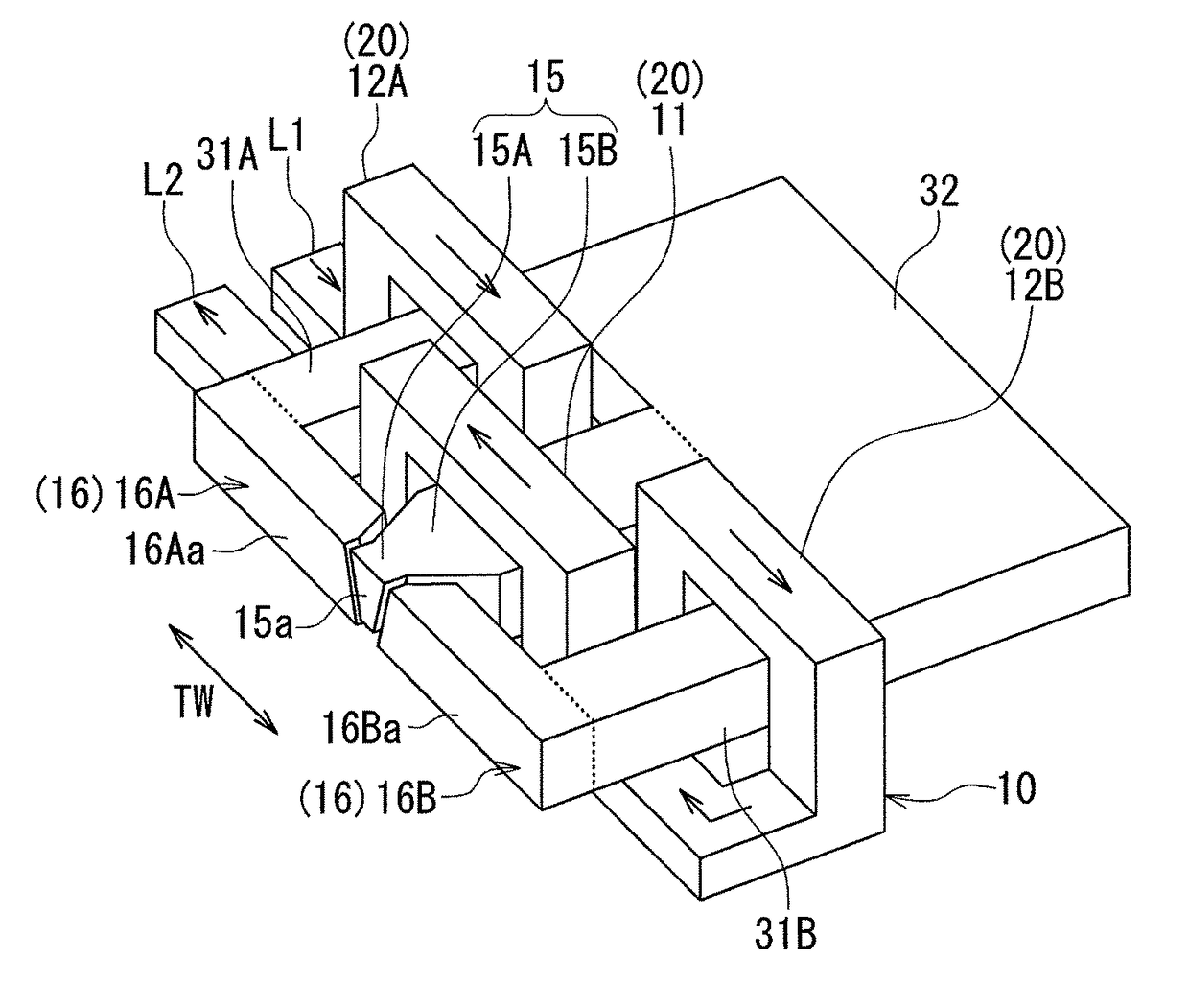

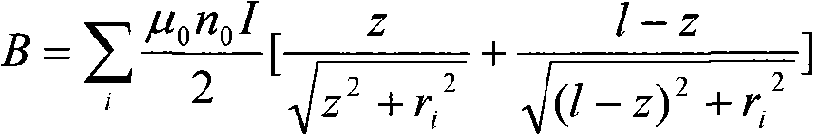

Magnetic memory

ActiveUS20090207724A1Reduce variationReduce reverse currentApparatus for flat record carriersSolid-state devicesMagnetizationMagnetic memory

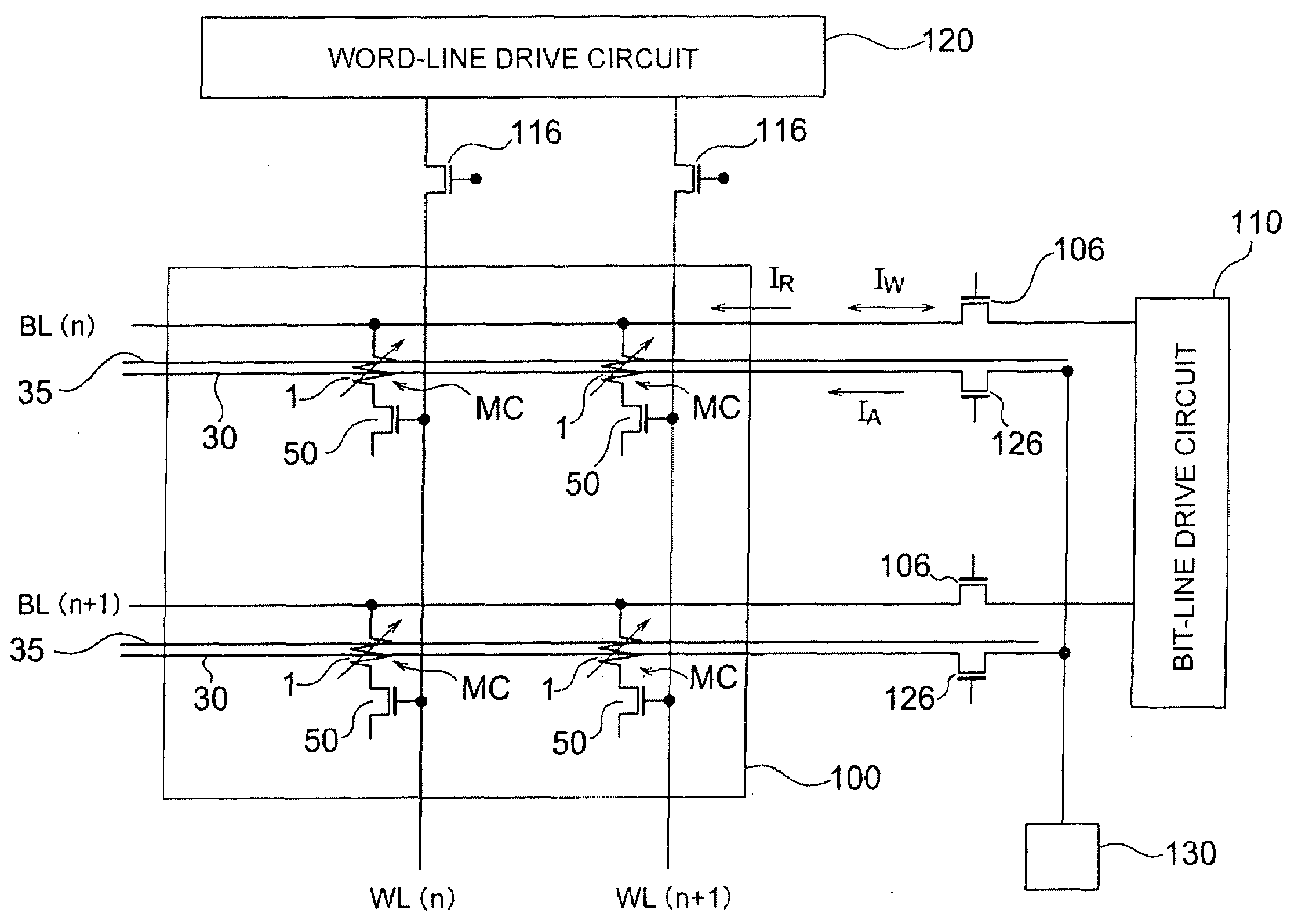

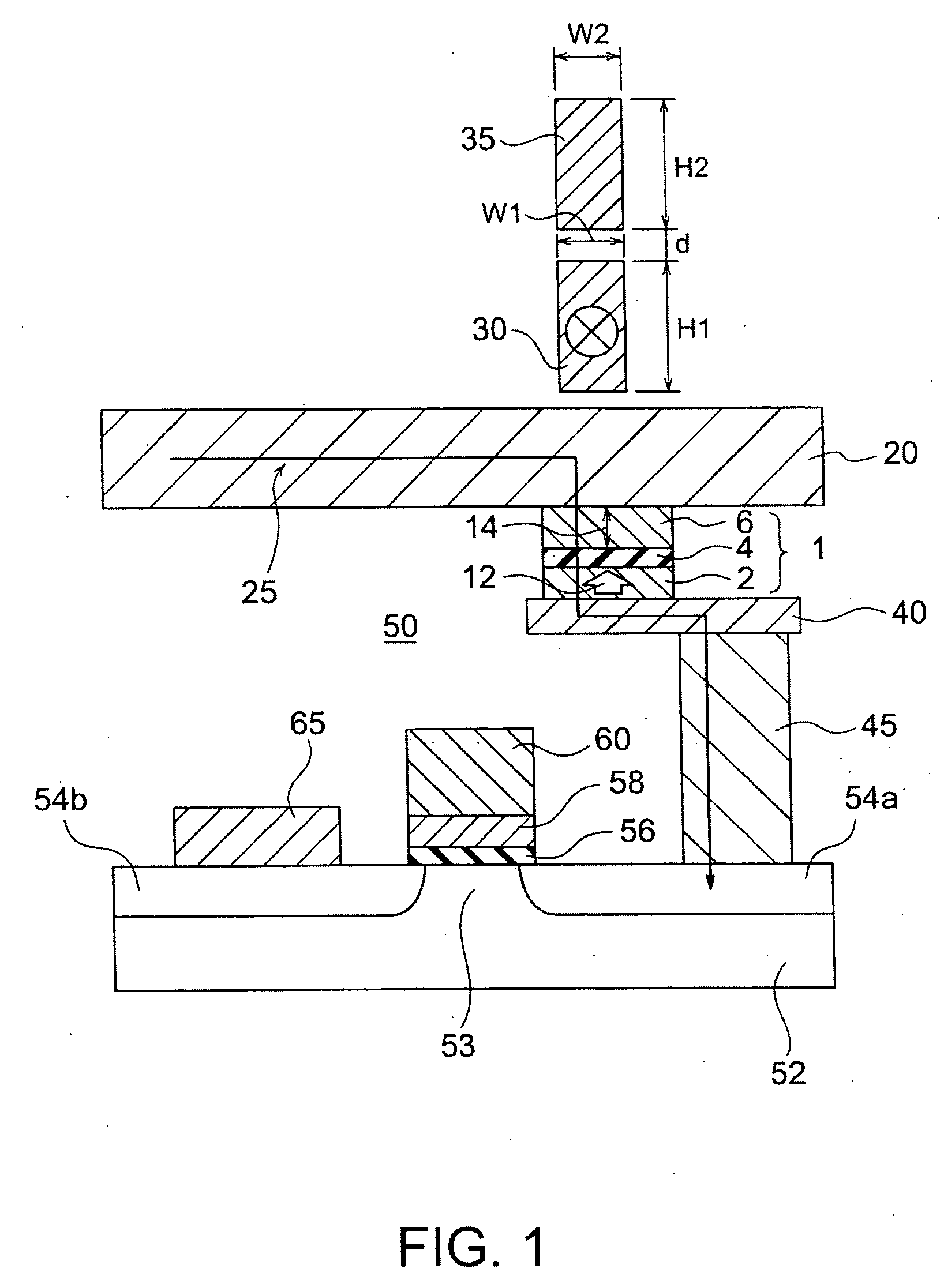

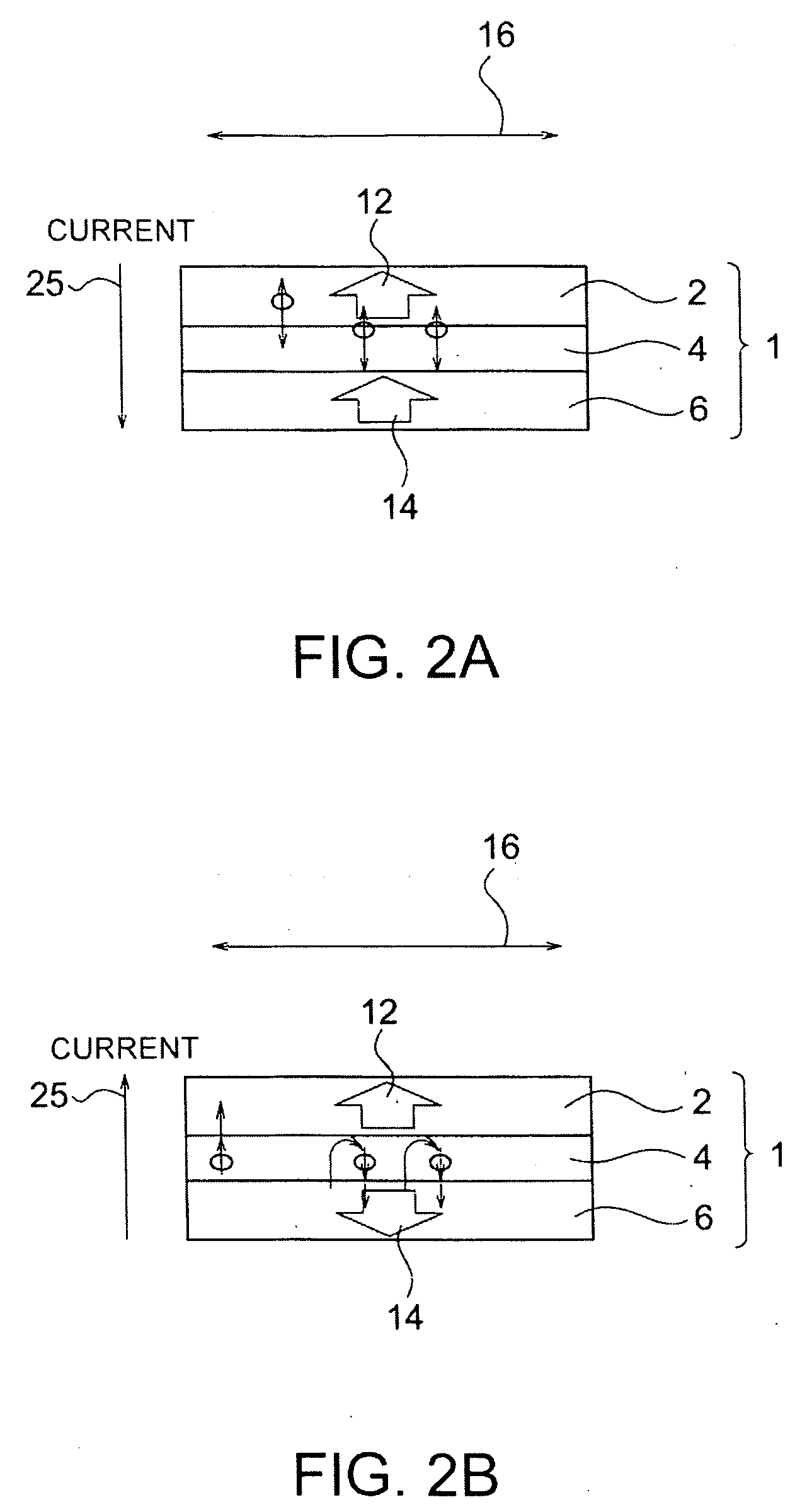

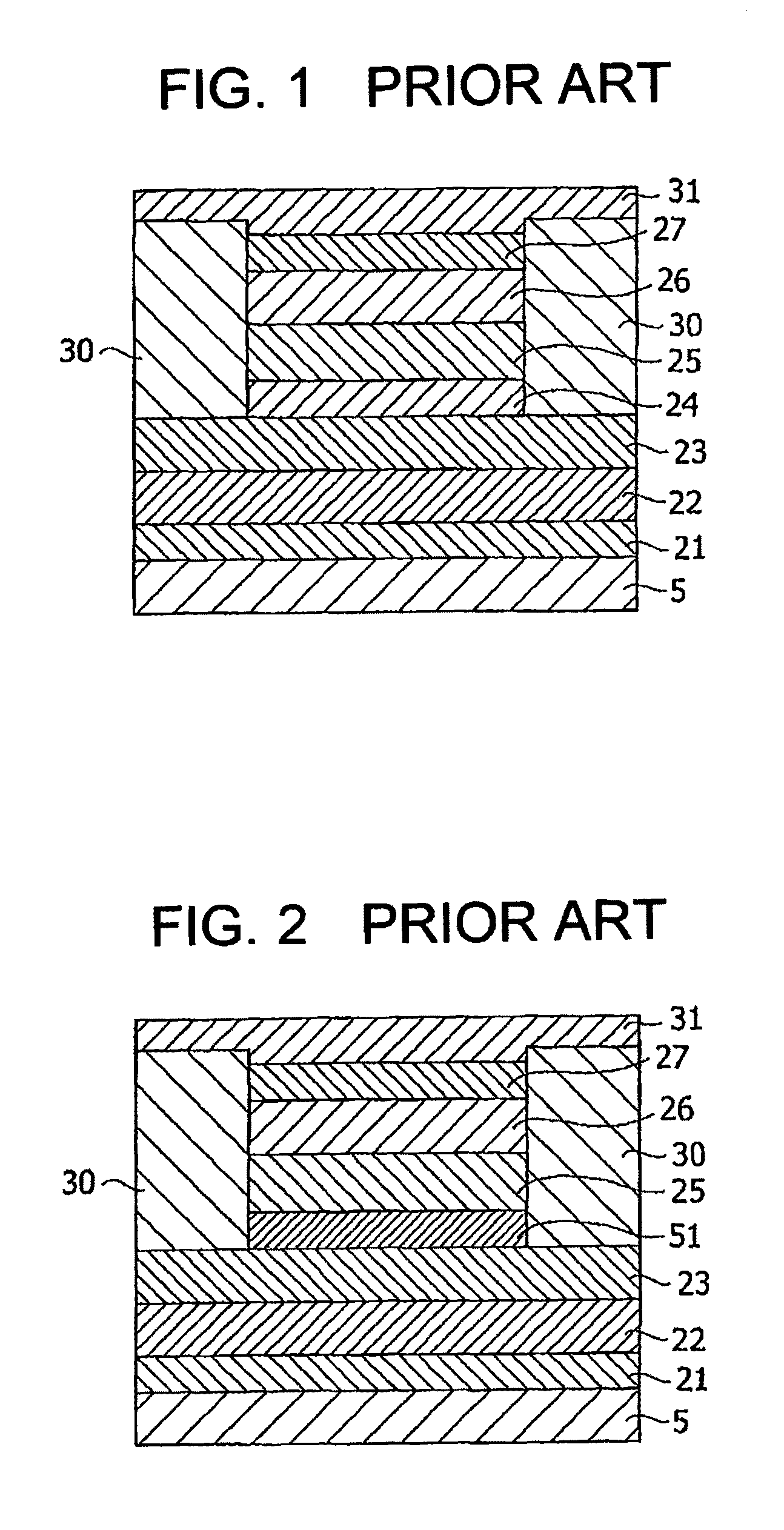

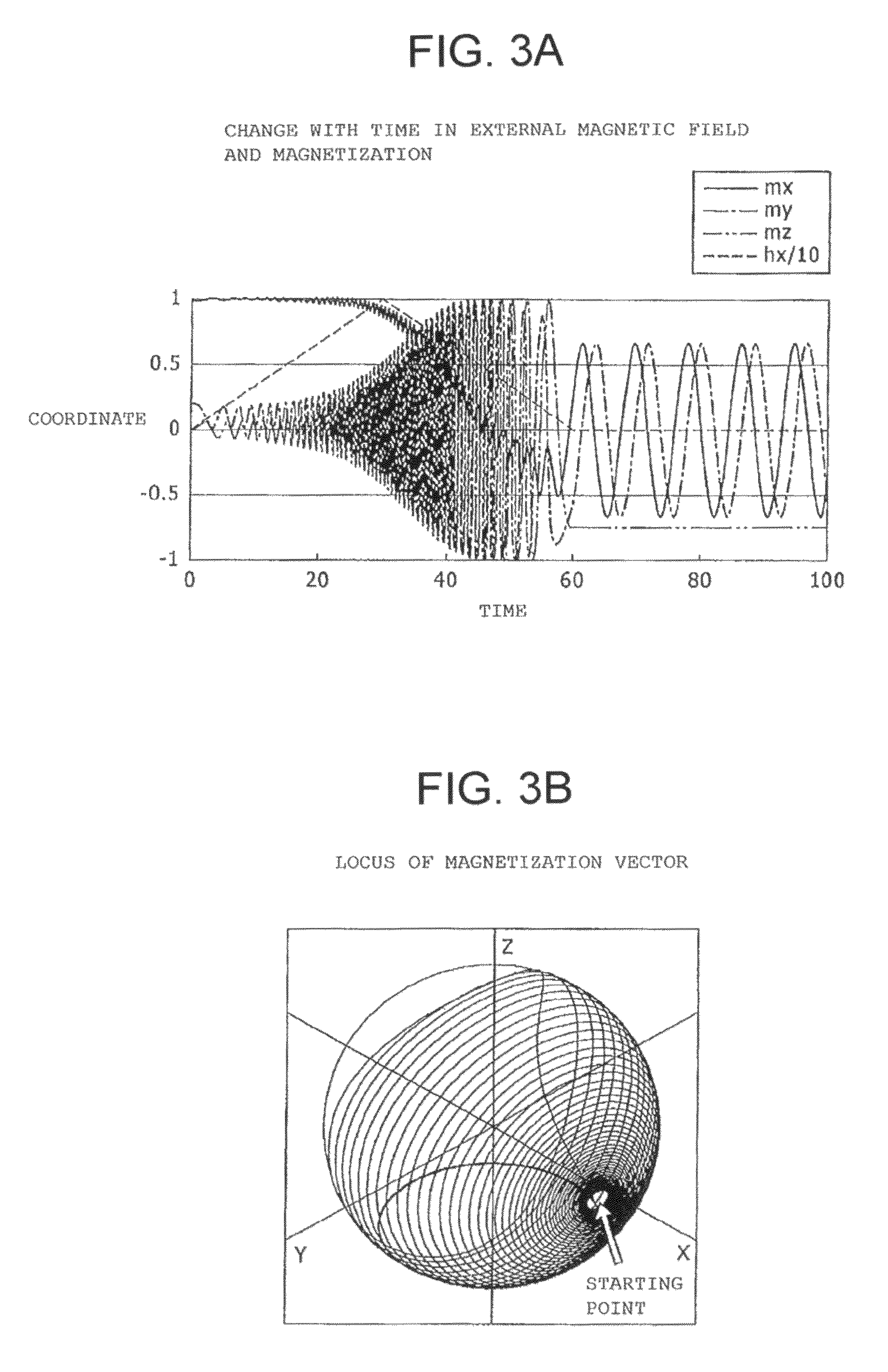

A magnetic memory is provided with a memory cell. The memory cell includes a magnetic recording element, an interconnection to generate a radio-frequency current-induced magnetic field and a ground line. The magnetic recording element is provided with a first magnetic layer whose magnetization direction is substantially fixed, a magnetic recording layer whose magnetization direction is substantially reversed by spin-polarized electrons passing through the magnetic recording layer and a first nonmagnetic layer provided between the first magnetic layer and the magnetic recording layer. The interconnection is provided above the magnetic recording element to generate a radio-frequency current-induced magnetic field acting in a direction substantially perpendicular to a magnetization easy axis of the magnetic recording layer. The ground line is provided on a side opposite to the magnetic recording element with respect to the interconnection.

Owner:KIOXIA CORP

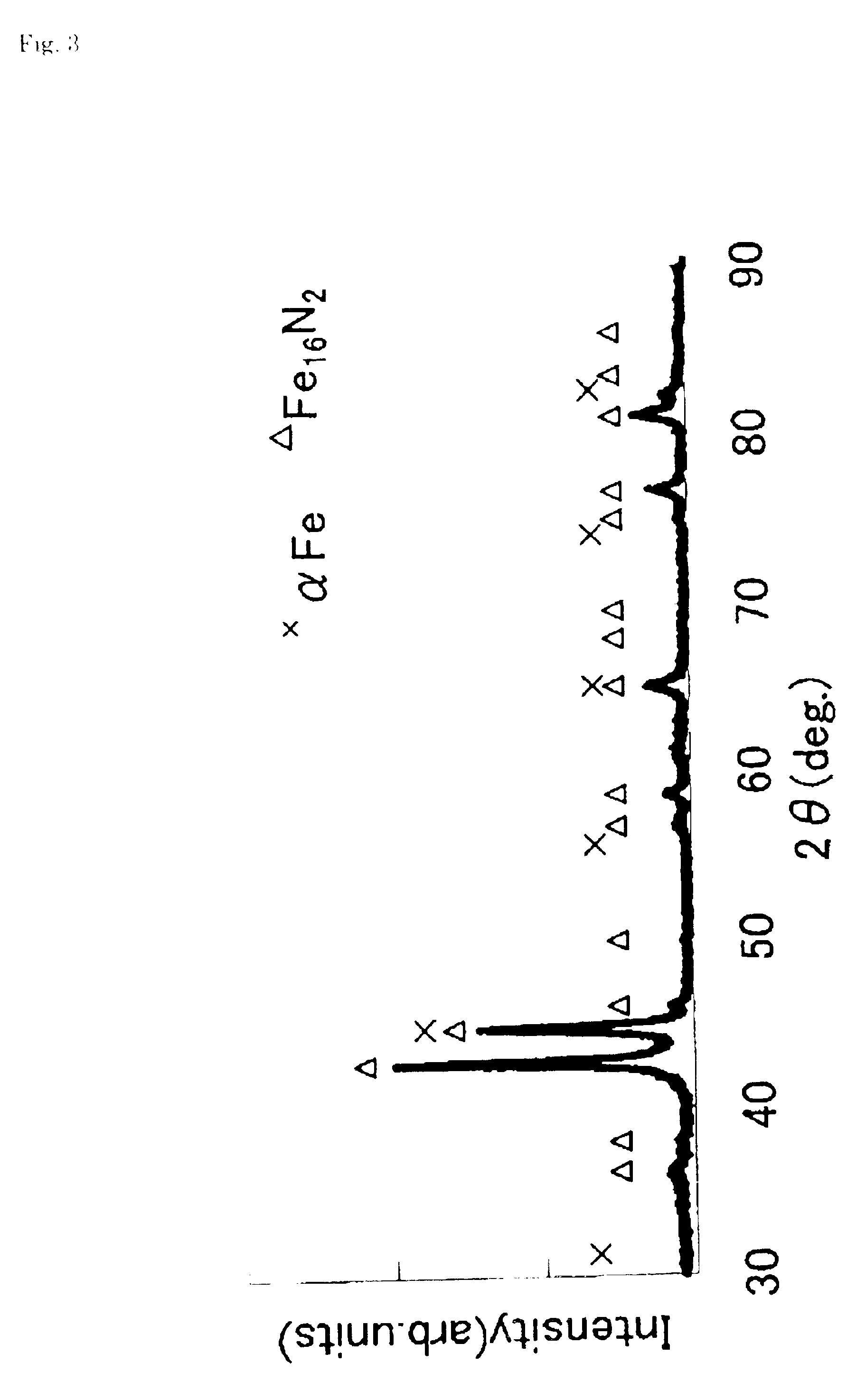

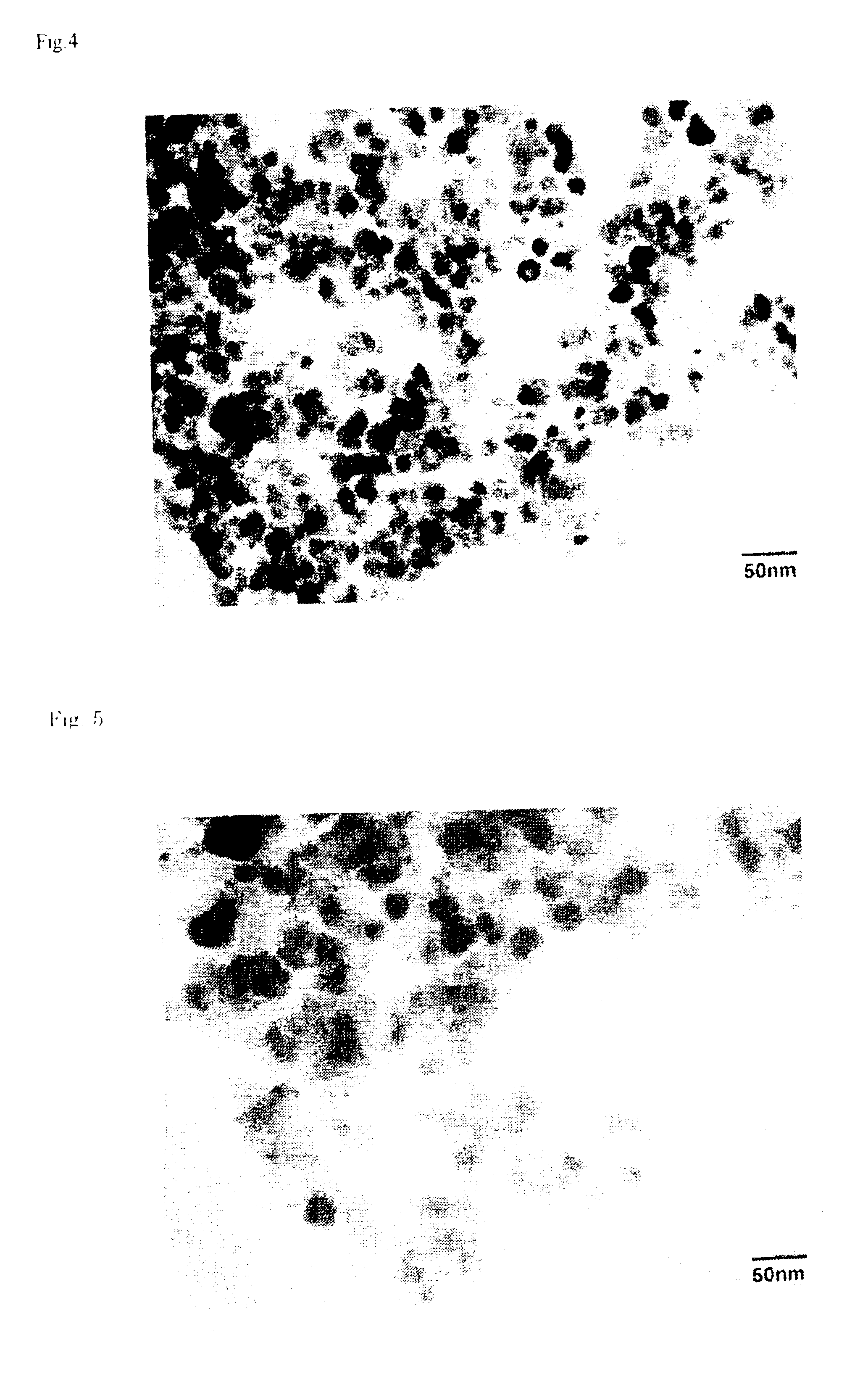

Magnetic powder, method for producing the same and magnetic recording medium comprising the same

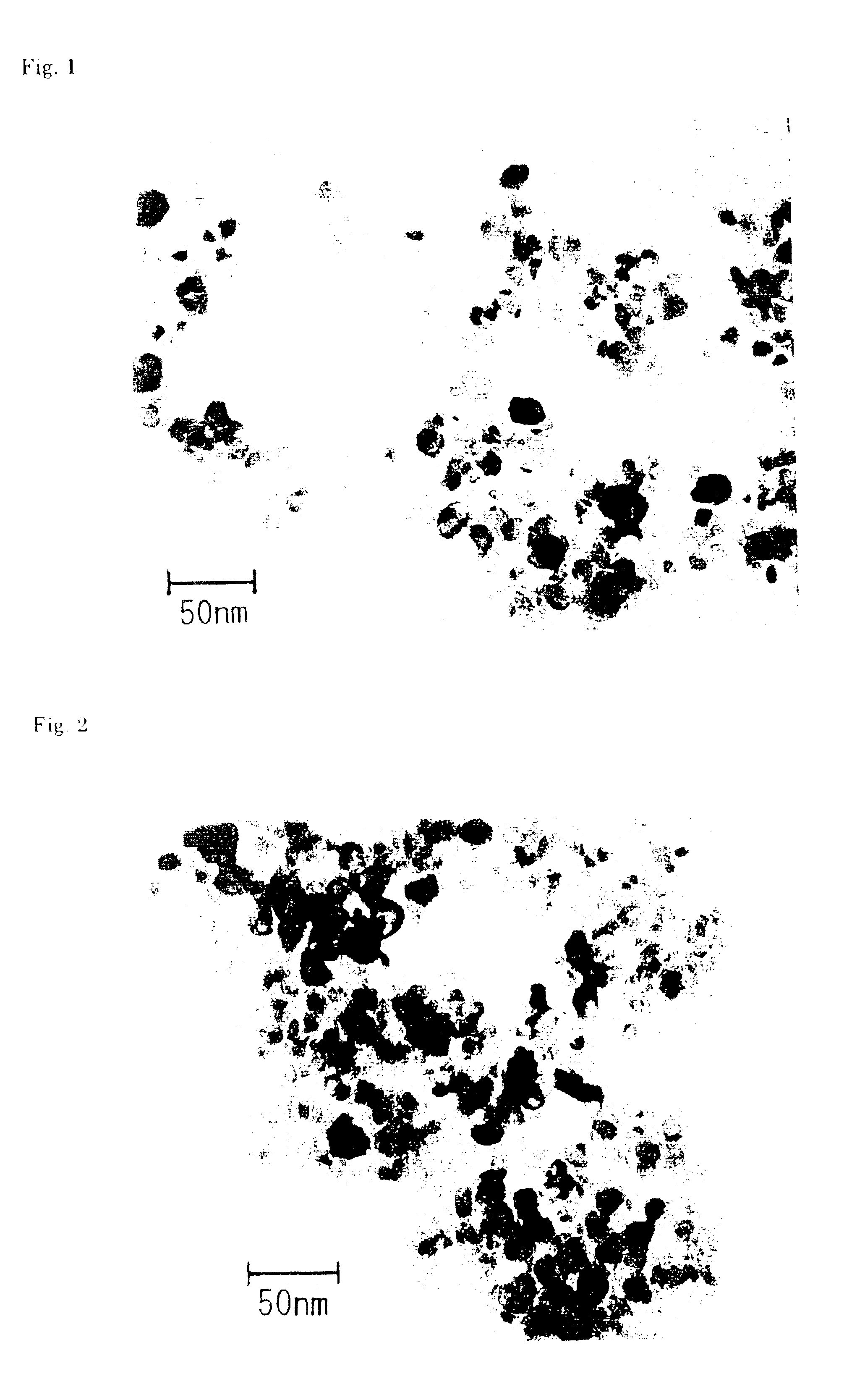

InactiveUS6964811B2Recording characteristicImprove recording effectMaterials with ironNanomagnetismEllipsoidal particleMagnetization

A magnetic powder consisting of substantially spherical or ellipsoidal particles comprising a transition metal which comprises iron and a rear earth element which is mainly present in the outer layer of the magnetic powder particles, and having a particle size of 5 to 200 nm, a coercive force of 80 to 400 kA / m and a saturation magnetization of 10 to 25 uWb / g.

