Novel magnetic fluid bearing and manufacturing method thereof

A manufacturing method and magnetic fluid technology, applied in the directions of bearings, bearing components, shafts and bearings, etc., can solve the problems that the magnetic fluid cannot be evenly distributed, affect the bearing performance, etc., achieve good chemical stability, excellent physical and mechanical properties, reduce The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

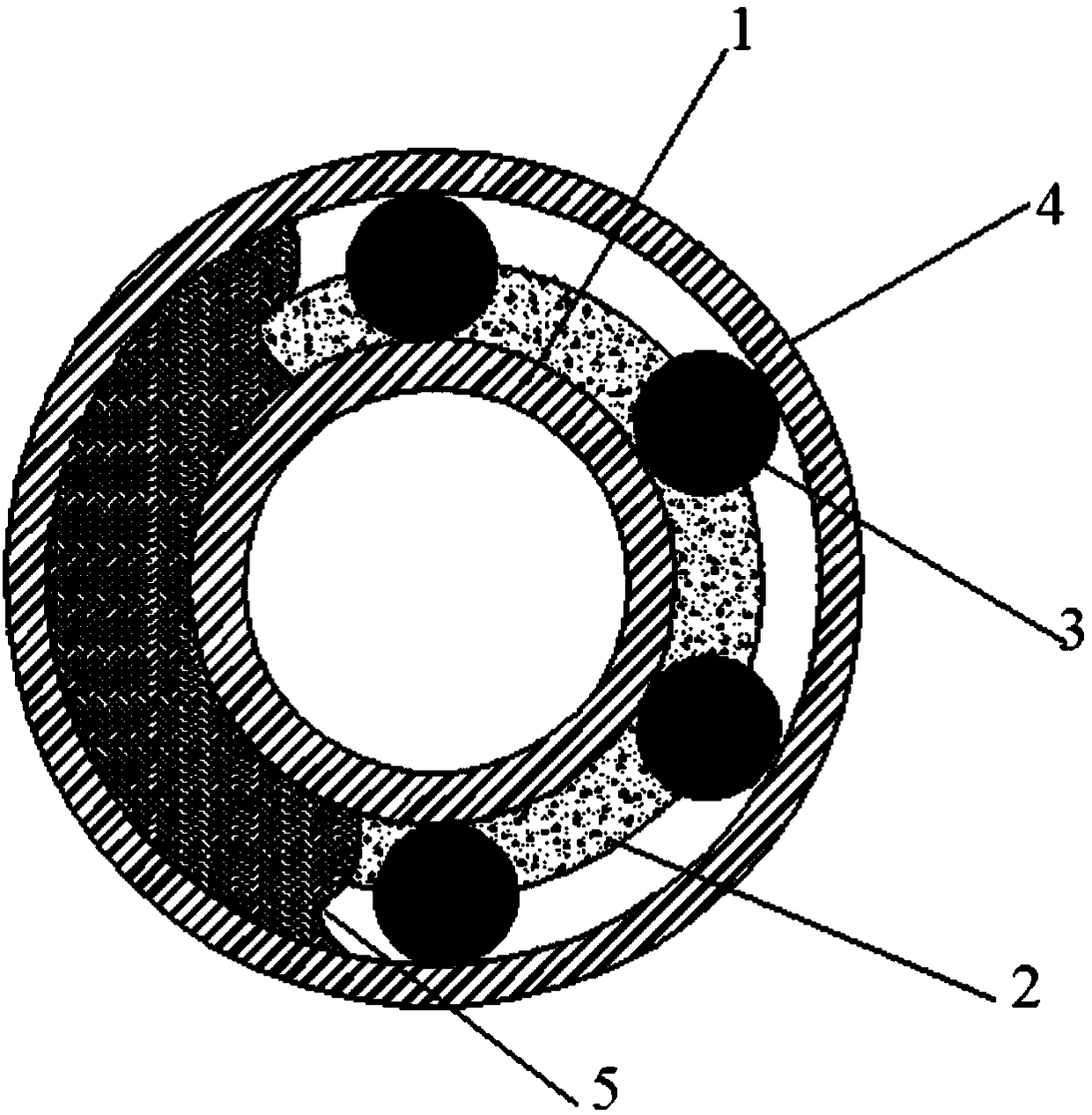

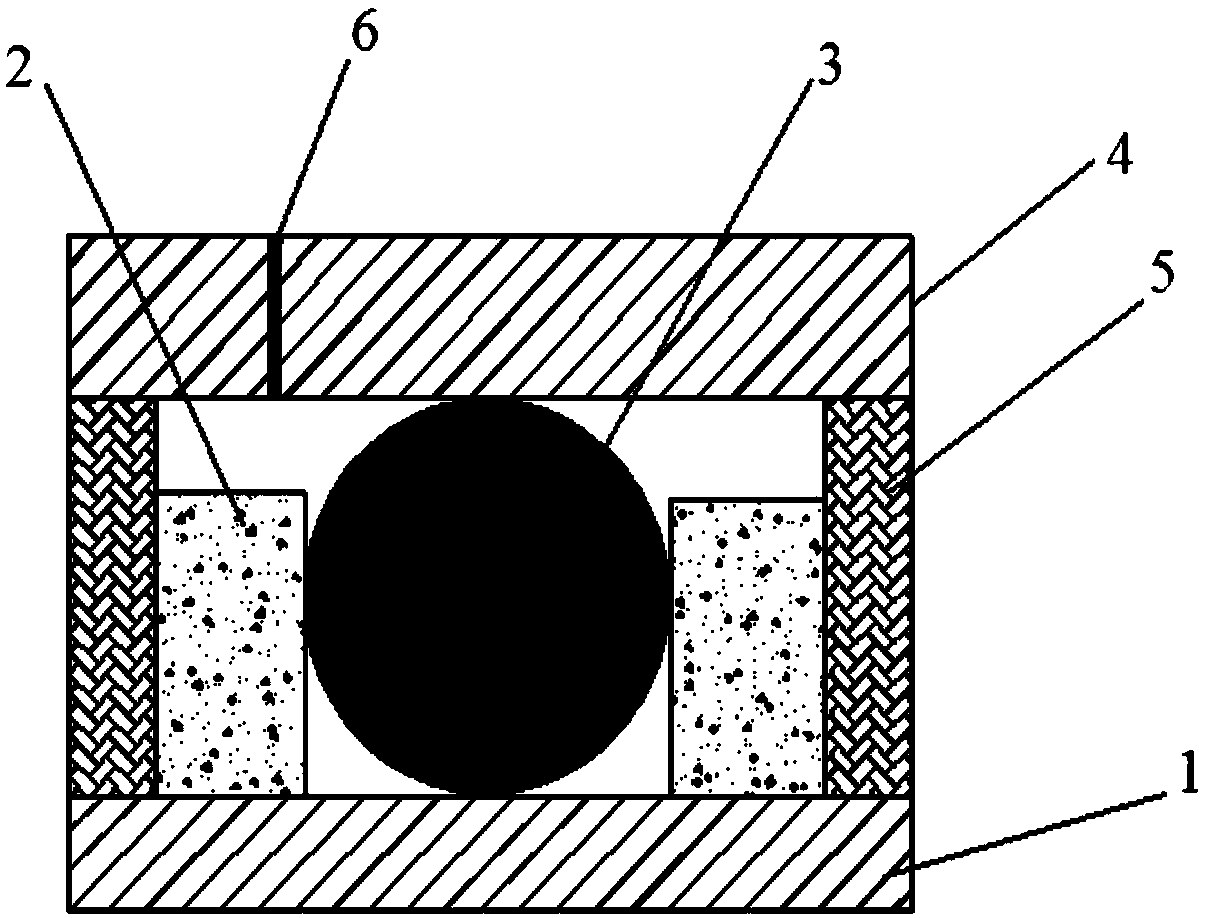

[0036] A new type of magnetic fluid bearing, specifically as Figure 1-2 As shown, it includes bearing inner ring 1, permanent magnet cage 2, rolling element 3 and bearing outer ring 4 arranged in sequence from inside to outside; bearing inner ring 1 is set in bearing outer ring 4, and permanent magnet cage 2 is set in On the outer wall of the bearing inner ring 1, the rolling elements 3 are arranged on the permanent magnet cage 2, and the two sides of the magnetic fluid bearing are also provided with a bearing sealing cover 5, the upper end of the bearing sealing cover 5 is connected with the inner wall of the bearing outer ring 4, and the lower end It is connected with the outer wall of the bearing inner ring 1, and a sealed cavity is formed between the bearing sealing cover 5, the inner wall of the bearing outer ring 4 and the outer wall of the bearing inner ring 1, and magnetic fluid is injected into the cavity.

