Besides-star wheel magnetic detector

A technology of extraterrestrial wheels and magnetic detection, which is applied in the field of magnetic detection machines, can solve the problems of slow rhythm, inability to clearly display the defects of the inner spherical surface, and inability to adapt to mass production requirements, and achieve the effect of low failure rate and sufficient magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

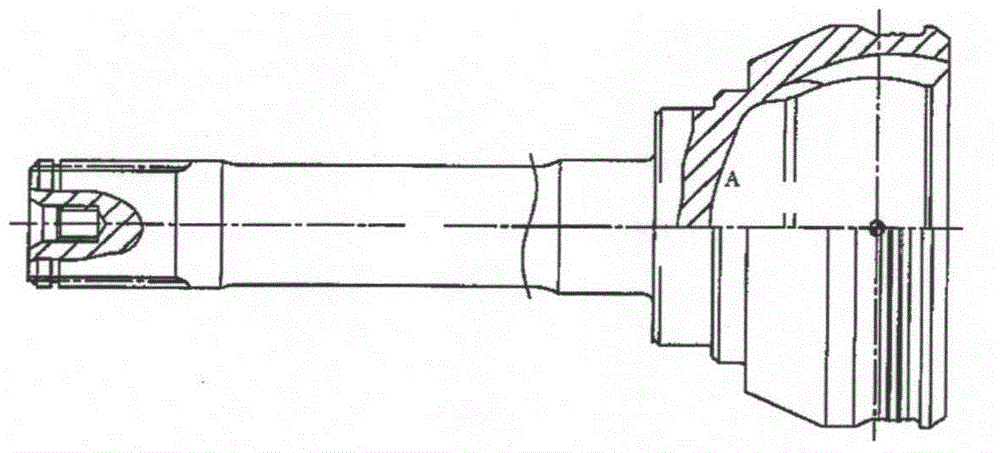

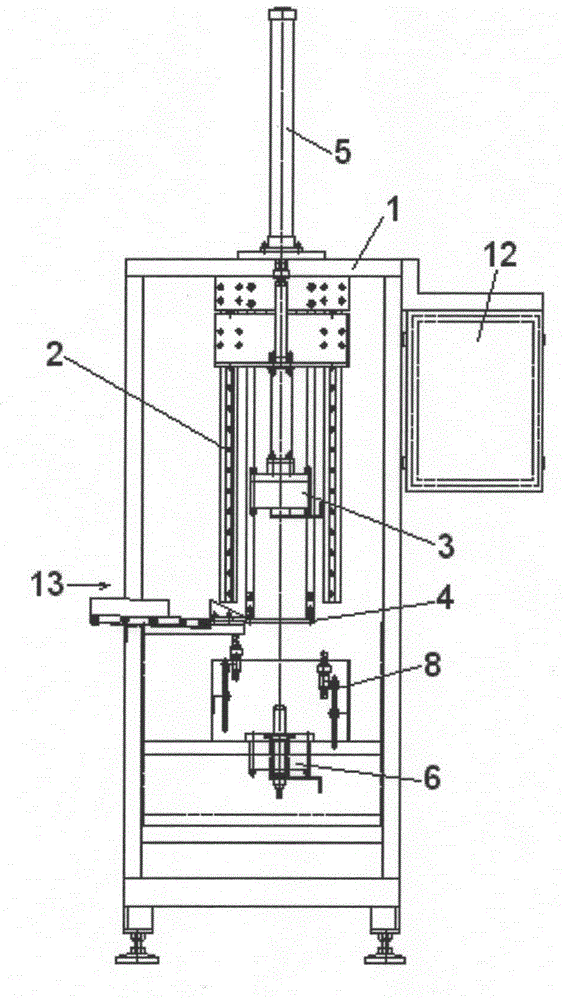

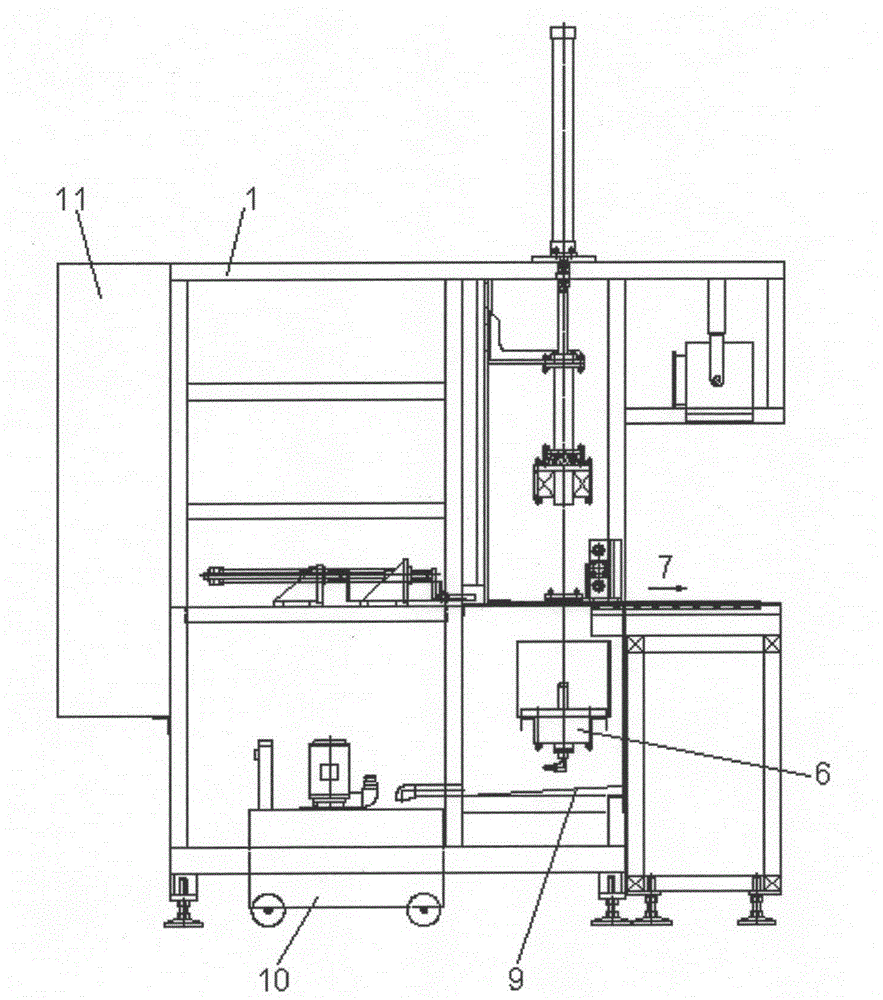

[0024] Such as figure 1 As shown, it is a schematic diagram of the outer star wheel workpiece targeted by the magnetic detector, and an inner spherical surface A is provided on the inner side of the outer star wheel. The outer star wheel magnetic detector provided by the invention is as figure 2 and image 3 As shown, including the main body 1, two linear guide rails 2 are installed on the main body 1, the moving collet coil device 3 and the outer star wheel workpiece carrying platform 4 can move on the linear guide rail 2; Groove 9, the lower part of the fixed chuck coil device 6 is arranged in the liquid collecting tank 9, the fixed chuck coil device 6 and the moving chuck coil device 3 are coaxially installed, and have an internal spray function; The outer spray head 8 has a liquid leakage port leading to the magnetic suspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com