Owner:FUJIFILM CORP

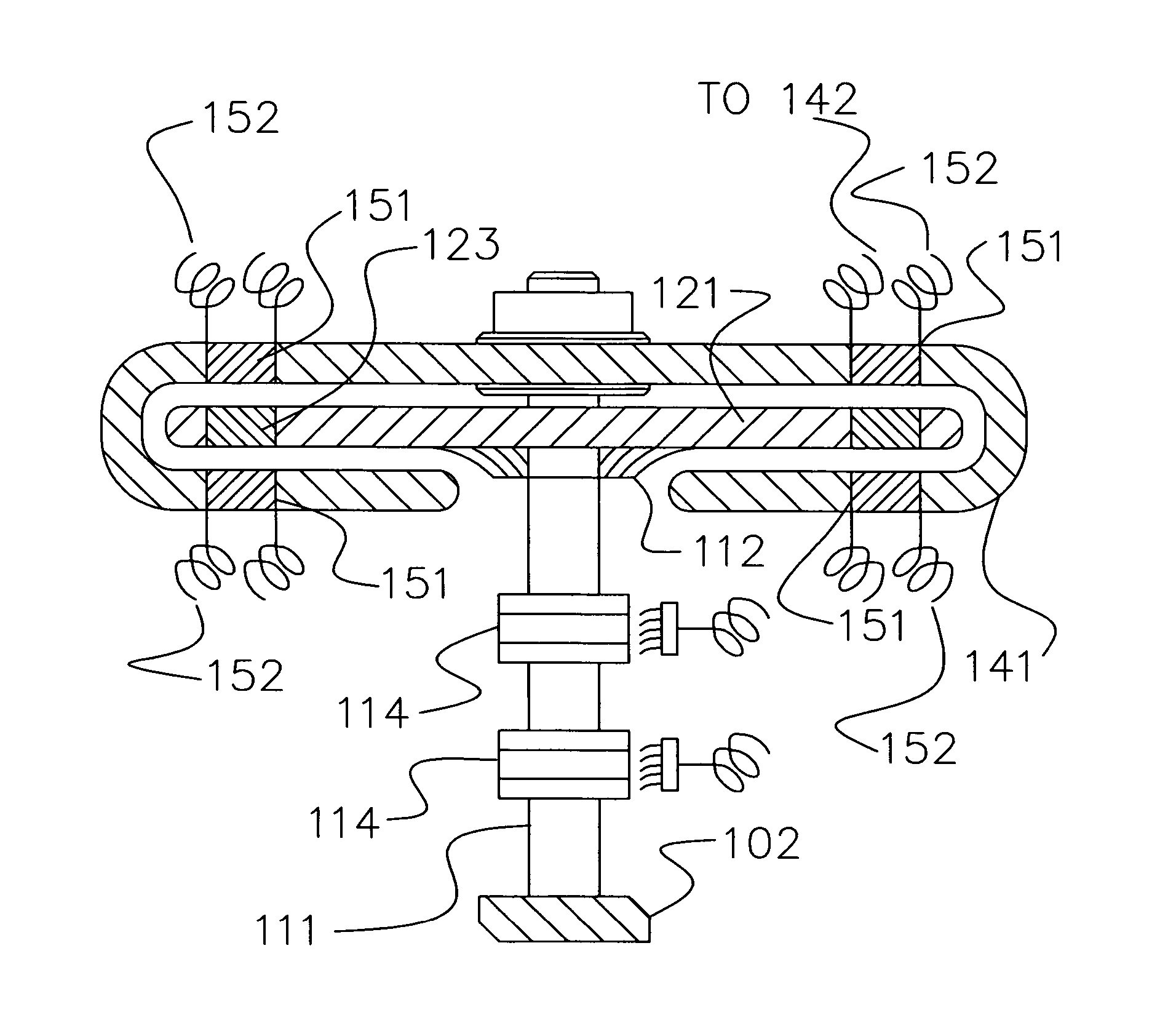

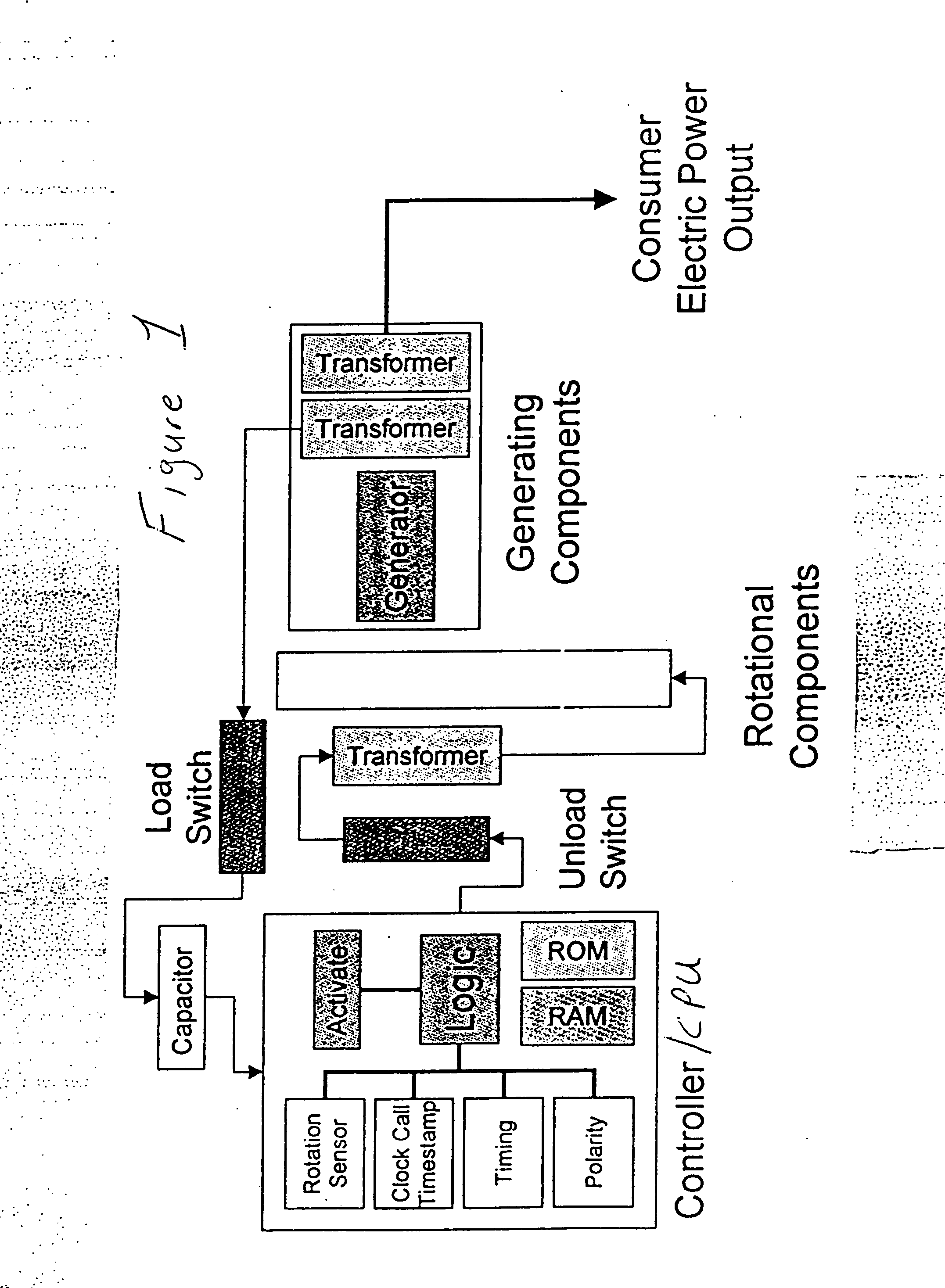

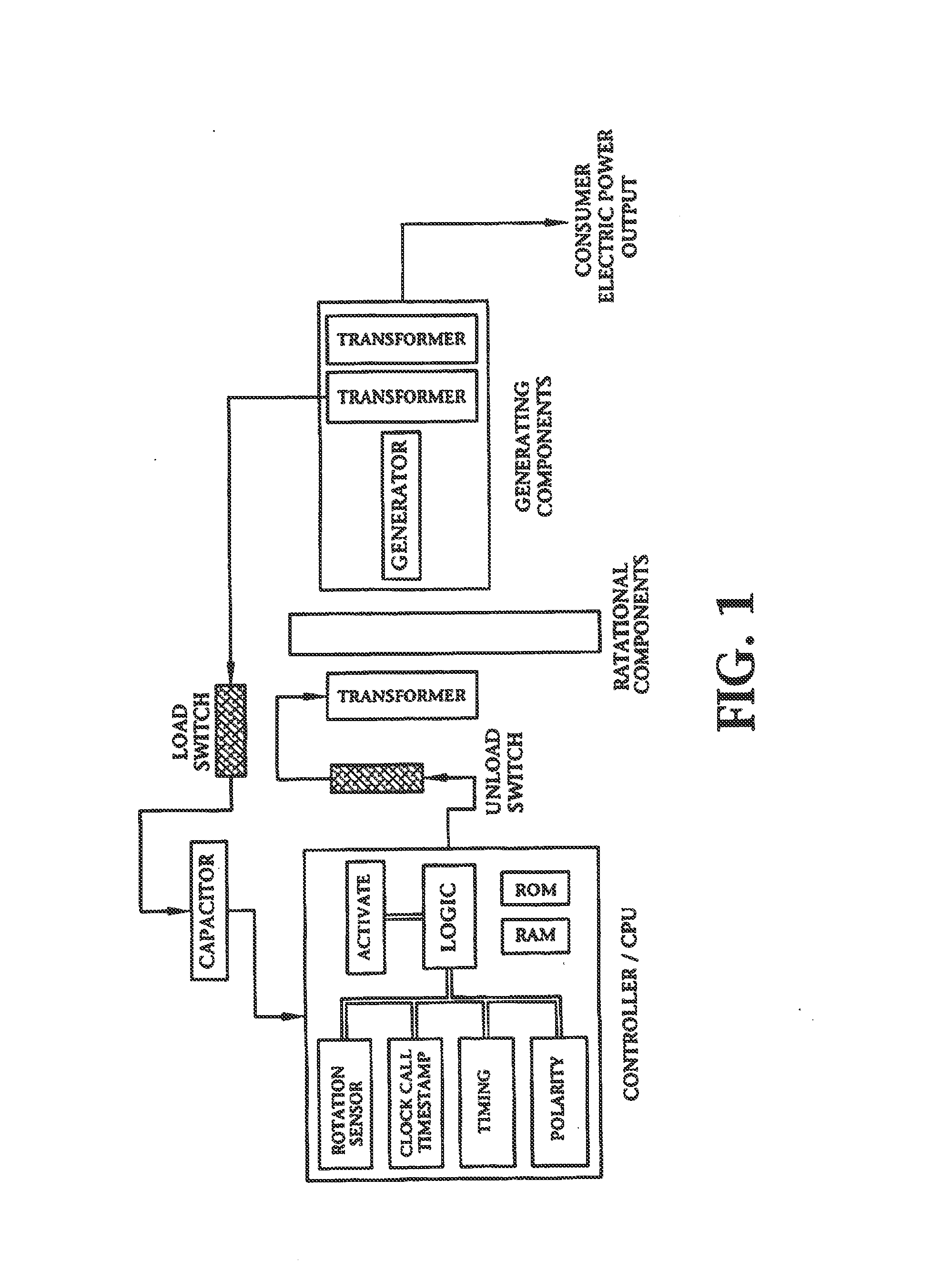

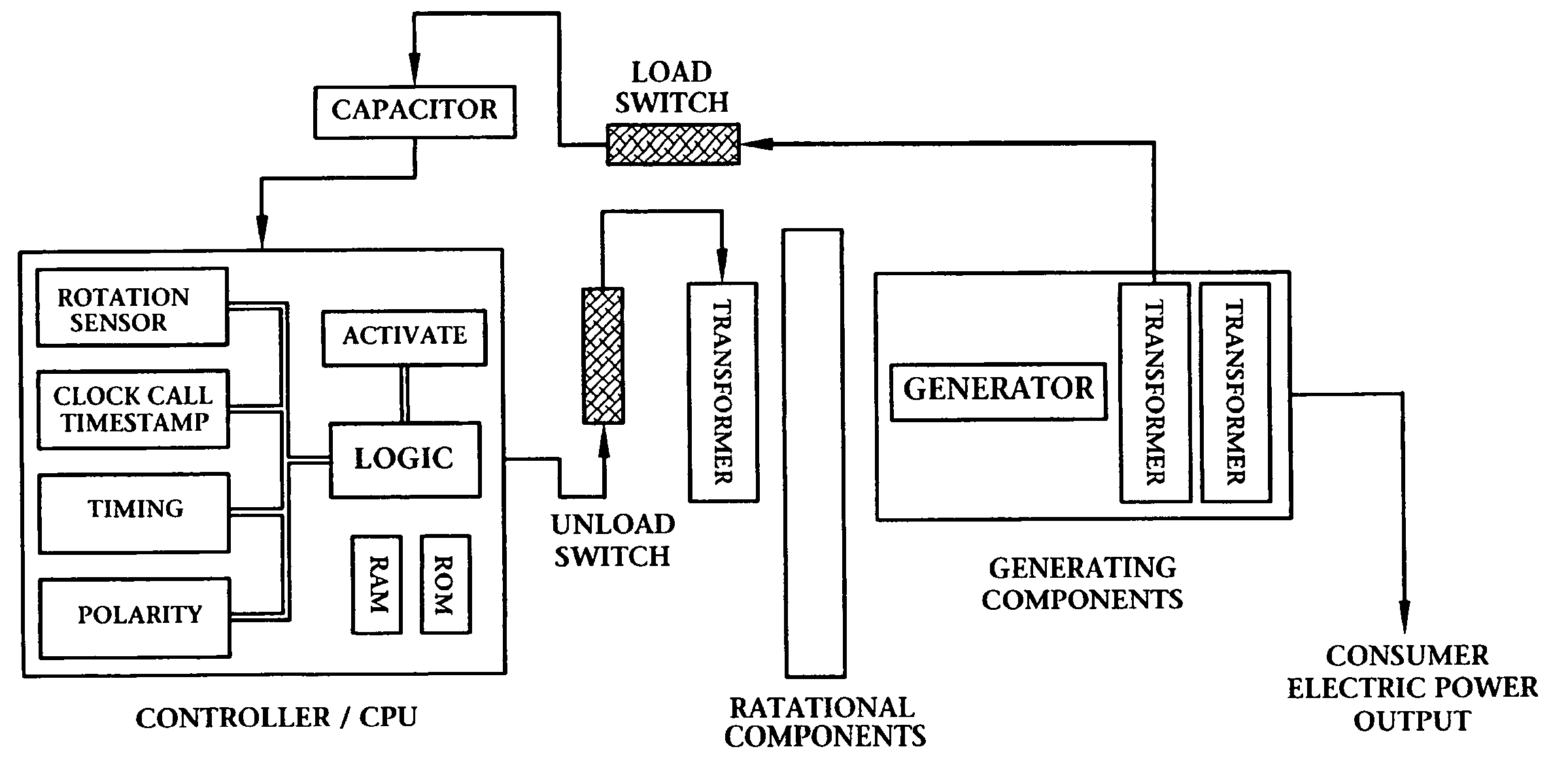

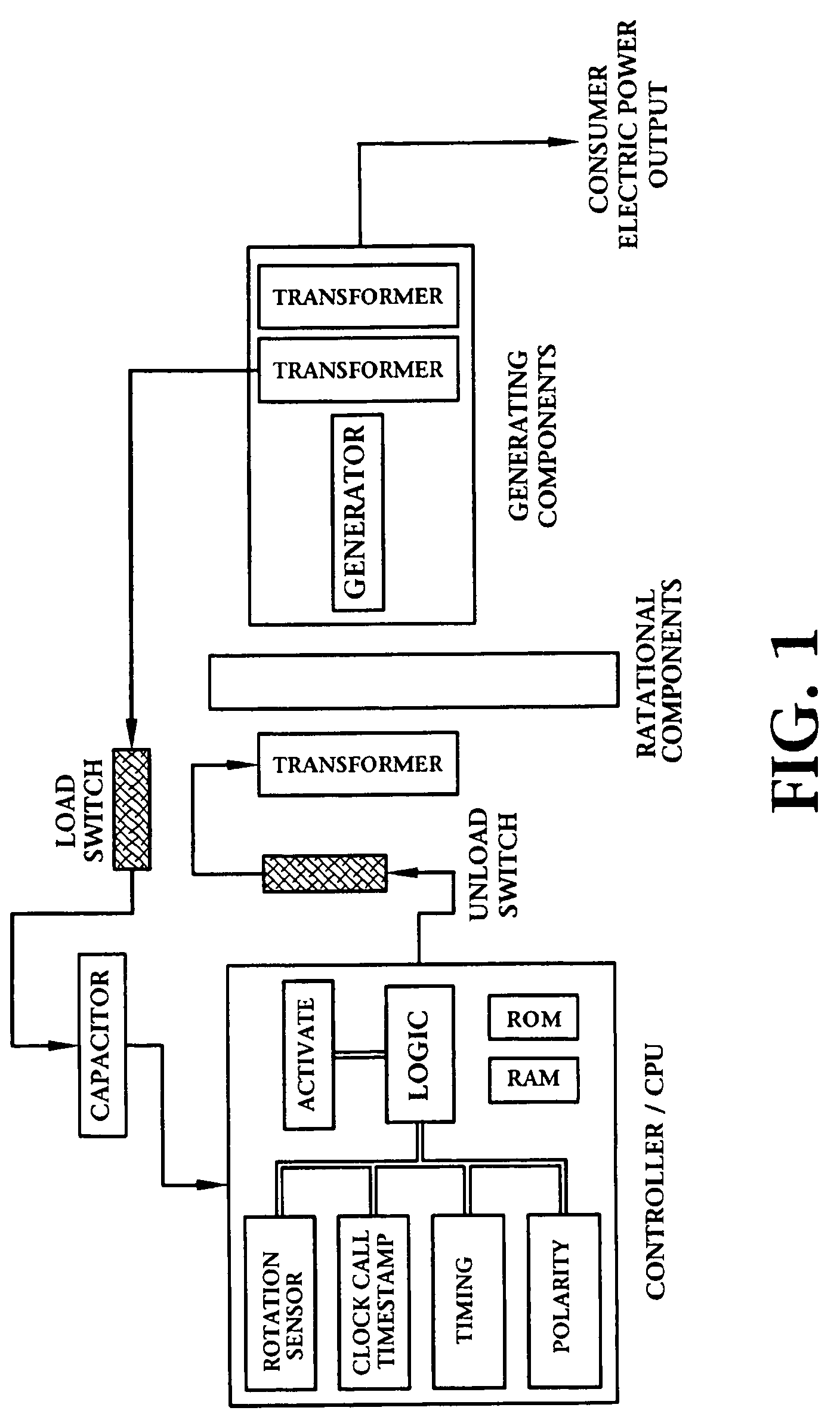

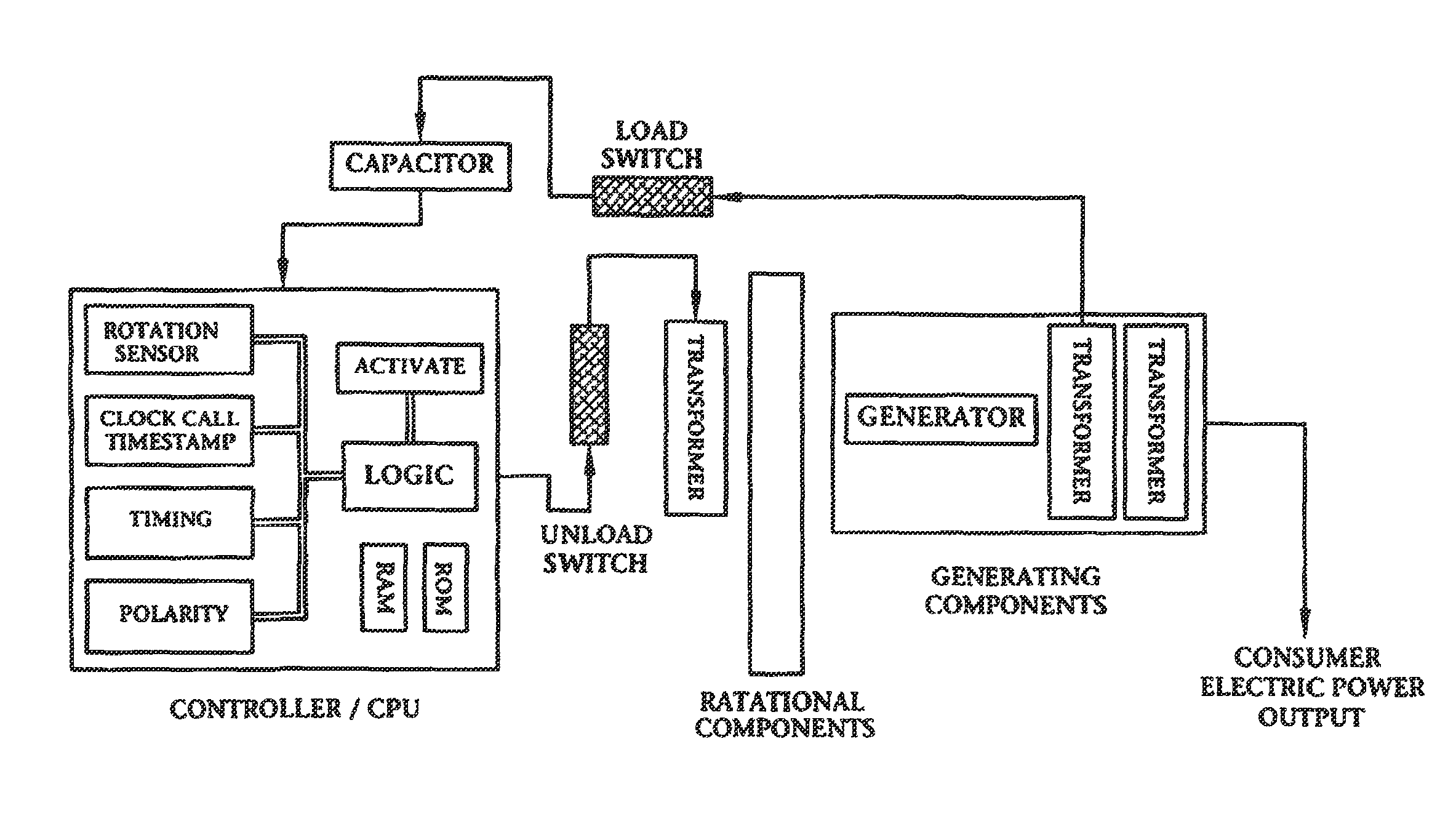

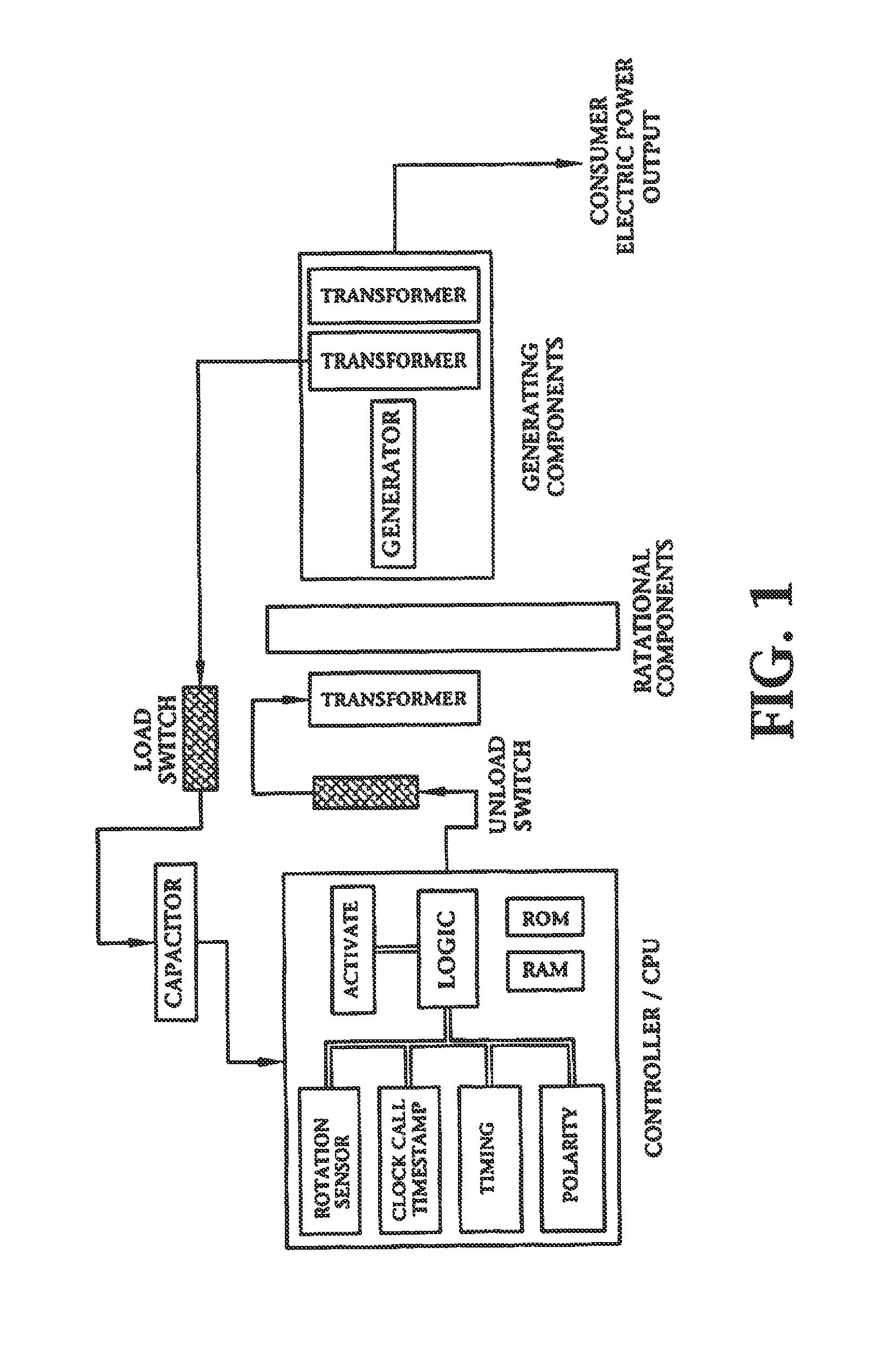

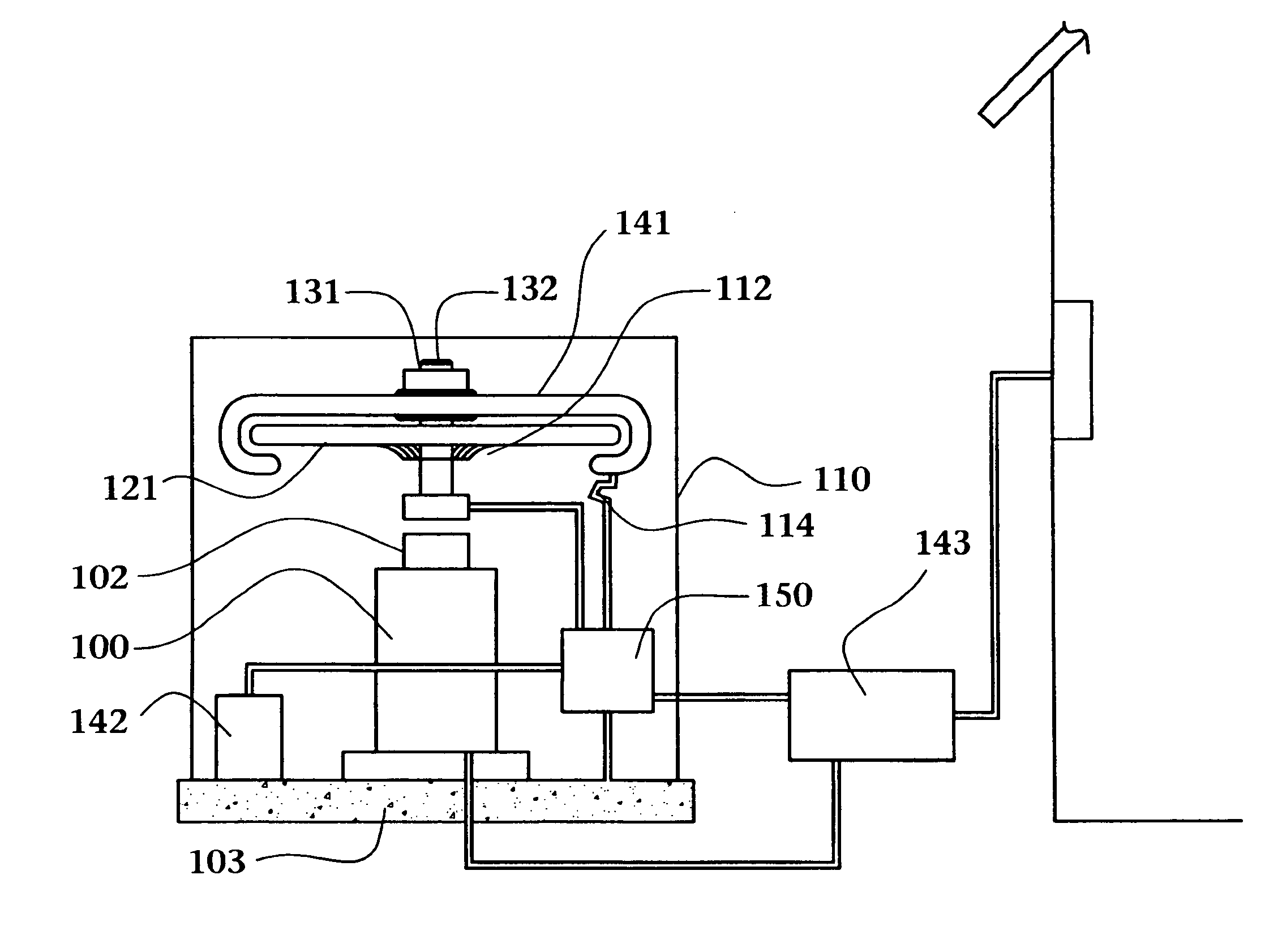

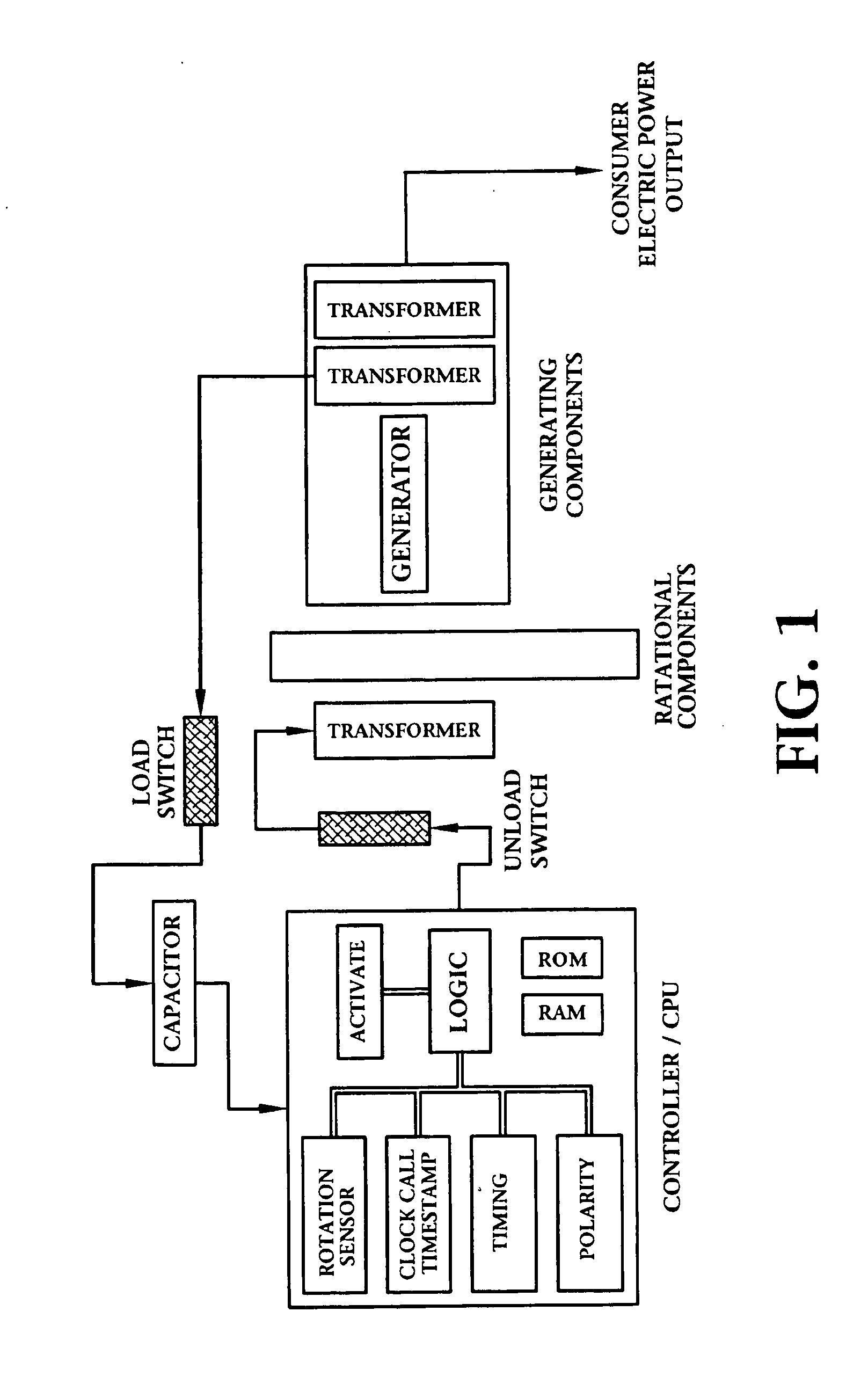

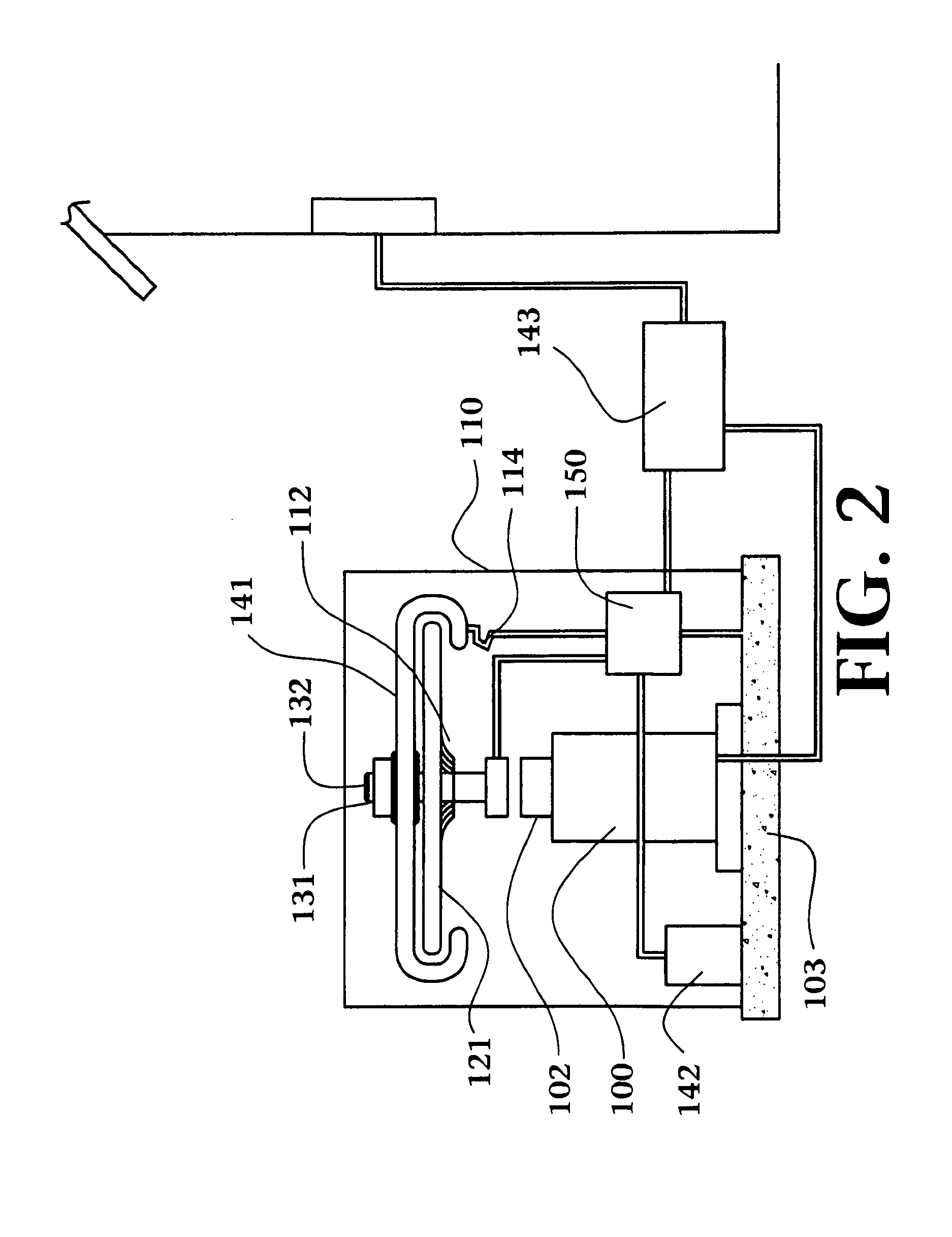

Electro-motive machine using halbach array

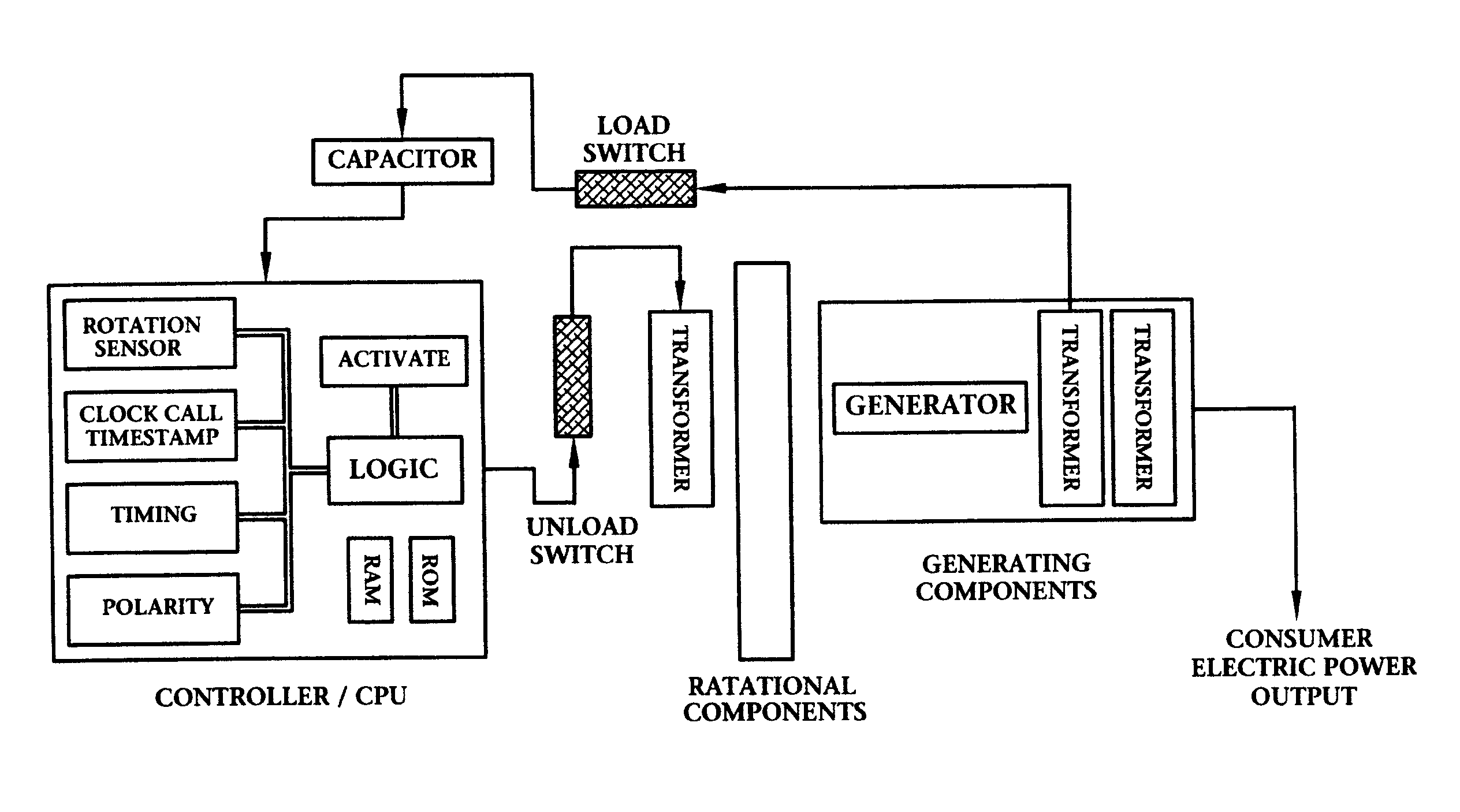

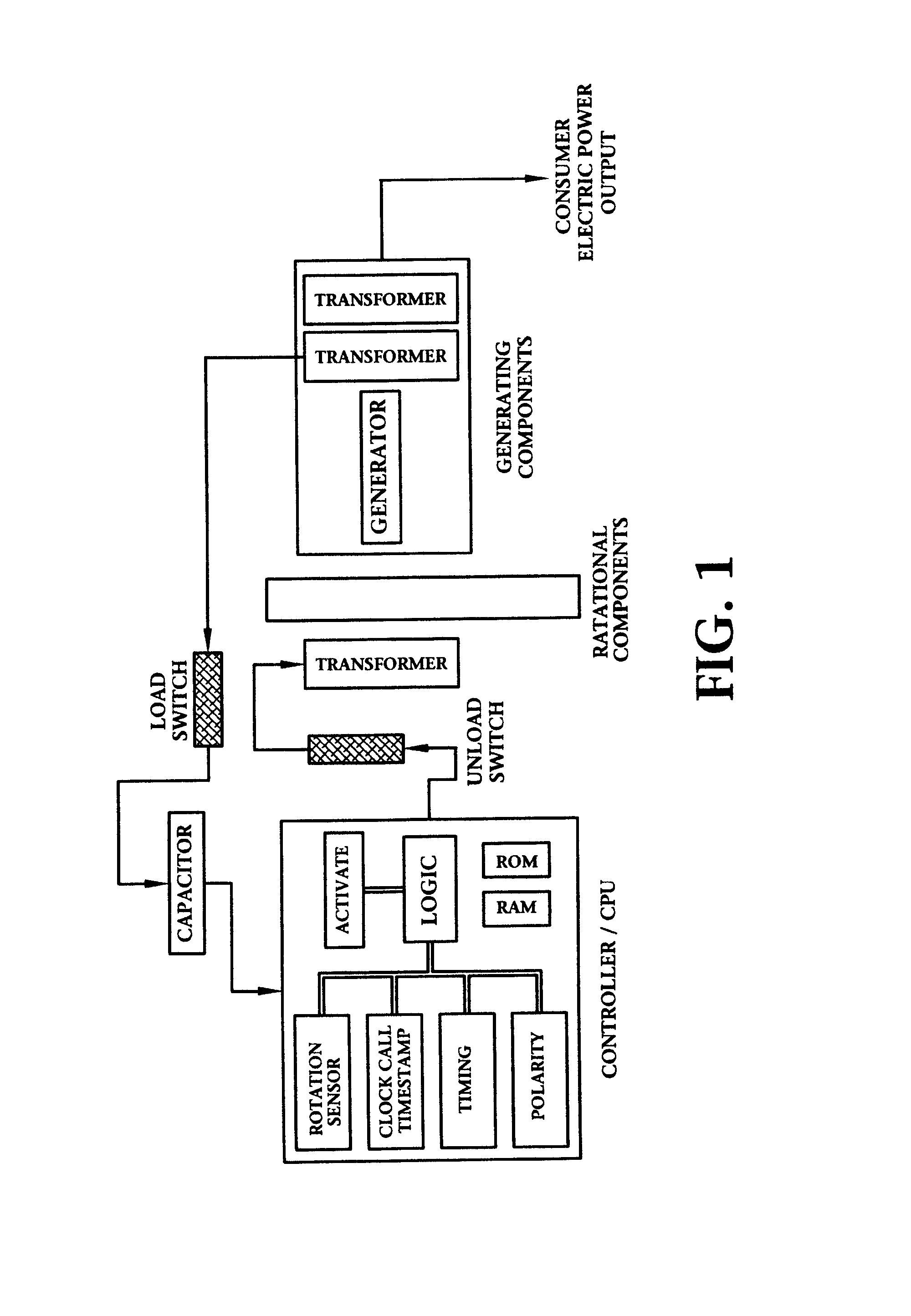

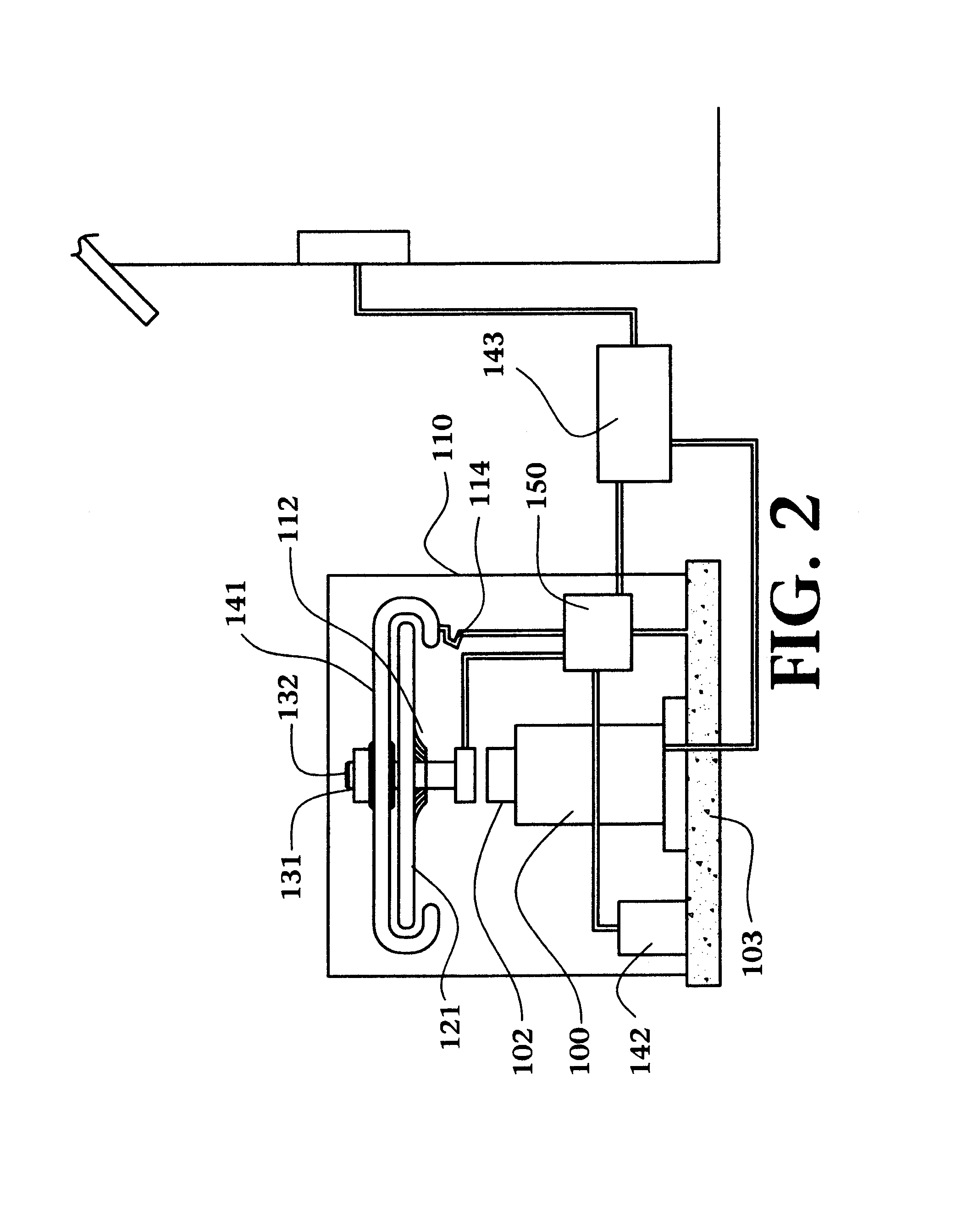

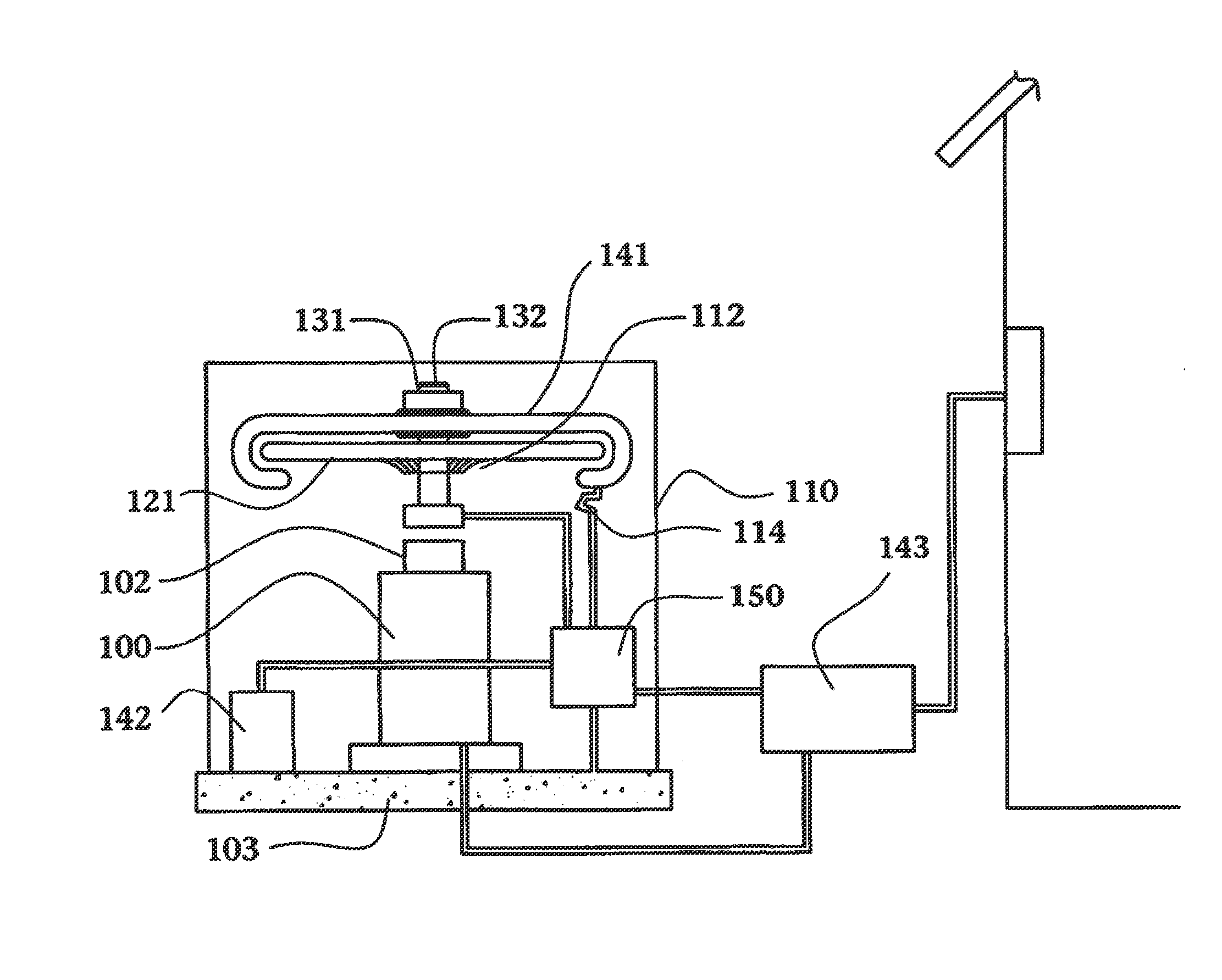

InactiveUS20070029889A1Fast magnetizationIncrease polarityMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsEngineeringRotational energy

A Halbach array is radially disposed in an environment optimized for efficiency and controlled for efficient generation and use of power in order to generate, establish, and maintain a desired level of rotational energy with enhanced efficiency.

Owner:DUNN TOM +3

Magnetic memory

ActiveUS8077509B2Reduce variationReduce reverse currentApparatus for flat record carriersMechanical record carriersMagnetizationMagnetic memory

A magnetic memory is provided with a memory cell. The memory cell includes a magnetic recording element, an interconnection to generate a radio-frequency current-induced magnetic field and a ground line. The magnetic recording element is provided with a first magnetic layer whose magnetization direction is substantially fixed, a magnetic recording layer whose magnetization direction is substantially reversed by spin-polarized electrons passing through the magnetic recording layer and a first nonmagnetic layer provided between the first magnetic layer and the magnetic recording layer. The interconnection is provided above the magnetic recording element to generate a radio-frequency current-induced magnetic field acting in a direction substantially perpendicular to a magnetization easy axis of the magnetic recording layer. The ground line is provided on a side opposite to the magnetic recording element with respect to the interconnection.

Owner:KIOXIA CORP

Electro-motive machine using Halbach array