[0037] The cage 2 is a permanent magnet, and the magnetic f...

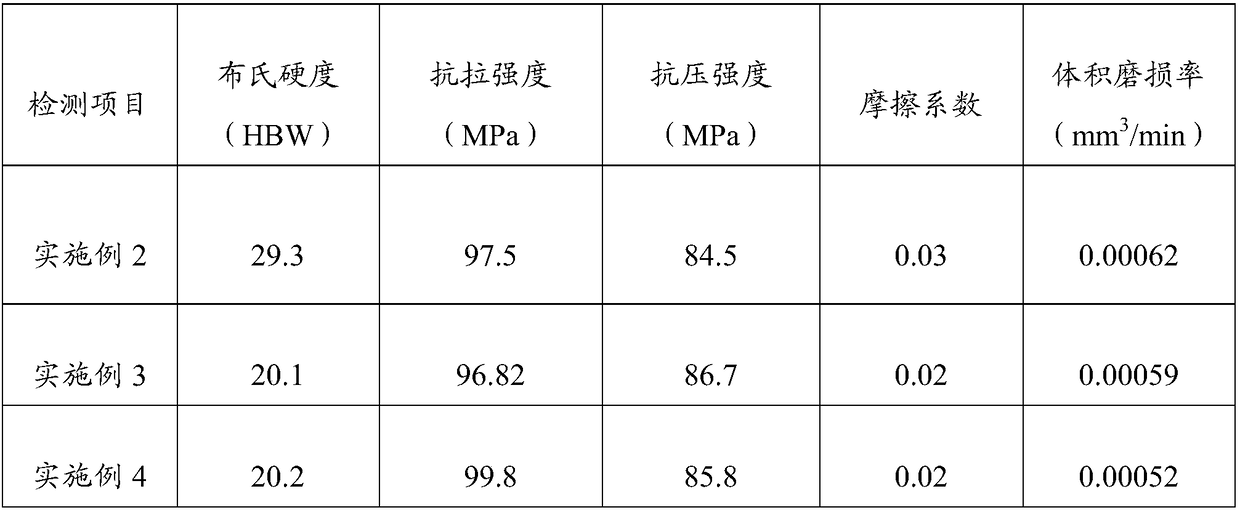

Embodiment 2

[0040] A method for manufacturing a novel magnetic fluid bearing, specifically implemented according to the following steps:

[0041] Step 1, surface treatment of bearing inner ring 1 and bearing outer ring 4

[0042]Step 1.1, soak the original bearing inner ring and the original bearing outer ring in the deoxidizing solution, and then conduct ultrasonic treatment at 20°C for 10 minutes, wherein the ultrasonic treatment power is 1.5kW / m 3 , the frequency is 300kHz; after the treatment, the deoxidized bearing inner ring and the deoxidized bearing outer ring are respectively obtained;

[0043] Wherein, the deoxidizing solution is formed by mixing a hydrofluoric acid solution with a concentration of 10% and a nitric acid solution with a concentration of 10% according to a volume ratio of 1:1;

[0044] In step 1.2, place the deoxidized bearing inner ring and the deoxidized bearing outer ring in step 1.1 in a hydrogen furnace, and keep them warm at 600°C for 20 hours. After the he...

Embodiment 3

[0054] A method for manufacturing a novel magnetic fluid bearing, specifically implemented according to the following steps:

[0055] Step 1, surface treatment of bearing inner ring 1 and bearing outer ring 4

[0056] Step 1.1, soak the original bearing inner ring and the original bearing outer ring in the deoxidizing solution, and then conduct ultrasonic treatment at 30°C for 8 minutes, wherein the ultrasonic treatment power is 1.5kW / m 3 , the frequency is 300kHz; after the treatment, the deoxidized bearing inner ring and the deoxidized bearing outer ring are respectively obtained;

[0057] Wherein, the deoxidizing solution is formed by mixing a hydrofluoric acid solution with a concentration of 10% and a nitric acid solution with a concentration of 10% according to a volume ratio of 1:1;

[0058] In step 1.2, place the deoxidized bearing inner ring and the deoxidized bearing outer ring in step 1.1 in a hydrogen furnace, and keep warm at 580° C. for 25 hours, and after the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com