Shrimp shell based magnetic hierarchical porous carbon surface imprinting material, and preparation method and applications thereof

A technology of imprinted materials and multi-level pores, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve problems such as threats to human and organism health, refractory biodegradation, etc., to promote Effect of aromatization reaction, high specific surface area, and high pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] (1) Preparation of magnetic hierarchical porous carbon based on shrimp shell

[0056] The discarded Pingdingshan Baiguihu prawn shells were washed repeatedly with distilled water to remove various impurities, air-dried for drying, and ground into powder for later use. Add the above materials into a phosphoric acid solution with a mass concentration of 10%-20% and stir. The mass ratio of shrimp shell powder to phosphoric acid solution (activator) is 1:1-4. Heating for 2-5 hours; vacuum drying for 12-24 hours at a temperature of 100°C-120°C to obtain the active raw material of shrimp shell; mixing the active raw material of shrimp shell obtained above with ethanol with a concentration of 0.05-0.3g / ml ferric chloride The solution is mixed according to the mass ratio of 4:15-20, fully stirred and mixed evenly, and vacuum-dried in an oven at 80-100°C until constant weight. Put the above materials into a tube furnace, under the protection of inert gas nitrogen, the gas flow ...

Embodiment 1

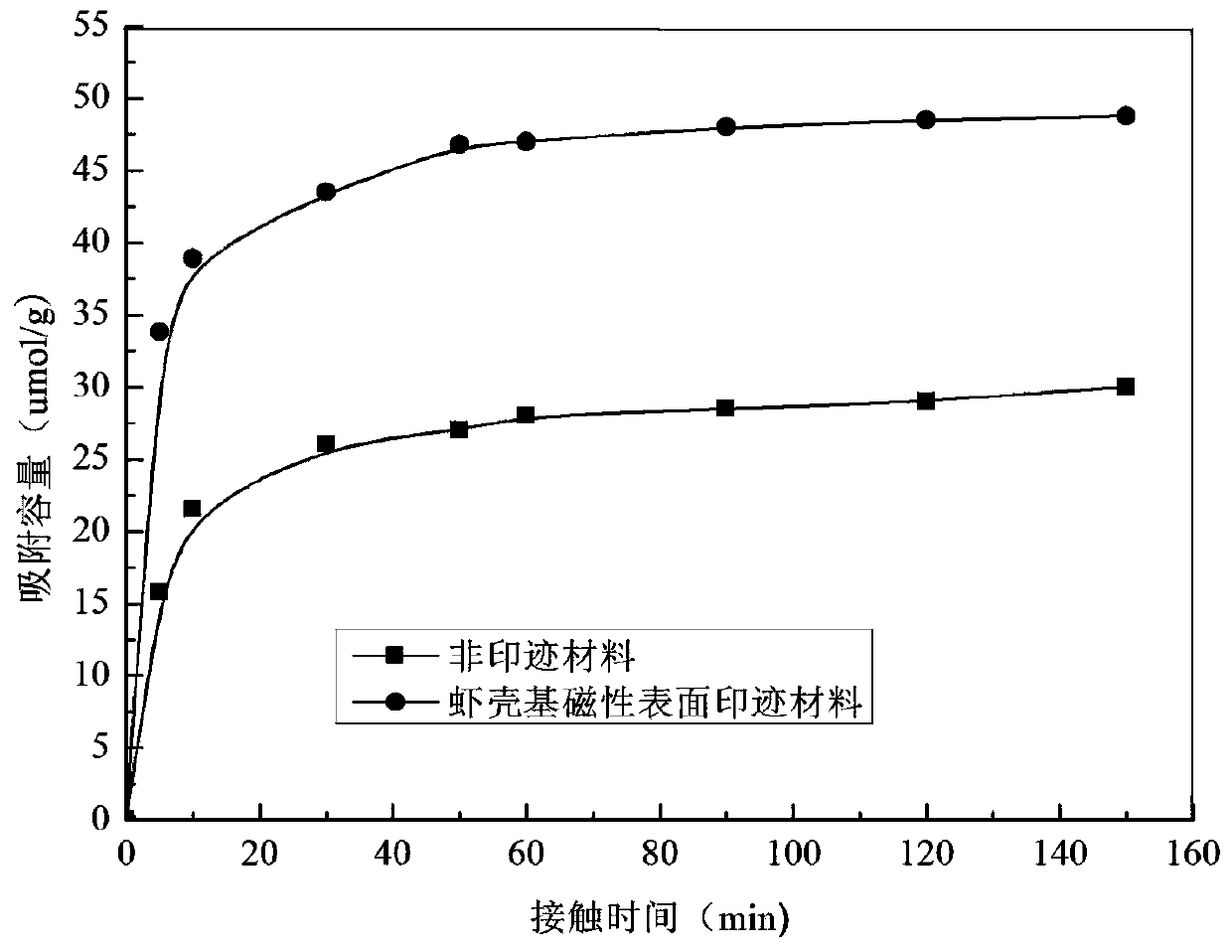

[0070] Take 25 ml of BPA solution with an initial concentration of 150 μmol / L into a centrifuge tube, add 10 mg of shrimp shell-based magnetic hierarchical porous carbon surface imprinted material and non-imprinted adsorption material, and place the test solution in a room temperature water bath for 5, After 10, 30, 45, 60, 90, 120 and 150 min, the supernatant was separated and collected with a permanent magnet, and the concentration of unadsorbed BPA was measured with a UV-Vis spectrophotometer to calculate the adsorption capacity.