InactiveUS7352096B2Fast magnetizationIncrease polarityMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsRotational energyEngineering

A Halbach array is radially disposed in an environment optimized for efficiency and controlled for efficient generation and use of power in order to generate, establish, and maintain a desired level of rotational energy with enhanced efficiency.

Owner:DUNN TOM +3

Magnetic terylene fibre and producing method thereof

InactiveCN101168865AMagnetic long-lastingImproving the role of healthcareMelt spinning methodsMonocomponent polyesters artificial filamentSiliconMagnetic powder

The invention relates to magnetic terylene fiber and the production method thereof. The fiber is characterized in that mixture comprises 40 to 82 percent of PET chips, 16 to 65 percent of magnetic powder, 1 to 4 percent of silicon surface activating agent, and 2 to 1 percent of modifying agent, the average particle diameter of the magnetic powder is lower than or equal to 30 nanometers; the average particle diameter of the silicon surface activating agent is lower than or equal to 65 nanometers. The production process of the fiber comprises fiber spinning material manufacturing, fiber manufacturing, and fiber magnetizing treatment. The fiber of the invention has better magnetic health care capability, and according to the difference of the modifying agent, the fiber also has antibiosis and other functions.

Owner:SHENGHONG GRP CO LTD

Electro-motive machine using halbach array electrons trapped in electromagnetic coils and using hybrid coils to harvest back electromotive force

ActiveUS20130099703A1Fast magnetizationIncrease polarityMotor/generator/converter stoppersAC motor controlRotational energyEngineering

A Halbach array is radially disposed in an environment optimized for efficiency and controlled for efficient generation and use of power in order to generate, establish, and maintain a desired level of rotational energy with enhanced efficiency and in order to make the most efficient use of electromotive forces and magnetic fields which are either intentionally created for the operation of the apparatus or which result from the operation of the apparatus.

Owner:MAGLEV ENERGY

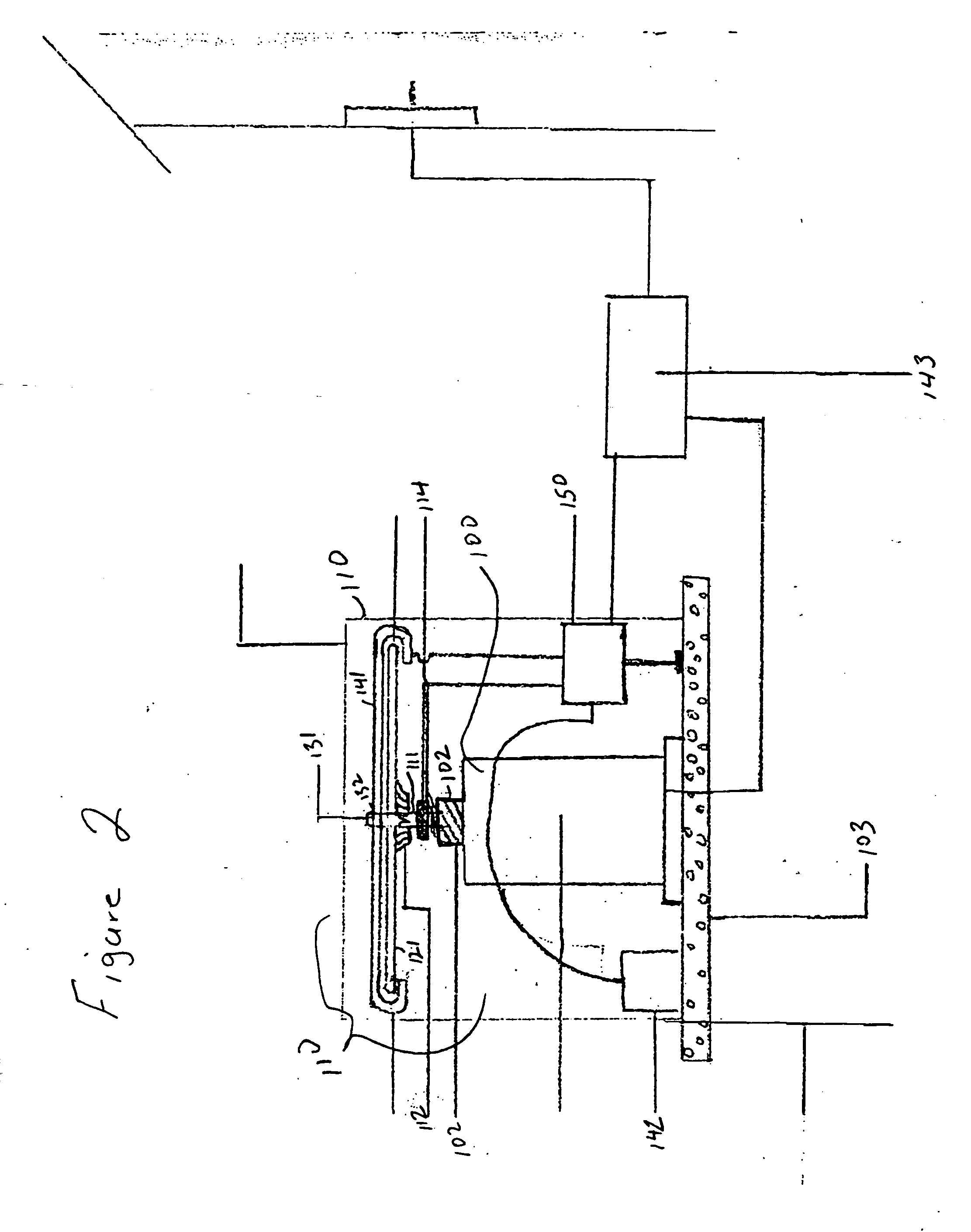

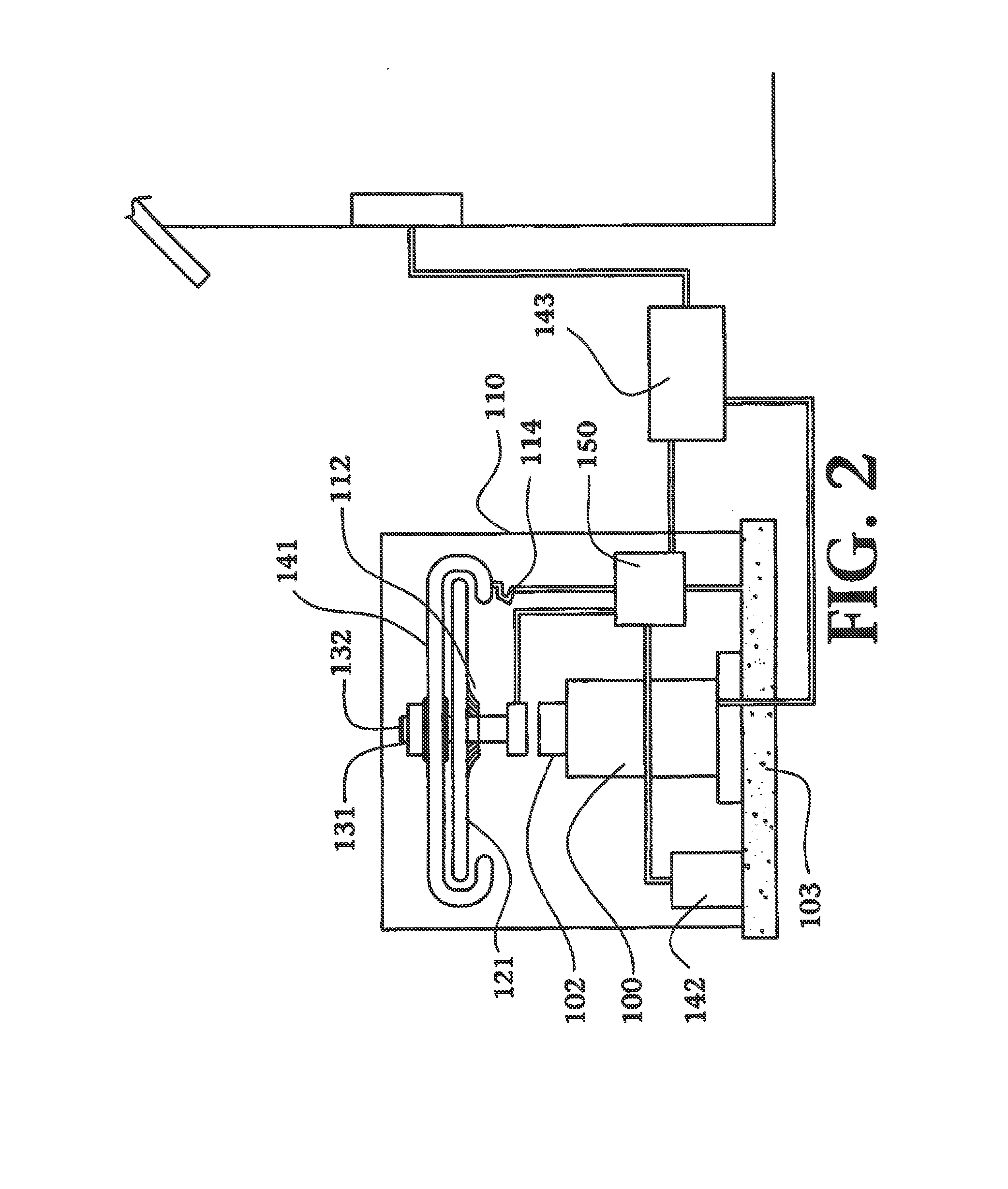

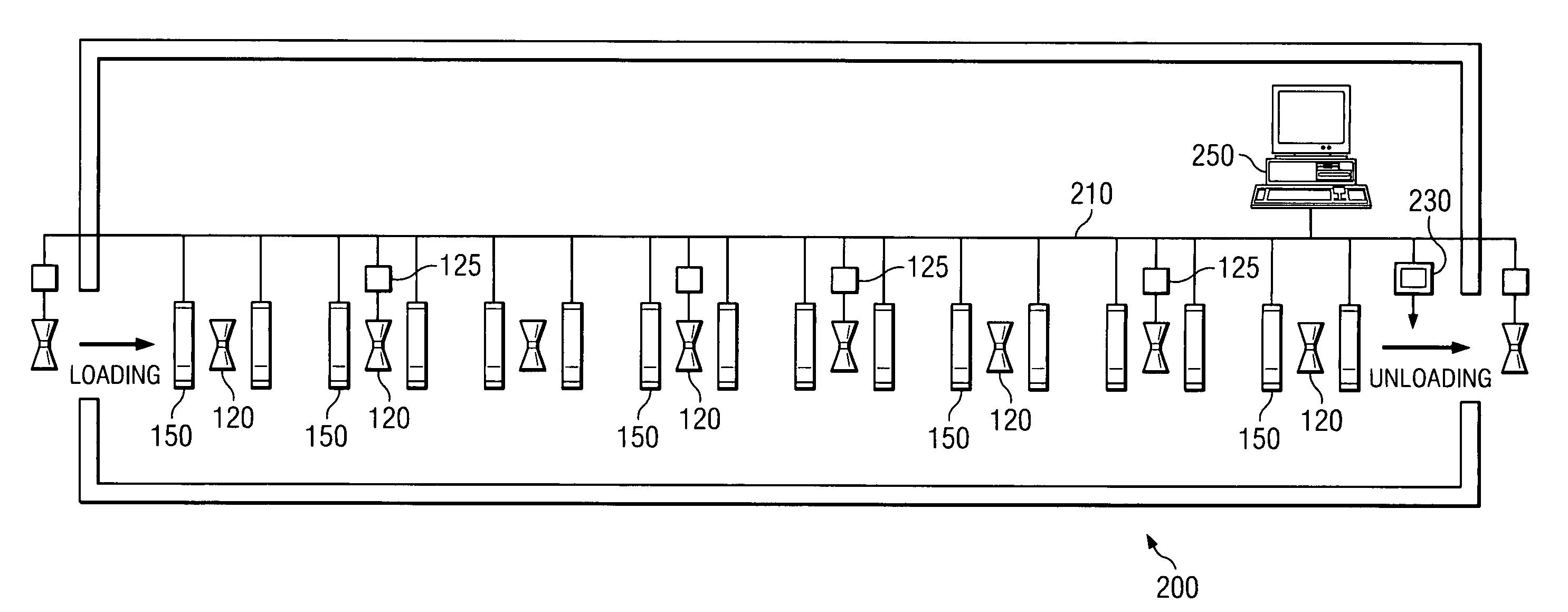

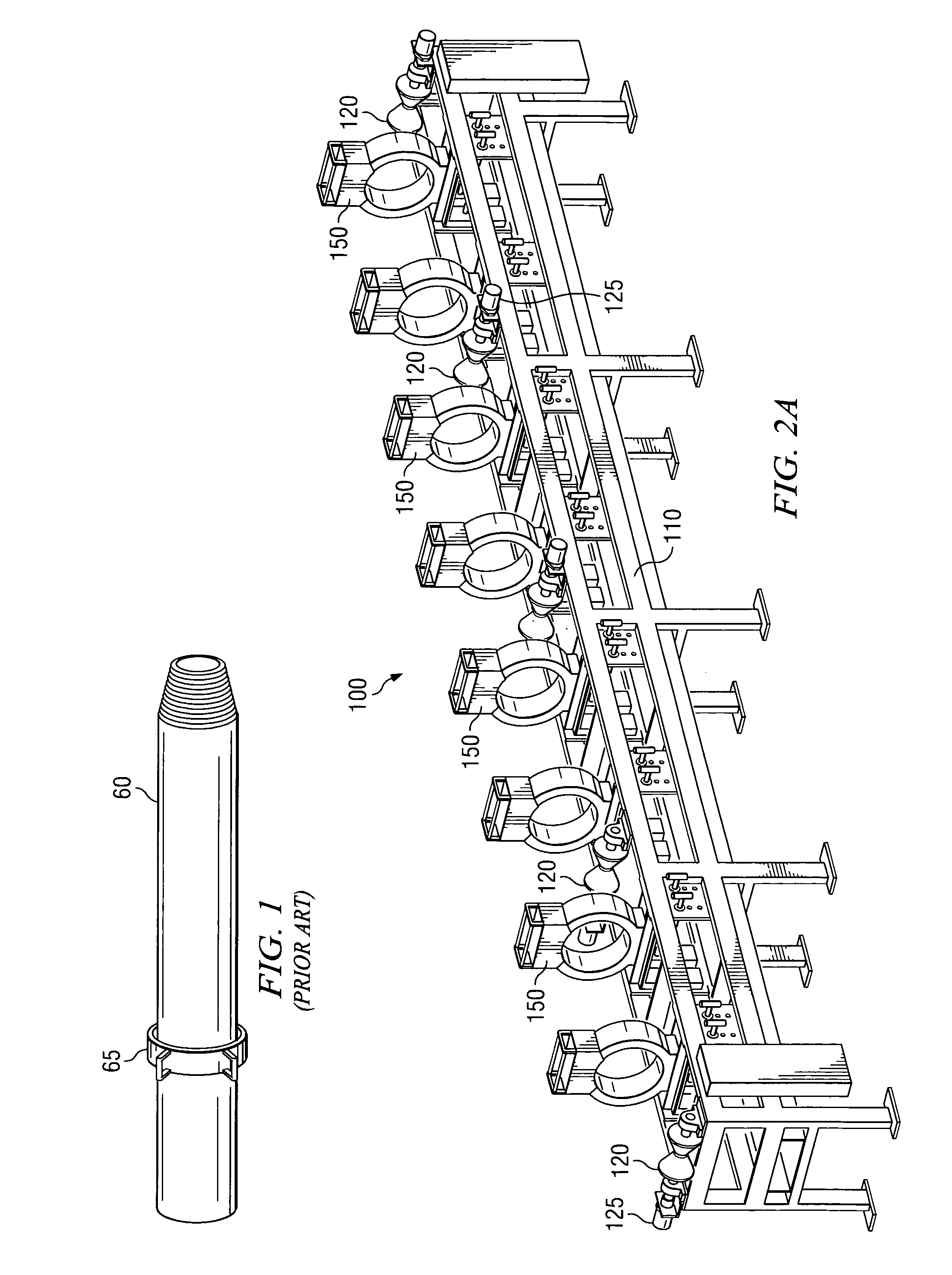

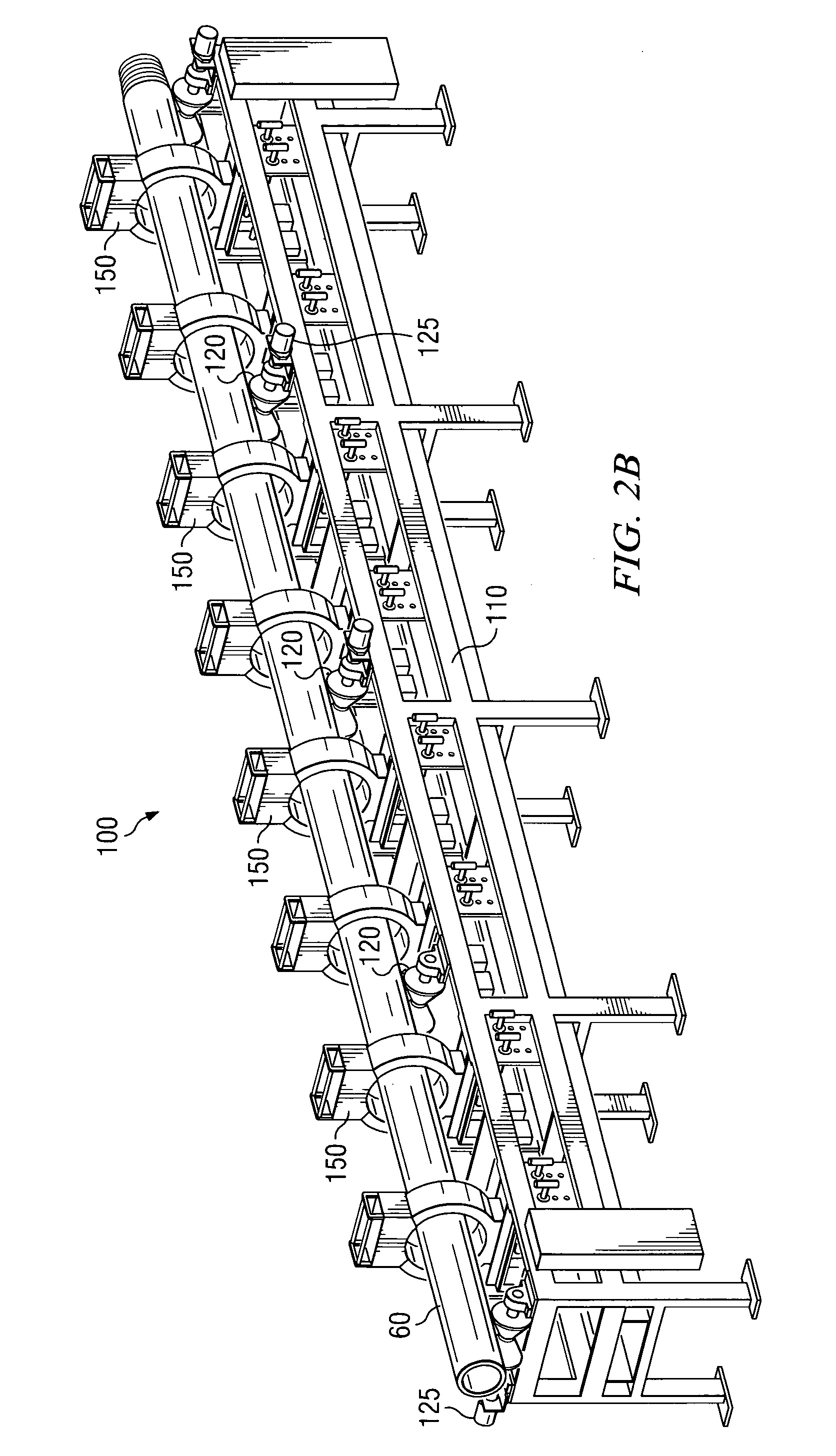

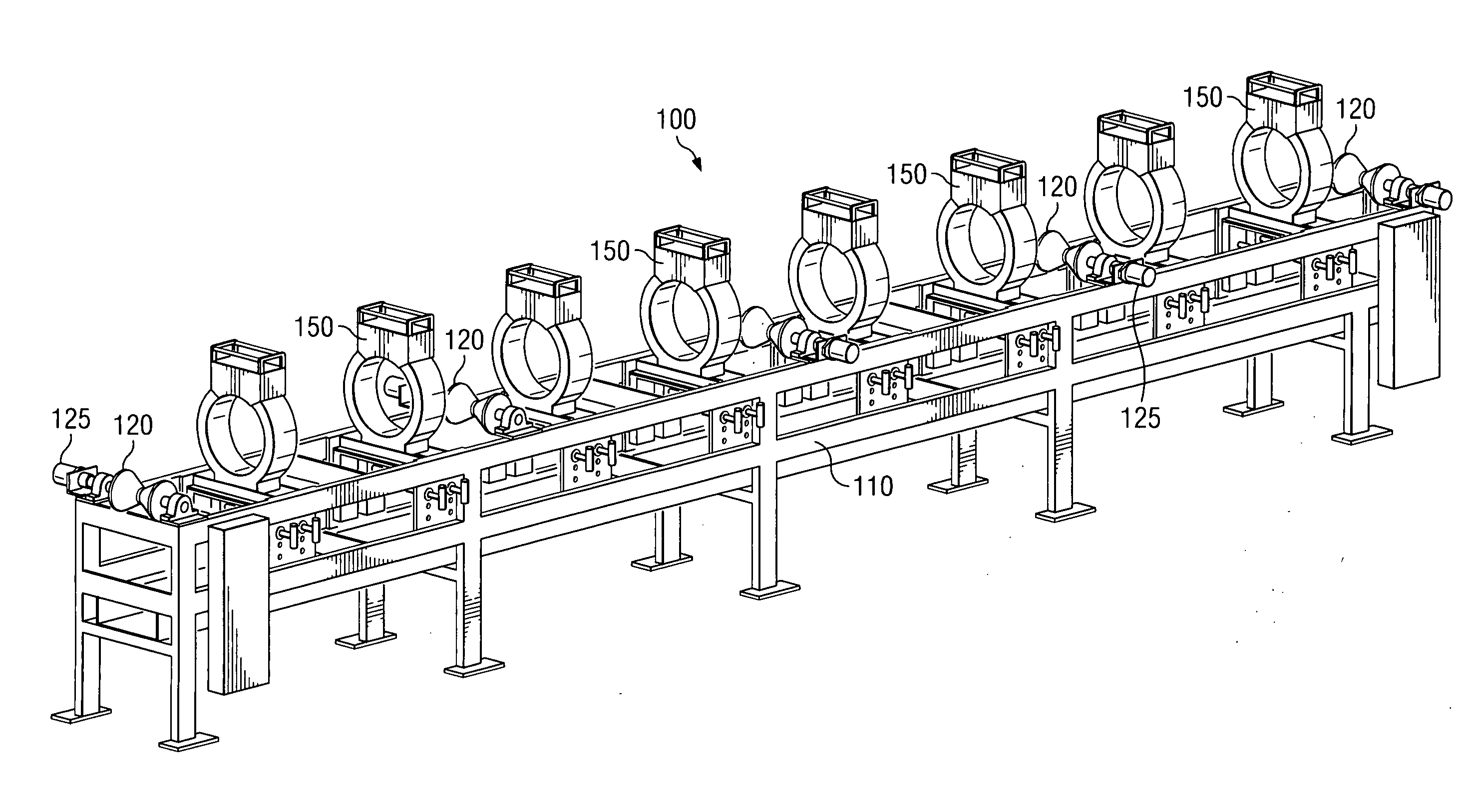

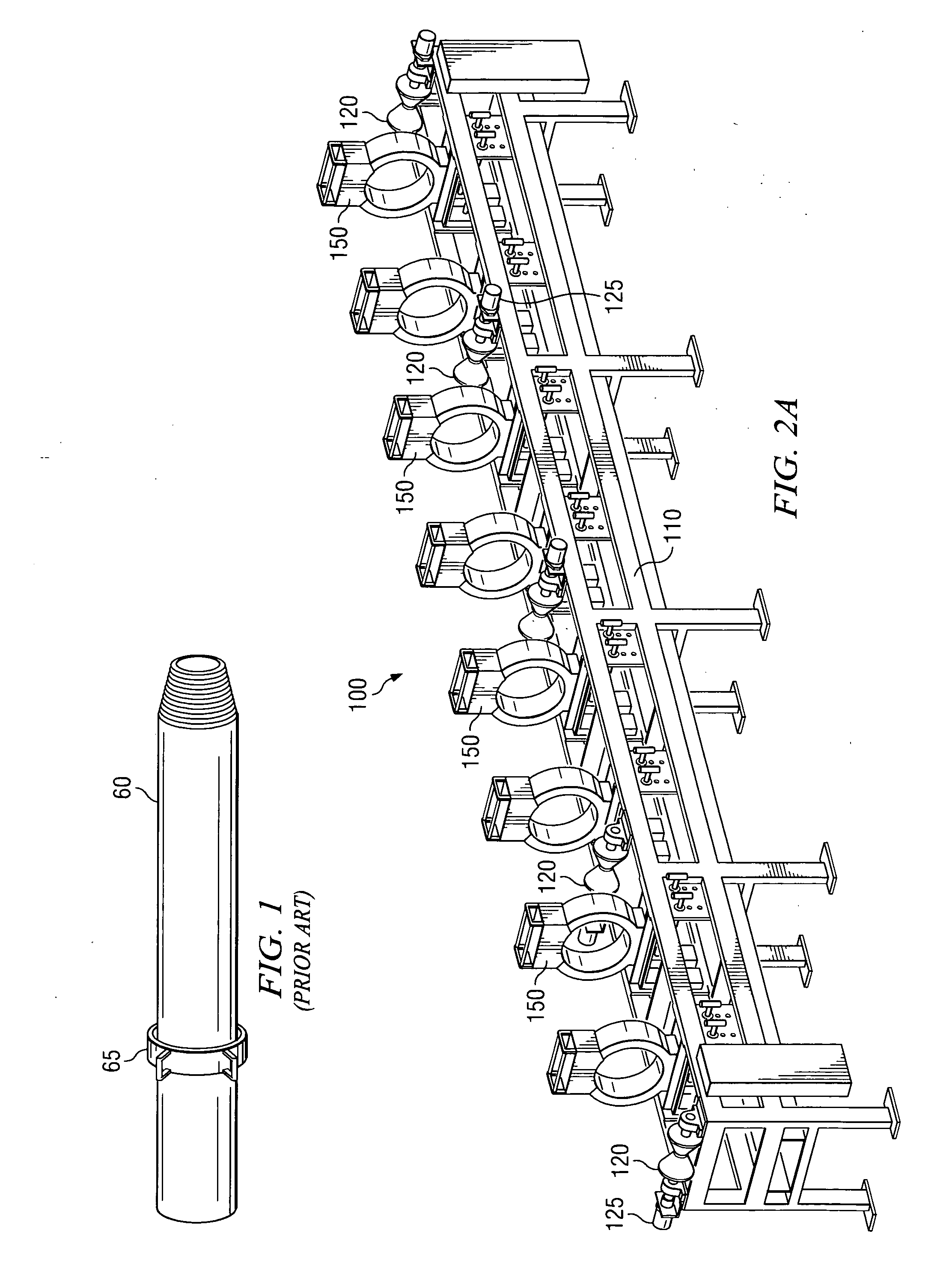

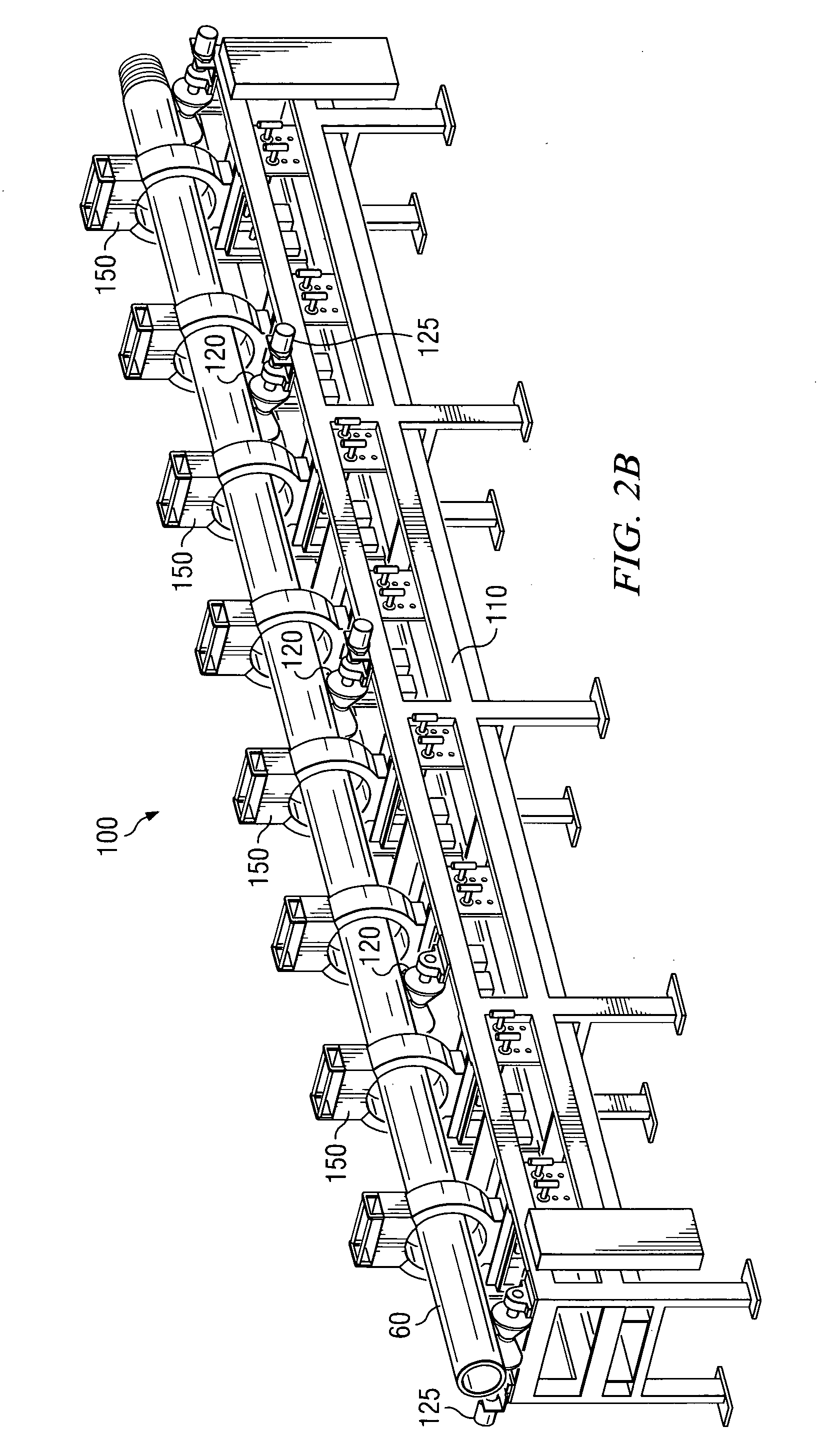

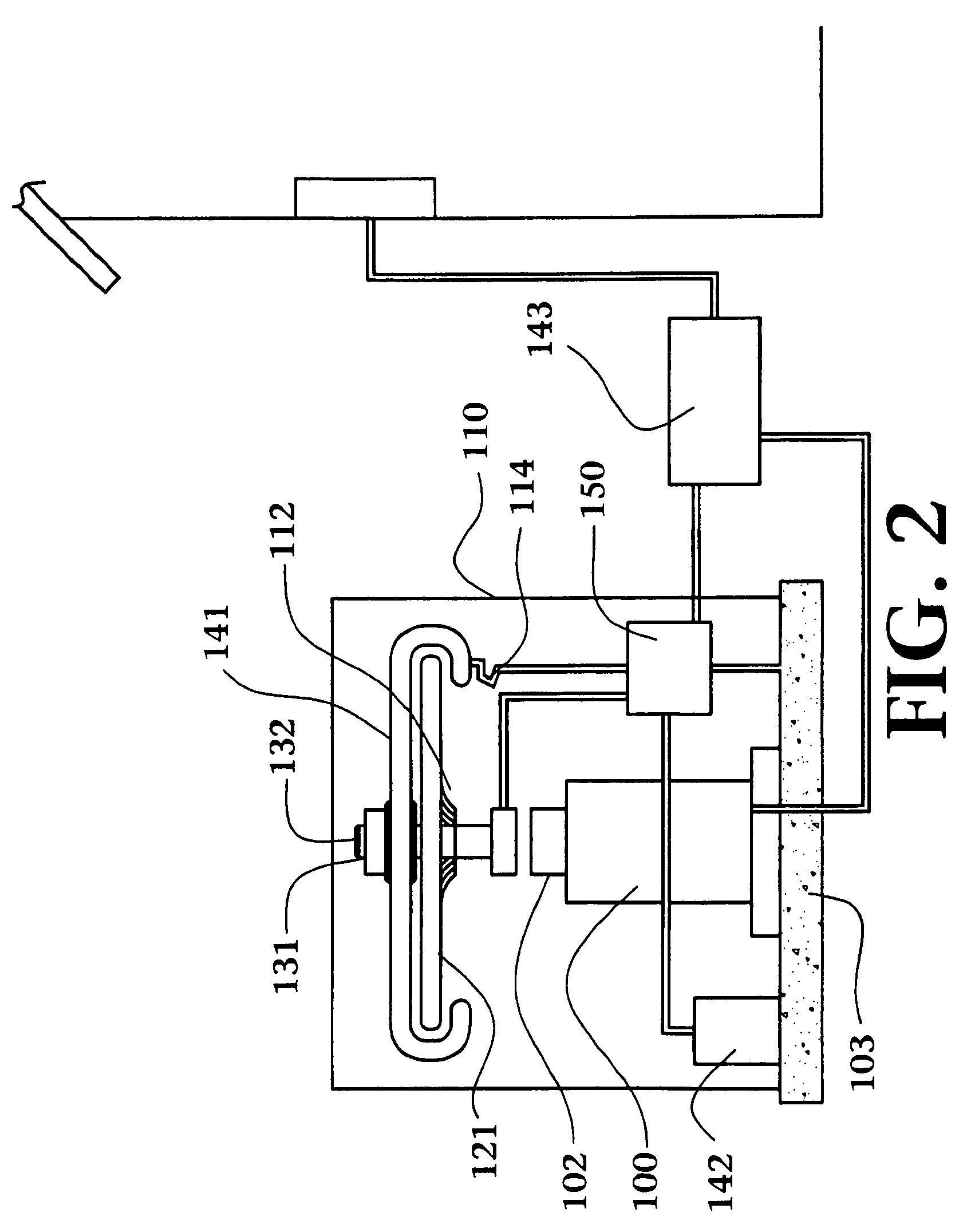

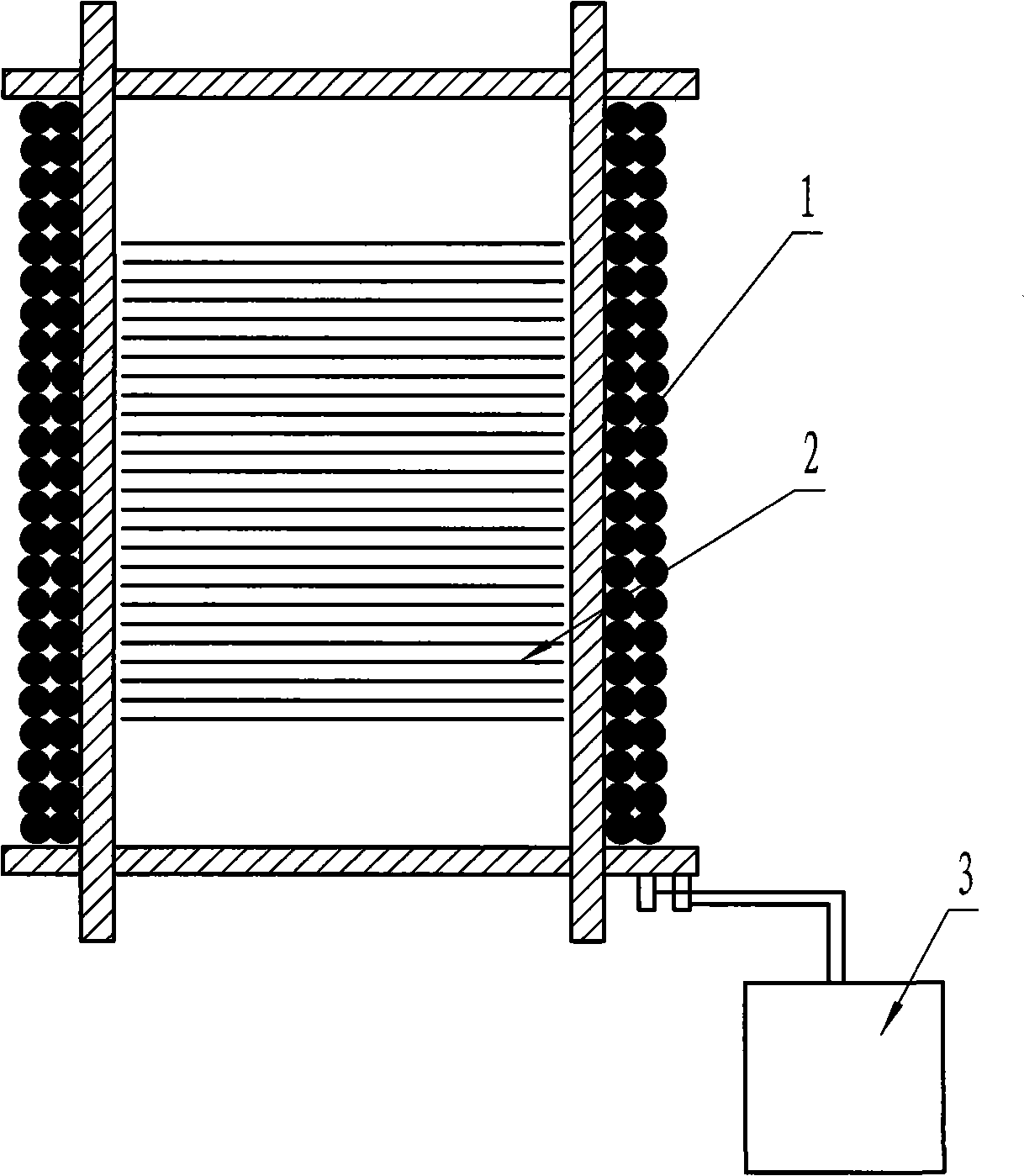

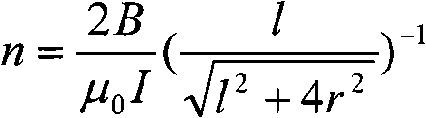

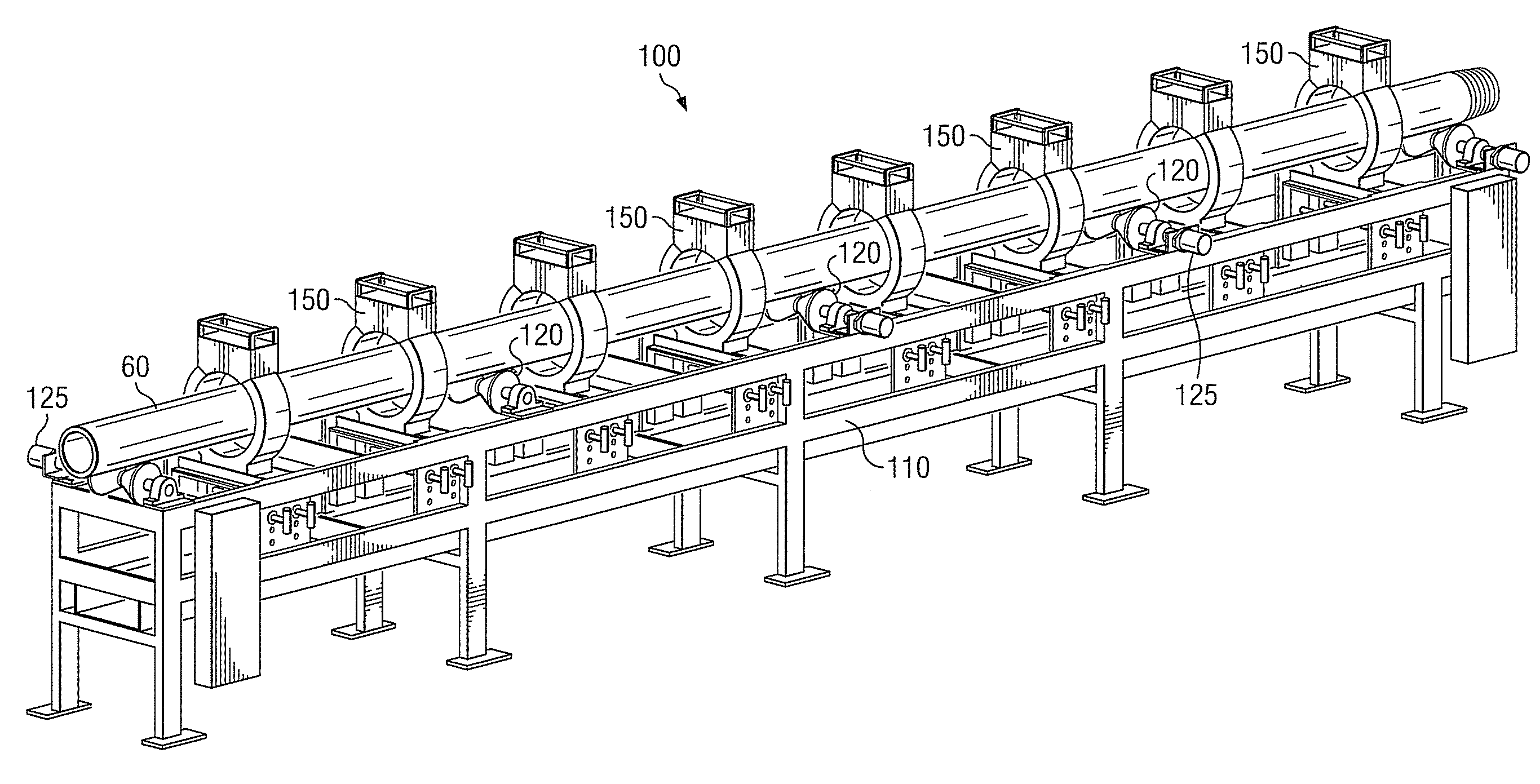

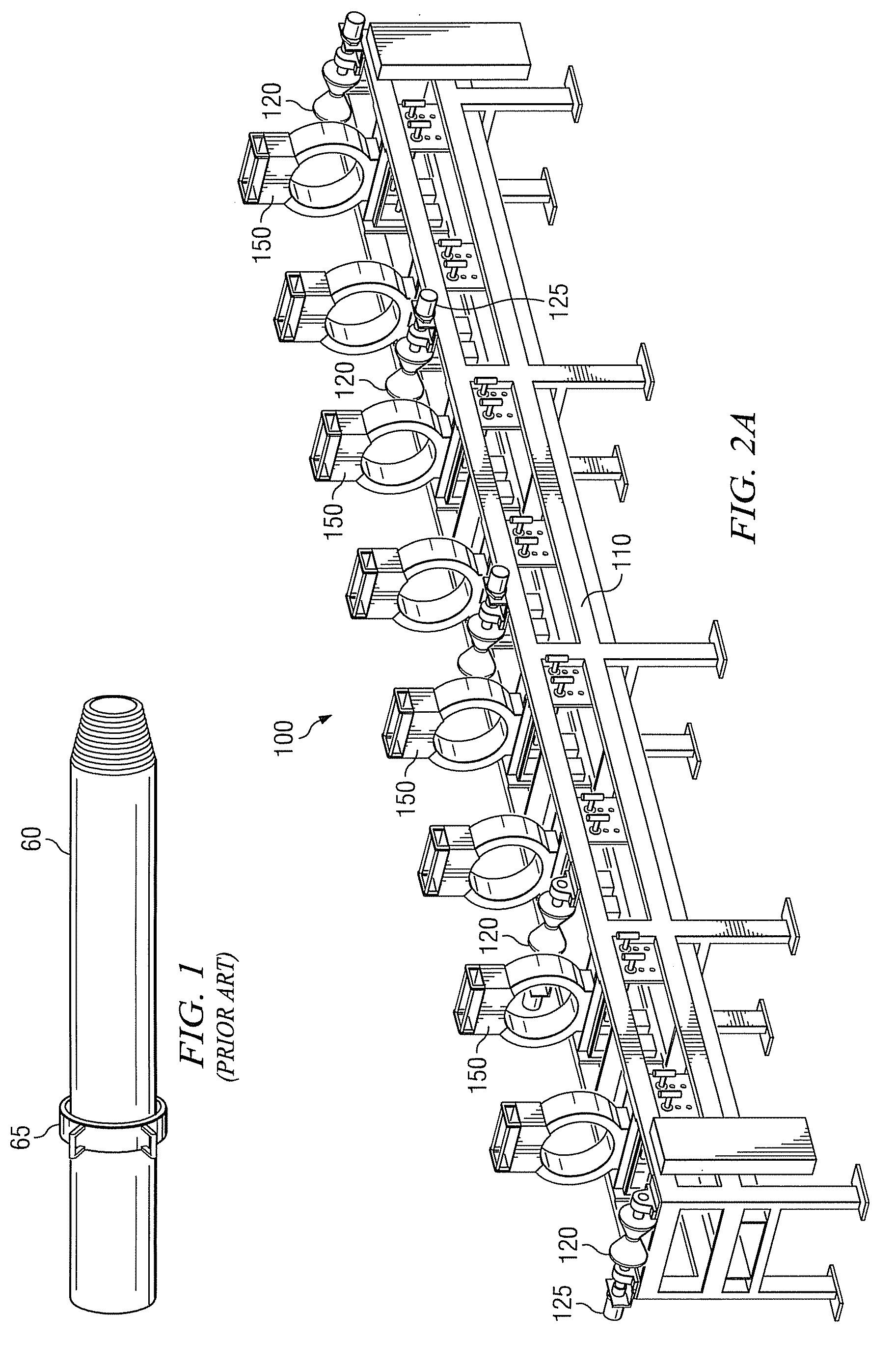

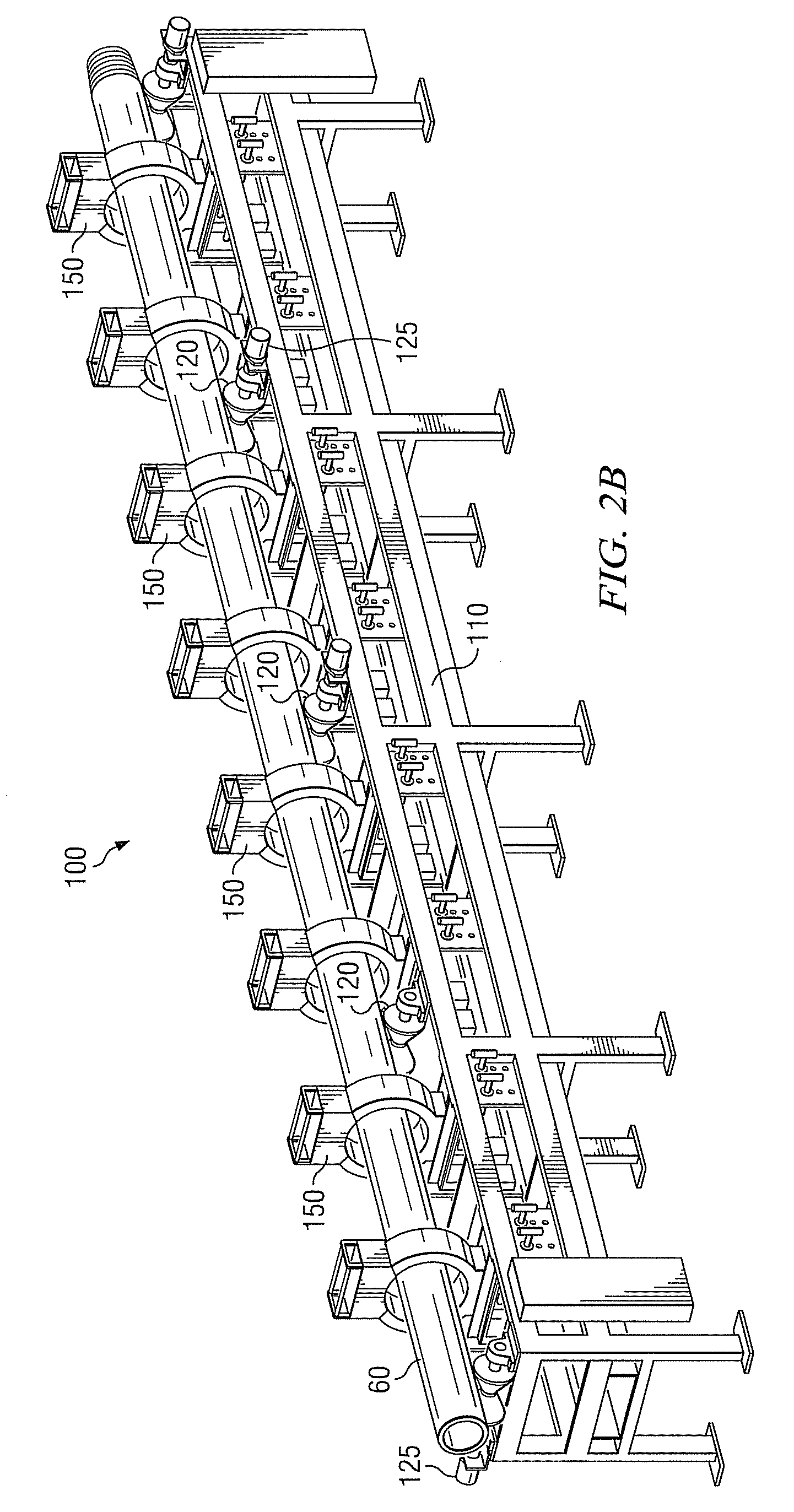

Apparatus and method for magnetizing casing string tubulars

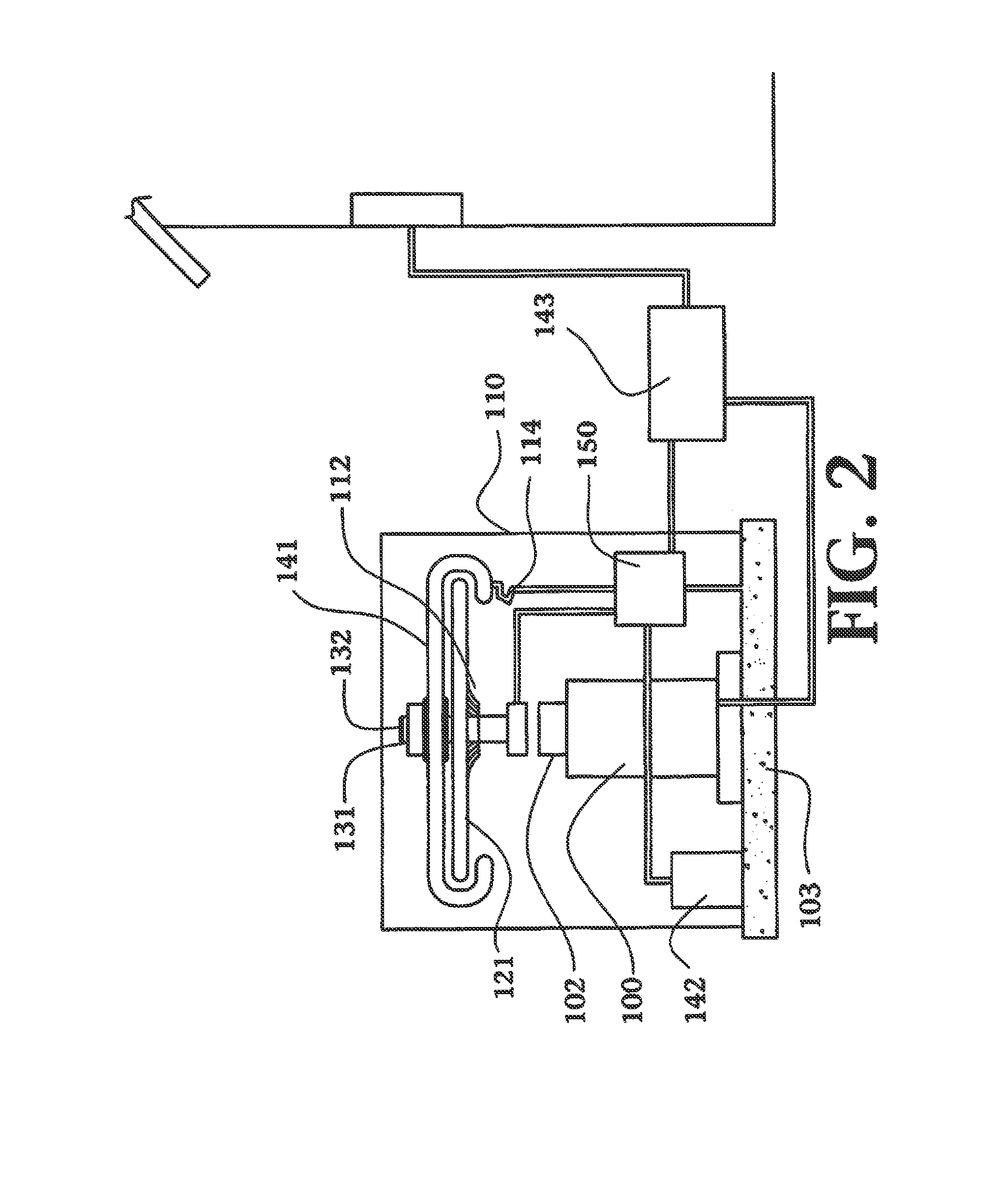

InactiveUS7538650B2Accurate distance measurementAccurate placementElectromagnets without armaturesAutomatic controlMagnetization

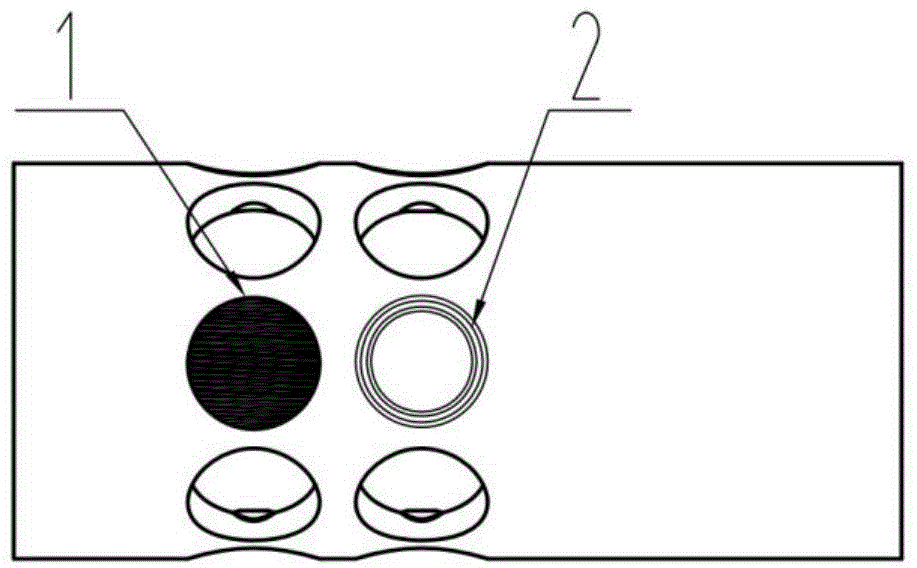

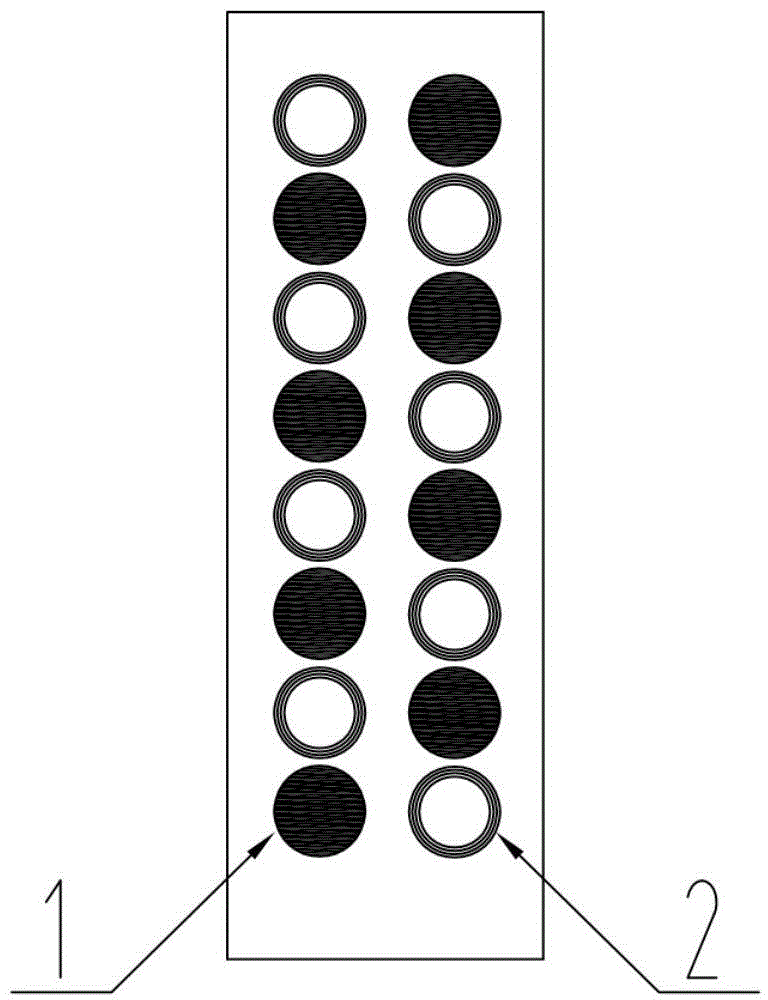

An apparatus for magnetizing a wellbore tubular includes a plurality of co-axial magnetizing coils deployed on a frame. The coils are typically deployed about a track on which the tubular may be traversed. Exemplary embodiments may further include a magnetic field sensor disposed to measure the imparted magnetic field along the length of the tubular as it is removed from the track after magnetization. Exemplary embodiments of this invention provide for semi-automated control of tubular magnetization and thereby enable a repeatable magnetic pattern to be imparted to each of a large number of wellbore tubulars.

Owner:SCHLUMBERGER TECH CORP

Apparatus and method for magnetizing casing string tubulars

InactiveUS20080012672A1Accurate well placementImprove quality controlElectromagnets without armaturesAutomatic controlMagnetization

An apparatus for magnetizing a wellbore tubular includes a plurality of co-axial magnetizing coils deployed on a frame. The coils are typically deployed about a track on which the tubular may be traversed. Exemplary embodiments may further include a magnetic field sensor disposed to measure the imparted magnetic field along the length of the tubular as it is removed from the track after magnetization. Exemplary embodiments of this invention provide for semi-automated control of tubular magnetization and thereby enable a repeatable magnetic pattern to be imparted to each of a large number of wellbore tubulars.

Owner:SCHLUMBERGER TECH CORP

Electro-motive machine using Halbach array and electrons trapped in electromagnetic providing current

ActiveUS8183731B2Fast magnetizationIncrease polarityElectronic commutation motor controlMotor/generator/converter stoppersRotational energyEngineering