[0071] from image 3 It can be seen from the above that at the beginning, with the increase of the adsorption time, the adsorption capacity increased rapidly, and the adsorption reached equilibrium after 50 min. During the entire adsorption time, the adsorption capacity of the shrimp shell-based magnetic hierarchical porous carbon surface imprinted material was greater than that of the non-imprinted adsorption material. BPA adsorption capacity, s...

Embodiment 2

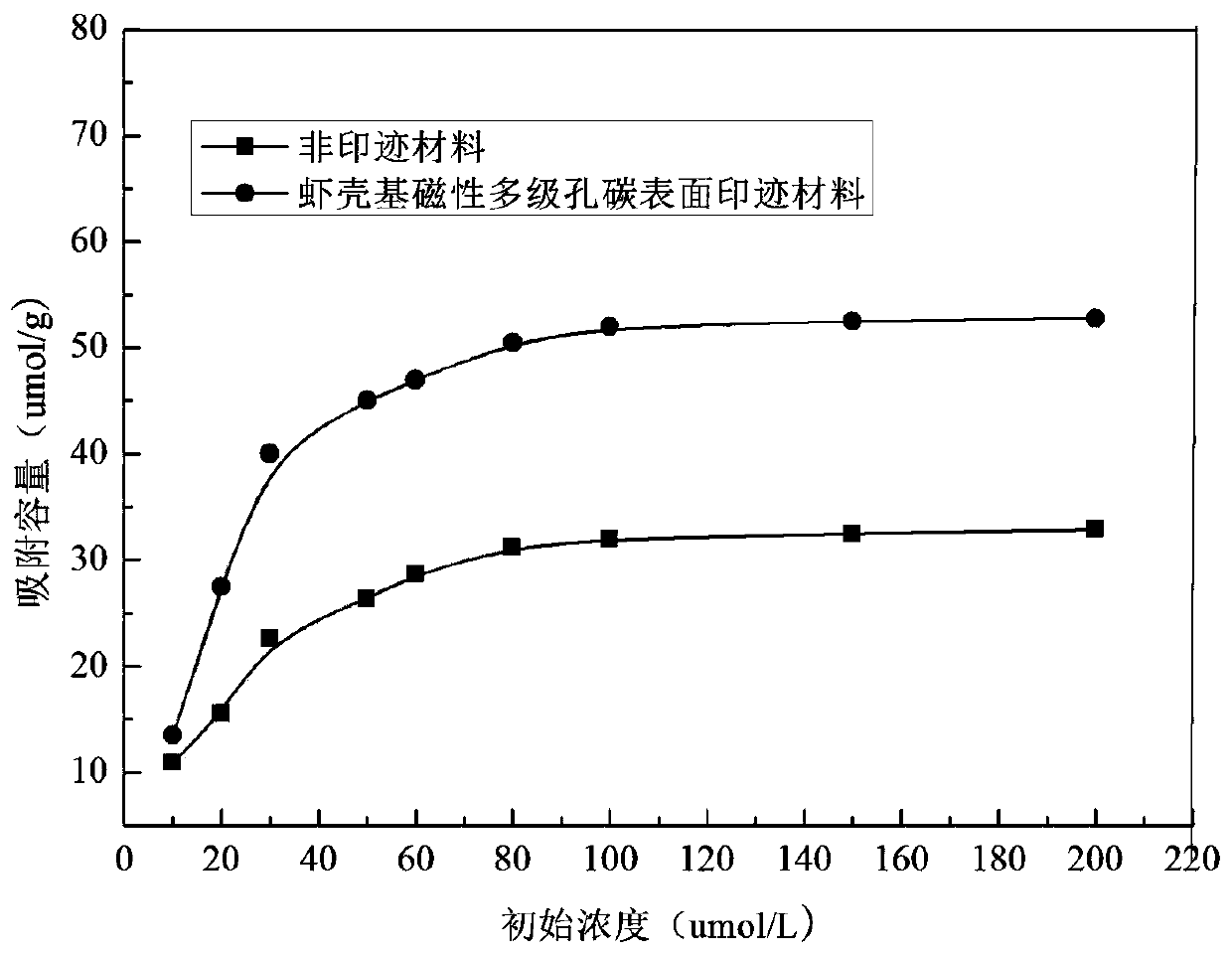

[0073] Take 25ml of BPA solution with initial concentrations of 10, 20, 30, 50, 60, 80, 100, 150, and 200 μmol / L, respectively, into a centrifuge tube, and add 10 mg of shrimp shell-based magnetic hierarchical porous carbon surface imprinting material and non-ferrous material respectively. To imprint the adsorption material, the test solution was placed in a water bath at room temperature for 24 hours, the supernatant was separated and collected with a permanent magnet, the concentration of unadsorbed BPA was measured with a UV-Vis spectrophotometer, and the adsorption capacity was calculated.

[0074] like Figure 4 As shown, the saturated adsorption capacity of the imprinted adsorption material was 51.55 umol / g, which was higher than that of the non-imprinted adsorption material of 31.26 umol / g, indicating that the imprinted adsorption material had a large number of imprinted pores and had a good imprinting effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com