A Halbach array is radially disposed in an environment optimized for efficiency and controlled for efficient generation and use of power in order to generate, establish, and maintain a desired level of rotational energy with enhanced efficiency.

Owner:EPSTEIN MARTIN +1

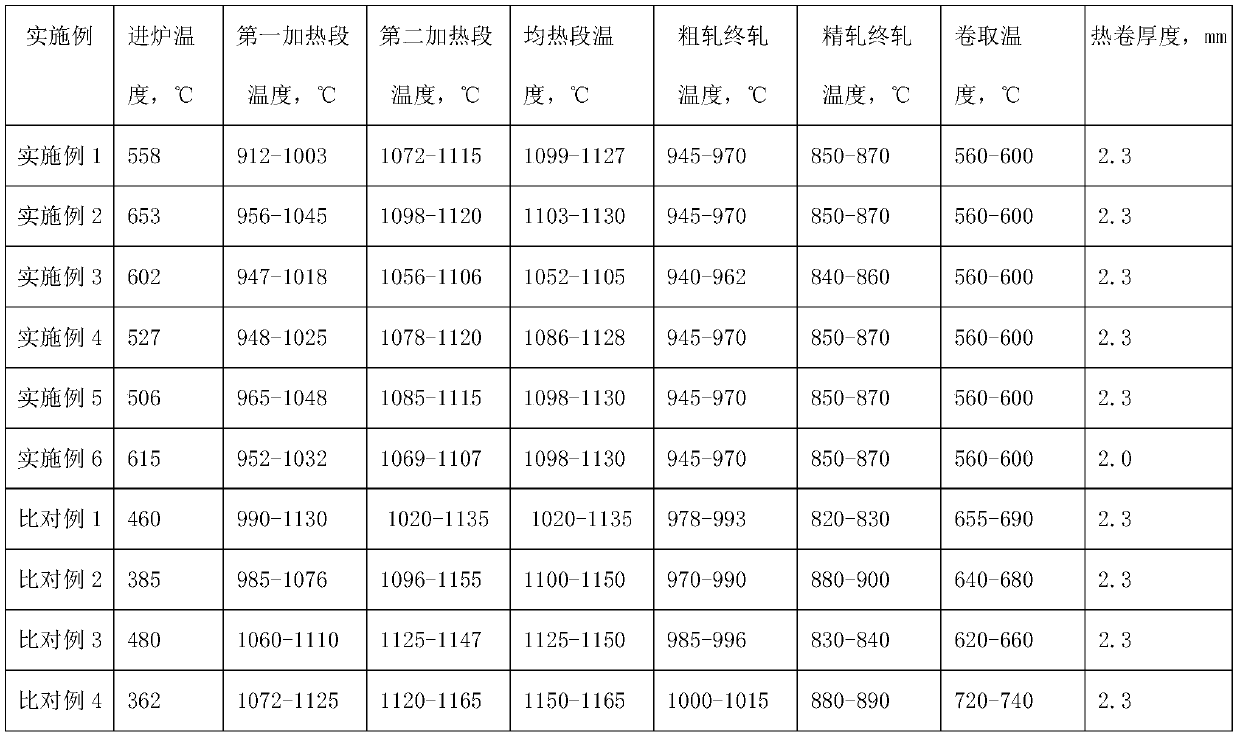

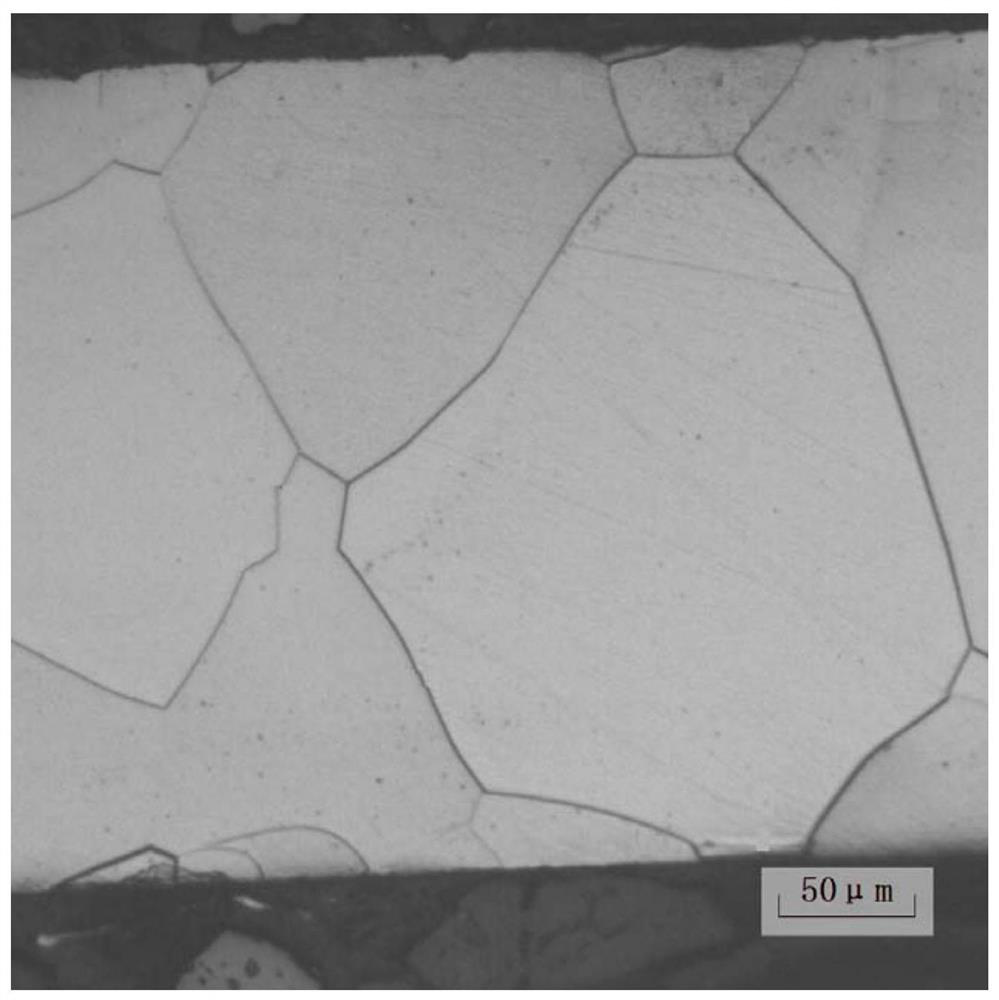

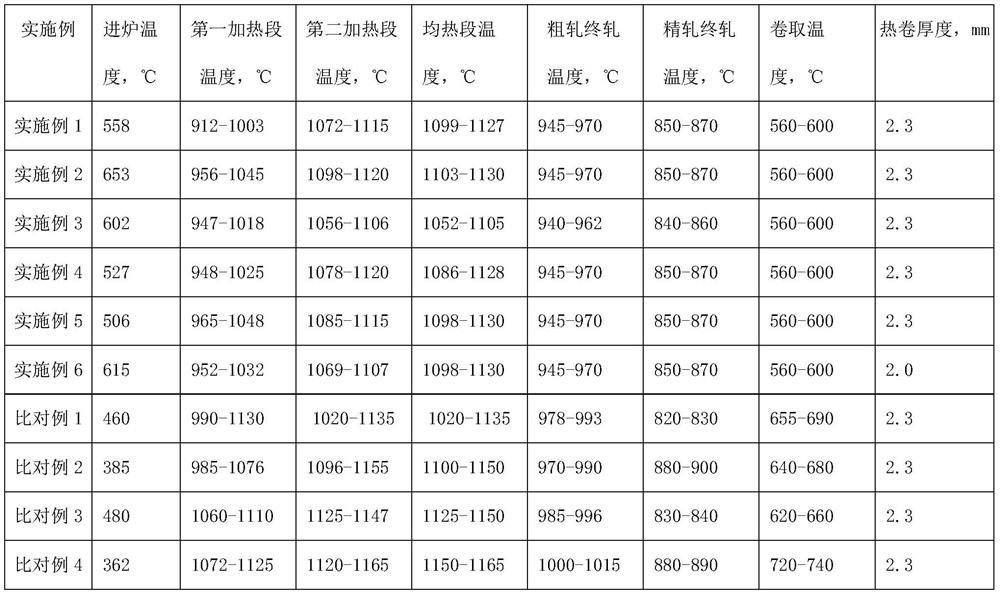

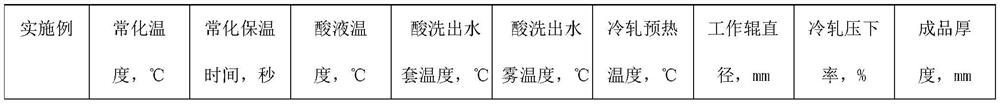

Non-oriented electrical steel for variable-frequency air conditioner and manufacturing method of non-oriented electrical steel

ActiveCN111304518AFast magnetizationReduce iron lossFurnace typesProcess efficiency improvementElectrical steelUltimate tensile strength

The invention provides non-oriented electrical steel for a variable-frequency air conditioner and a manufacturing method of the non-oriented electrical steel. The non-oriented electrical steel is prepared from the components: less than or equal to 0.0020% of [C], 0.20%-0.50% of [Mn], less than or equal to 0.0025% of [S], less than or equal to 0.020% of [P], 2.80%-3.4% of [Si], 0.20%-1.20% of [Al],less than or equal to 0.0025% of [N], 0.01-0.10% of [Sn], the balance of Fe and inevitable residual elements. The manufacturing method comprises the steps: steelmaking, continuous casting, heating, hot rolling, normalizing, acid pickling, cooling, annealing, cooling and coating. The product thickness is 0.25-0.30 mm, the product iron loss P1.5 / 50 is less than or equal to 2.15 W / kg, the magnetic polarization intensity J5000 is greater than or equal to 1.65 T, the magnetizing velocity is high, the iron loss is low, the non-oriented electrical steel is suitable for the working conditions of a compressor of the variable-frequency air conditioner, the size and the weight of the variable-frequency air conditioner can be reduced, power consumption is reduced, and resources and energy are saved.

Owner:新余钢铁股份有限公司

Electro-motive machine using halbach array electrons trapped in electromagnetic coils and using hybrid coils to harvest back electromotive force

ActiveUS8513849B2Fast magnetizationIncrease polarityMagnetic circuit rotating partsStructural associationElectromotive forceCounter-electromotive force

A Halbach array is radially disposed in an environment optimized for efficiency and controlled for efficient generation and use of power in order to generate, establish, and maintain a desired level of rotational energy with enhanced efficiency and in order to make the most efficient use of electromotive forces and magnetic fields which are either intentionally created for the operation of the apparatus or which result from the operation of the apparatus.

Owner:MAGLEV ENERGY

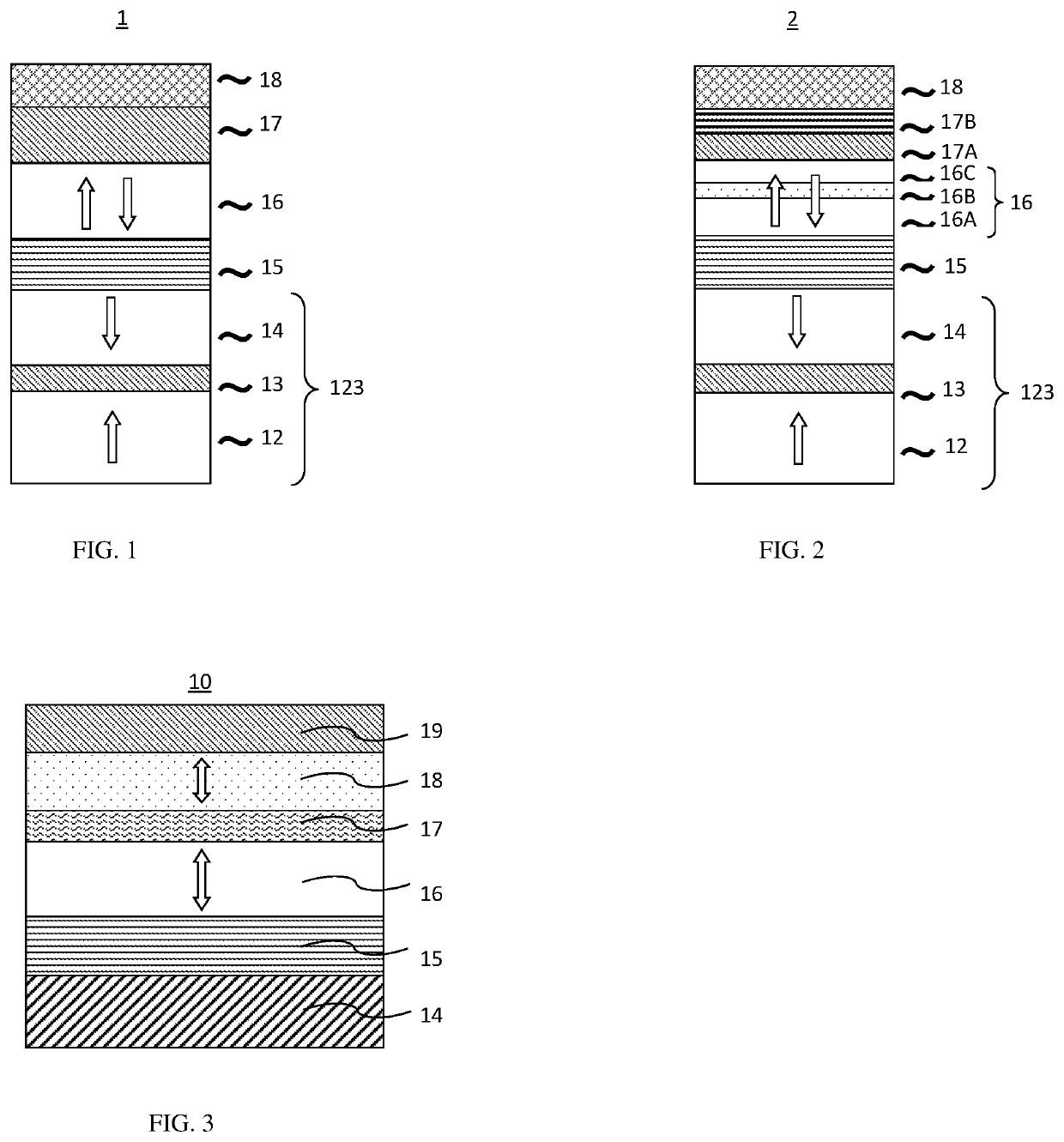

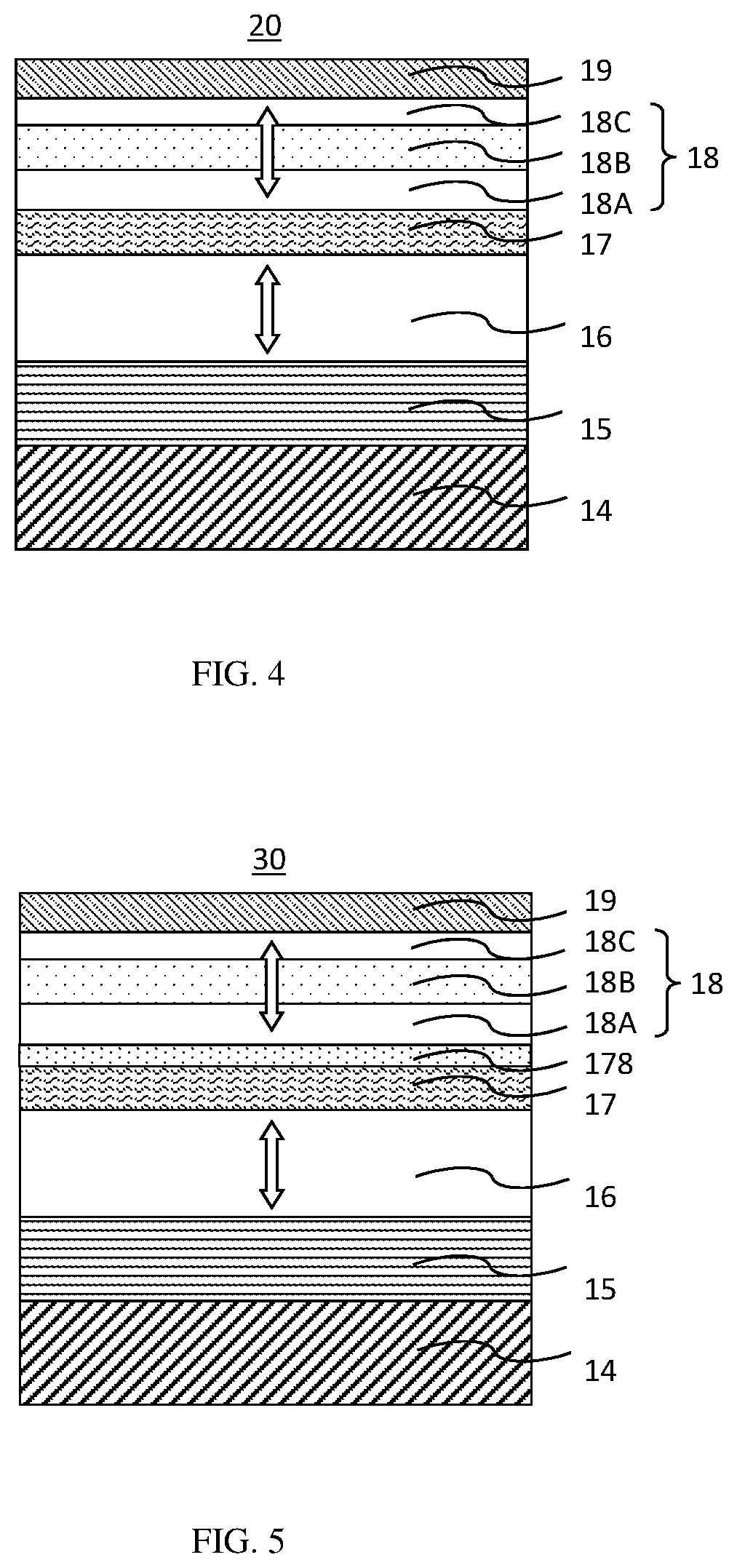

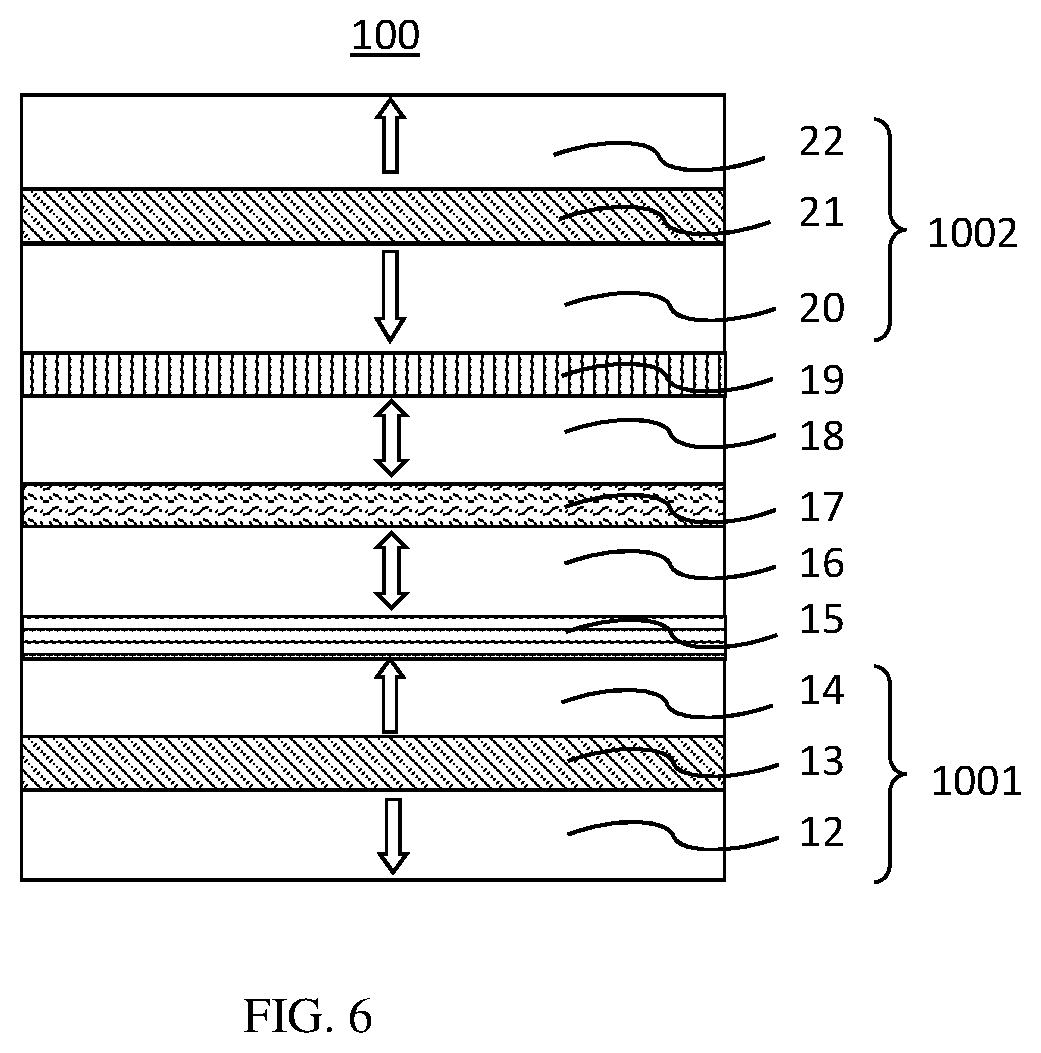

Magnetoresistive element having a composite recording structure

PendingUS20220238799A1Sufficient high damping constantDecreased mobilityGalvano-magnetic material selectionGalvano-magnetic device detailsFerroicsMaterials science

A method of forming a bottom-pinned magnetoresistive element comprising a composite recording structure that includes a first magnetic free layer and a second magnetic free layer containing Ni atoms, separated by an oxide spacing layer. The first magnetic free layer is Ni-free and the first magnetic free layer and the second magnetic free layer are magnetically parallel-coupled. A magnetic STT-enhancing structure is further provided atop the cap layer, wherein the magnetic STT-enhancing structure comprises a first magnetic material layer atop the cap layer and having a perpendicular magnetic anisotropy and an invariable magnetization anti-parallel to the magnetization direction of the reference layer, a second anti-ferromagnetic coupling (AFC) layer atop the first magnetic material layer, and a second magnetic material layer atop the second AFC layer.

Owner:GUO YIMIN +2

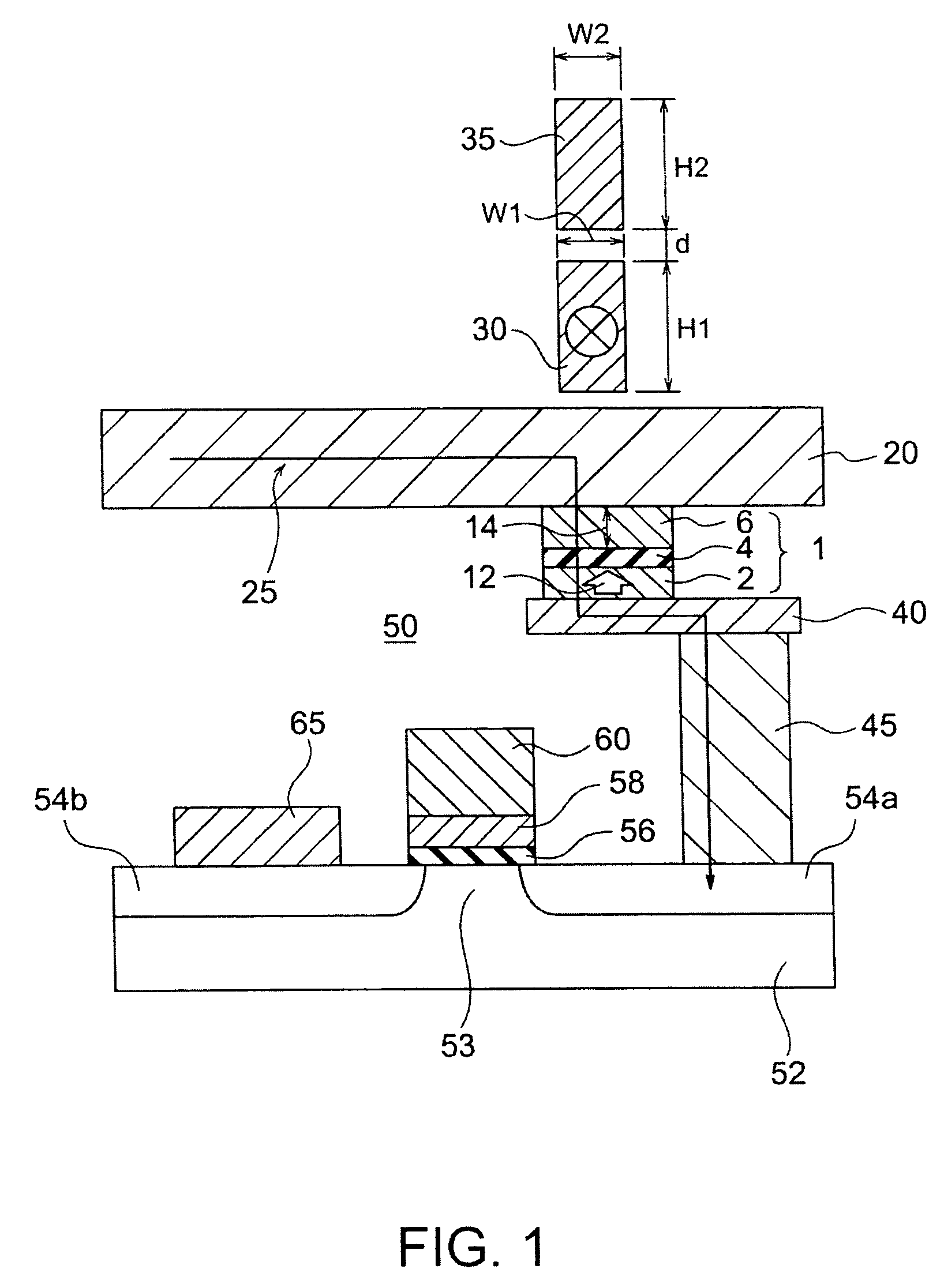

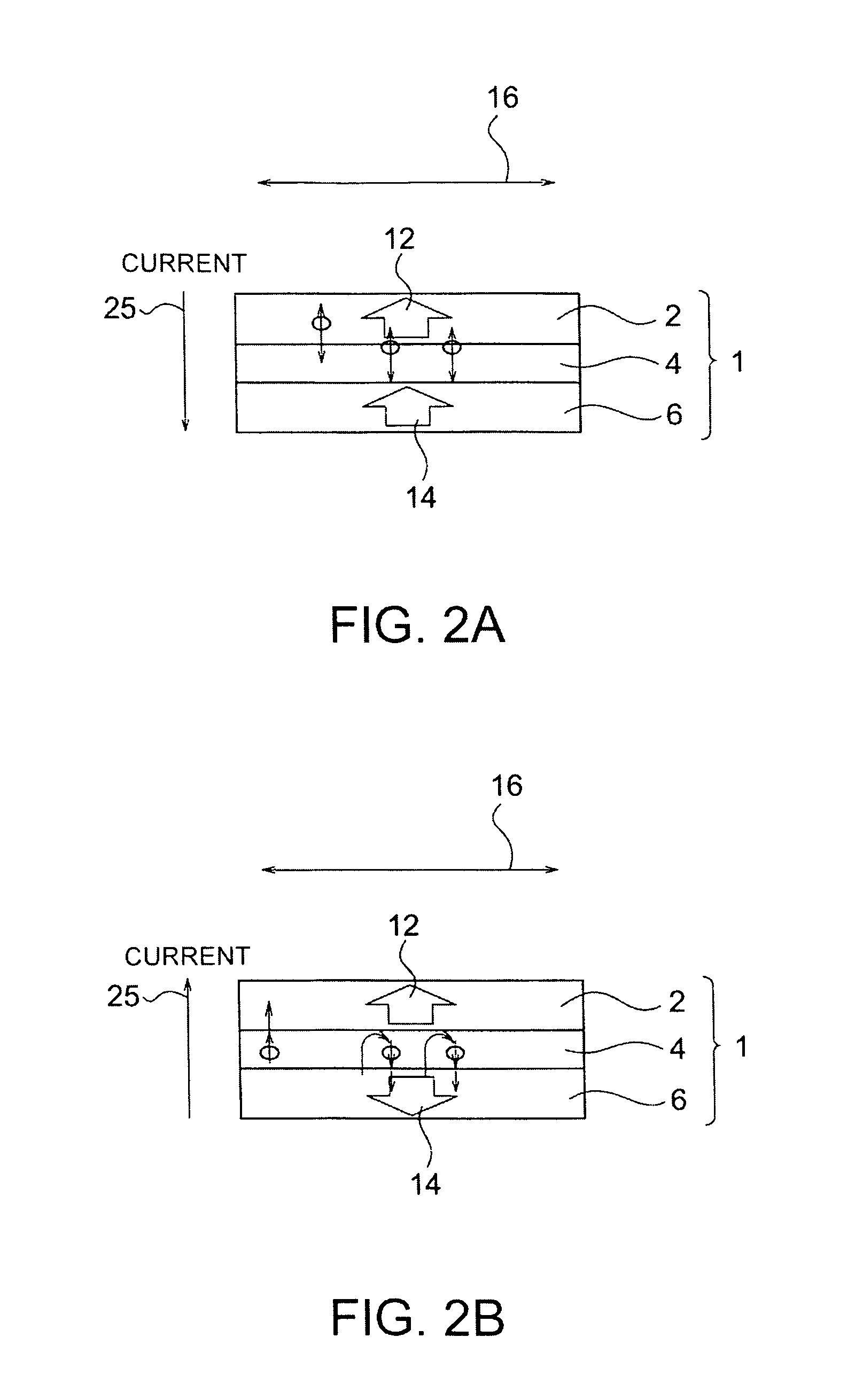

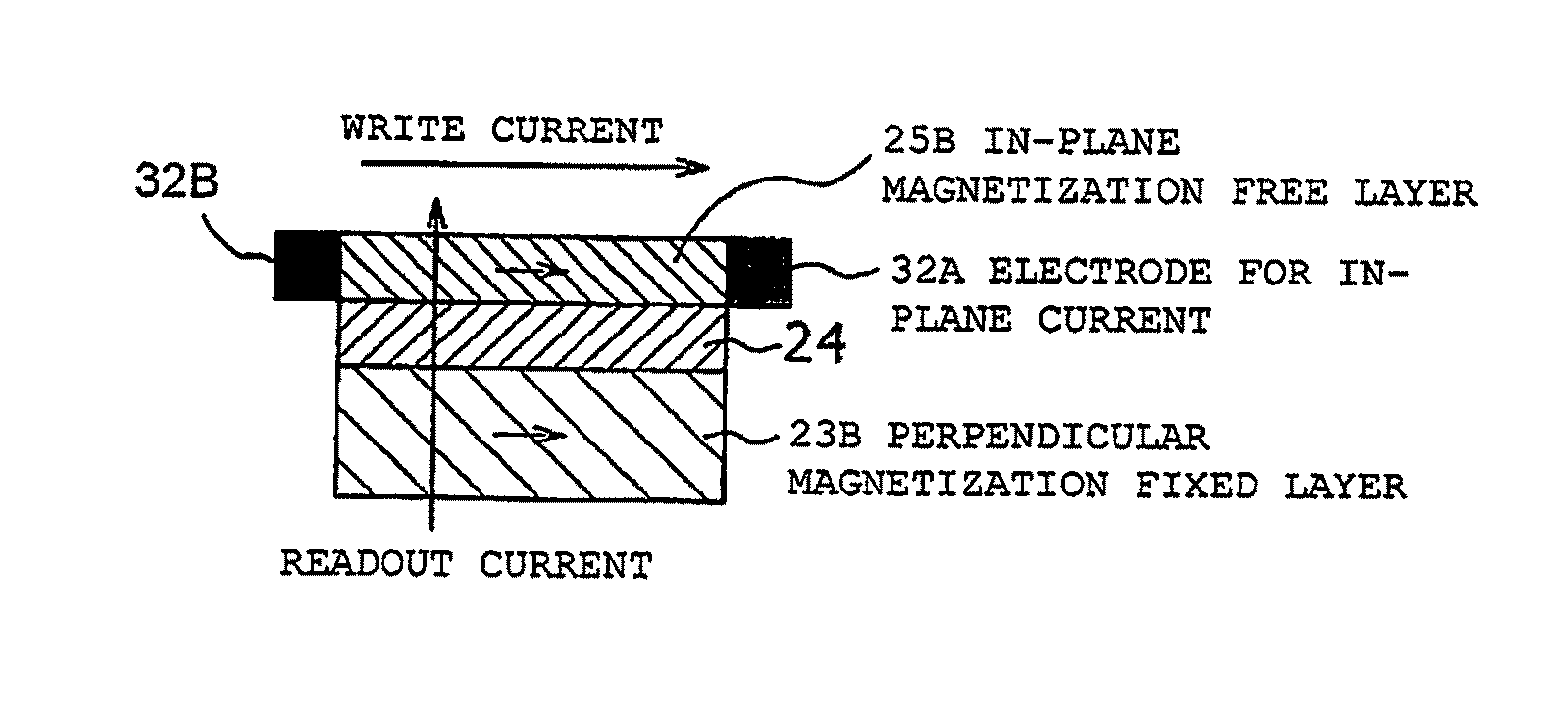

Spin-valve recording element and storage device

ActiveUS20110143166A1Improve recording densityReduce magnetizationNanomagnetismMagnetic measurementsEngineeringSpin valve

A spin-valve element has a pair of ferromagnetic layers having mutually different coercive forces, sandwiching an insulating layer or a nonmagnetic layer therebetween. The in-plane shape of the spin-valve element is substantially circular in shape but is provided, in the peripheral portion, with a plurality of cutouts NS, NW, NE, NN. Preferably, the shape of at least one cutout be made different from that of others. Moreover, a storage device that employs such a spin-valve element is provided.

Owner:III HLDG 3

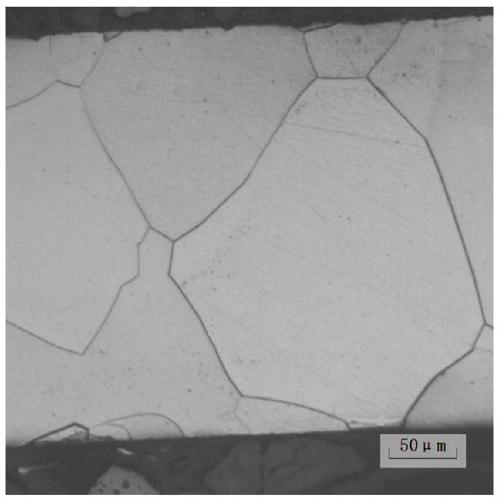

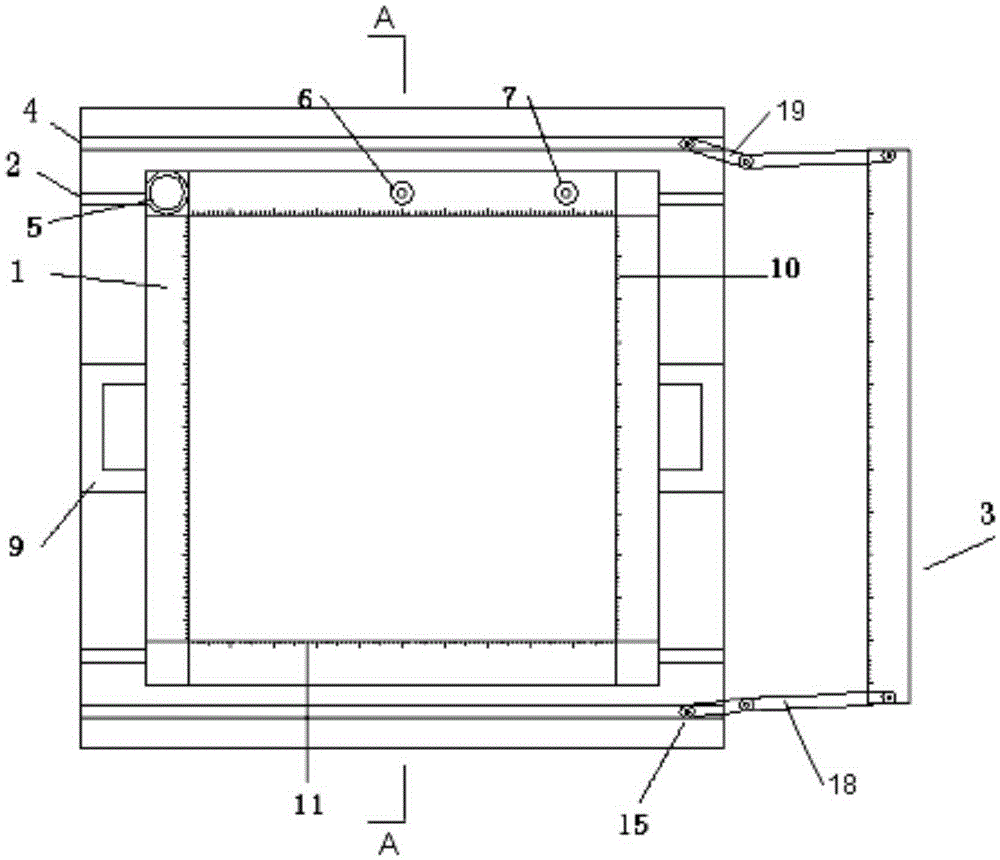

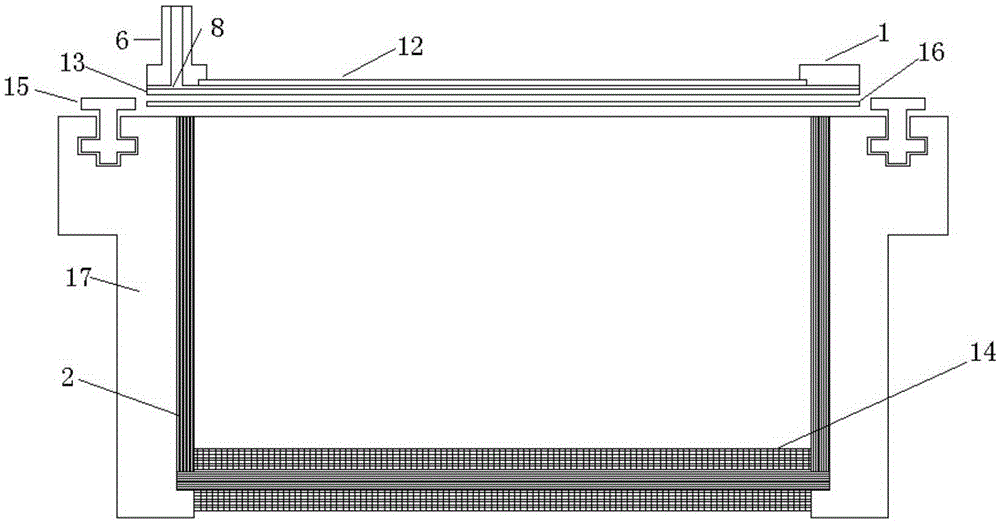

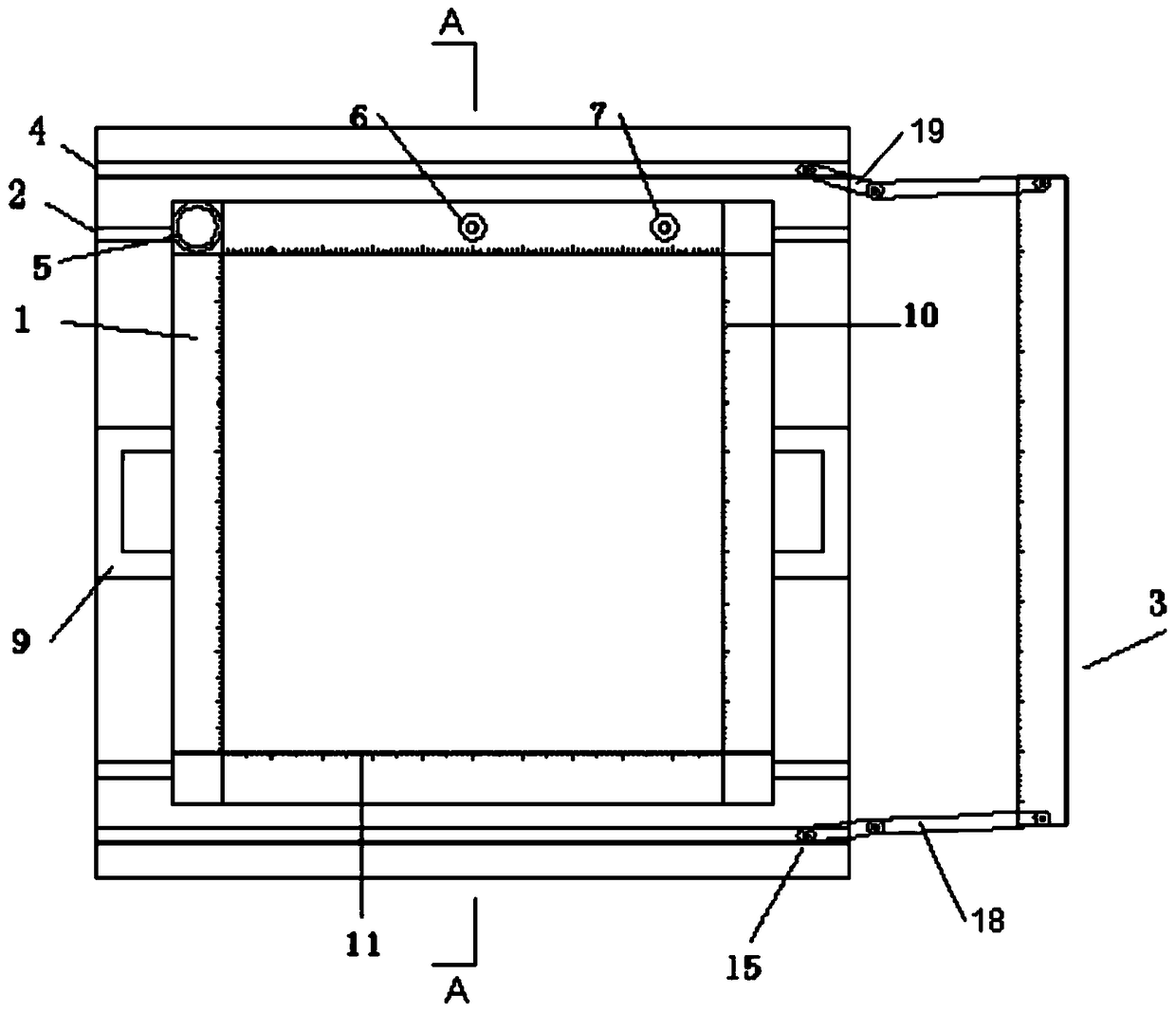

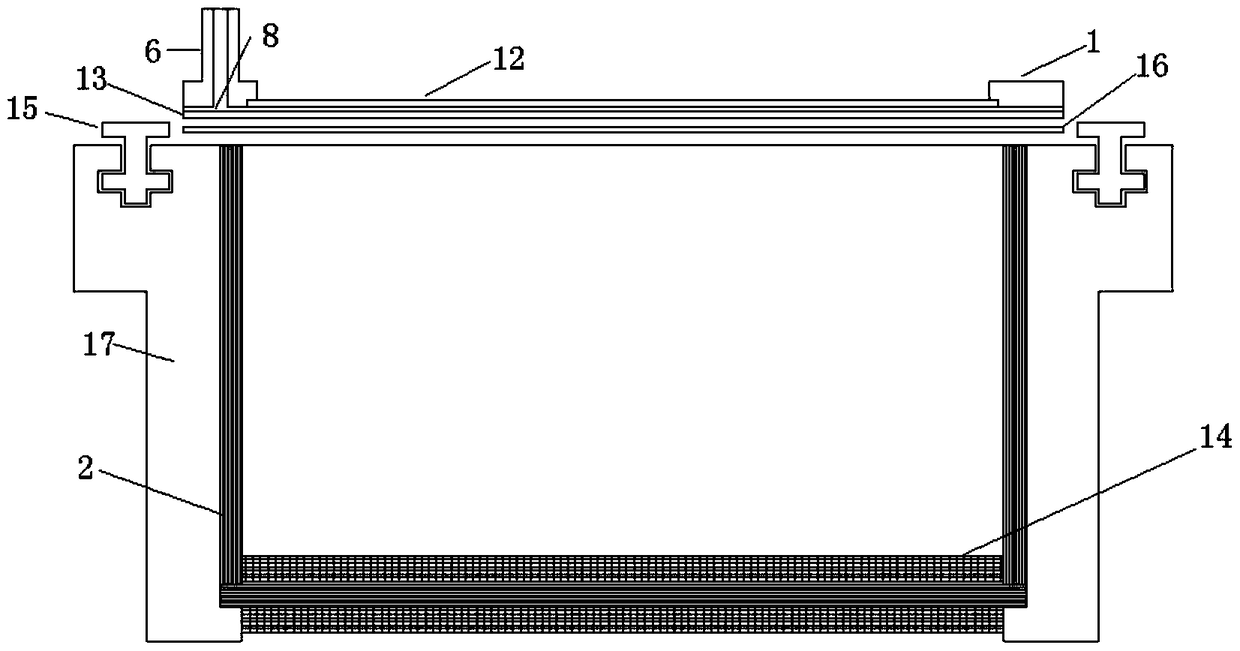

Device for rapidly measuring grain size and magnetic domain wall width of oriented silicon steel sheet

ActiveCN105300859AAccurate measurementAvoid mutual contaminationParticle size analysisIndividual particle analysisInternal pressureFast measurement

The invention discloses a device for rapidly measuring the grain size and magnetic domain wall width of an oriented silicon steel sheet. The device comprises a sample platform and a developing component, wherein the developing component comprises a display window and a contact layer; the display window is a transparent glass plate or a transparent hard plastic plate; a liquid storage cavity used for containing a developing suspension liquid is formed between the display window and the contact layer; the display window is provided with a suspension liquid injection hole used for injecting the developing suspension liquid into the liquid storage cavity and a liquid storage cavity closed hole used for balancing the internal pressure of the liquid storage cavity; the suspension liquid injection hole and the liquid storage cavity closed hole can be opened or closed as needed; a magnet yoke is arranged in the sample platform and is provided with a magnetizing winding; after being electrified, the magnetizing winding is capable of magnetizing the oriented silicon steel sheet put on the sample platform. By virtue of adopting the powder pattern method theory, the device is capable of rapidly measuring the grain size and magnetic domain wall width of the oriented silicon steel sheet.

Owner:武汉钢铁有限公司

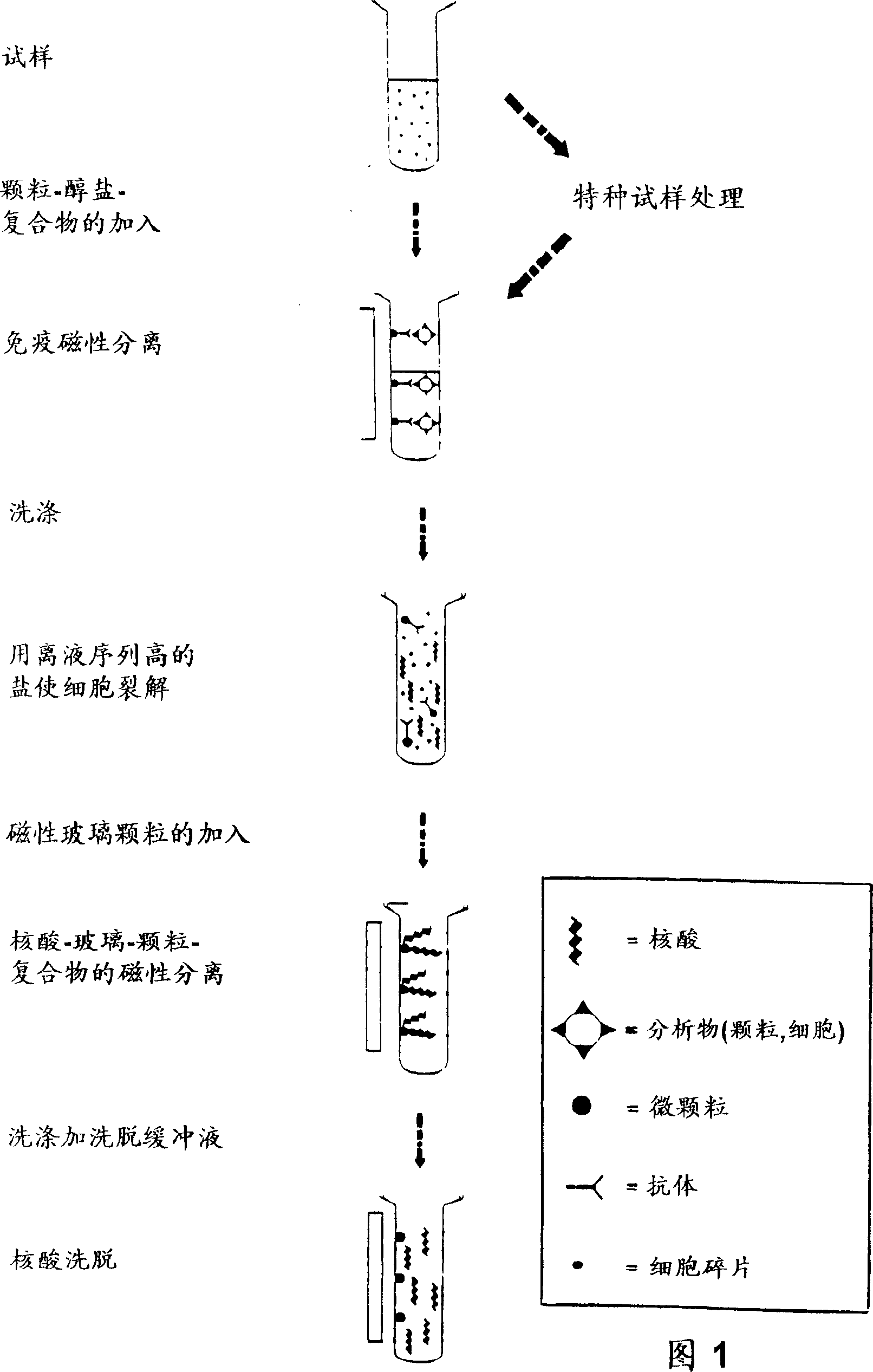

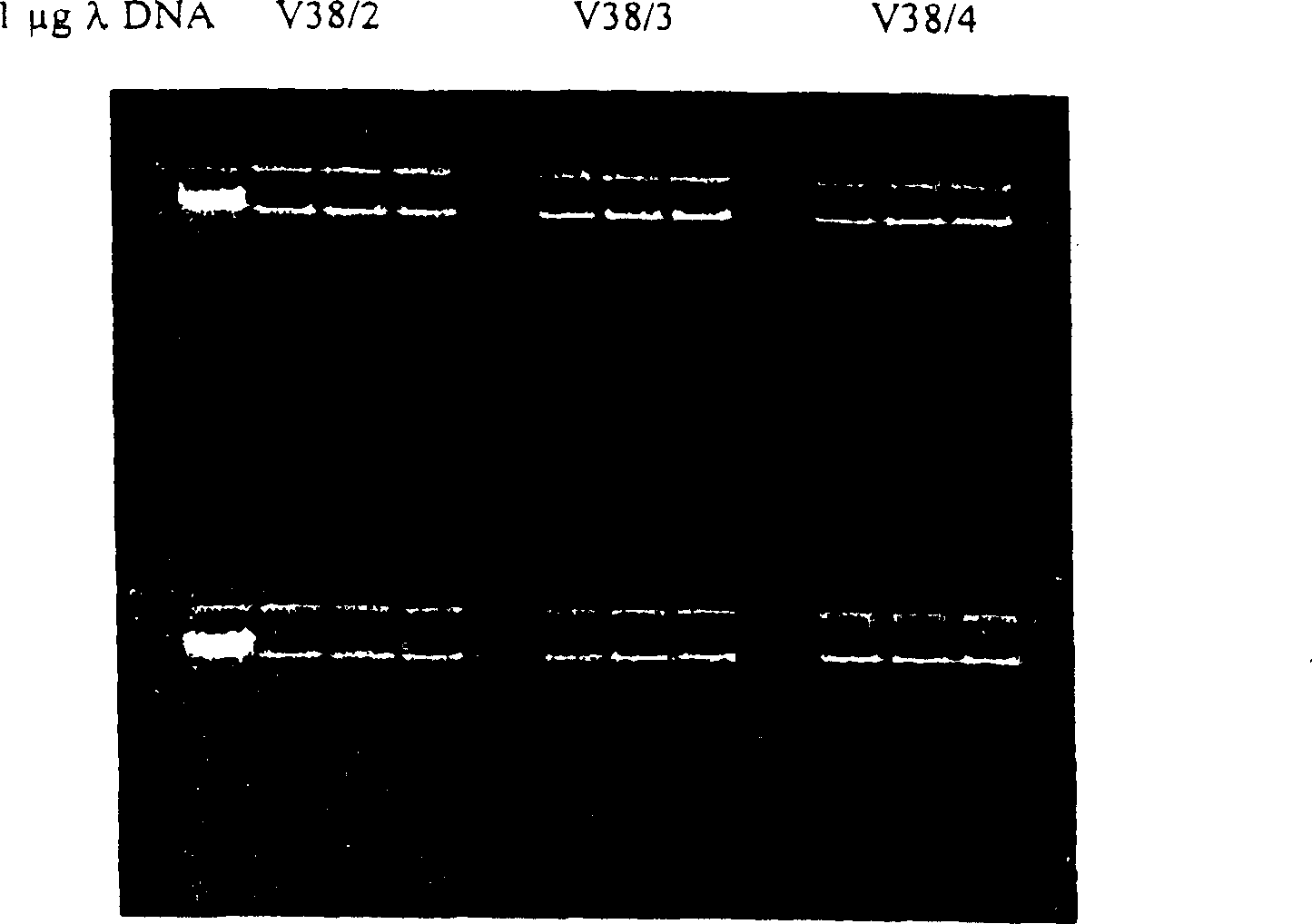

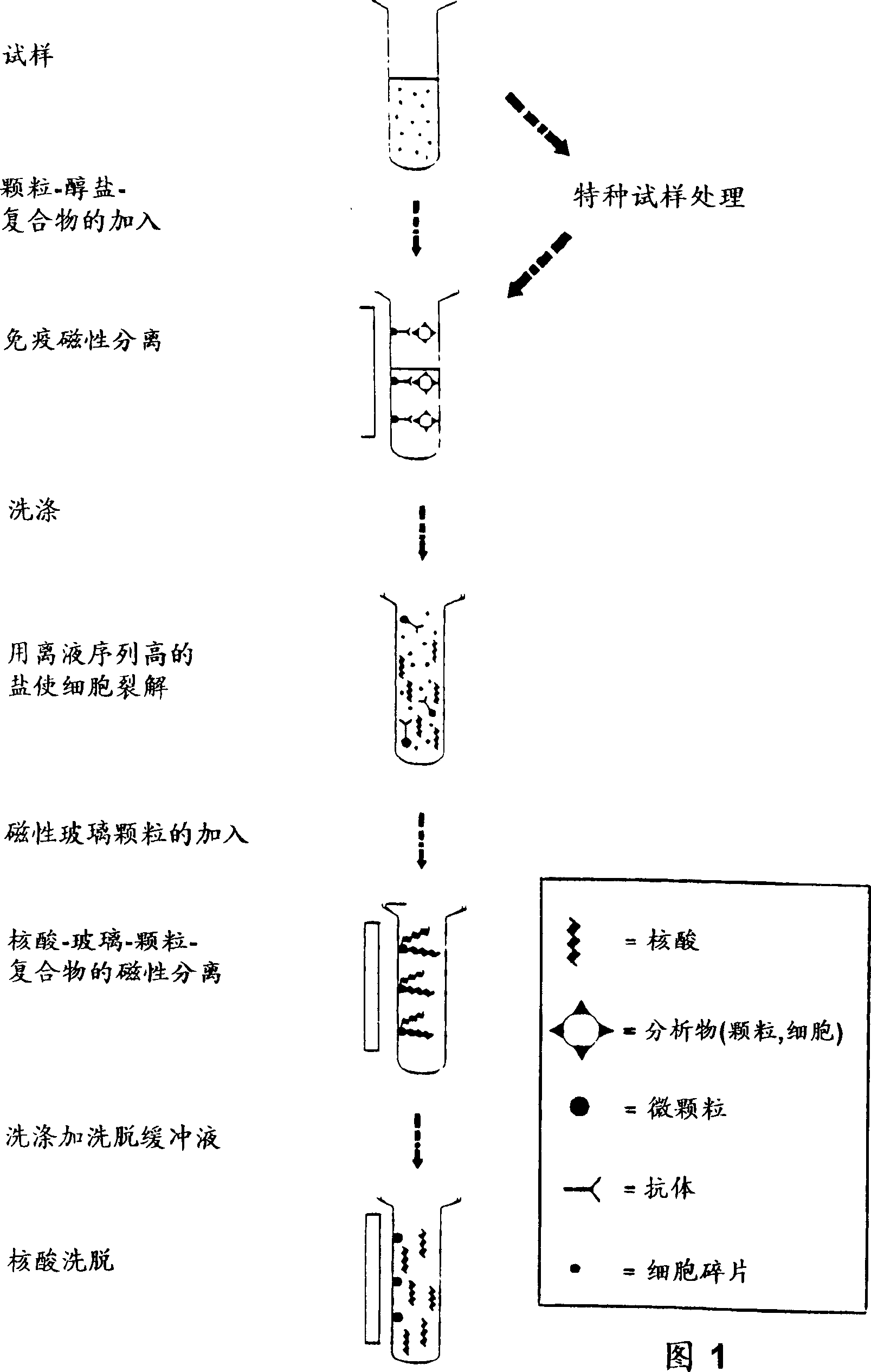

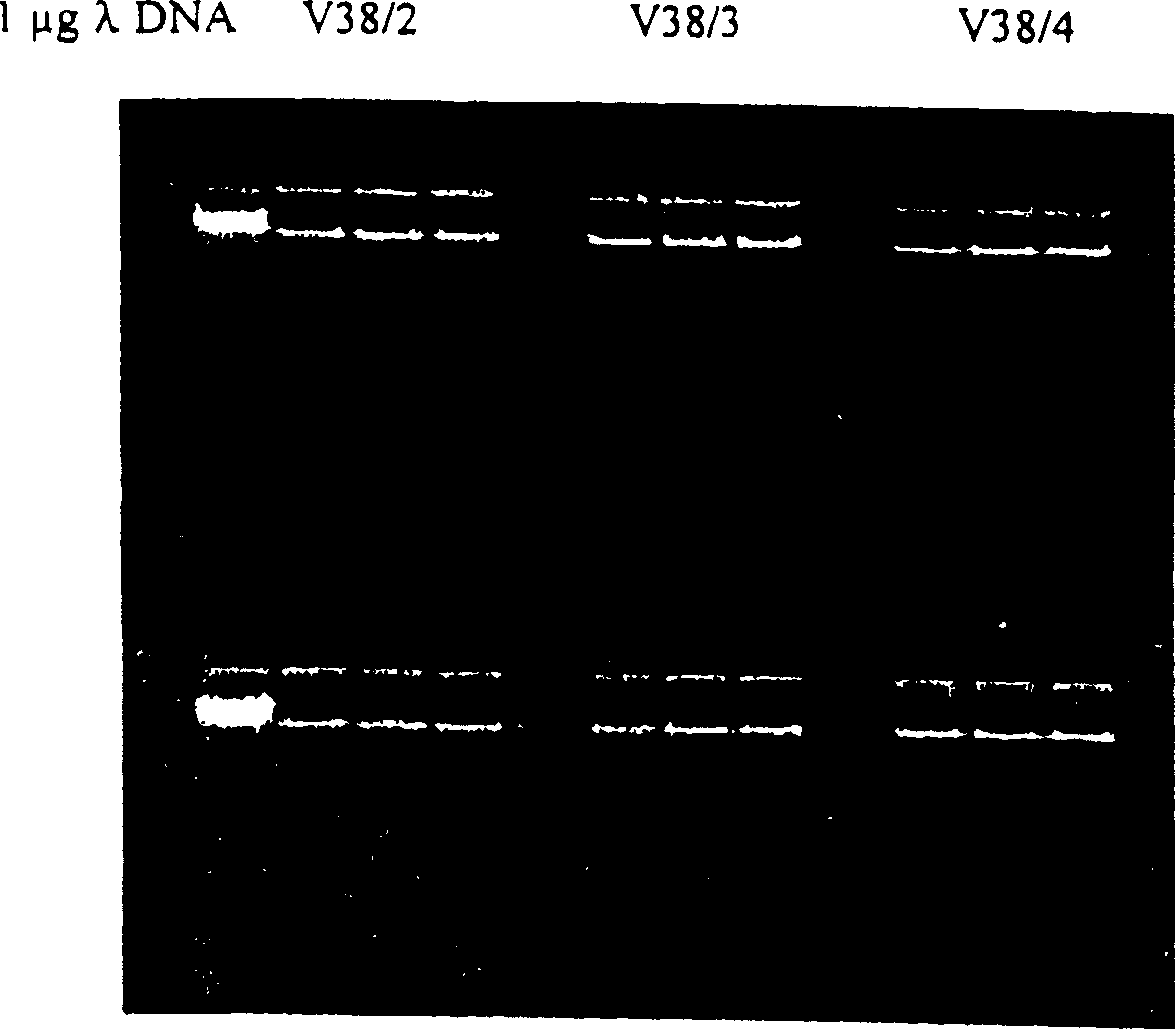

Enzyme reaction method for nucleic acid and composition for separating nucleic acid

Owner:ROCHE DIAGNOSTICS GMBH

Novel magnetic fluid bearing and manufacturing method thereof

ActiveCN108412894ARich microvoid structureAvoid influenceRolling contact bearingsBearing componentsRolling resistanceEngineering

The invention discloses a novel magnetic fluid bearing which comprises a bearing inner ring, a permanent magnet retainer, a rolling element and a bearing outer ring sequentially arranged from inside to outside. The bearing inner ring is arranged in the bearing outer ring; the permanent magnet retainer is arranged on an outer wall of the bearing inner ring; the rolling element is arranged on the permanent magnet retainer; bearing sealing covers are further arranged on two sides of the magnetic fluid bearing; the upper ends of the bearing sealing covers are connected with an inner wall of the bearing outer ring; the lower ends of the bearing sealing covers are connected with an outer wall of the bearing inner ring; a sealed cavity is formed among the bearing sealing covers, the inner wall ofthe bearing outer ring and the outer wall of the bearing inner ring; and a magnetic fluid is injected into the cavity. In addition, the invention further provides a manufacturing method of the novelmagnetic fluid bearing. The novel magnetic fluid bearing provided by the invention realizes magnetic fluid rolling friction without dry friction, is small in friction force, good in lubricating effectand high in sealing performance so as to be non-impact, stable, silent or noise-lowest during rotating, and is particularly suitable for high-rotating-speed and dusty environments.

Owner:NANCHANG INST OF TECH

Electro-motive machine using halbach array and electrons trapped in electromagnetic providing current

ActiveUS20110025239A1Fast magnetizationIncrease polarityElectronic commutation motor controlMotor/generator/converter stoppersEngineeringRotational energy

A Halbach array is radially disposed in an environment optimized for efficiency and controlled for efficient generation and use of power in order to generate, establish, and maintain a desired level of rotational energy with enhanced efficiency.

Owner:EPSTEIN MARTIN +1

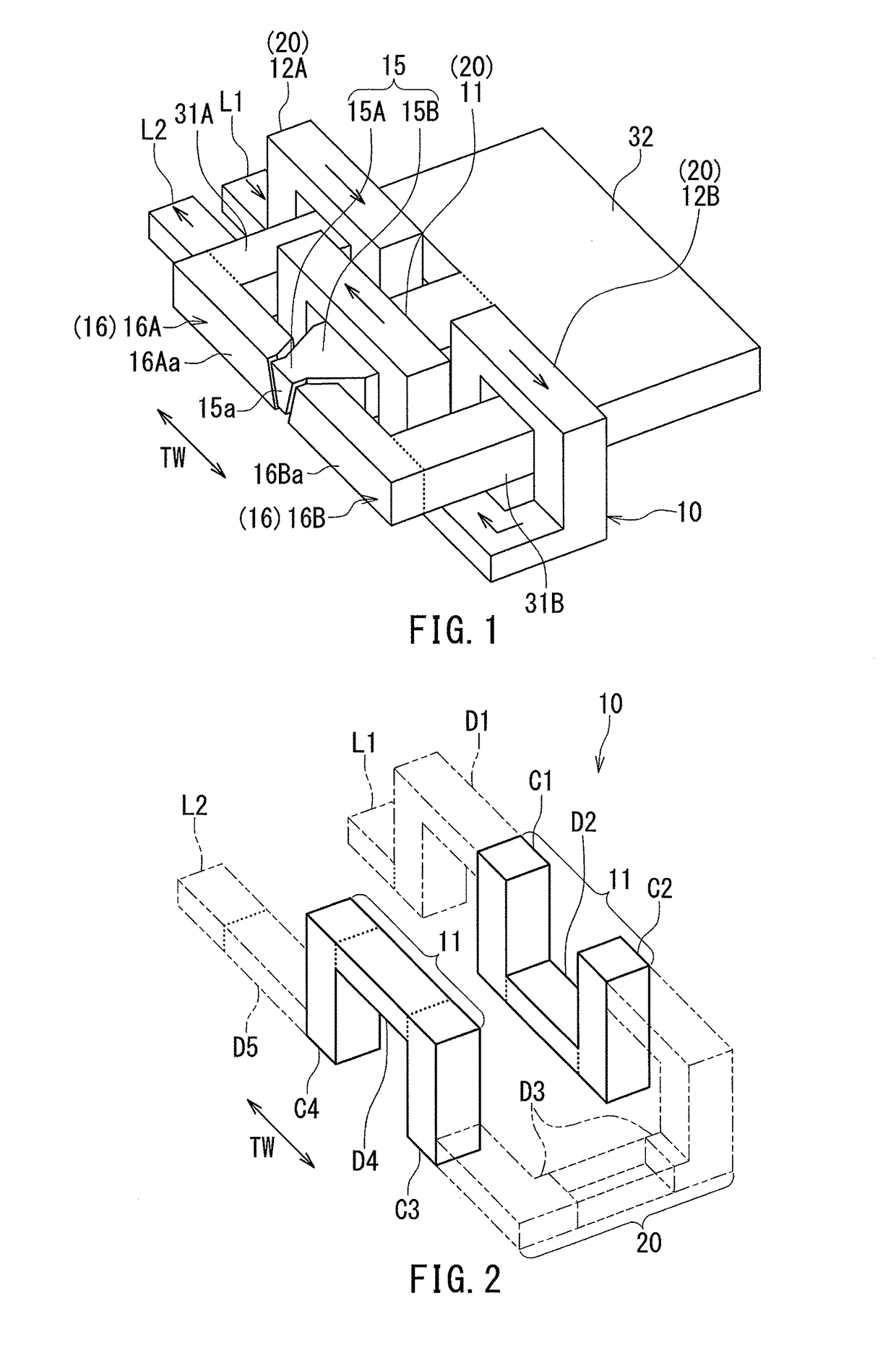

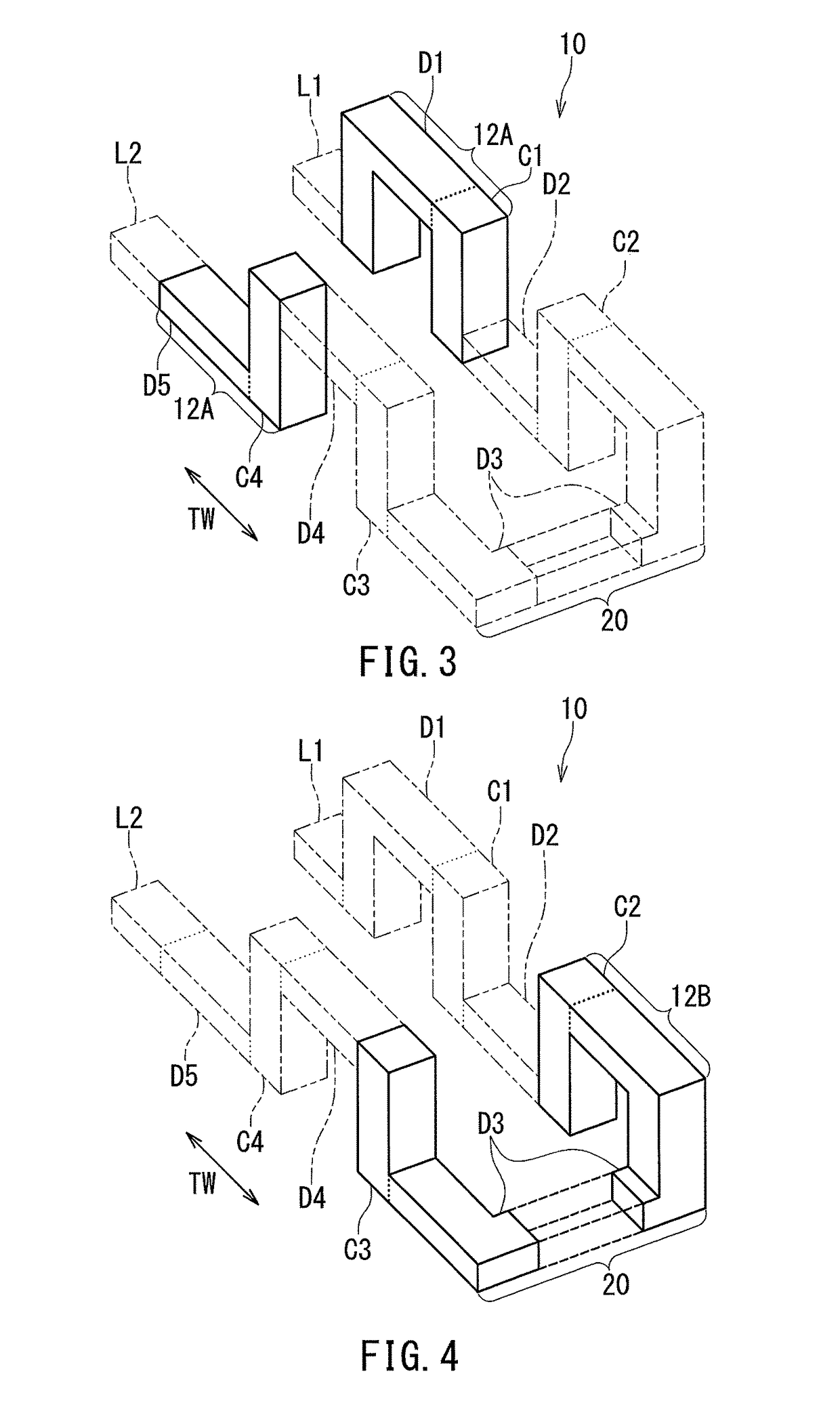

Magnetic head for perpendicular magnetic recording including a coil for individually driving a main pole and a yoke

ActiveUS9620153B1Fast magnetization reversalFast magnetizationConstruction of head windingsRecord information storageMagnetic polesEngineering

A magnetic head includes a coil, a main pole, a write shield and first and second yokes. The first and second yokes are connected to the write shield. The coil includes a main coil portion for driving the main pole, a first sub-coil portion for driving the first yoke, and a second sub-coil portion for driving the second yoke. A magnetic field produced in the main pole by the main coil portion and a magnetic field produced in each of the first and second yokes by the first and second sub-coil portions are in directions opposite to each other.

Owner:HEADWAY TECH INC

Enzyme reaction method for nucleic acid and composition for separating nucleic acid

InactiveCN1974781BEasy to separateDifficult to deal withNanomagnetismEnzymologyEnzymeFerromagnetic particle

Owner:ROCHE DIAGNOSTICS GMBH

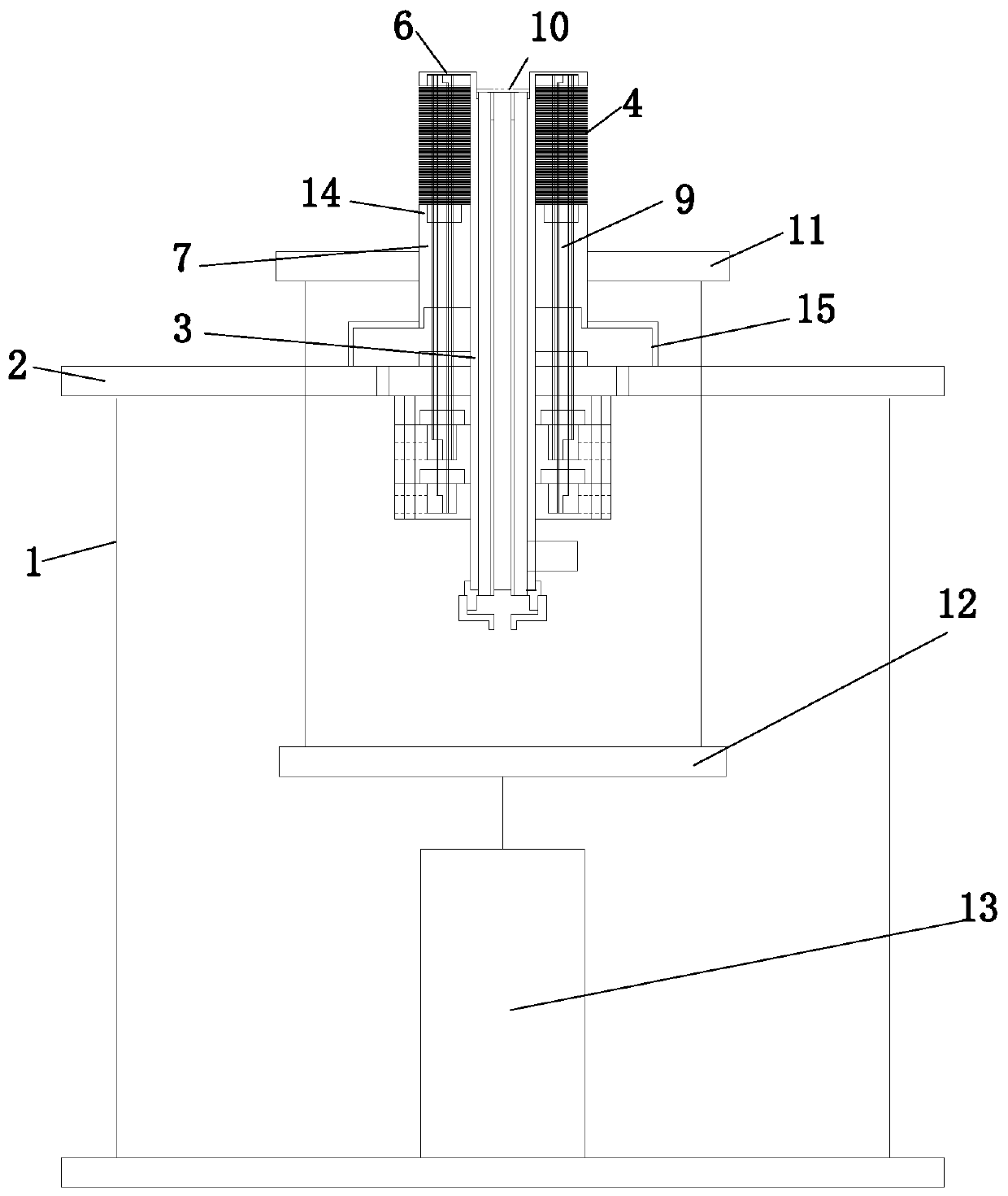

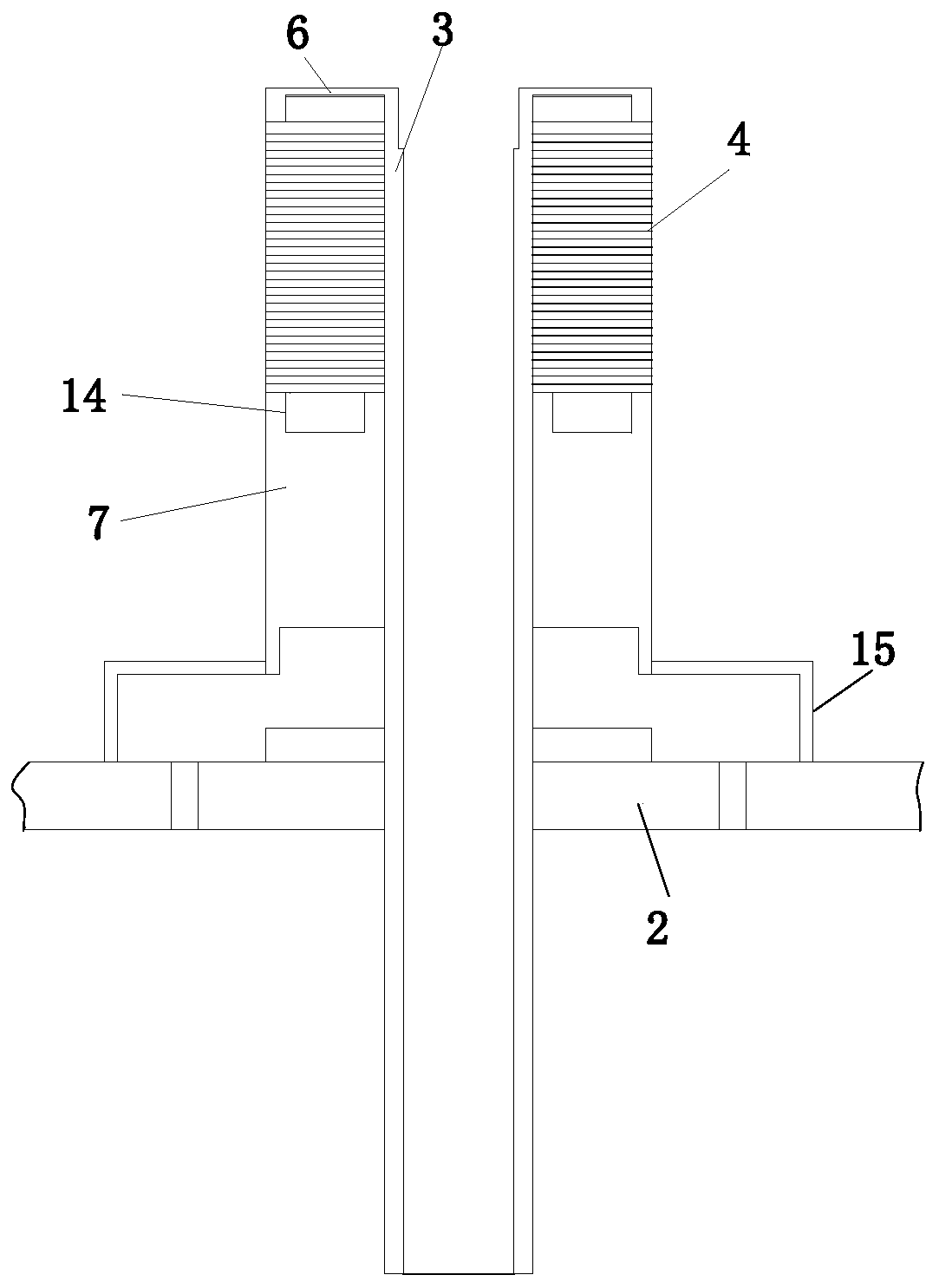

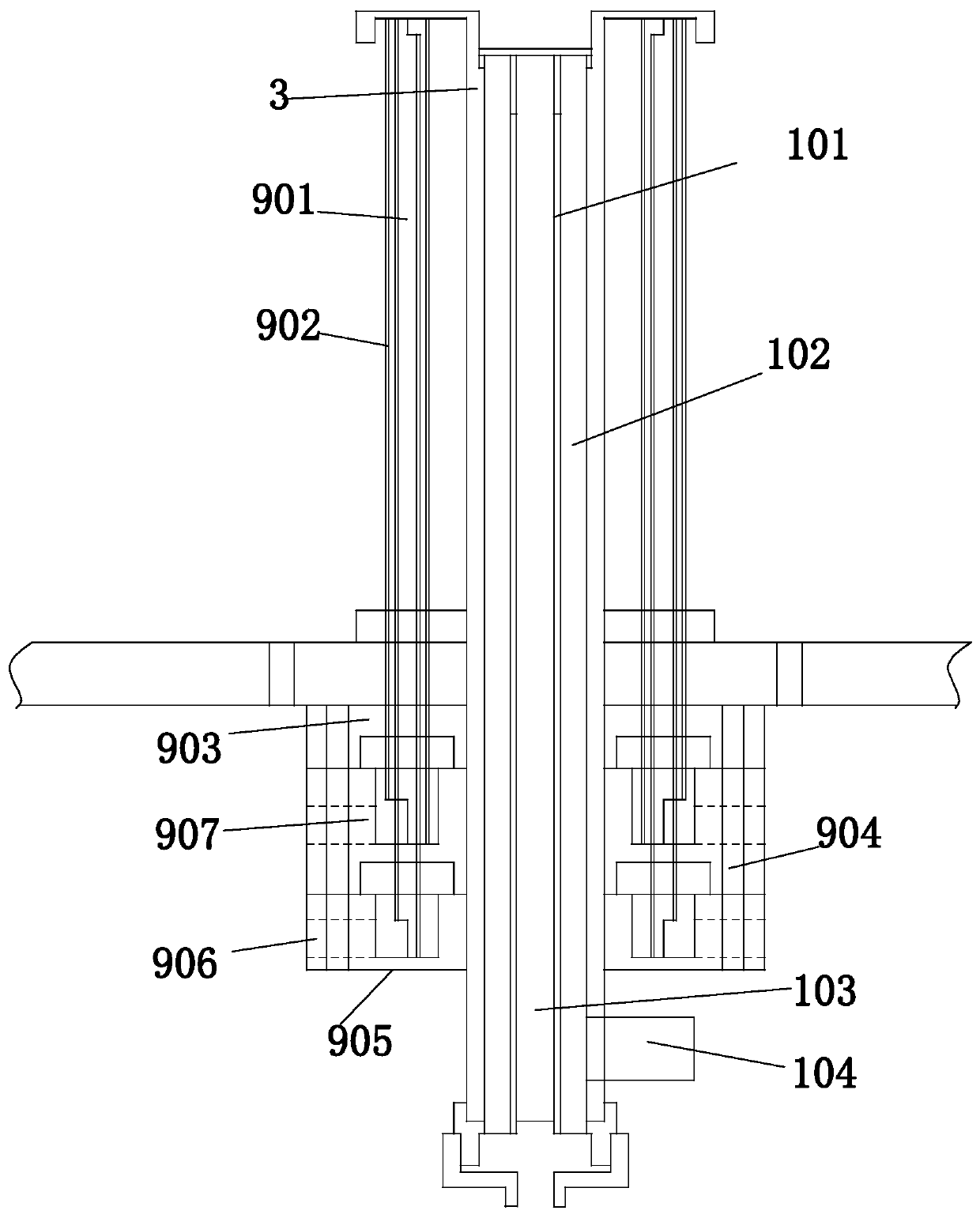

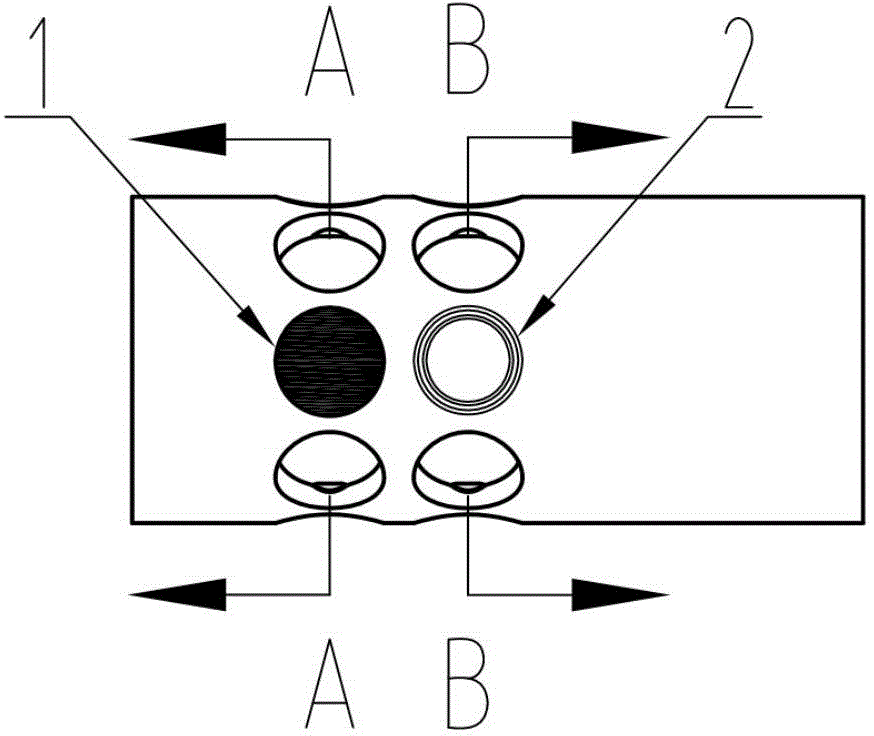

Double-inner-water-cooling quadrupole oblique magnetic sine wave magnetizing head

PendingCN110266155AFast magnetizationStable magnetizationTransformers/inductances coolingMagnetic bodiesCooling effectEngineering

The invention discloses a double-inner-water-cooling quadrupole oblique magnetic sine wave magnetizing head; the double-inner-water-cooling quadrupole oblique magnetic sine wave magnetizing head comprises a rack, wherein a panel is arranged at the upper end of the rack, and a central sleeve is arranged in the middle of the panel; an iron core lamination group is arranged on the outer side of the upper part of the center sleeve; a winding group is wound on the iron core lamination group; the upper end and the lower end of the iron core lamination group are provided with an upper buckling plate and a lower buckling plate respectively; a plurality of winding grooves which are uniformly distributed are formed in the iron core lamination group; a winding cooling assembly is arranged in each winding groove, and an iron core cooling assembly is arranged on the inner side of the center sleeve; a discharging plate is further arranged on the outer side of the iron core lamination group, and a supporting frame is arranged below the discharging plate, and a lifting air cylinder fixed at the bottom of the rack is arranged below the supporting frame. The magnetizing head has the advantage that the cooling effect can be effectively improved.

Owner:HUZHOU YUEQIU MOTOR

Low-frequency high-gradient magnetic field scale inhibiting cleaner

InactiveCN101254968AImprove permeabilityFast magnetizationWater/sewage treatment by magnetic/electric fieldsCopper wireSteel wool

The invention belongs to a low frequency and high gradient magnetic field scale-buster, which belongs to the scale-buster manufacturing field. The invention is characterized in that a solenoid is made by coiling copper wire, magnetized steel wool with higher magnetic inductivity is arranged inside the solenoid coil, and a low frequency power supply is connected with the magnetized steel wool to make the scale-buster. The inventive steel wool is positioned to be perpendicular to the magnetic lineation, a high gradient magnetic field with 100 to 1000T / m can be generated near the steel wool and is perpendicular to the magnetized steel wool. The scale-buster has the advantages that the structure is simple, the installation and the operation are convenient, the occupied space is small, the cost is low, no secondary pollution exists, and the energy-saving and consumption-reducing and scale inhibition effects are good. The scale-buster can be applied to the industrial cycle cooling water, boilers and the pipeline thereof, and other systems, and belongs to the green environmental protection technology.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Spin-valve recording element and storage device

ActiveUS8679653B2Improve recording densityReduce magnetizationNanomagnetismMagnetic measurementsIn planeEngineering

A spin-valve element has a pair of ferromagnetic layers having mutually different coercive forces, sandwiching an insulating layer or a nonmagnetic layer therebetween. The in-plane shape of the spin-valve element is substantially circular in shape but is provided, in the peripheral portion, with a plurality of cutouts NS, NW, NE, NN. Preferably, the shape of at least one cutout be made different from that of others. Moreover, a storage device that employs such a spin-valve element is provided.

Owner:III HLDG 3

Ferromagnetic thin-walled tube circumferential AC magnetization magnetic flux leakage detection array probe

InactiveCN105806929AImprove anti-interference abilityAchieving Axial Flaw DetectionMaterial magnetic variablesResistive sensorsNuclear power

The invention belongs to the technical field of nuclear power station ferromagnetic thin-walled tube inward-passing electromagnetic nondestructive test and other ferromagnetic thin-walled tube electromagnetic nondestructive test and relates to a ferromagnetic thin-walled tube circumferential AC magnetization magnetic flux leakage detection array probe. The array probe comprises two rows of giant magneto resistive sensors and excitation coils uniformly distributed along a pipe circumferential direction, in each row, the giant magneto resistive sensors and excitation coils are arranged at intervals and the giant magneto resistive sensors and excitation coils in the two rows are staggered. When a pipe is detected, the two adjacent excitation coils in the first row of the coils are excited, then other excitation coils in the first row are orderly excited, after all the coils in the single row are excited, the two excitation coils in the second row close to the excitation coils in the first row are excited and then other excitation coils in the second row are orderly excited. The array probe realizes detection of small caliber sample pipe axial defects.

Owner:CHINA NUCLEAR POWER OPERATION TECH +1

Method for Magnetizing Casing String Tubulars

InactiveUS20090195340A1Accurate distance measurementAccurate placementElectromagnets without armaturesElectric/magnetic detectionAutomatic controlMagnetization

A method for magnetizing a wellbore tubular includes a positioning a wellbore tubular substantially coaxially in a plurality of longitudinally spaced magnetizing coils deployed on a frame. The coils are selectively connected and disconnected from electrical power such that a circumferential electrical current flows in each of the coils to impart a predetermined magnetic field pattern to the tubular. Exemplary embodiments of this invention provide for semi-automated control of tubular magnetization and thereby enable a repeatable magnetic pattern to be imparted to each of a large number of wellbore tubulars.

Owner:SCHLUMBERGER TECH CORP

Apparatus for rapid measurement of grain size and magnetic domain wall width of grain-oriented silicon steel sheets

ActiveCN105300859BAccurate measurementAvoid mutual contaminationParticle size analysisIndividual particle analysisContact layerEngineering

The invention discloses a device for rapidly measuring grain size and magnetic domain wall width of oriented silicon steel sheet, which comprises a sample stage and a displaying part; the displaying part includes a display window and a contact layer, and the display window is transparent A glass plate or a transparent hard plastic plate, a liquid storage cavity for filling the visible suspension is formed between the display window and the contact layer; The suspension injection hole, and the closed air hole of the liquid storage chamber used to balance the pressure in the liquid storage chamber, the suspension injection hole and the closed air hole of the liquid storage chamber can be opened or closed as required; the sample table is provided with a magnetic The yoke is provided with a magnetizing winding, and when the magnetizing winding is energized, the oriented silicon steel sample placed on the sample stage can be magnetized. The device adopts the principle of powder grain method, which can quickly and accurately measure the grain size and magnetic domain wall width of grain-oriented silicon steel sheets.

Owner:武汉钢铁有限公司

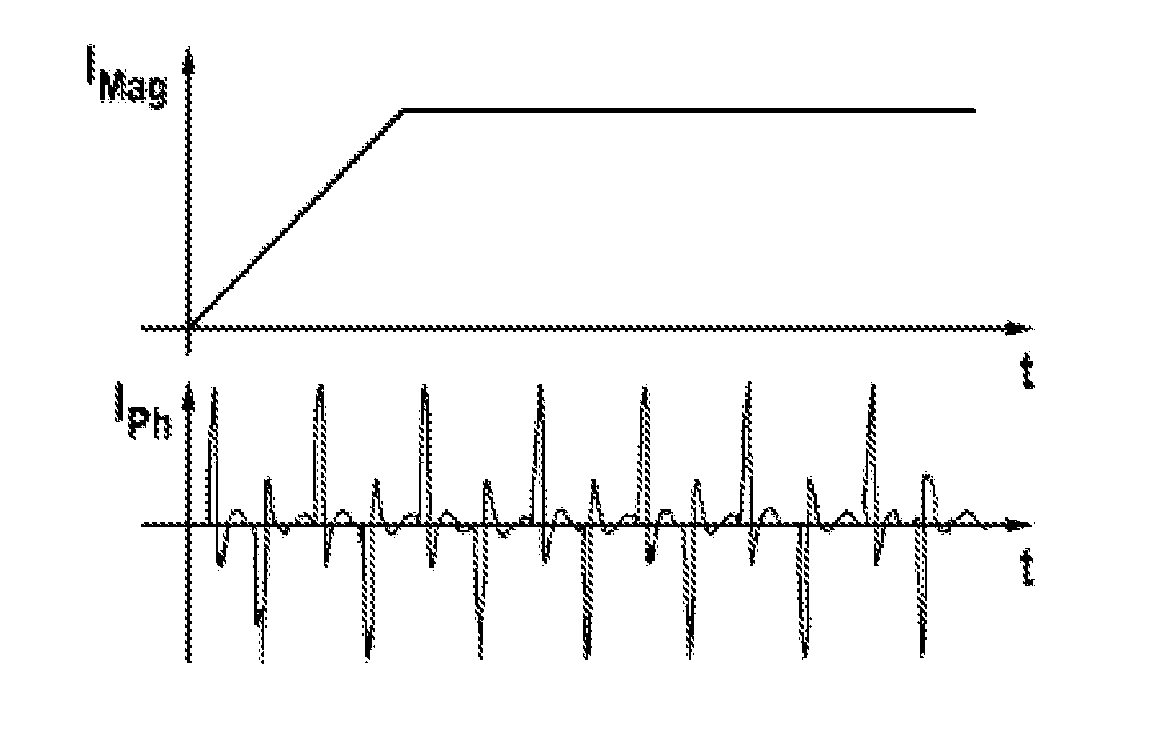

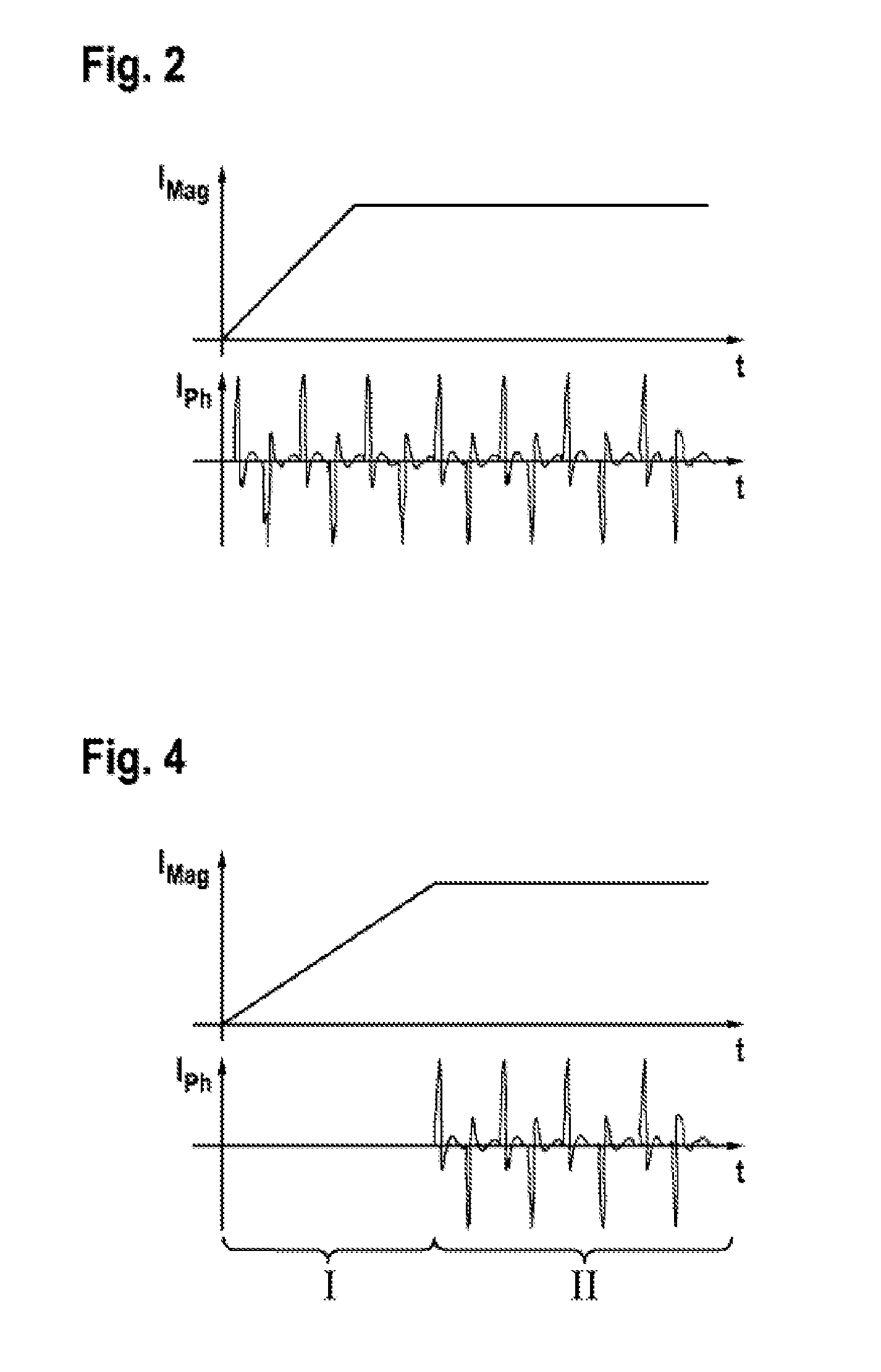

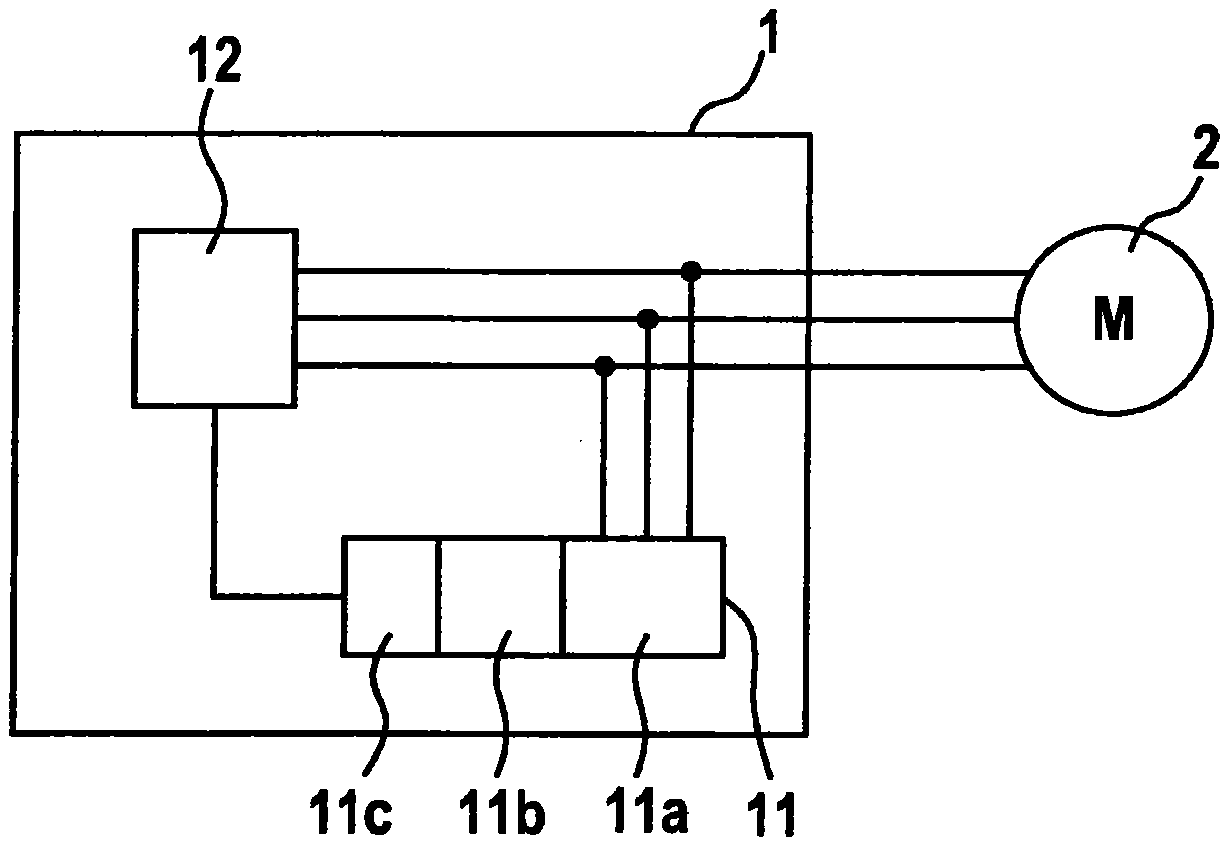

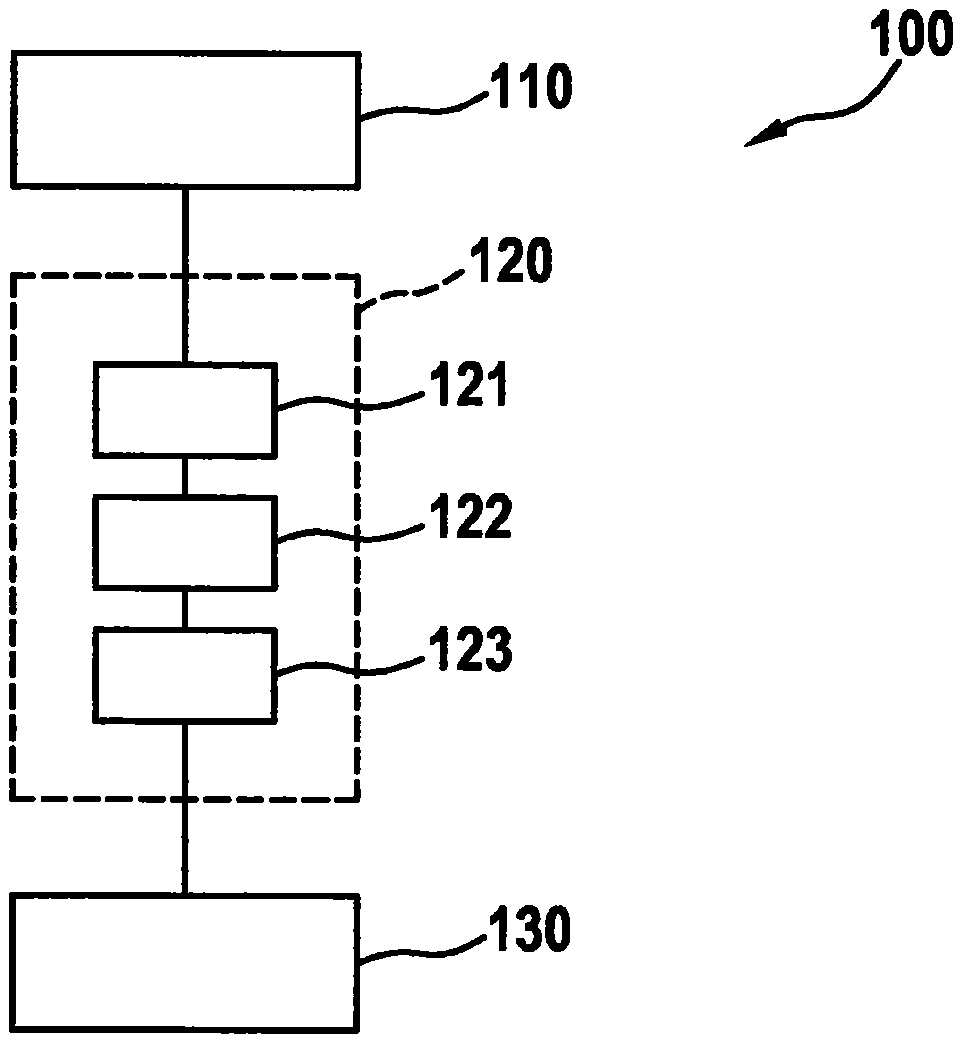

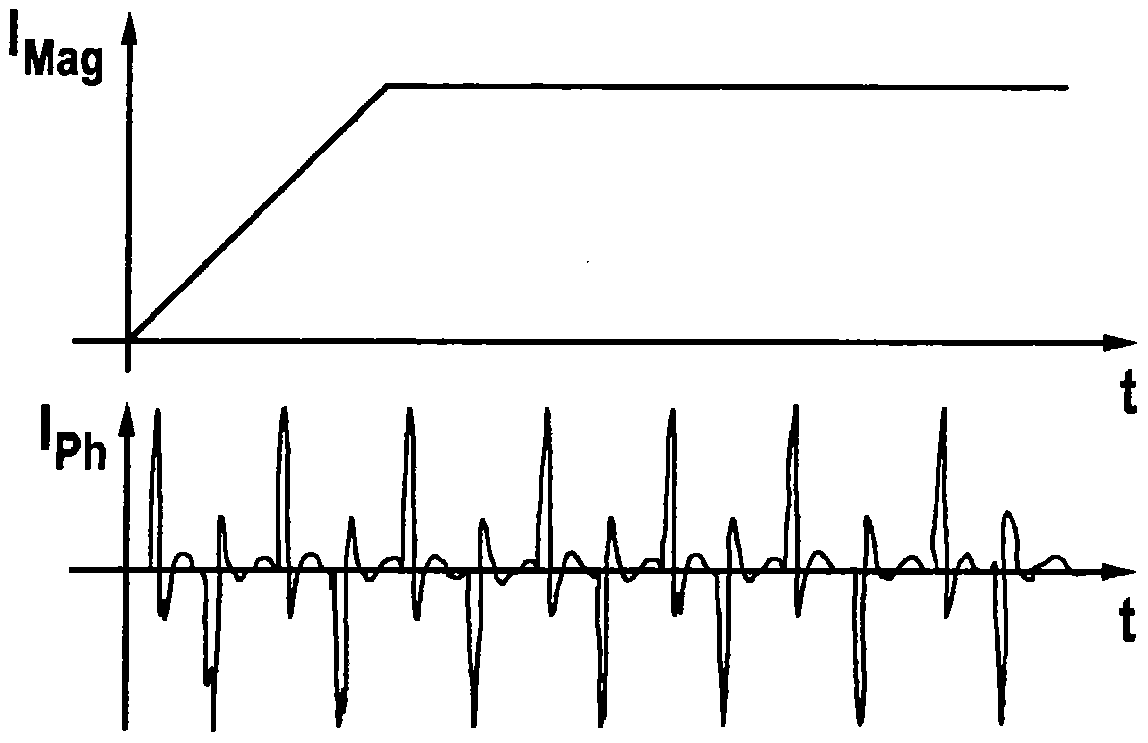

Control device for an asynchronous machine and method for operating an asynchronous machine

InactiveUS20160105137A1Accurate settingMagnetized significantly more quicklyElectronic commutation motor controlElectric motor controlElectric machineOperation mode

The present invention provides a method and a device to determine the rotor field angle of an asynchronous machine even during the magnetising phase, in which the rotor field of a rotor of the asynchronous machine is built up. The asynchronous machine can then be actuated in a controlled operating mode even during the magnetising phase. The startup properties of the asynchronous machine can thus be improved, the magnetising phase of the asynchronous machine is shortened and it is possible to set a desired torque even during the magnetising phase.

Owner:ROBERT BOSCH GMBH

A kind of non-oriented electrical steel for frequency conversion air conditioner and its manufacturing method

ActiveCN111304518BReduce iron lossFast magnetizationFurnace typesProcess efficiency improvementSteelmakingElectrical steel

The invention provides a non-oriented electrical steel for frequency conversion air conditioner and its manufacturing method. , [Si]2.80%‑3.4%, [Al]0.20%‑1.20%, [N]≤0.0025%, [Sn]0.01‑0.10%, the balance is Fe and unavoidable residual elements; manufacturing method: steelmaking , continuous casting, heating, hot rolling, normalization, pickling, cold rolling, annealing, cooling and coating; the thickness of the product of the present invention is 0.25-0.30mm, and the iron loss of the product is P 1.5 / 50 ≤2.15W / kg, magnetic polarization J 5000 ≥1.65T, fast magnetization speed, low iron loss, suitable for the working conditions of inverter air conditioner compressors, can reduce the volume and weight of inverter air conditioners, reduce power consumption, and save resources and energy.

Owner:新余钢铁股份有限公司

Control device for an asynchronous machine and method for driving an asynchronous machine

ActiveCN105432013BAccurate torqueFast magnetizationElectronic commutation motor controlElectric motor controlMagnetizationEngineering

The invention proposes a method and a device for ascertaining the rotor field angle of an asynchronous machine already during the magnetization phase in which the rotor field of the asynchronous machine rotor is to be established. The asynchronous machine can then be controlled in controlled work already during the magnetization phase. As a result, the starting behavior of the asynchronous machine can be improved, the magnetization phase of the asynchronous machine is shortened and the desired torque can already be generated during the magnetization phase.

Owner:ROBERT BOSCH GMBH

Permanent magnet and manufacturing method thereof

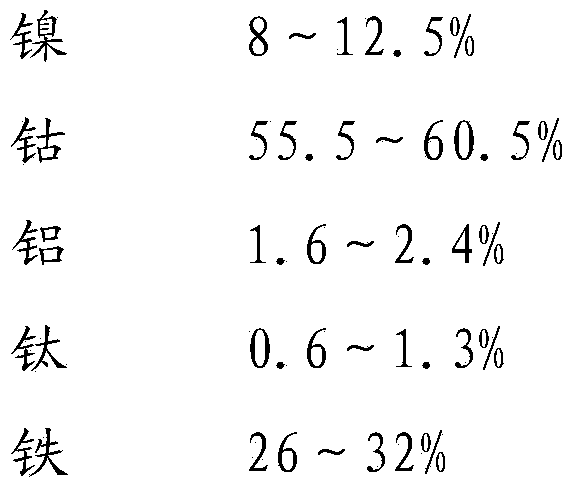

ActiveCN103484724AMeet the needs of developmentImprove coercive forceMagnetic materialsMagnetizationCobalt

The invention discloses a permanent magnet comprising the following components in percentage by weight: 8-12.5% of nickel, 55.5-60.5% of cobalt, 1.6-2.4% of aluminum, 0.6-1.3% of titanium and 26-32% of iron. The invention also discloses a manufacturing method of the permanent magnet. The manufacturing method comprises the steps of fully mixing the raw materials in proportion to form a pre-melting material; performing vacuum melting and casting to melt the pre-melting material and cast the pre-melting material into an ingot; forging and rolling the ingot to prepare a section material; drawing the section material to ensure that the section material is greatly deformed; performing texture orientation; performing heat treatment. The permanent magnet has the residual magnetism Br of 1400-1500mT and the coercive force Hc of 2.0-3.2kA / m, has higher residual magnetism and lower coercive force compared with the conventional magnetic material, can be applied to high-precision relays, has the characteristics of rapid magnetization and demagnetization, and can meet requirements for the development of aerospace products.

Owner:杭州科德磁业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com